Rear axle flange ring welding device with adjusting structure and for automobile

A technology for adjusting structures and welding devices, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of increasing the welding difficulty of welding personnel, prone to slipping, and unable to fix the drive axle housing of the rear axle, etc., to achieve reduction Risk of burns, avoidance of turning and slipping, effect of reducing difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

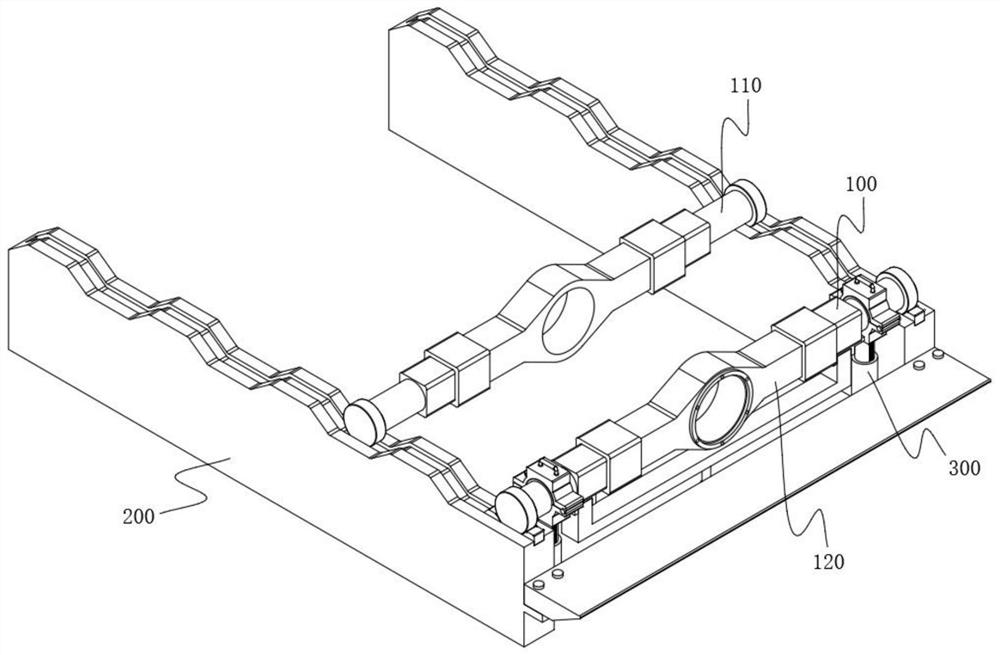

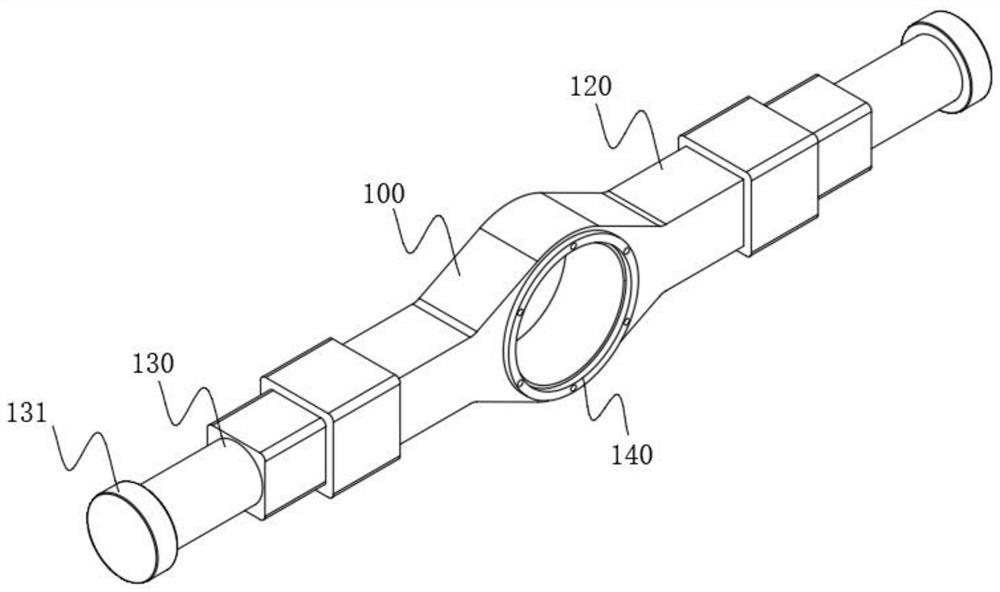

[0069] The invention provides a rear axle flange welding device with an adjustment structure for automobiles, please refer to Figure 1-Figure 17 , including a rear axle 100 and a welding frame 200 arranged at the bottom of the rear axle 100, the welding frame 200 includes two support plates 210, and the two support plates 210 are respectively arranged on the left and right sides of the rear axle 100, and the rear axle 100 includes a drive axle housing 130 , a wheel hub 131 is provided at the end of the drive axle housing 130 , and an adjustment mechanism 300 is provided between the two support plates 210 near the front side.

[0070] It should be noted that the rear axle 100 is provided with the rear axle 110 to be welded and the welded rear axle 120 during the welding process, please refer to figure 1 As shown, the front side is the welded rear bridge 120, and the rear side is the rear bridge 110 to be welded.

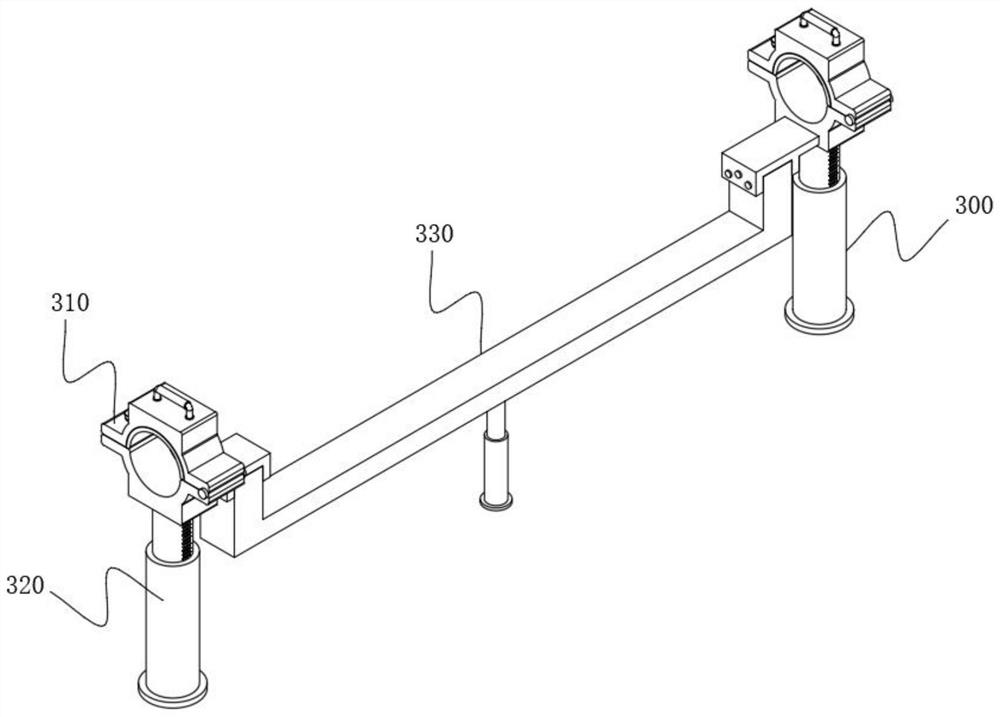

[0071] In addition, the adjustment mechanism 300 includes at l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com