Full automatic dip soldering machine

A tin dipping machine, fully automatic technology, applied in the direction of tin feeding device, auxiliary device, manufacturing tools, etc., can solve the problems that the consistency of processing technology is difficult to meet, the product quality cannot be guaranteed, etc., and achieve compact structure and low production cost. Low, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

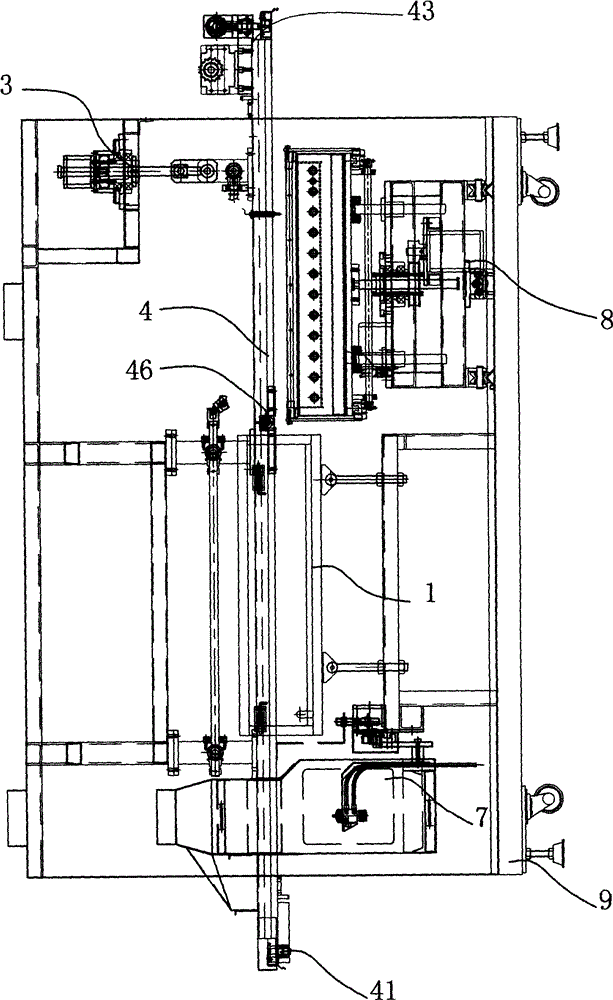

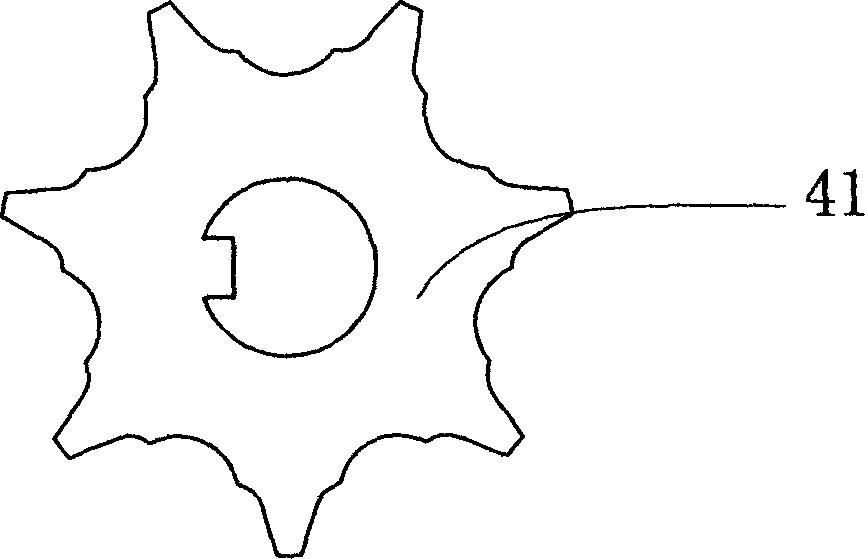

[0027] See attached Figure 1-11 , it comprises body 9, spray device 7 is installed in body 9, preheating device 1, automatic lifting type tin stove 8, angle deflection device 3, PCB board conveying line 4; The main beam 47 of PCB board conveying line 4 is installed The sprocket 41 and the main beam 47 are equipped with a hinge 46 , a chain joint 42 and a transmission assembly 43 .

