General sand core structure and usage method of supercharger on foundry production line

A casting production line and supercharger technology, which is applied to casting equipment, casting molding equipment, cores, etc., to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

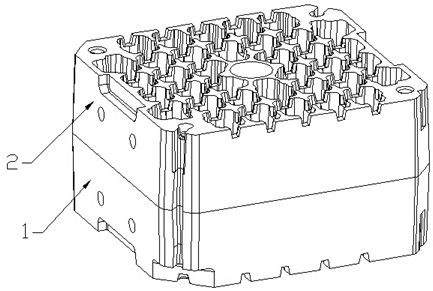

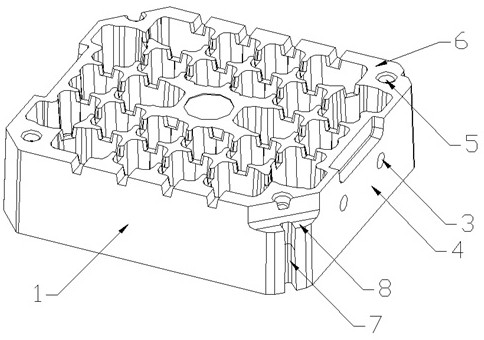

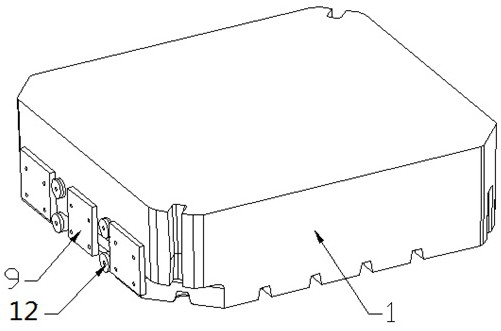

[0036] In order to better understand the purpose, structure and function of the present invention, the structure and usage method of a universal sand core for a supercharger on a foundry production line of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0037] Such as Figure 1-Figure 5 As shown, the present invention comprises: be used on casting production line, the lower casing 1 of turbocharger universal sand core, the upper casing 2 that clamps on the lower casing 1, wherein, lower casing 1 and upper casing 2 are provided with respectively Clamping positioning 3, clamping tightening 4, transport pallet positioning 5 and transport pallet 6, in order to facilitate the handling when the upper shell 1 and the lower shell 2 are combined together, the lower shell 1 is also provided with a hoisting guide 7 and a hoisting plane 8;

[0038] The clamping positioning 3 is a hole-like structure; and it is arranged on a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com