Steel structure system for precisely positioning side wall total assembly frames

A precise positioning, steel structure technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low positioning accuracy, sturdy and complex mechanism, unable to meet the needs of high-quality production, and achieve repeatable positioning accuracy. High, simple and reliable positioning method, and the effect of improving the quality of body welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

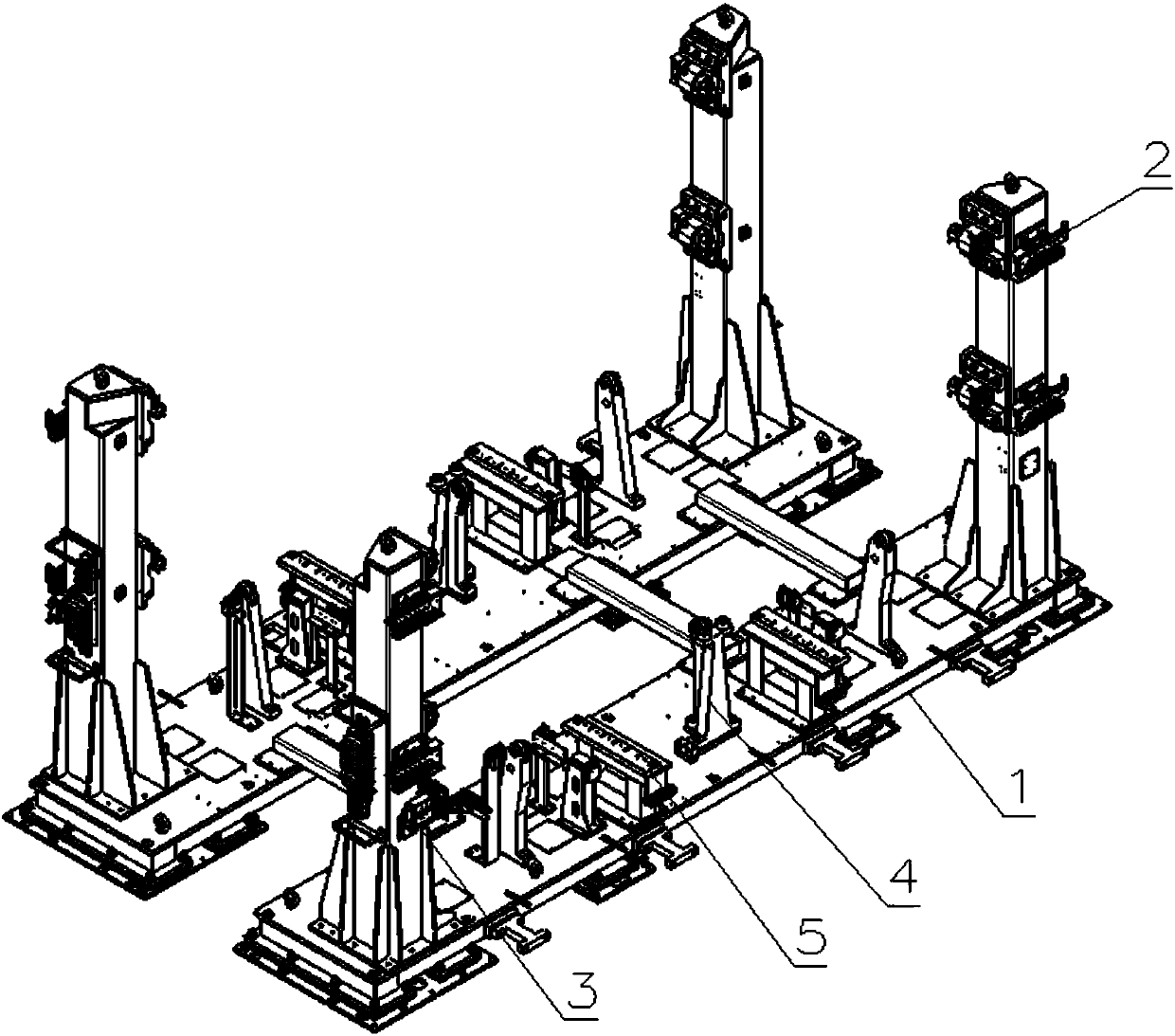

[0032] A steel structure system for the precise positioning of the frame of the side enclosure assembly, such as figure 1 As shown, it is used in the body-in-white welding production line, including:

