Multi-vehicle-type automatic part feeding device

A multi-model, automatic technology, applied in auxiliary devices, conveyor control devices, conveyor objects, etc., can solve the problems of low automobile welding efficiency, difficult for machines to accurately pick up parts, reduce factory automation rate, etc., to save labor costs. , high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

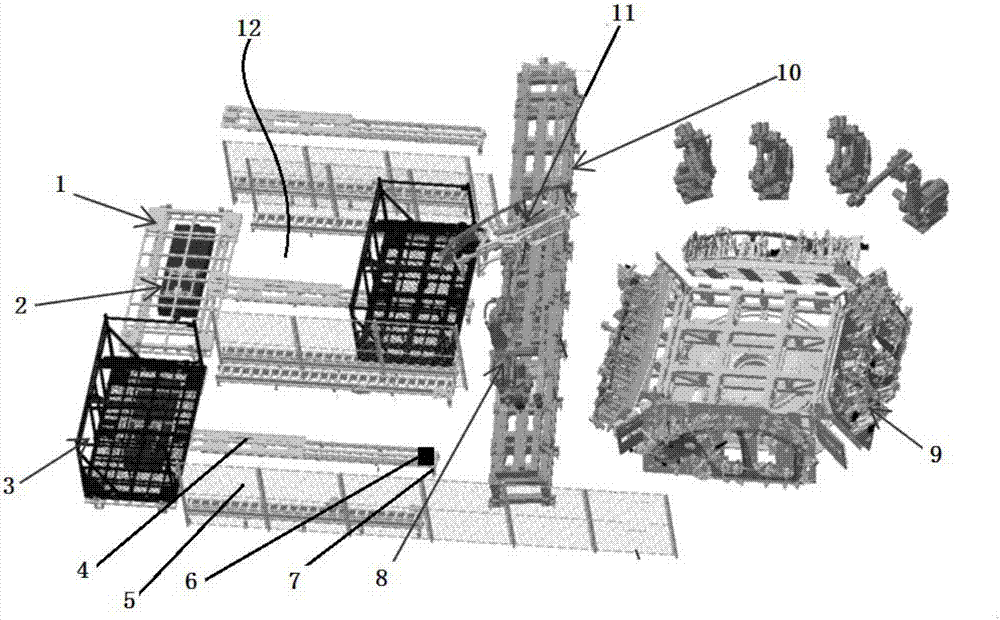

[0021] An automatic loading device for multiple vehicle models, its structure is as follows: figure 1 As shown, it includes a material transport unit, a material positioning unit, a material grabbing unit, and a turntable fixture 9. The material positioning unit includes two fixing frames 12 that match the material transport unit. When working, the material transport unit transports the parts to the corresponding model. Fixed in the fixed frame 12, the material grabbing unit grabs the parts in the material transport unit to the turntable fixture 9 to carry out the next process.

[0022] The material transportation unit includes a pallet 2 for placing parts, an AGC trolley 1 for driving the pallet 2 to move, and a material rack 3. Inside the material rack 3, there is a telescopic hook for fixing the pallet 2. When working, the AGC trolley 1 is pulled and placed The pallet 2 with parts enters the inside of the material rack 3, and the telescopic hook catches the pallet 2. Throu...

Embodiment 2

[0026] A device similar to that of Embodiment 1 is adopted, the difference is that the device of this embodiment is provided with a PLC controller, which can control the running track of the AGC trolley, control the stretching and opening and closing of the telescopic hook on the material rack, and control The expansion and opening and closing of the telescopic claws on the drag chain, the control of the operation of the motor, the movement of the mechanical arm on the moving guide rail and the running track of the mechanical arm improve the automation of the entire device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com