Mixed flow coating line and mixed flow coating method for standard compartment and van vehicles

A van and painting line technology, which is applied in spraying devices, paint booths, etc., can solve the problem that the car painting production line cannot realize the co-production of standard cars and vans.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

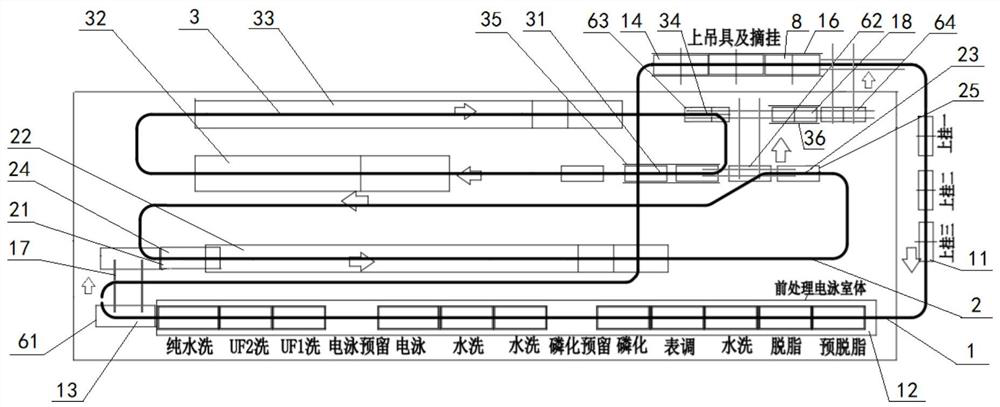

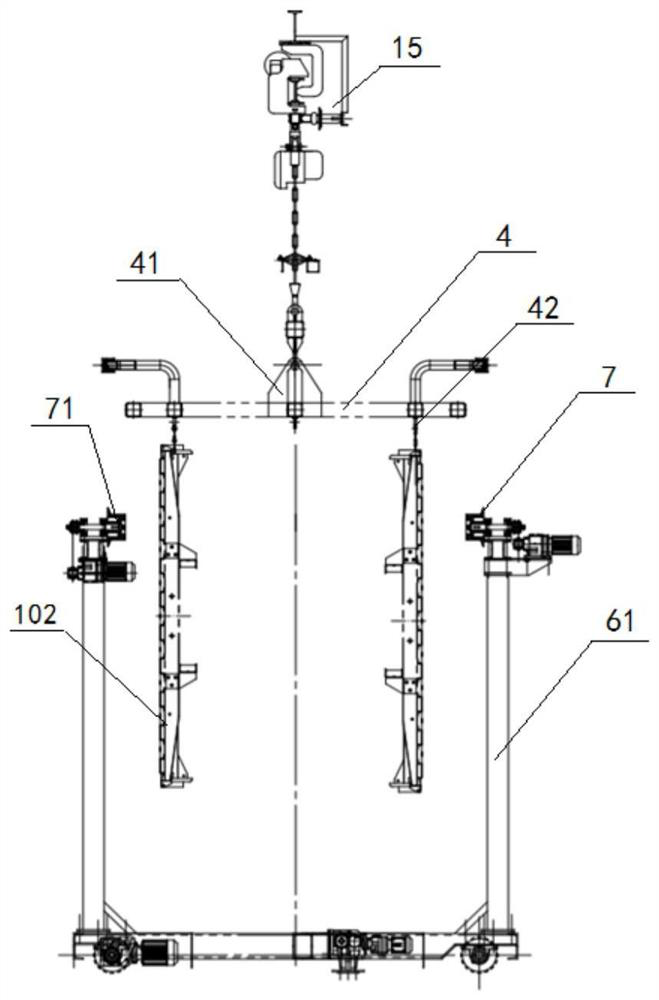

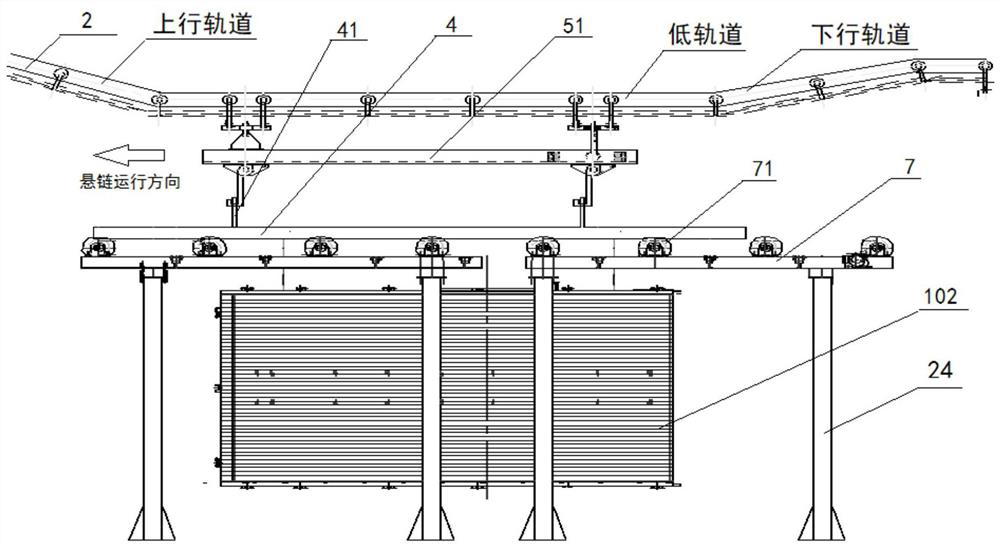

[0125]A mixed-flow coating line for standard cars and vans, comprising a pre-treatment track 1, a primer treatment catenary 2 and a topcoat treatment catenary 3, the pre-treatment track 1 is located on one side of the primer treatment catenary 2 , the other side of the primer treatment catenary 2 is a topcoat drying catenary 3; the pretreatment track 1 is a circular track, and the primer treatment catenary 2 and the topcoat treatment catenary 3 are ring A catenary, a plurality of electric hoists 15 slidingly matched with the pretreatment track 1 are hung, a mobile hanger 4 is hung on the bottom of the electric hoist 15, and a lifting lug 41 is arranged on the top of the mobile hanger 4, and the workpiece hanger The bottom is provided with a plurality of hanging holes 42, the primer-treated catenary 2 is provided with a primer drying catenary hook 51, and the top-coated catenary 3 is provided with a topcoat-treated catenary hook 52 ; The bottom of the ring-shaped pre-processing...

Embodiment 2

[0144] Embodiment 2 basic content is the same as embodiment 1, and its difference is:

[0145] In the fifth step, after the mobile hanger 4 that hangs the primer treatment workpiece breaks away from the primer treatment catenary 2 and moves to the top of the second translation trolley 62, it is judged whether the workpiece hung on the mobile hanger 4 is a standard or not. Car floor 102;