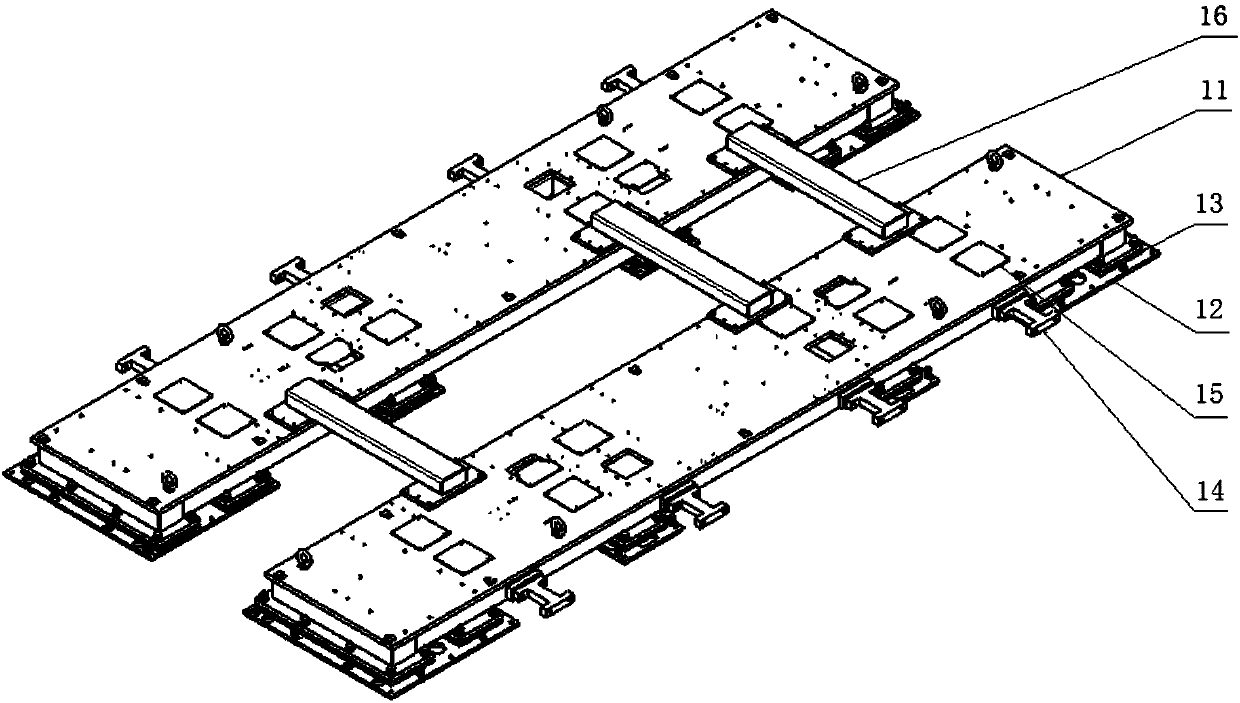

[0033] Bottom frame unit 1: located at the bottom, used for the support and installation of each functional unit, such as figure 2 As shown, the base frame unit 1 includes a pair of base frames 11, an adjustment plate 13 disposed at the lower end of the base frame 11, a patterned cover plate 15 disposed on the upper portion of the base frame 11, and an external device connector 14 disposed on the side of the base frame 11. The lower part of the adjustment plate 13 is provided with an anchor plate 12, and the bottom frame 11 is connected by a connecting beam 16.

[0034] Guide rail unit 5: set on the floor frame unit 1, and dock with the mobile equipment that conveys the overall assembly frame around the side, such as Image 6 As shown, it includes a rail mounting part 51 , a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com