Patents

Literature

154results about How to "Small transmission error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

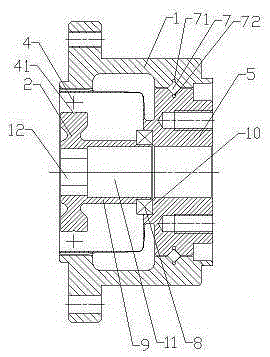

Bevel gear based on conjugate curves and meshing pair thereof

ActiveCN103075493AEasy to processImprove contact strengthToothed gearingsPortable liftingEngineeringContact Transmission

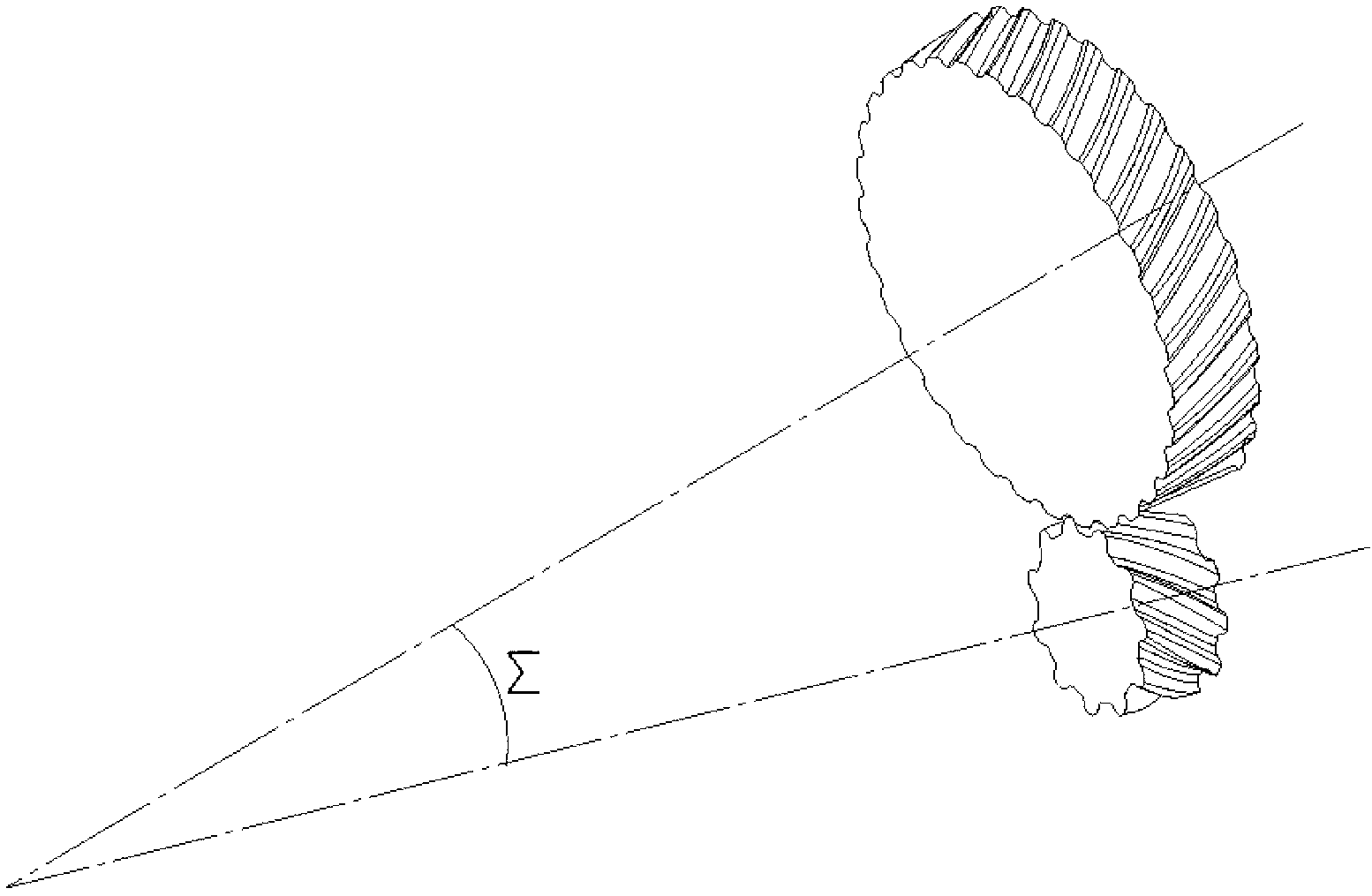

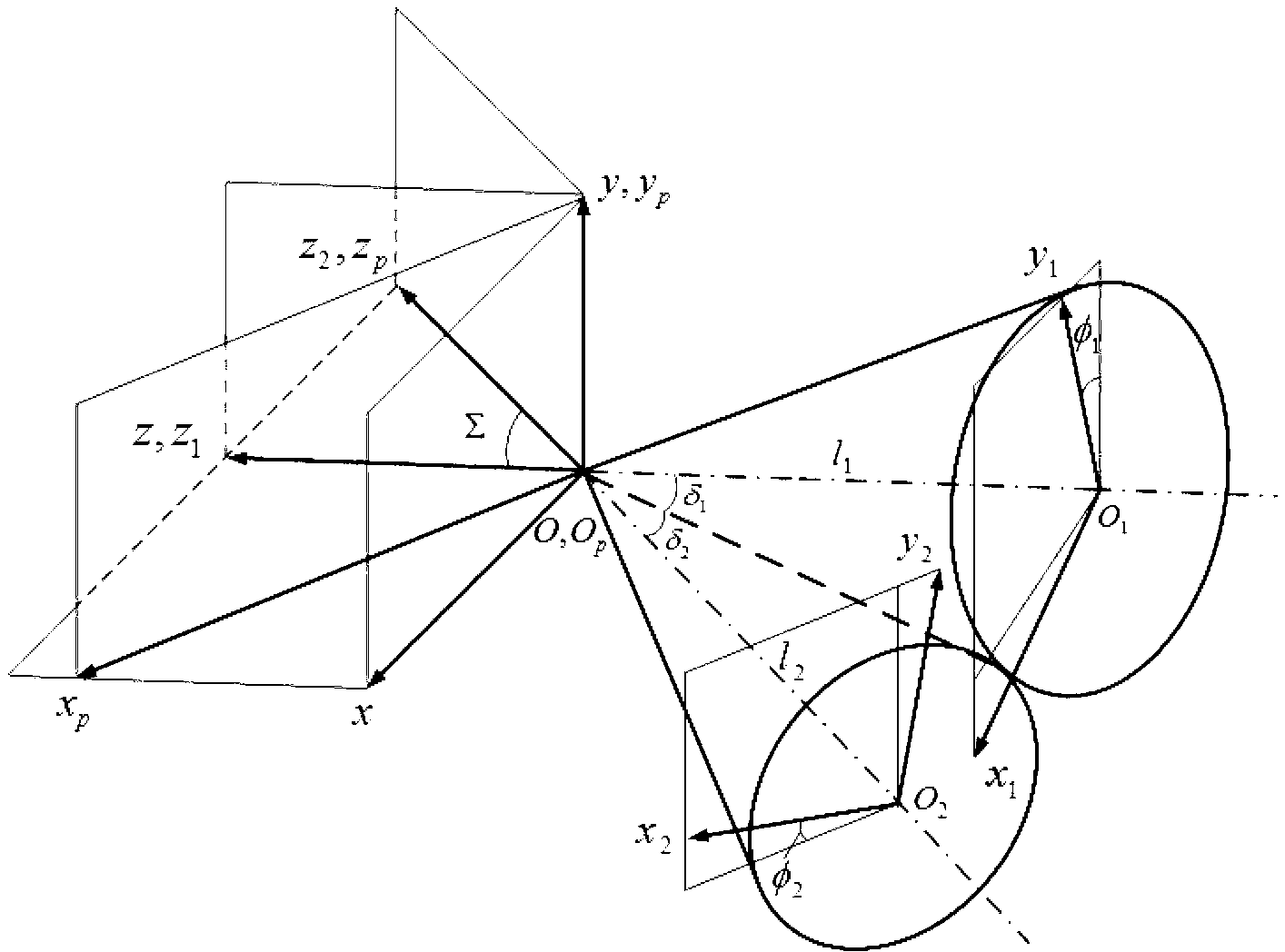

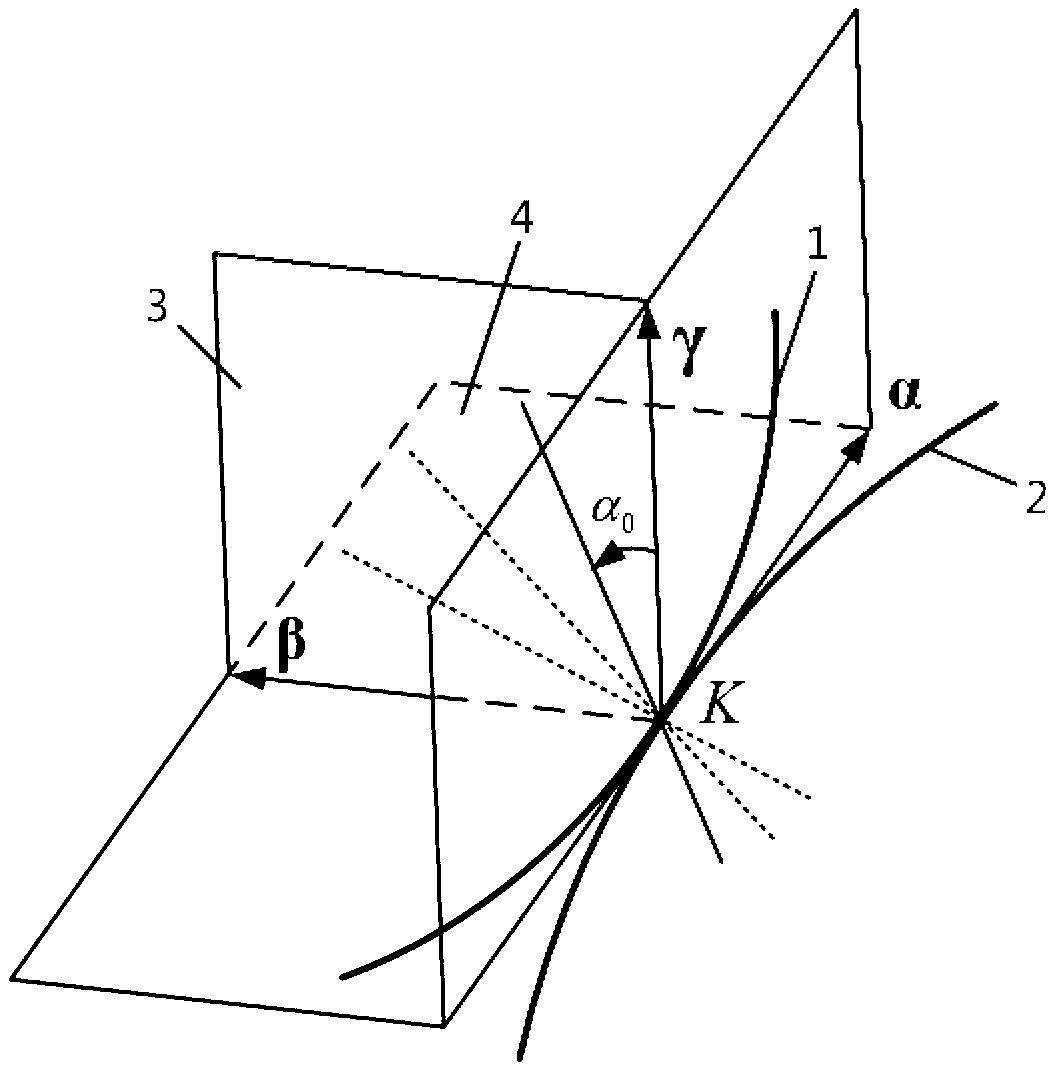

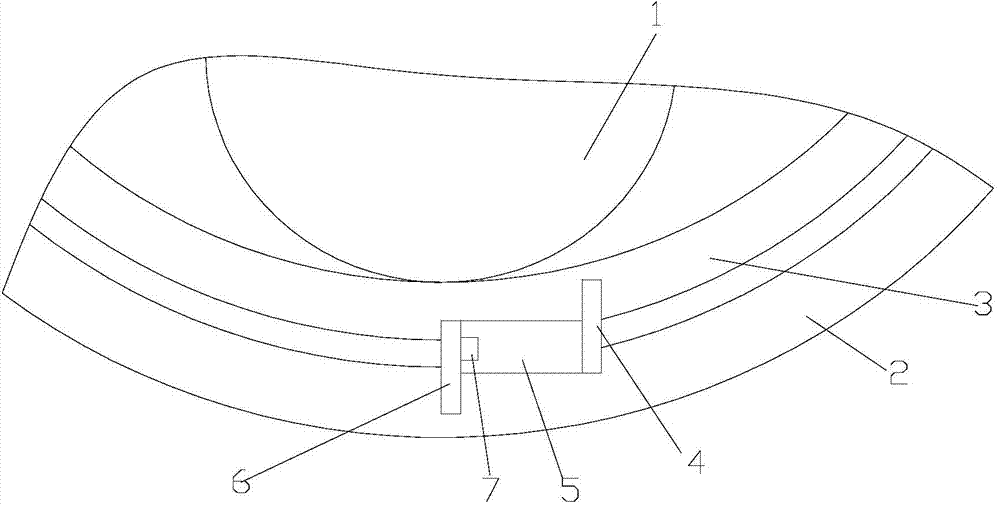

