A kind of nickel-based electrode for welding uns N10276 nickel-based alloy and its preparation method

A nickel-based electrode and nickel-based alloy technology, applied in welding equipment, welding medium, metal processing equipment, etc., can solve the problems of poor all-position welding process, poor surface brightness, uneven weld formation, etc., and achieve good Excellent welding process performance, stable performance, and reasonable formula ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further specifically described below through specific examples, but the present invention is not limited to the examples.

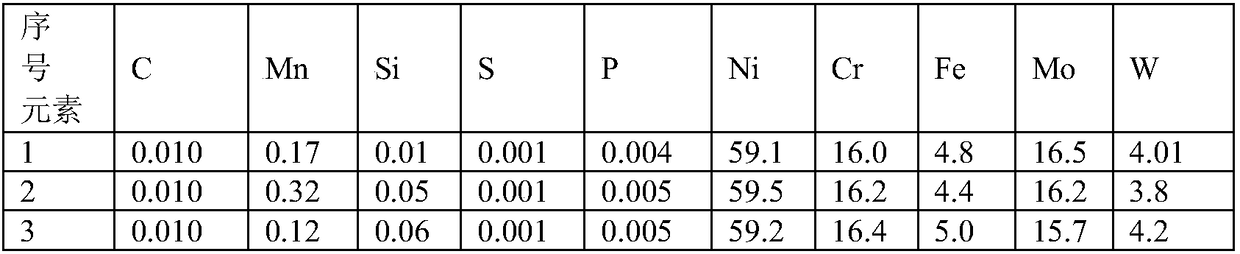

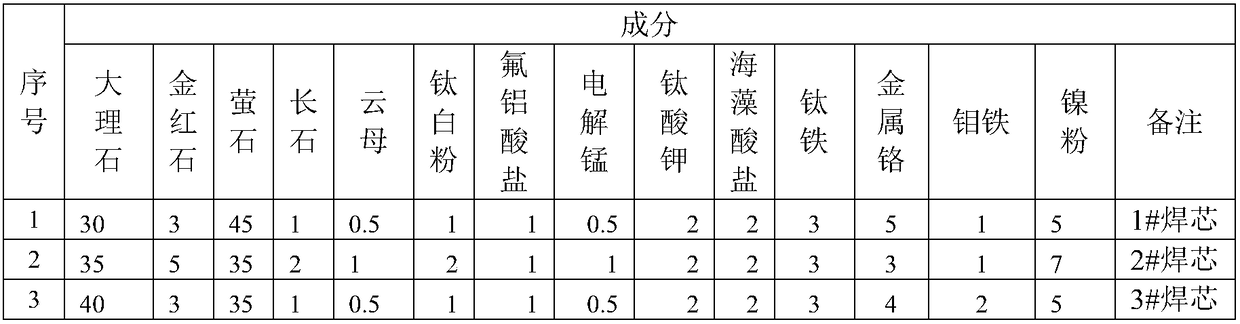

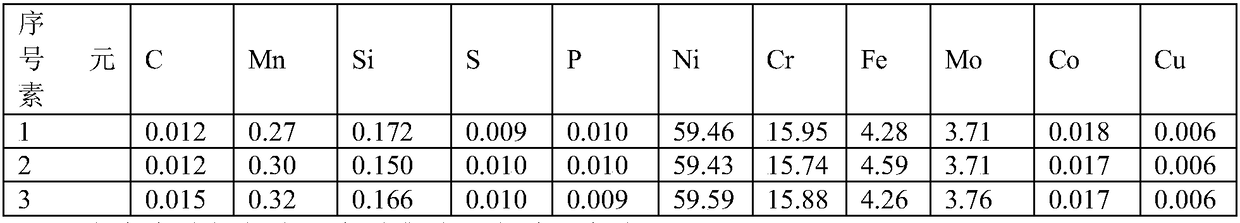

[0024] A nickel-based electrode for welding UNS N10276 nickel-based alloy of the present invention includes a welding core and a coating covering the welding core, and the weight percentages of the chemical components of the welding core are respectively (wt%): C ≤0.015%, Mn≤0.50%, Si≤0.15%, S≤0.010%, P≤0.015%, Cr15.0%-17.0%, Mo15.0%-17.0%, W3.0%-4.5%, Fe4. 0%-7.0%, the balance is Ni and inevitable impurities; the weight percentages of the components in the drug skin are respectively: rutile powder 3-8%, marble powder 30-45%, fluorite powder 35-50% %, feldspar powder 1-5%, mica 0.5-2%, titanium dioxide 1.0-3%, fluoroaluminate 0.5-1.5%, electrolytic manganese 0.5-1.5%, potassium titanate 2-5%, alginate 1 ~3%, soda ash 0.3%~1.0%, metal chromium 2%~5%, molybdenum iron 1%~2%, nickel powder 5%~10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com