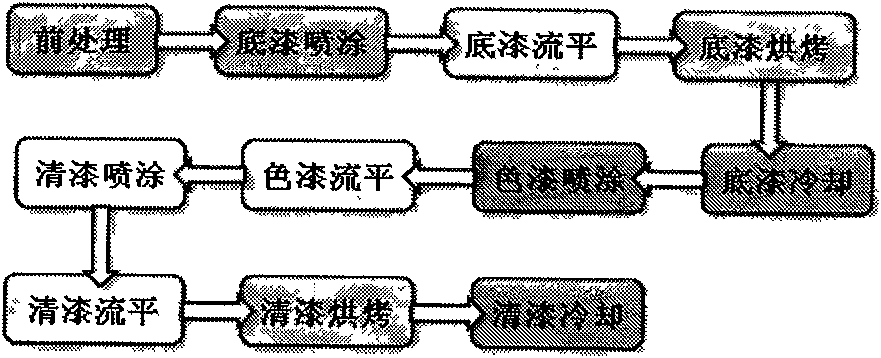

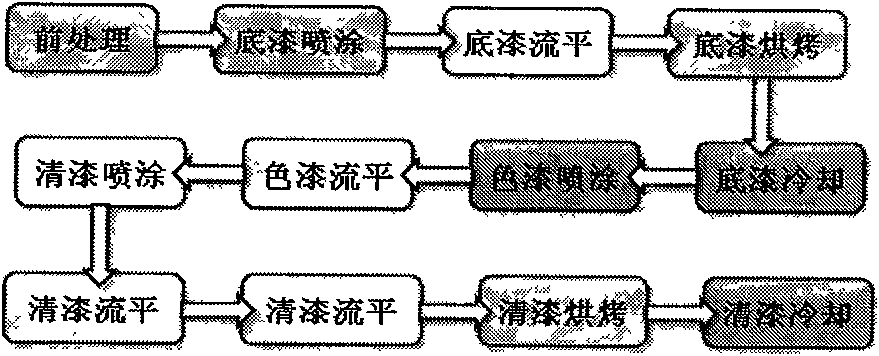

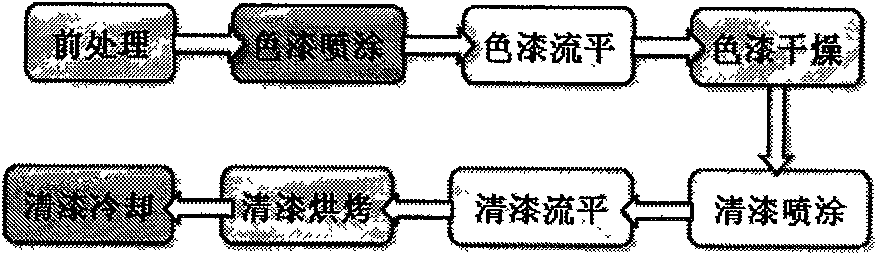

Oil paint coating line-based process for coating water paint in two layers on automotive plastic exterior trimming part

A technology for exterior parts and production lines, used in coatings, devices for applying liquid to surfaces, and surface pretreatment, etc., which can solve problems such as energy consumption, high quality risk, and long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] From the technical point of view, the following technical difficulties need to be solved:

[0011] 1) Substrate pretreatment 2) Water-based topcoat and oil-based paint isolation technology 3) Paint film drying

[0012] 1. Substrate pretreatment

[0013] It includes three steps of water washing and drying, flame treatment, and electrostatic dust removal; the purpose of water washing is to remove grease, garbage, particles and other pollutants on the surface of the substrate that affect the performance and appearance of the paint film. Oil-based paints and water-based paints are at this point consistent. Generally, flame treatment is not required in high-temperature oily paint systems, but flame treatment is a necessary process in low-temperature systems to increase the surface energy of the substrate and increase the adhesion of the paint film. In order to meet the quality requirements, different paint manufacturers have surface energy parameter requirements for flame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com