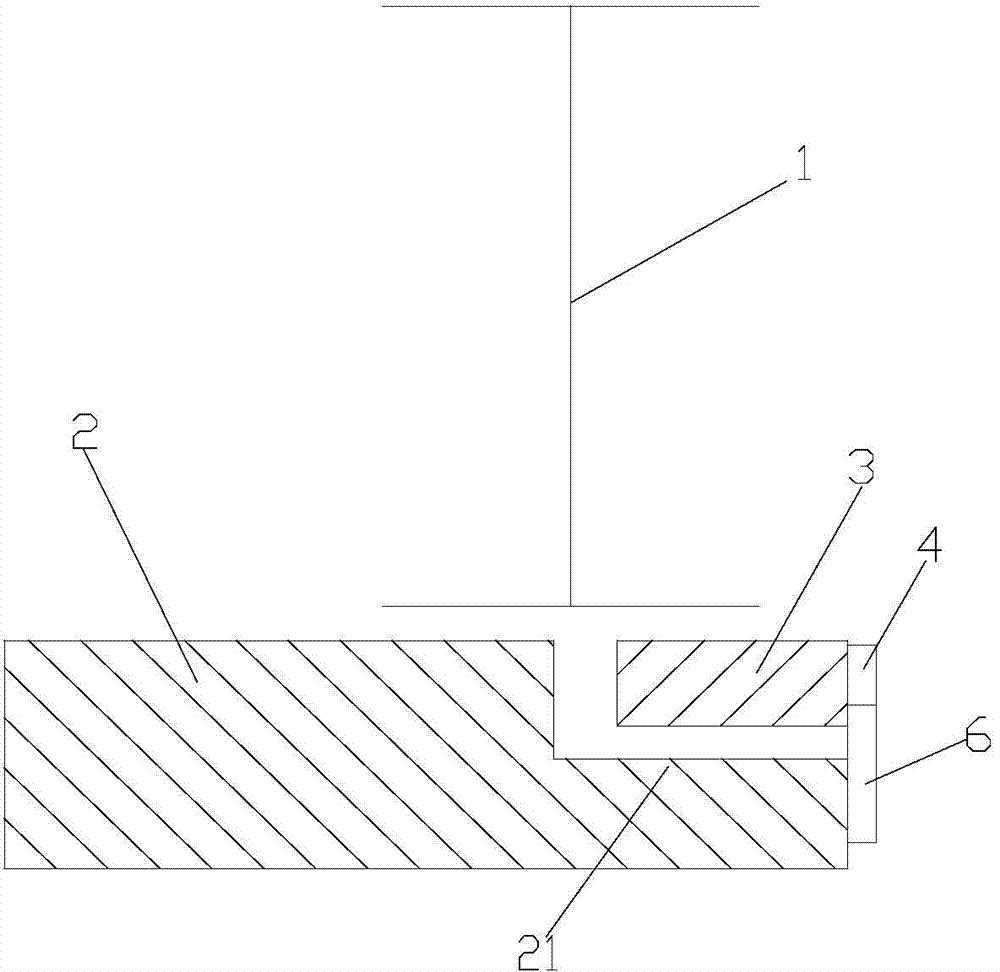

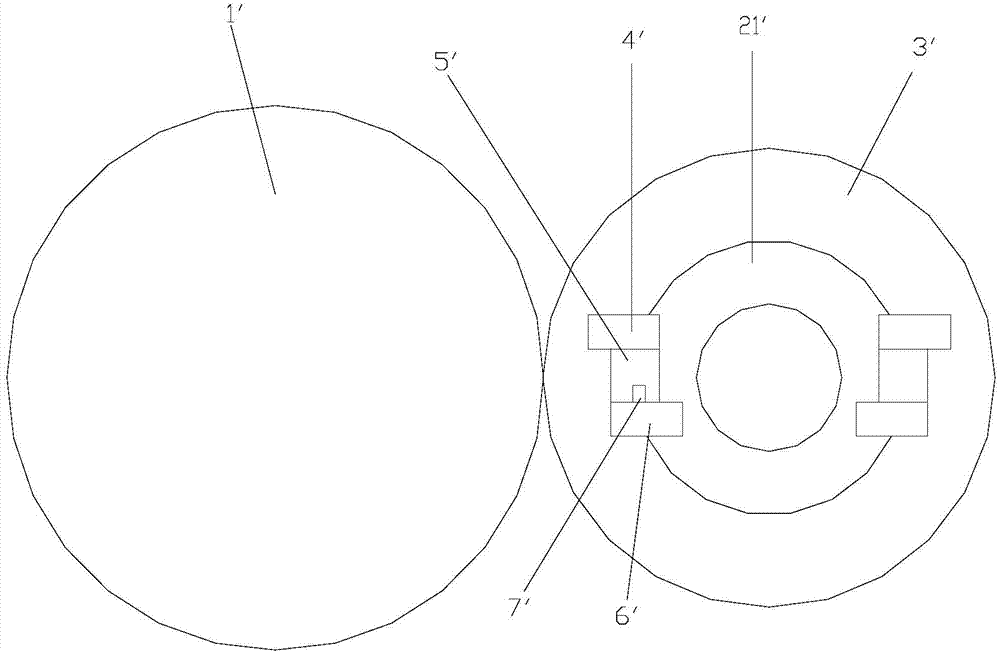

The invention discloses a bevel gear based on conjugate curves and a meshing pair thereof. The meshing pair comprises a bevel gear I and a bevel gear II which are mutually in point meshing and have arc tooth profile curves, and a contact curve gamma1 consisting of meshing points on the tooth profile curve of the bevel gear I and a contact curve gamma2 consisting of meshing points on the tooth profile curve of the bevel gear II are conjugate curves. According to the bevel gear transmission meshing pair based on the conjugate curves, the tooth profile curves of the mutually meshed bevel gear I and bevel gear II are respectively in an arc shape, the meshed tooth surfaces of the bevel gear I and the bevel gear II move along the conjugate curves, the meshing characteristics of the contact curves are succeeded, and the meshing of the contact curves between the tooth surfaces is high in contact strength; a contact transmission process is close to pure rolling along an axial direction, and the transmission efficiency is high; the tooth surfaces are easy to process and manufacture, transmission errors are small, and the service life is long; under the conditions of equivalent transmission ratio and center distance, the selection and determination of a small tooth number and a large modulus can be realized; and the transmission requirements of high speed, heavy load, large power and high efficiency can be met.

