Rotary cup spraying method for primer of automobile exterior trimming part

A technology for exterior parts and automobiles, which is applied in the field of painting to achieve the effects of reducing the amount of paint mist, improving economic efficiency and improving appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

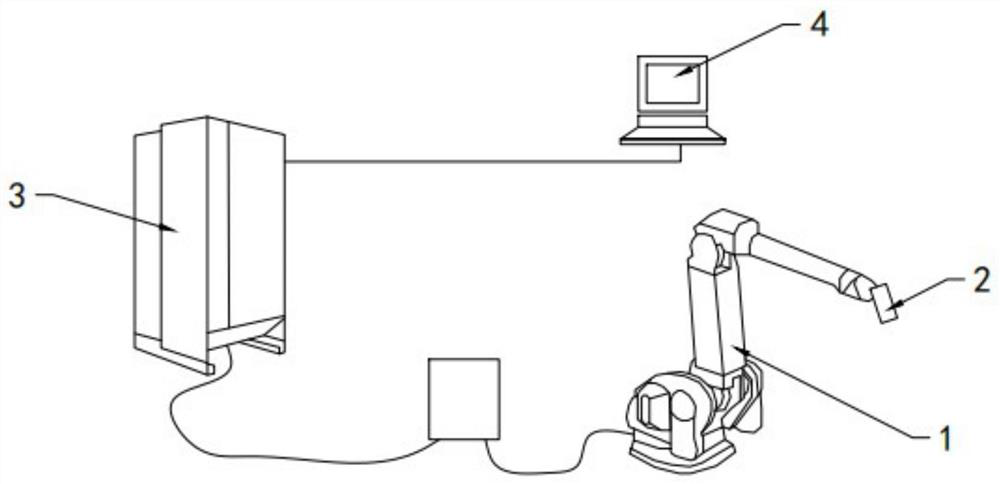

[0025] see figure 1 , the automotive exterior trim primer rotary cup spraying method comprises the following steps:

[0026] Ground the sled equipped with automotive exterior parts, and then fix the rotary cup atomizer 2 on the robot 1, and the robot 1 drives the rotary cup atomizer 2 to spray the primer to the surface of the automotive exterior parts; each robot 1 Control is performed through one control cabinet 3 , and each control cabinet 3 is controlled by a main PLC 4 .

[0027] The robot 1 used in this embodiment is an ABB spraying robot, and of course other robots can also be used. The robot 1 performs the spraying operation in the primer spray booth, and the main PLC 4 controls the walking track of the robot 1 in the spraying operation. The rotary cup atomizer 2 is fixed on the robot 1, and the automotive exterior parts are grounded, and the robot 1 drives the rotary cup atomizer 2 to spray the primer onto the surface of the automotive exterior parts.

[0028] Durin...

Embodiment 2

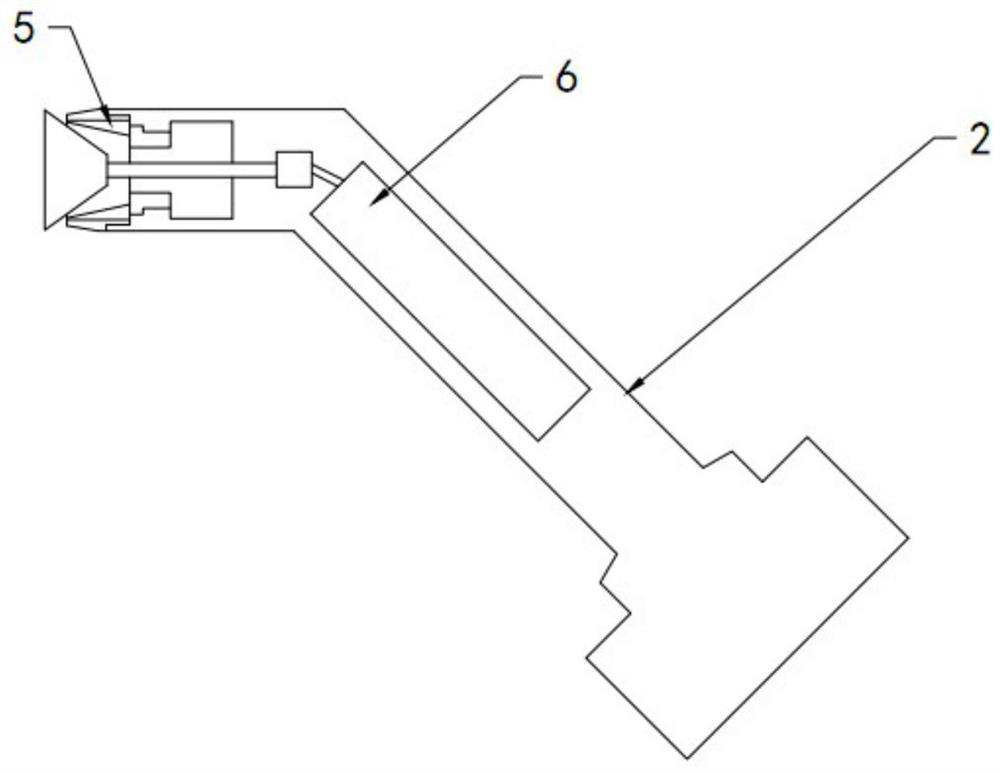

[0032] see figure 2 In this embodiment, a high-voltage generator 6 is provided in the rotary cup atomizer 2, the electrostatic high voltage of the rotary cup atomizer 2 is 0-90kV, an intelligent voltage controller is installed in the robot 1, and the high voltage generation is controlled by the intelligent voltage controller Device 6. Using electrostatic adsorption, the atomized paint is charged and adsorbed to the surface of the product. In the rotary cup atomizer 2, there is also an integral air cap 5, the rotating cup head is arranged inside the integral air cap 5, and several compressed air channels are arranged around the rotating cup head on the shaping air cap, and the spraying width is installed in the robot 1. The air control system controls the size of the shaping airflow in the shaping air cap 5 through the spraying width air control system to spray the size of the width.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com