Corrosion-resistant flux-cored welding wire used for gas shielded welding

A gas shielded welding and corrosion resistance technology, applied in welding media, manufacturing tools, welding equipment, etc., can solve the problem of poor sulfuric acid dew point corrosion effect, etc. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with specific embodiment the present invention is described in detail,

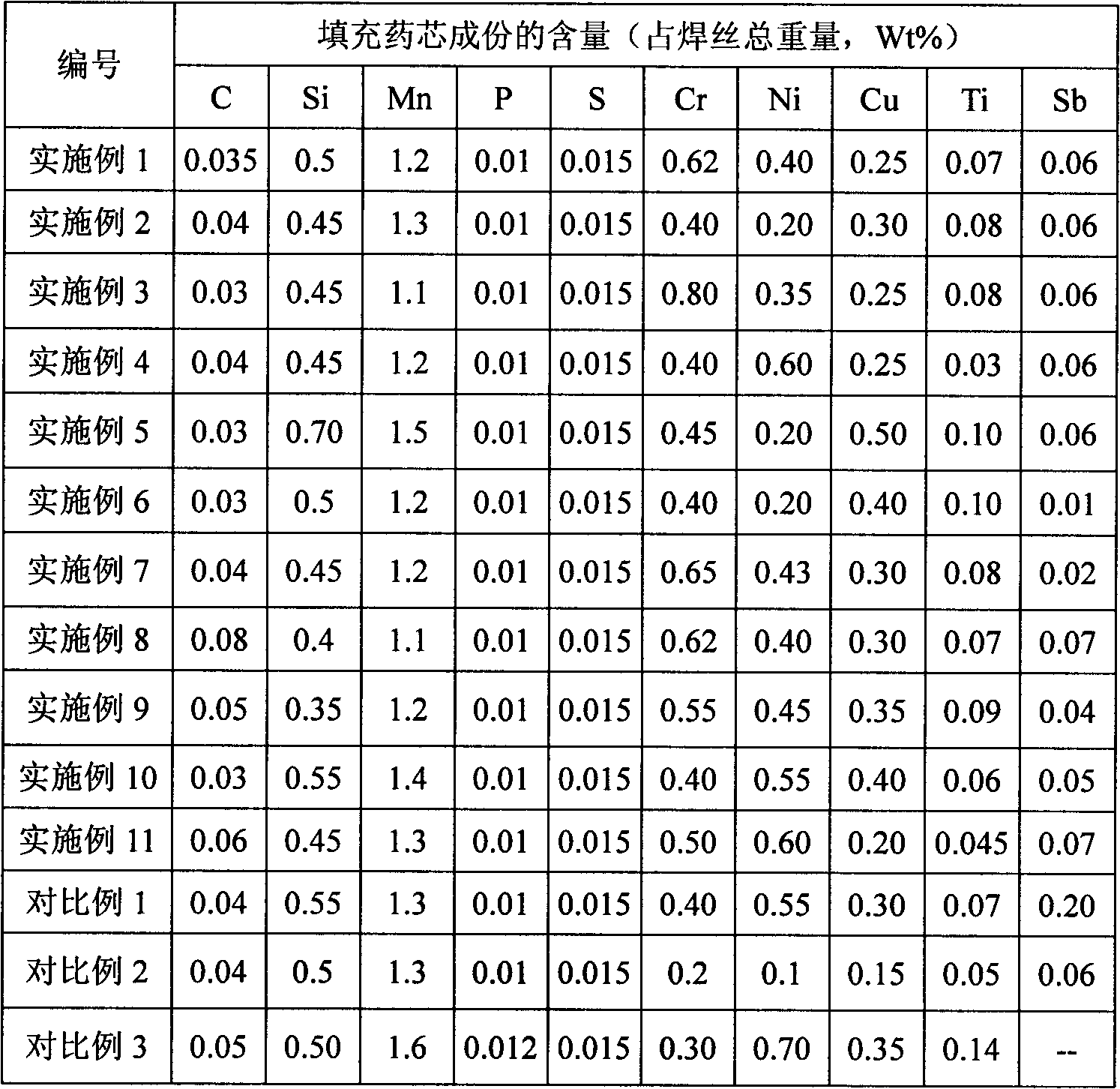

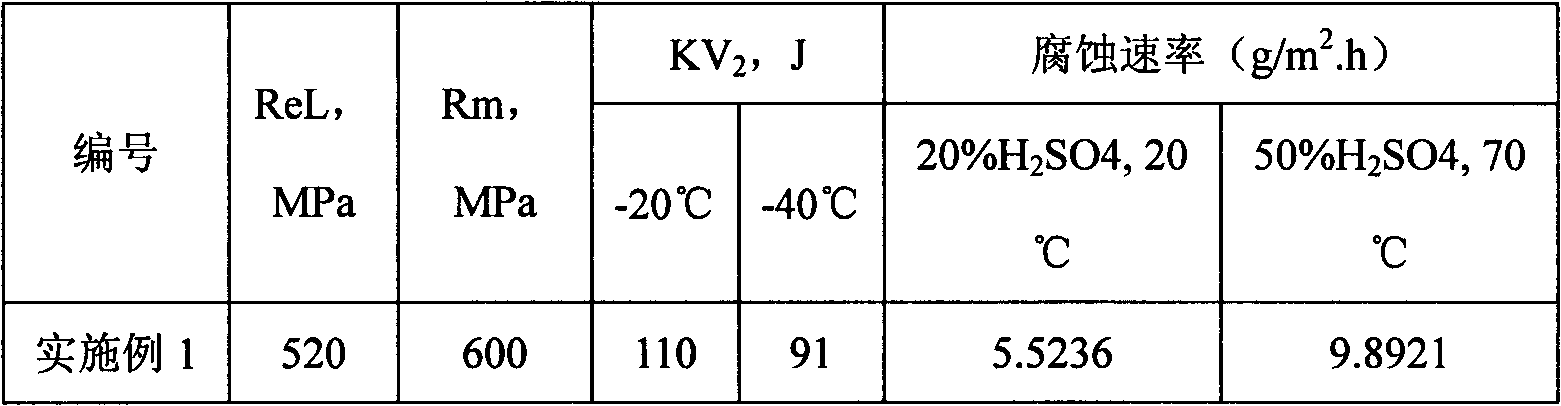

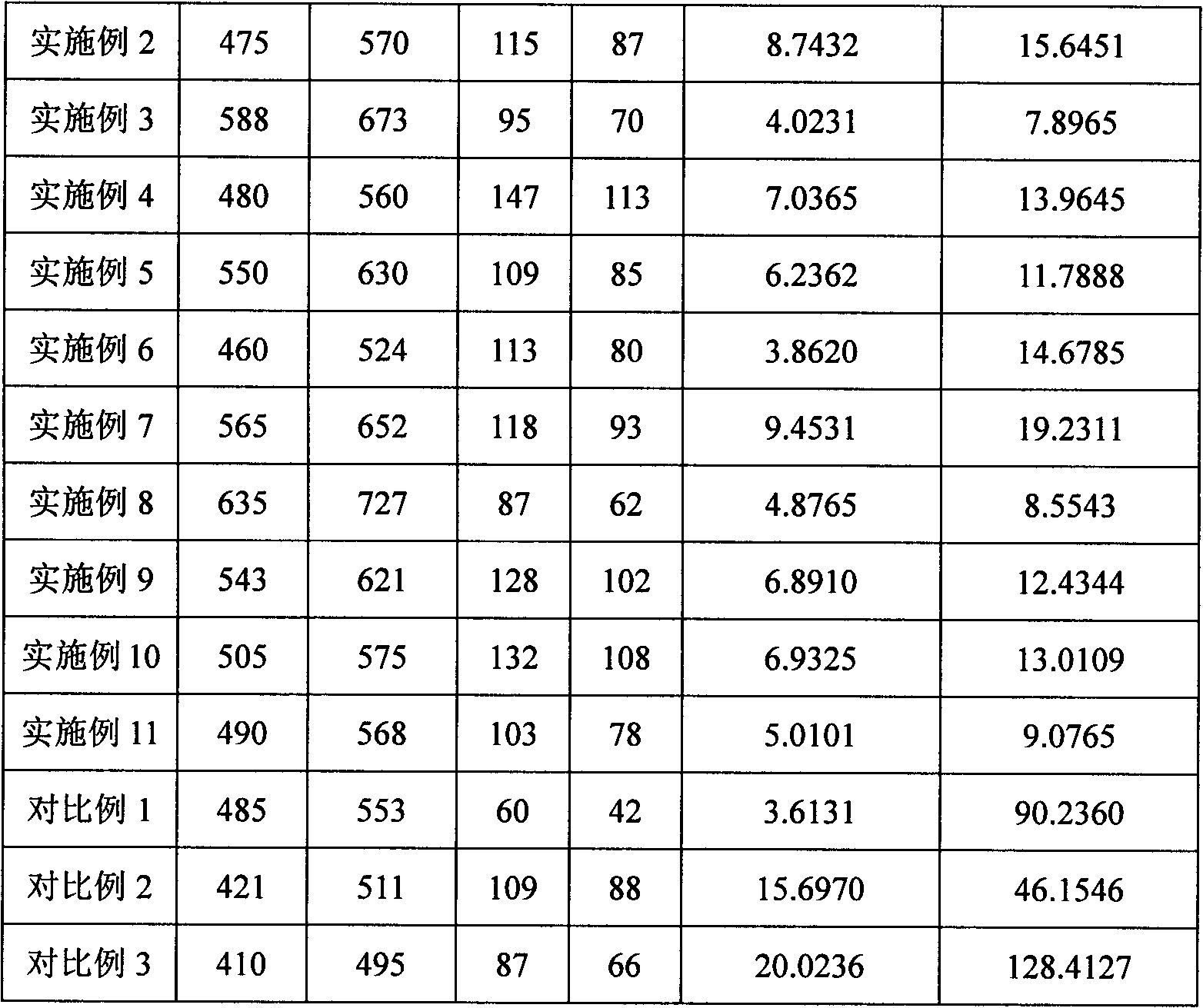

[0028] In the welding wire of the present invention, the percentages of the alloy elements in the alloy powder in the total mass of the welding wire are: C: 0.03% to 0.08%, Si: 0.3% to 0.7%, Mn: 1.1% to 1.5%, Cu: 0.2% to 0.5% %, Cr: 0.4%~0.8%, Ni: 0.2%~0.6%, Ti: 0.03%~0.1%, Sb: 0.02%~0.10%, S≤0.015%, P≤0.02%, while controlling Cu / Sb elements The scale range is between 4.0 and 8.0. Flux-cored welding wire is produced by using cold-rolled steel strip, the thickness of which is 0.9mm, and the width is 10mm. The particle size of the alloy powder used is 80-100 mesh. After the steel strip is rolled by a flux-cored wire rolling mill, the shape of the end face turns into V-U-O in turn, and the alloy powder is mixed evenly and added to the welding wire when the welding wire is rolled to a U shape according to a certain filling rate, and finally it can be formed into a φ4.6mm powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com