Owner:CHONGQING UNIV

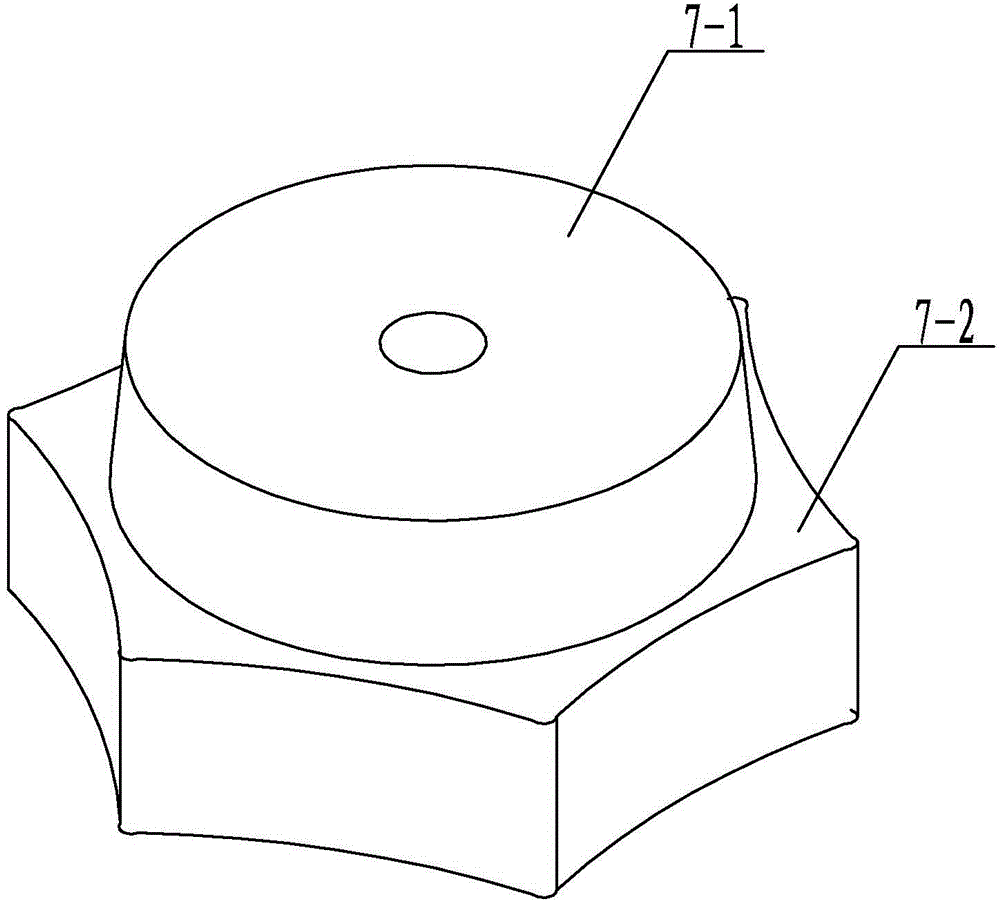

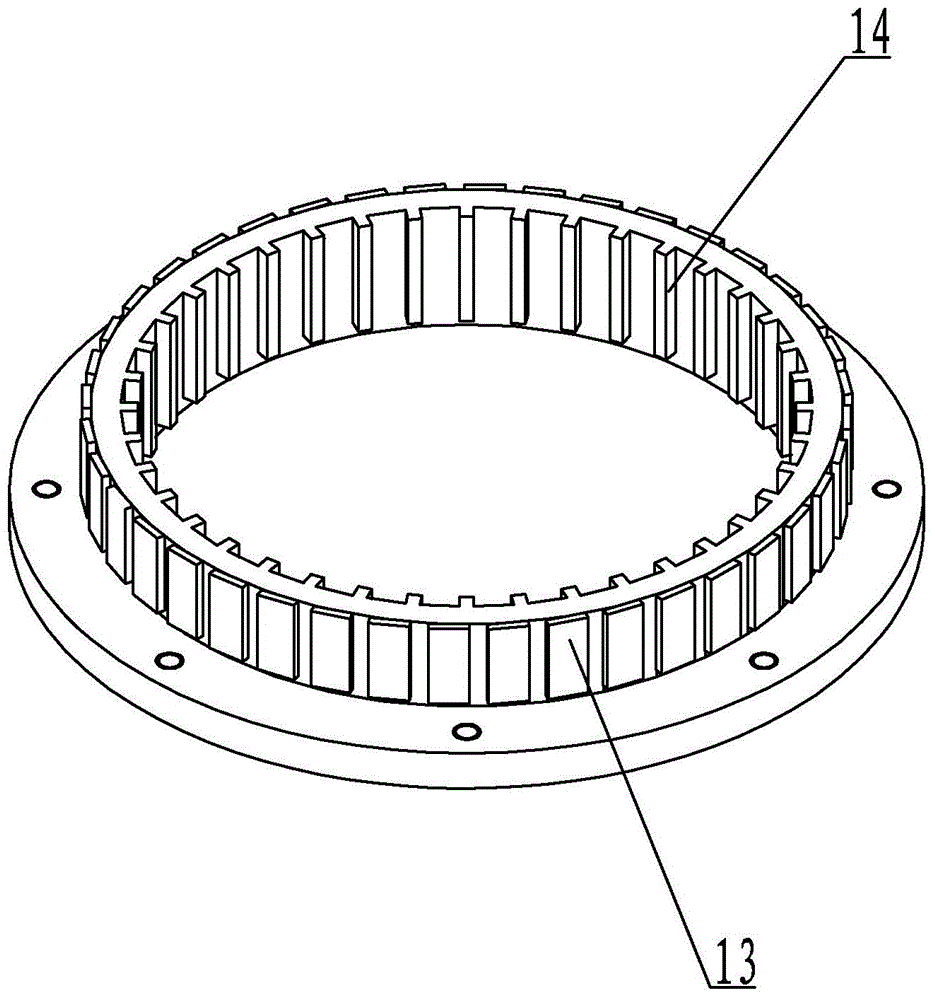

Machine jellyfish driven by embedded type cylindrical motor

ActiveCN104149953AEffectively control the movement positionAchieve continuous advancementPropulsive elements of non-rotary typeElectricityAbdominal cavity

The invention relates to a machine jellyfish, in particular to a machine jellyfish driven by an embedded type cylindrical motor. The problem that an existing bionic jellyfish robot is limited in moving range, small in effective water spraying size and small in driving force and is not suitable for a complex water flow environment in nature is solved. A mechanical abdominal cavity end cover, a sleeve and a bottom disc base of the machine jellyfish are in sealing connection from top to bottom in sequence. A cylindrical traveling wave ultrasonic motor is arranged on the bottom disc base. A transmission cam is located in the middle of the cylindrical traveling wave ultrasonic motor. A plurality of piezoelectric ceramic pieces are evenly distributed on the outer cylinder wall of the cylindrical traveling wave ultrasonic motor. A plurality of rectangular bosses which are arrayed vertically are evenly distributed on the inner cylinder wall of the cylindrical traveling wave ultrasonic motor. The other end of each arm pushing force rod is connected with a multi-joint arm. Each arm pushing force rod and the sleeve are connected through a pushing force rod guiding flange. An auxiliary spring is arranged between each pushing force guiding flange and an arm pushing force rod close to one side of a double-idler-wheel part. The machine jellyfish is used for unmanned underwater carrying.

