A copper laser welding device and method

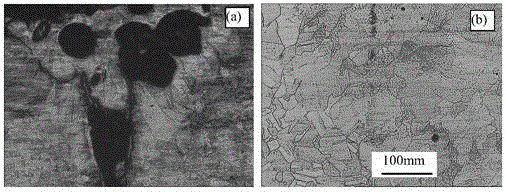

A laser welding and laser welding head technology, applied in the field of red copper laser welding devices, can solve the problems of poor surface quality, discontinuous welding seam, excessive welding heat input, etc. Measures Reliable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

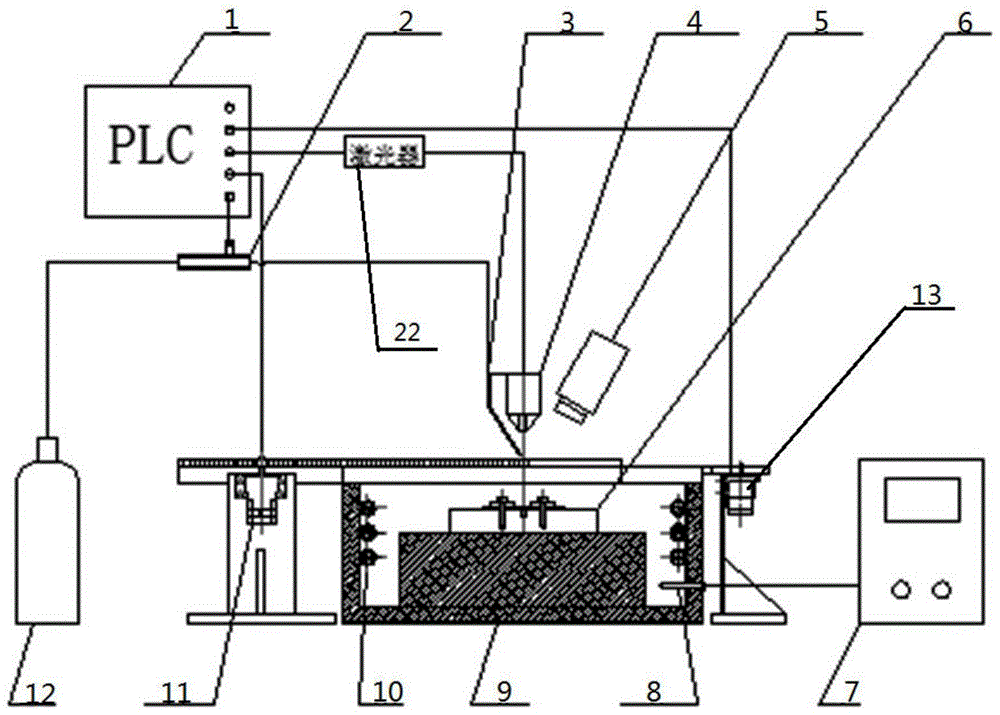

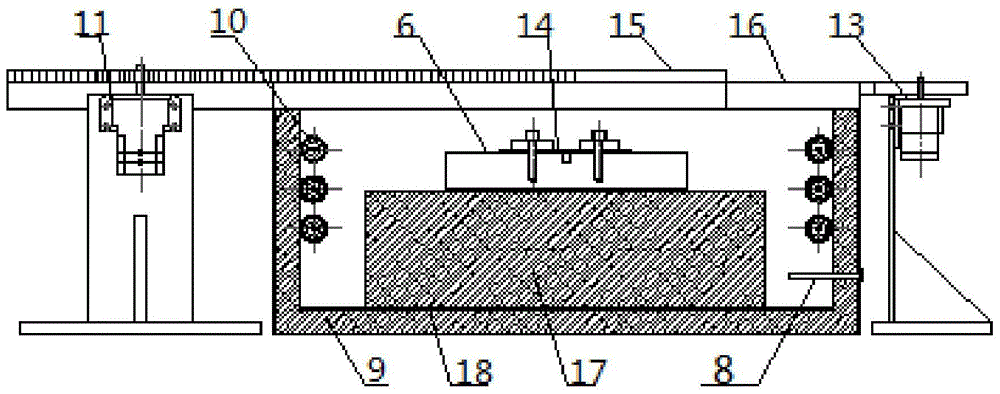

[0035] Such as figure 1 A red copper laser welding device shown has a control system, a laser welding system, a preheating mechanism and a temperature control mechanism, wherein the control system is a PLC controller 1, the laser welding system includes a laser 22 and a laser welding head 4, and the temperature control mechanism includes Temperature control box 7, thermocouple 8 and infrared thermometer 5, such as figure 2 The shown preheating mechanism includes heating insulation box 9, insulation brick 17, fixture 6, dry heating heating pipe 10, cover plate 16, pumping plate 15, motor I13 and II11. Insulation brick 17 is arranged on the inside of the casing of heating insulation box 9, and clamp 6 is arranged on insulation brick 17 and is used for fixing workpiece 14, and several dry-burning heating pipes 10 extend box body on the both side walls in heating insulation box 9. Axially evenly distributed, the cover plate 16 and the pumping plate 15 are respectively arranged a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com