Steel beam machining device

A technology for processing devices and steel beams, applied in auxiliary devices, metal processing equipment, manufacturing tools, etc., can solve problems affecting construction efficiency, difficulty in ensuring consistent welding quality, affecting steel beam processing quality and processing efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

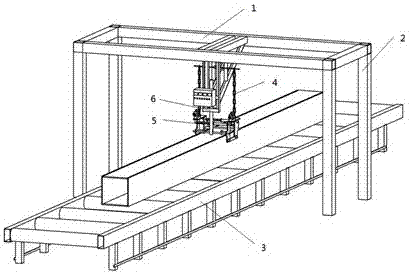

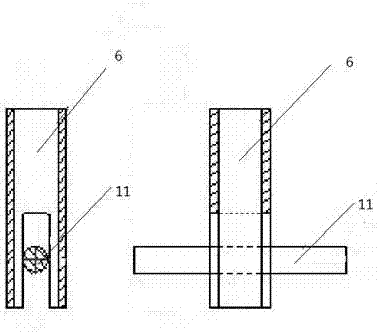

[0010] Embodiment 1, a kind of steel beam processing device, it comprises gate-shaped support 2, conveying roller 3, is provided with gate-shaped support 2 matched with conveying roller, is provided with beam 1 on the gate-shaped support, is provided with traction on beam 1 Rod 6, the bottom groove of draw bar 6 is fixed with the pull bar 17 of welding trolley, is provided with pulley on crossbeam, is equipped with chain 4 in the pulley, and one end of chain 4 is fixedly connected with drag bar 17 on welding trolley 5, The welding trolley is provided with a welding torch.

[0011] In this embodiment, the steel beam to be welded is placed on the transfer roller 3, the part to be welded corresponds to the welding torch, the transfer roller 3 is started, the steel beam body moves, and the welding device is opened at the same time, and the welding trolley 5 is operated by the drawbar. Can ride on the steel beam body and slide, so that the welding torch on the welding trolley 5 can...

Embodiment 2

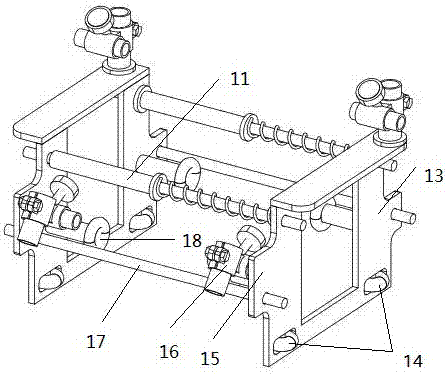

[0012] Embodiment 2, this embodiment further defines the structure of the welding trolley 5 on the basis of the embodiment 1. The welding trolley is as follows: a fixed rod 11 is provided between two support plates 13, and The two ends of the support plate 13 are respectively provided with fixed clamping plates 15, and two corresponding fixed clamping plates 15 are fixed with drag rods 17; Bolts are provided with running wheels 14 on both sides of the bottom of the support plate 13, guide rollers 18 are provided at the middle of the base plate, and a welding torch fixing cartridge 16 is provided at the end of the support plate 13, and the welding torch clamp is fixed on the fixing cartridge. 16; in this embodiment, the distance between the two support plates 13 can be adjusted through the screw and bolt devices on the fixed rod 11 and the drag rod 17, so as to adapt to the processing needs of steel beams of different sizes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com