Owner:HARBIN INST OF TECH

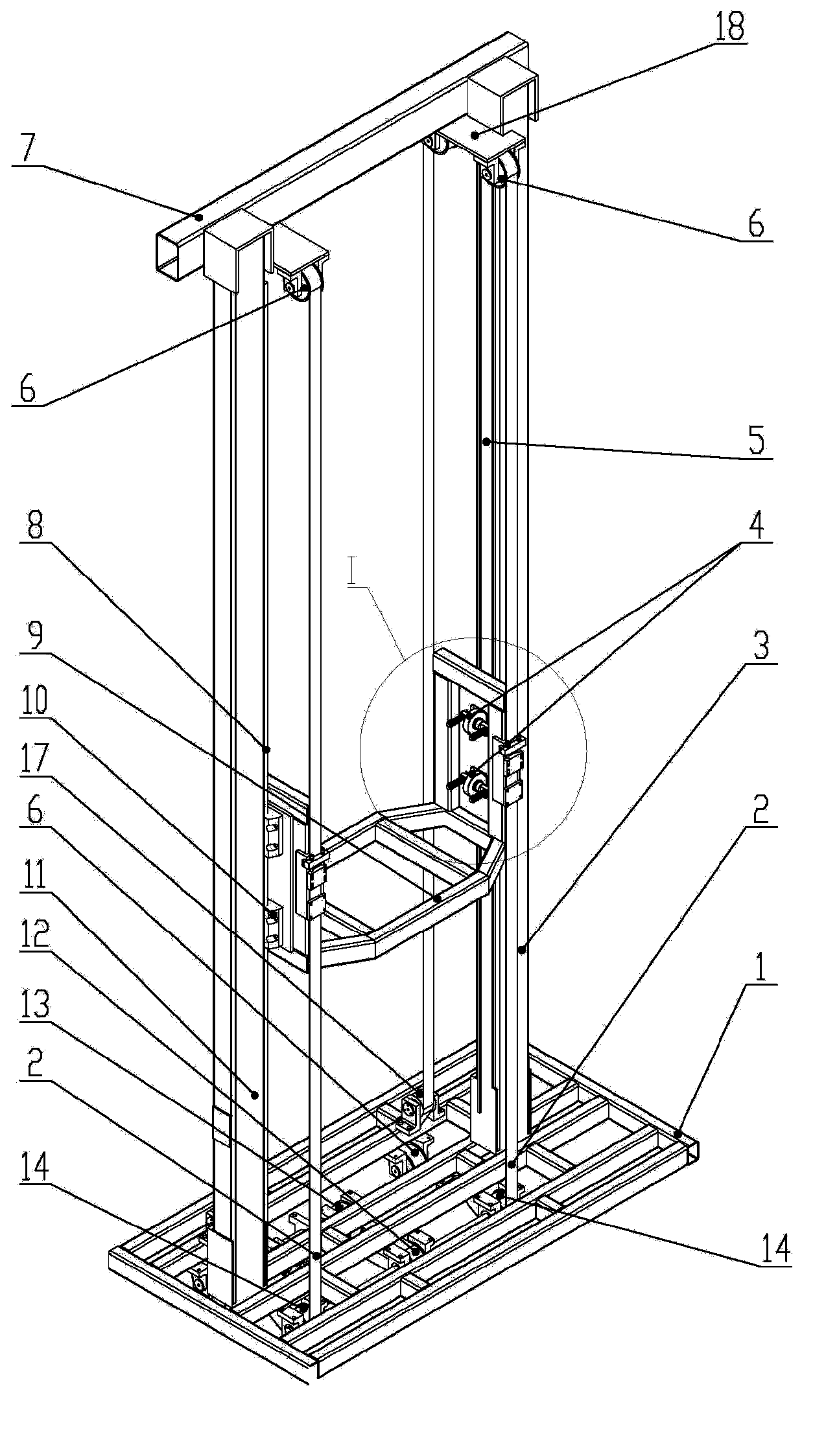

