Automobile coating drying and conveying device and conveying control method thereof

A conveying device and coating technology, applied in conveyor control devices, devices for coating liquid on surfaces, conveyors, etc., can solve the problems of lack of relative position constraints, waste of kinetic energy in drying furnaces, poor operation stability, etc. The effect of avoiding the risk of skid collision, stable and reliable operation, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

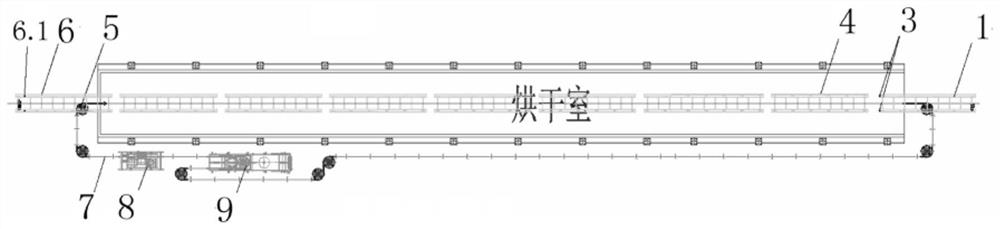

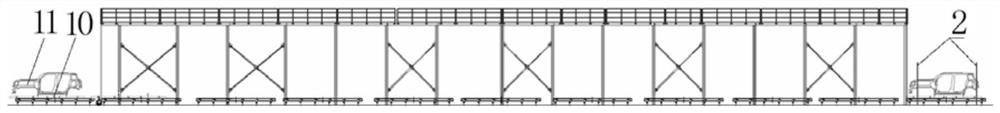

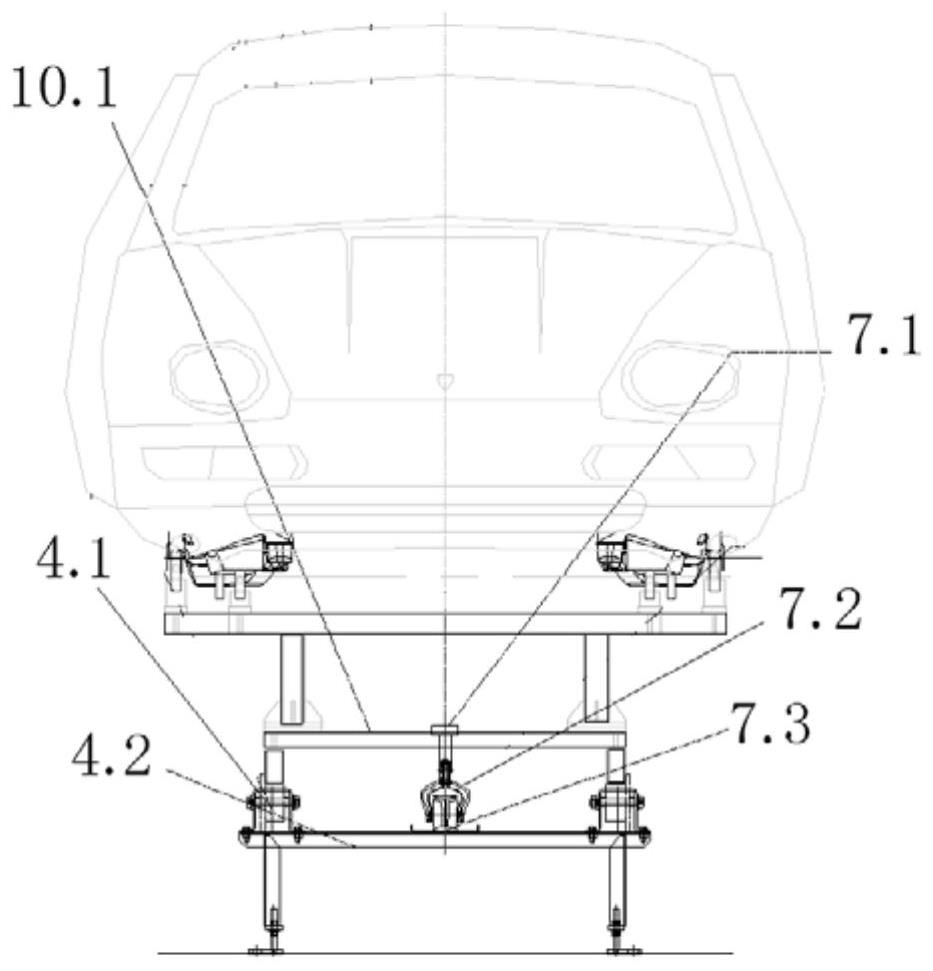

[0035] Ground reverse drying double-roller conveyor, when the sled 10 and the body 11 run quickly to the entrance variable speed unilateral roller bed 1, when the front section of the sled 10 touches the in-position switch 3, the drive motor of the entrance variable speed unilateral roller bed 1 stops At this time, the identification sensor 2 starts to automatically identify the vehicle body. After the identification is completed, the information is transmitted to the in-position switch 3 and the entrance variable speed unilateral roller bed 1 through the on-site PLC. At this time, the entrance variable speed single side roller bed 1 reduces the speed to Consistent with the chain 7.2, the track chain assembly 7 gradually rises from the bottom of the entrance variable-speed unilateral rolling bed 1 until the push head 7.1 hangs on the sled crossbeam 10.1 on the sled 10, and then the vehicle body is taken away; the sled 10 and When the upper body 11 runs to the exit variable-spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com