Laser-arc composite welding device based on heat input control and welding method

A hybrid welding and heat input technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of increased welding heat affected zone and thermal deformation, laser energy loss, increased welding heat input, etc. Heat-affected zone and thermal deformation, reducing heat input, achieving the effect of deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

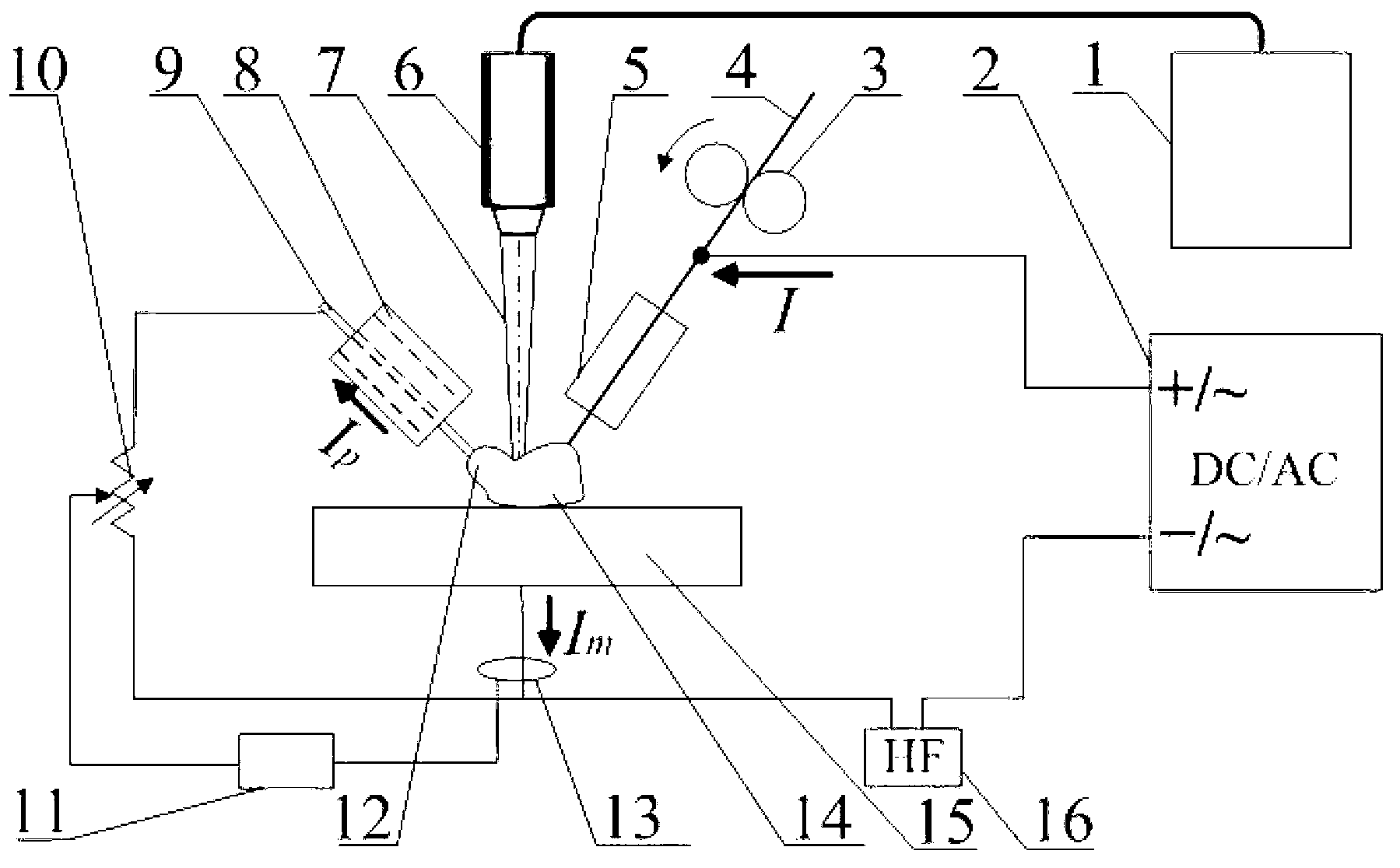

[0030] to combine figure 1 , which is an embodiment of non-melting electrode shunt control laser-arc hybrid welding heat input. This embodiment consists of fiber laser 1, arc welding power supply 2, wire feeding mechanism 3, melting electrode welding torch 5, and non-melting electrode welding torch (bypass welding torch) 8 , rheostat 10, rheostat controller 11, current sensor 13 and other components. The non-melting electrode welding torch 8 is filled with tungsten wire.

[0031] The steps of the welding method of the non-melting electrode shunt control laser-arc hybrid welding heat input device based on this embodiment are as follows:

[0032] Step 1: Process the part to be welded of the workpiece 15 into I-shaped, Y-shaped or V-shaped grooves as required. The surface is sanded and cleaned.

