Flywheel bolt screwing mechanism

A bolt and flywheel technology, which is applied in the field of flywheel bolt tightening mechanism, can solve the problems of incompatibility with powertrain, inability to achieve collinearity, and low efficiency, and achieve the effects of simple mechanism, reduced production cost, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

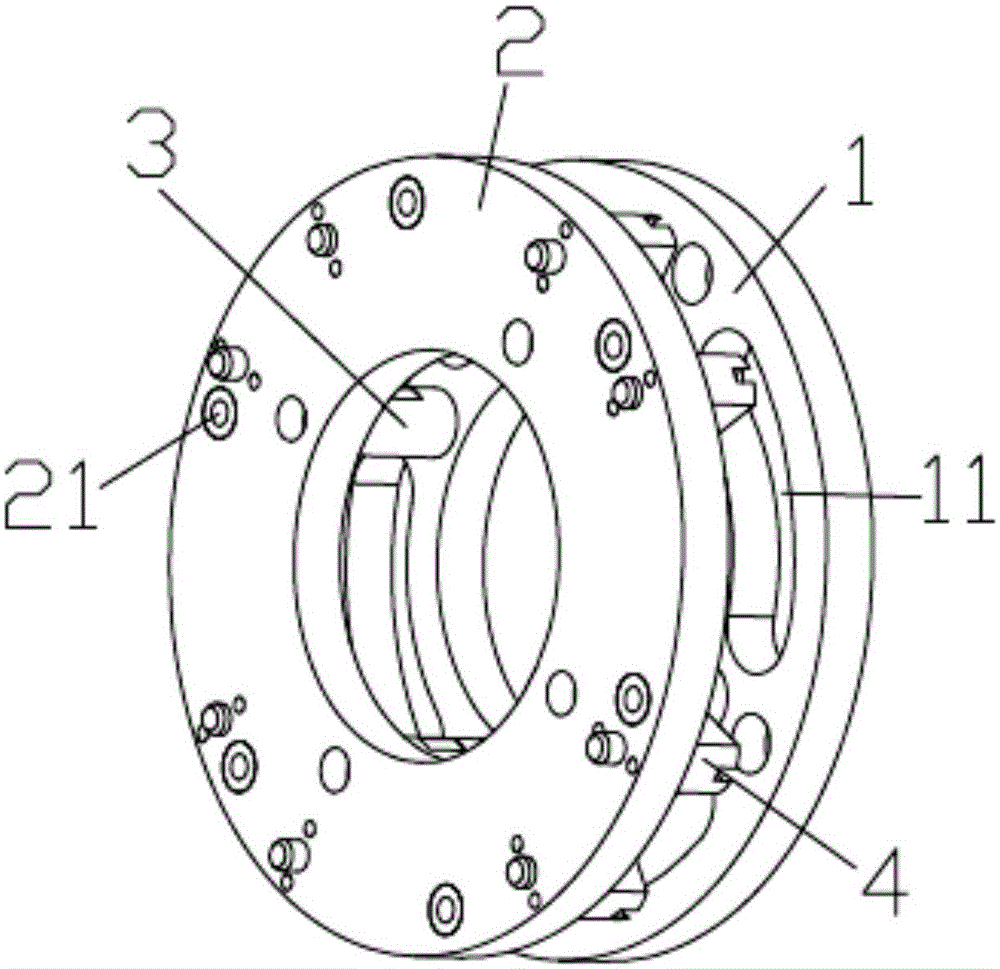

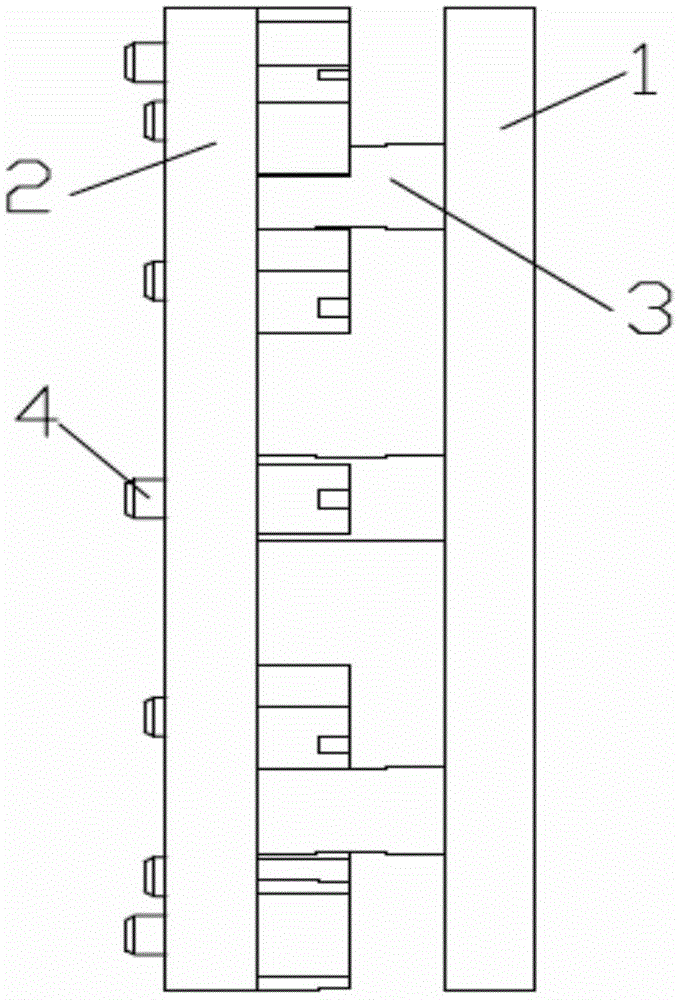

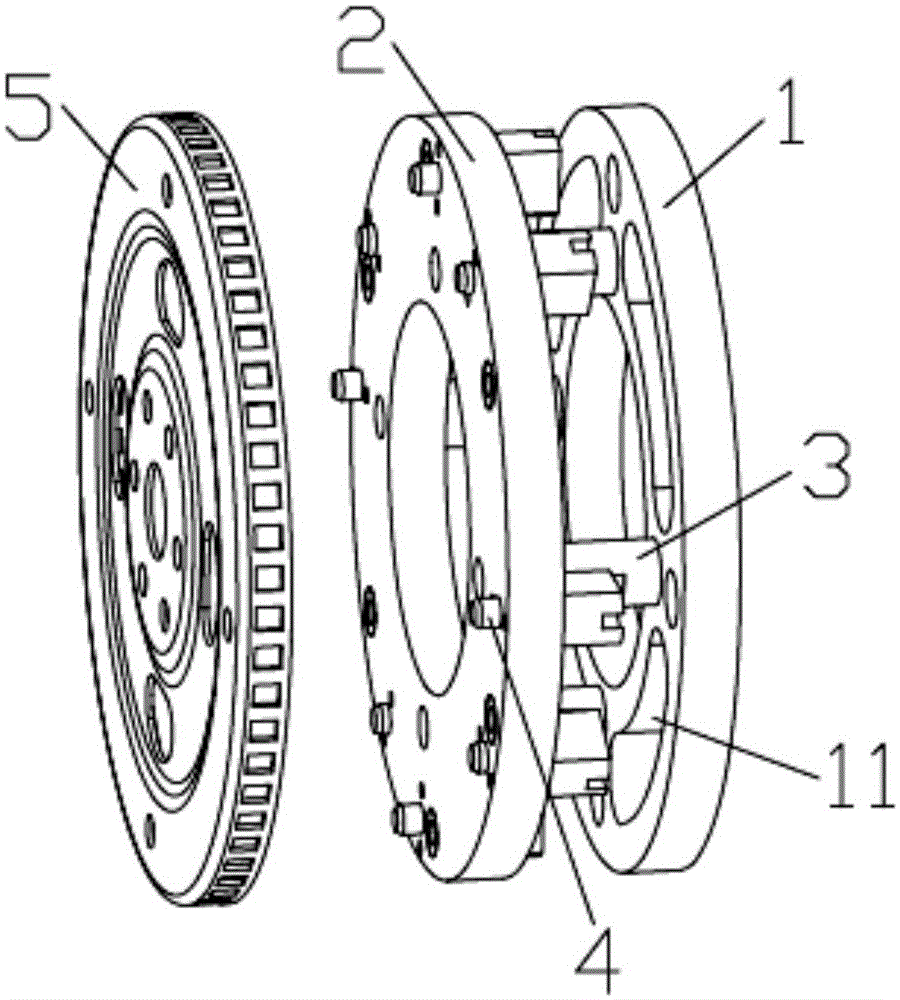

[0019] The flywheel bolt tightening mechanism of the present invention includes a bolt twisting rod, and a driving motor drives the bolt twisting rod to rotate, and also includes a positioning mechanism for positioning the flywheel. Such as figure 1 , 2 As shown, the locating mechanism is provided with a locating pin hole 21 cooperating with the pin on the flywheel 6 of the manual transmission engine and an elastic locating pin 4 cooperating with the locating hole on the flexible disk 5 of the automatic transmission engine, and the elastic locating pin 4 in the elastic locating pin 4 The positioning pin is limited by a spring, and the pin head end can elastically shrink into the pin seat. The combined positioning mechanism is applicable to the tightening of flywheels on automatic and manual t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com