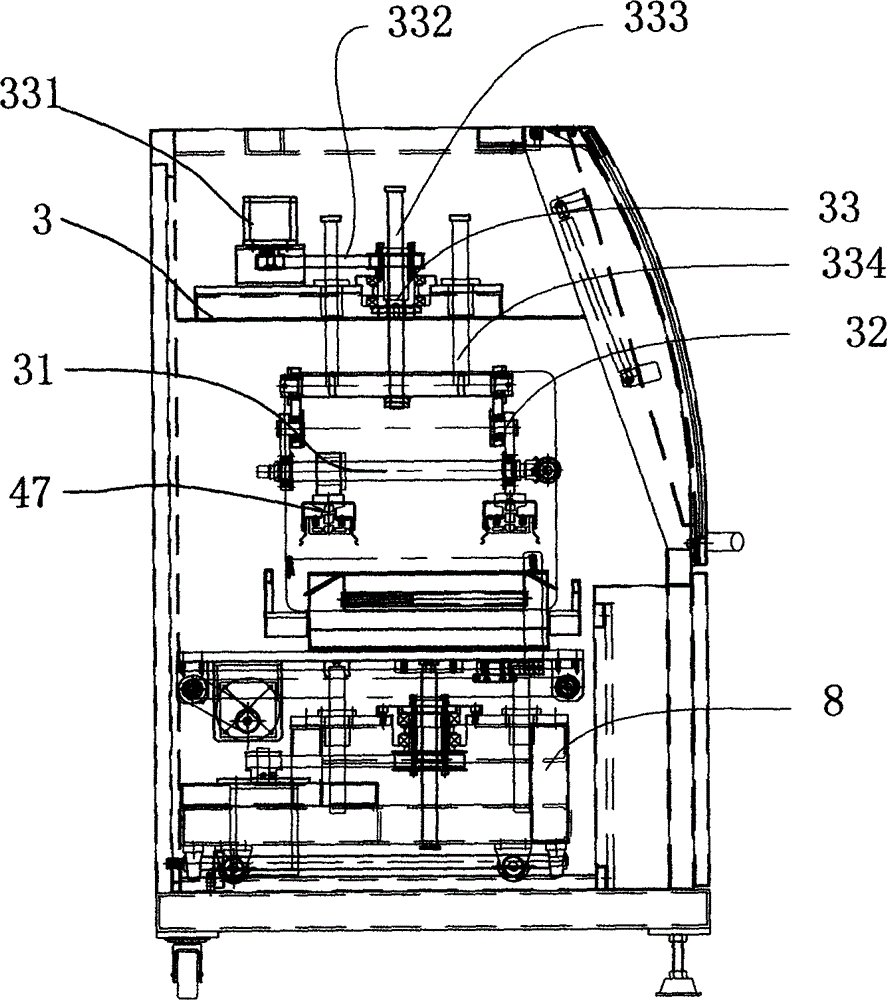

[0028] The angle deflection device 3 is equipped with a width adjusting screw 31, a movable joint 32, and a power transmission assembly 33;

[0029] The power transmission assembly 33 is equipped with a motor 331, a timing belt 332, a ball screw 333 and a linear shaft 334;

[0030] The power transmission assembly 33 can be installed above or below the main beam 47;

[0031] A sprocket 41 is installed on the main beam 47, and the sprocket 41 has 7 teeth;

[0032] Described girder 47 is equipped with hinge 46, and hinge 46 is made up of left hinge 461, right hinge 462, hinge pin 463, bearing 464;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com