[0033] Step 2: During welding, the melting electrode welding torch 5 and the non-melting electrode welding torch 8 can be placed on both the front and rear sides of the laser head 6, ...

specific Embodiment approach 2

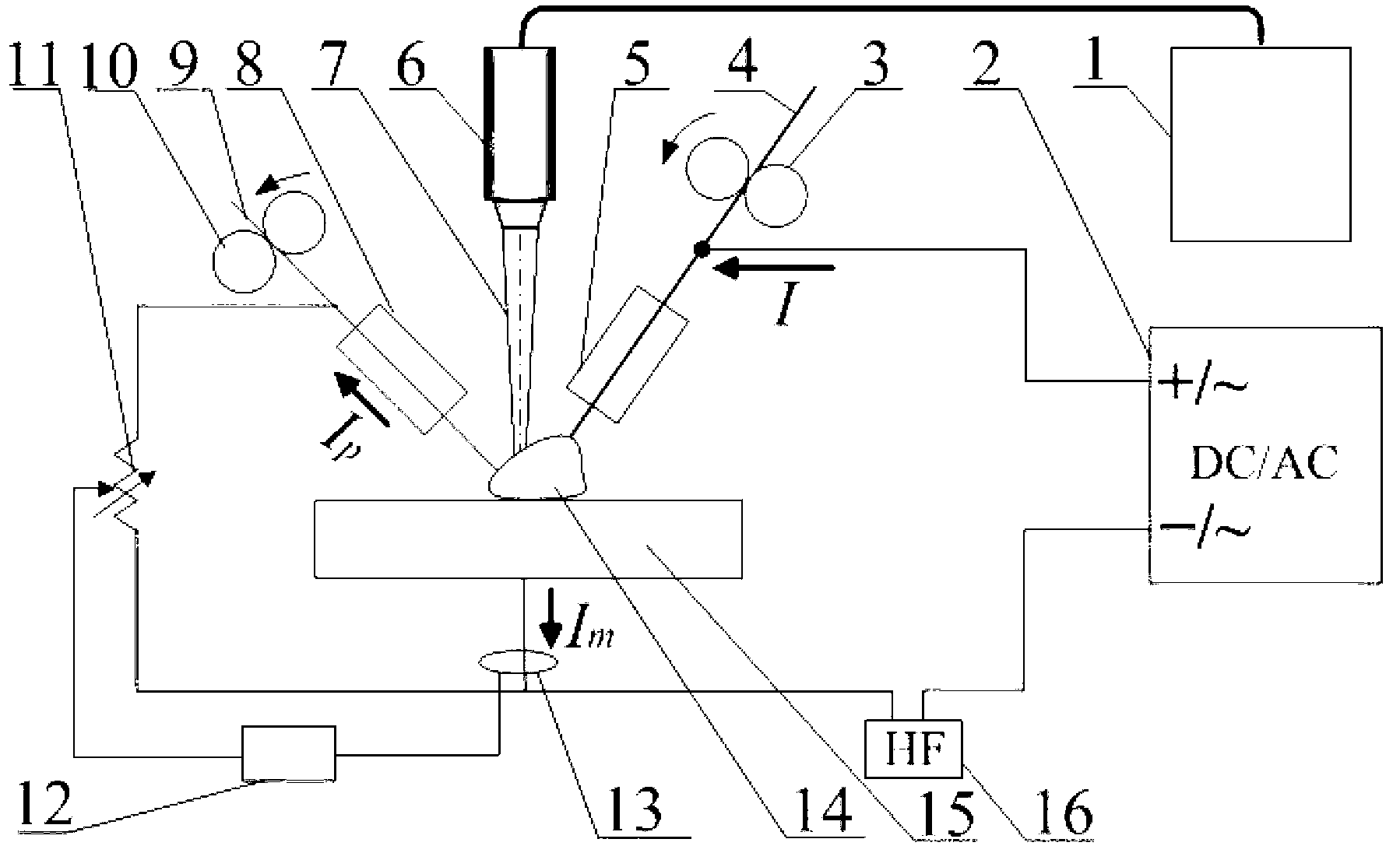

[0037] combine figure 2 , which is an embodiment of welding wire shunting to control the heat input of laser-arc hybrid welding. This embodiment consists of a fiber laser 1, an arc welding power source 2, a wire feeding mechanism 3, a main melting electrode welding torch 5, an auxiliary melting electrode welding torch 8, and a filler wire 9 , rheostat 11, rheostat controller 12, current sensor 13 and other components.

[0038] The steps of the welding method of the welding wire shunt control laser-arc hybrid welding heat input device based on this embodiment are as follows:

[0039] Step 1: Process the part to be welded of the workpiece 15 into an I-shaped, Y-shaped or V-shaped groove as required. Sand and wash.

[0040] Step 2: During welding, the main melting electrode welding torch 5 and the auxiliary melting electrode welding torch 8 can be placed on both the front and rear sides of the laser head 6, and can also be placed on the left and right sides of the laser head 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com