Automobile coil spring pressure unloading manipulator device and using method

A technology of coil springs and manipulators, which is applied in the field of automotive coil spring pressure unloading manipulators, can solve the problems that the impact force cannot be eliminated, affect the assembly of the subsequent process, and frighten the operators, so as to save hardware investment costs and human resource input costs. The production process is more humanized and intelligent, and the effect of expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In the following, in conjunction with the drawings, through the description of the implementation examples, the specific implementation of the present invention, such as the shape and structure of the various components involved, the mutual position and connection relationship between the various parts, the work and working principle of each part, etc. The detailed description.

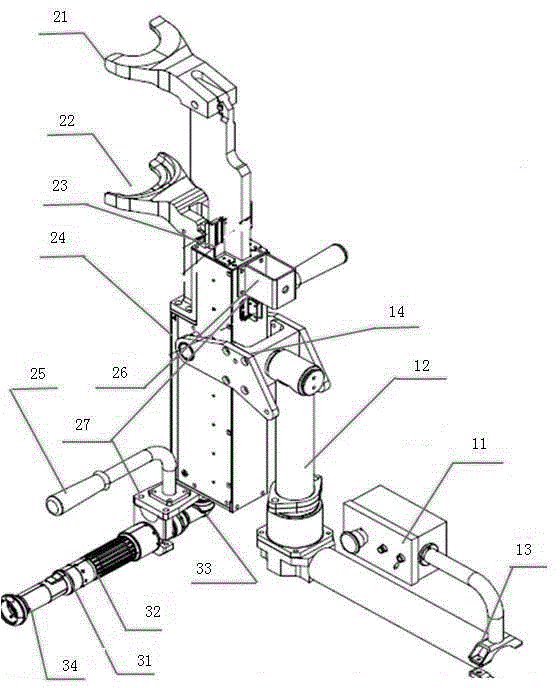

[0046] Such as figure 1 As shown, the automobile coil spring pressing and unloading manipulator device of the present invention includes: a manipulator assembly 1, a working assembly 2 and a power source 3.

[0047] The mechanical arm assembly 1 includes a positioning control button box 11, an L-shaped arm 12, a bolt thread fixing assembly 13 and a bearing connection mechanism 14. The positioning control button box 11 is fixed on the L-shaped arm 12 by the bolt thread fixing assembly 13. The positioning control button box 11 is used to position the manipulator in a proper position when the spring p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com