Fixture for anti-deformation machining of automobile aluminum alloy wheel

An aluminum alloy wheel hub and anti-deformation technology, applied in metal processing equipment, metal processing machine parts, manufacturing tools, etc., can solve problems such as slow production efficiency and rim deformation, and achieve rapid disassembly, good anti-slip performance, and simple and fast installation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

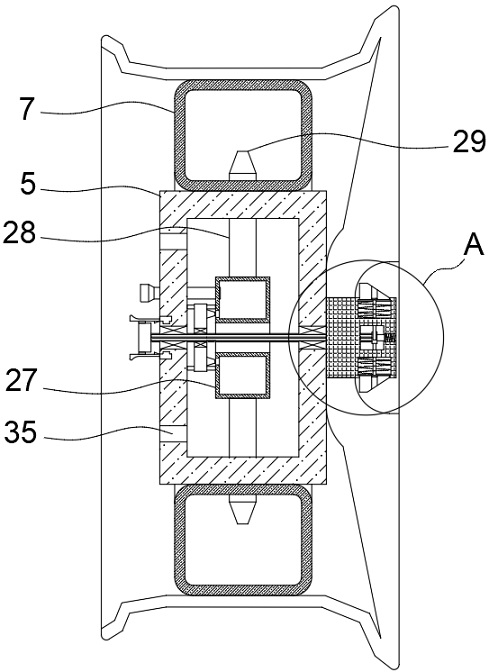

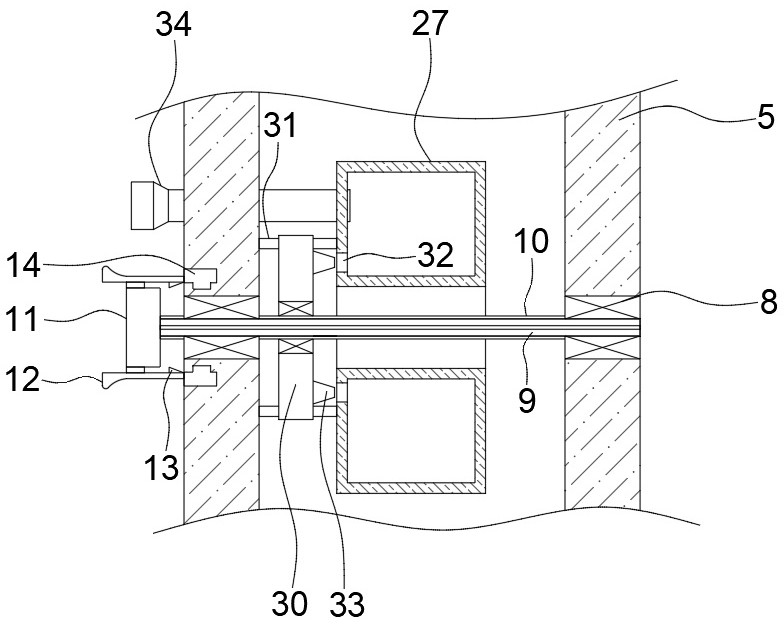

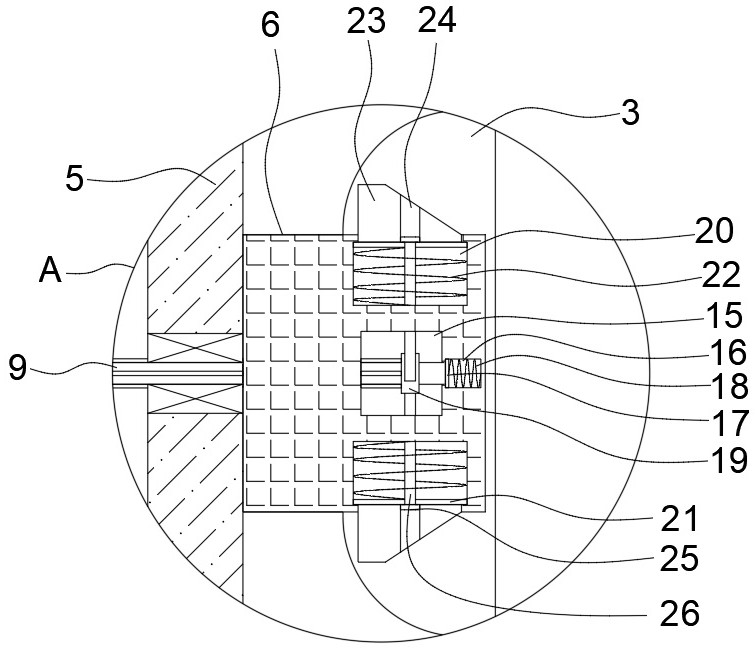

[0026] refer to Figure 1-5 , a clamp for anti-deformation processing of aluminum alloy wheels of automobiles, including a hub body, the hub body is composed of a wheel disc 1, a rim 2, a hole groove 3 and a center hole 4, and the hole groove 3 communicates with the center hole 4, and is used to fix the automobile The wheel shaft and the hub body are provided with a hollow column 5, the left center of the hollow column 5 is fixedly connected to the limit column 6, the limit column 6 slides through the center hole 4, and the outer peripheral surface of the hollow column 5 is fixedly sleeved with a rubber air bag 7, and the rubber airbag 7 When the airbag 7 is inflated, it can seamlessly fit the inner surface of the rim 2. The material of the rubber airbag 7 is non-slip rubber, which can effectively support the rim 2 and prevent its deformation during processing. In addition, the rubber airbag 7 has a good performance when inflated. Anti-slip performance, the center positions of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com