Lead screw lifting high-speed roller bed for conveying

A technology of screw lifting and conveying rollers, applied to conveyor objects, conveyor control devices, roller tables, etc., can solve problems such as difficulty in realizing multi-model co-line production, inappropriate coordination with various peripheral equipment, and large footprint. , to increase multi-model mixed production, reduce takt time loss, and achieve the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

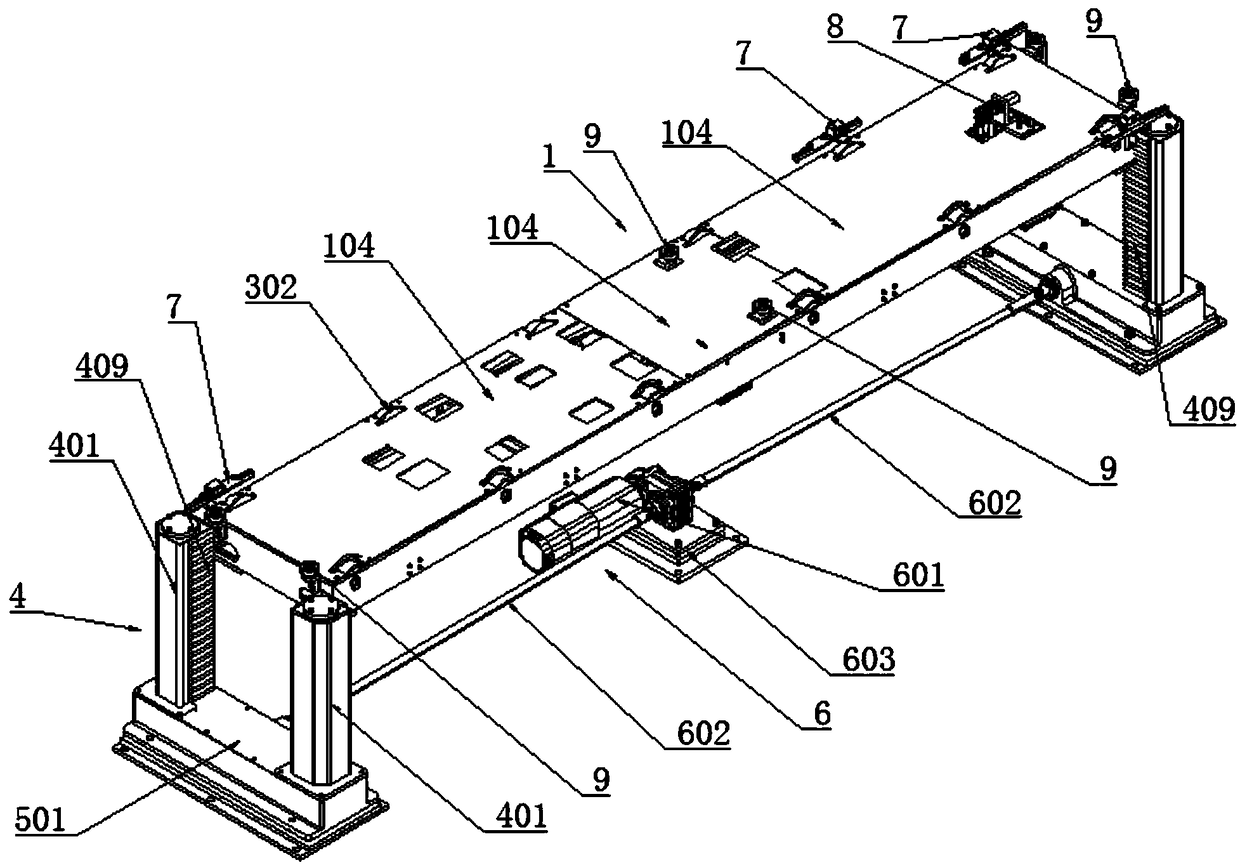

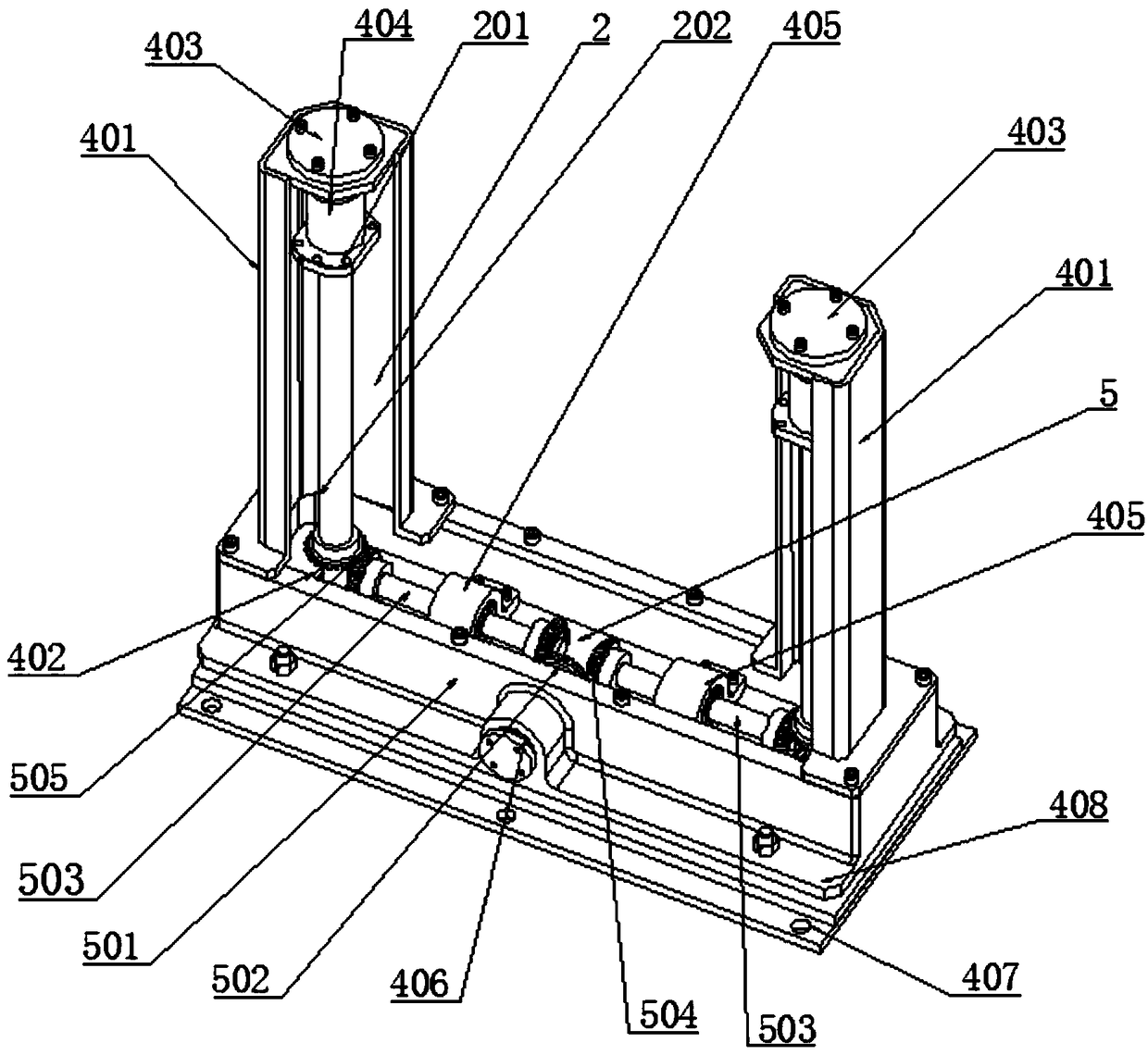

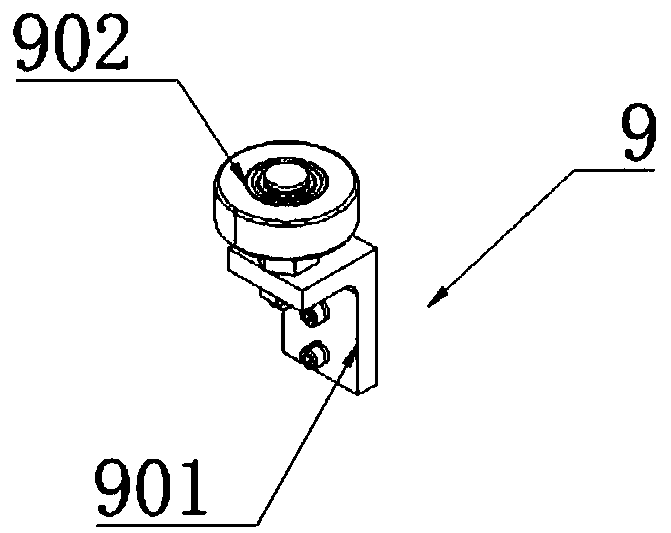

[0028] The specific embodiment of the present invention is like this: as Figure 1-5 As shown, a screw mandrel lifting high-speed roller bed for conveying comprises a conveying roller bed 1 and two supporting frames 4 arranged at both ends of the conveying roller bed 1, and each supporting frame 4 is provided with a support frame for supporting the conveying roller bed 1. Lead screw lifting mechanism 2, a lifting drive device 6 capable of driving two lead screw lifting mechanisms 2 is provided under the conveying roller bed 1, and a steering conversion mechanism connecting the lead screw lifting mechanism 2 with the lifting drive device 6 is provided on the support frame 4 5. The steering conversion mechanism 5 is inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com