LED lamp strip assembling device

A technology for LED light strips and LED light devices, which is applied in lighting and heating equipment, lighting devices, semiconductor devices of light-emitting elements, etc., can solve the problems of low welding accuracy, high cost, low efficiency, etc. The effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

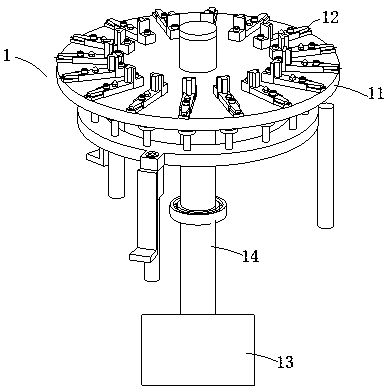

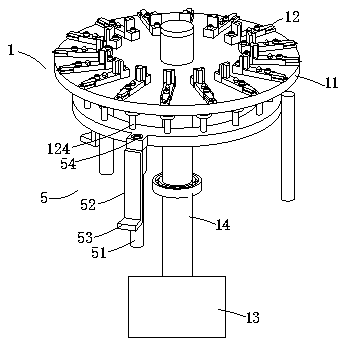

[0036] Such as Figure 1 to Figure 12As shown, an LED light strip assembly equipment includes a light strip assembly rotating disk device 1, an LED lamp feeding device 2, an LED light direction testing device 3, and a rotating LED light device are distributed on the circumference of the light strip assembly rotating disk device 1. 4. Screening defective LED lamp device 5, leg cutting device 6, fluxing flux device 7, color ring resistance device 8, LED lamp welding device 9, resistance measuring device 10.

[0037] The light strip assembly rotating disk device 1 is composed of a rotating disk 11, a lamp clip 12, and a servo motor 13. The rotating disk 11 is connected to the panel through a ball bearing. The middle part of the rotating disk 11 is connected to the servo motor 13 through a connecting rod 14. The lamp clips 12 are evenly arranged on the peripheral surface of the rotating disk 11 .

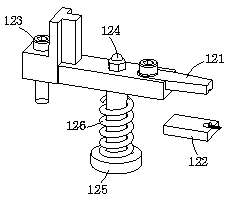

[0038] The lamp clip 12 has an up-and-down structure. The lamp clip includes an up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com