[0146] If the workpiece hanging on the mobile hanger 4 is not the standard compartment floor 102, then continue to carry out the topcoat catenary transfer;

[0147] If the workpiece hanging on the mobile hanger 4 is the standard compartment floor 102, then move the second translation dolly 62 to the transfer station 18 along the translation dolly track 17, and make the second translation dolly 62 and the transfer high roller rack 36 top The roller table 7 is connected, and the second translation trolley 62 is controlled to rotate with the top roller 71 of the transfer high-position roller fr...

Embodiment 3

[0149] Embodiment 3 basic content is the same as embodiment 2, and its difference is:

[0150] In the eighth step, if the finished workpiece hung on the mobile hanger 4 is the side panel 103 of the standard compartment or the front and rear panels 104 of the standard compartment, the front and rear panel removal trailer 91 is moved to control the lifting of the removal and hanging station 14. On the platform 8, the lifting platform 8 that controls the lifting station 14 rises, and the lifting platform 8 drives the front and rear panel trailers 91 to rise until the side panels 103 of the standard compartment or the front and rear panels 104 of the standard compartment are placed on the front and rear panel trailers. 91 and coordinate with the baffle plate 911, the operator removes the hook, the standard compartment side panel 103 and the standard compartment front and rear panels 104 are separated from the mobile hanger 4, the removal and hanging is completed, and the standard c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com