Processing method of automobile collision box

A processing method and crash box technology, applied in vehicle parts, transportation and packaging, etc., can solve the problems of complex crash box structure, difficulty in automation, complex processing process, etc., to improve welding quality and production efficiency, process simplification, and automation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

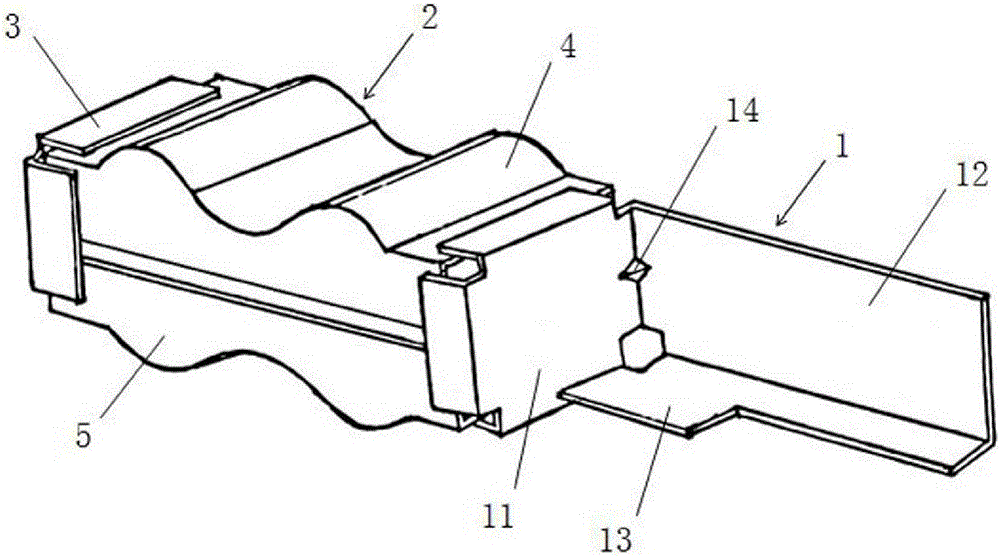

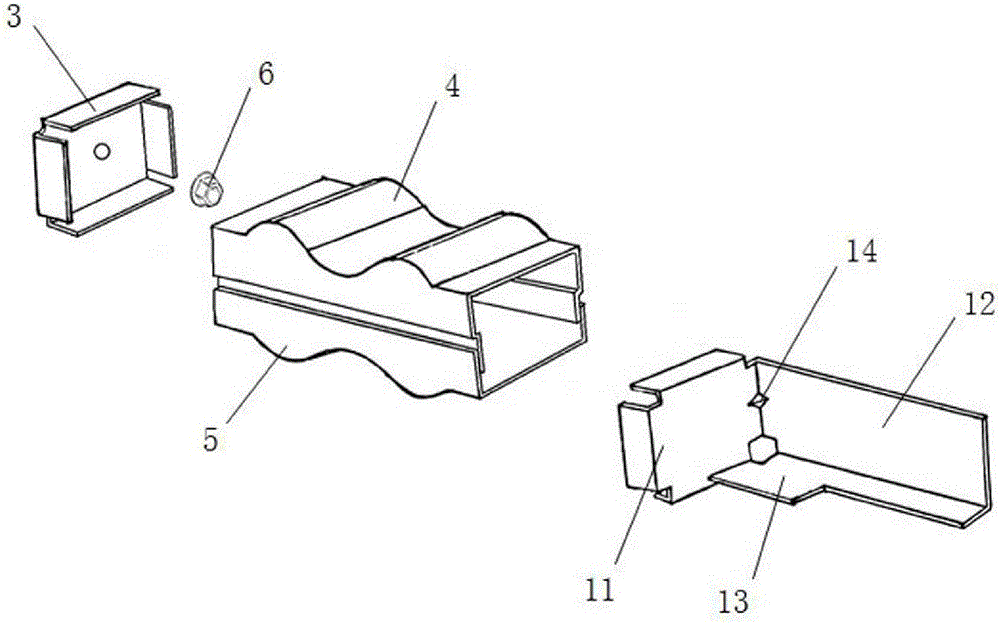

[0025] The present invention is a kind of processing method of automobile crash box, such as Figure 1 to Figure 2 As shown, the car crash box is made of sheet metal, and the cantilever 1 and the box body 2 of the car crash box are formed by welding the sheet metal parts. The processing method of the car crash box includes the following steps: The stamping process of the station produces various sheet metal parts: the cantilever 1, and the cover plate 3, the upper cover 4 and the lower cover 5 that form the box body 2, wherein the upper cover 4 and the lower cover 5 are both wavy curved surfaces and There are flanges on both sides. The cantilever 1 includes an L-shaped cover part 11 and a cantilever part 12, wherein the cover part 11 is provided with a flange and is welded with the box body 2. The cantilever part is provided with a supporting flange 13 to support The flange 13 is fixedly connected with the cover part 11; b) welding the nut 6 to the cover 3; c) welding the cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com