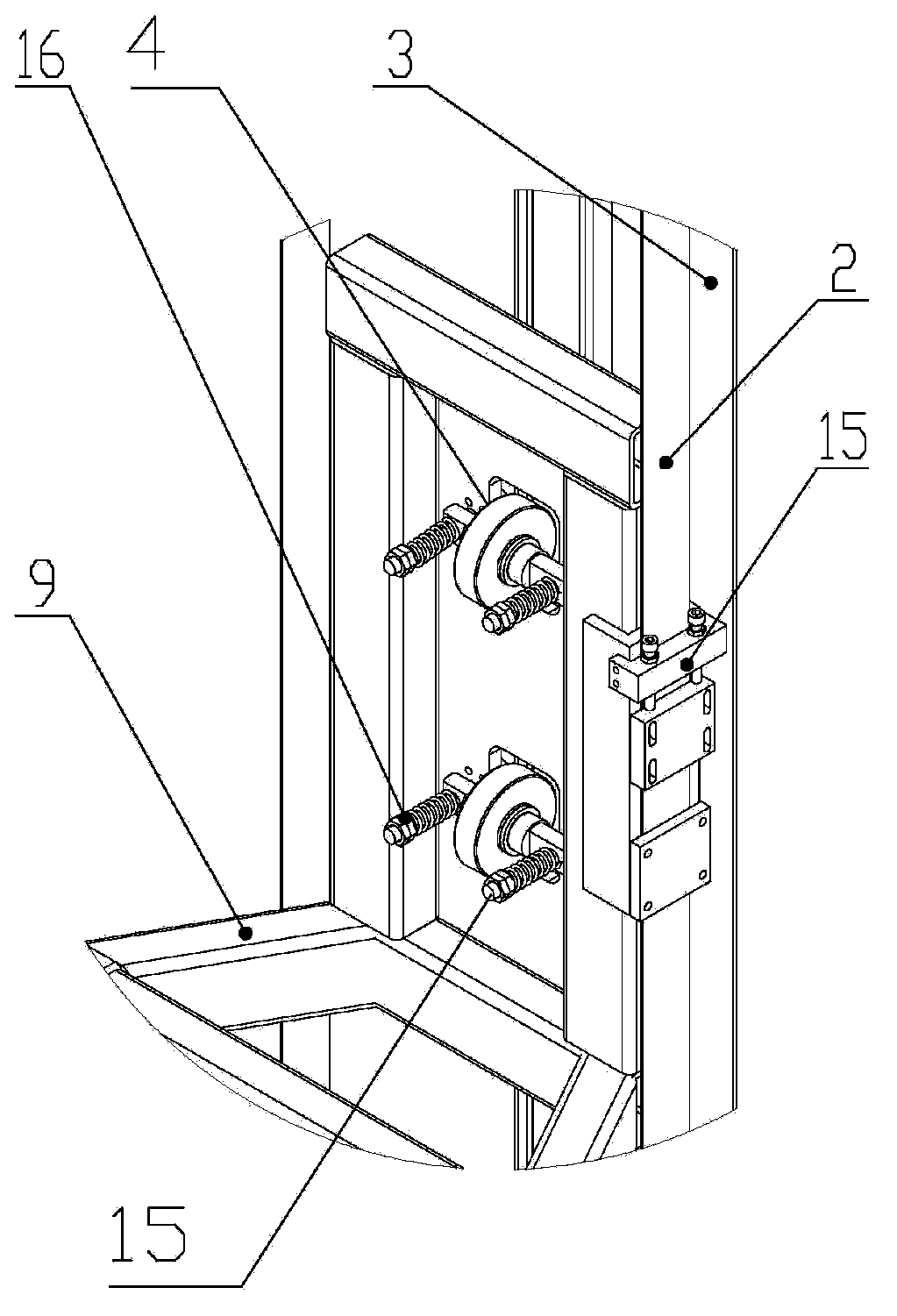

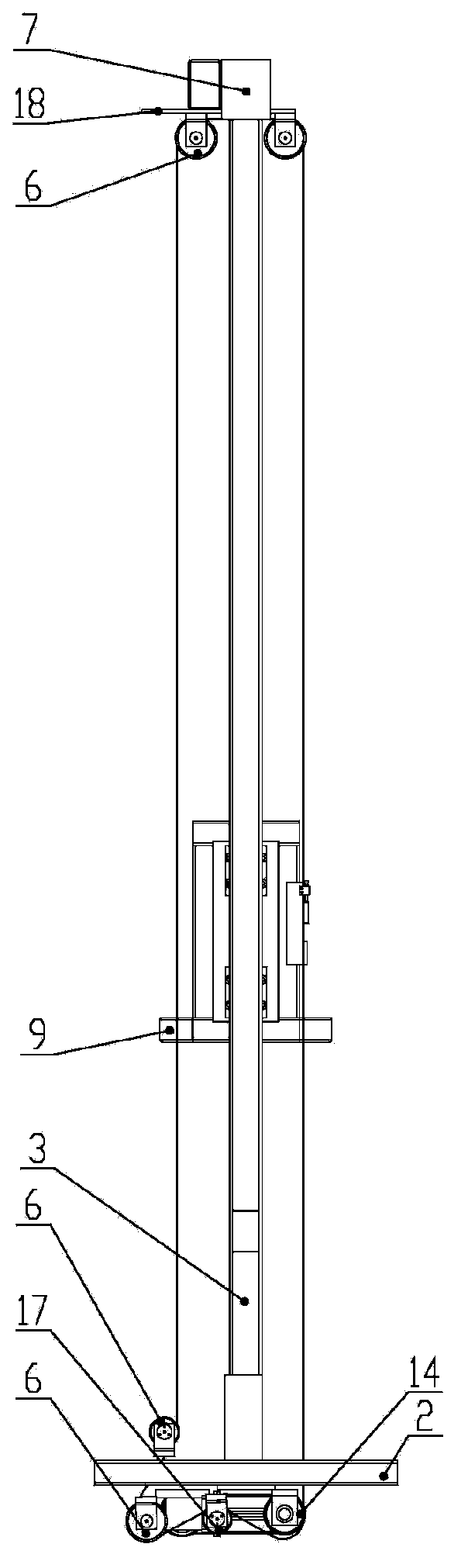

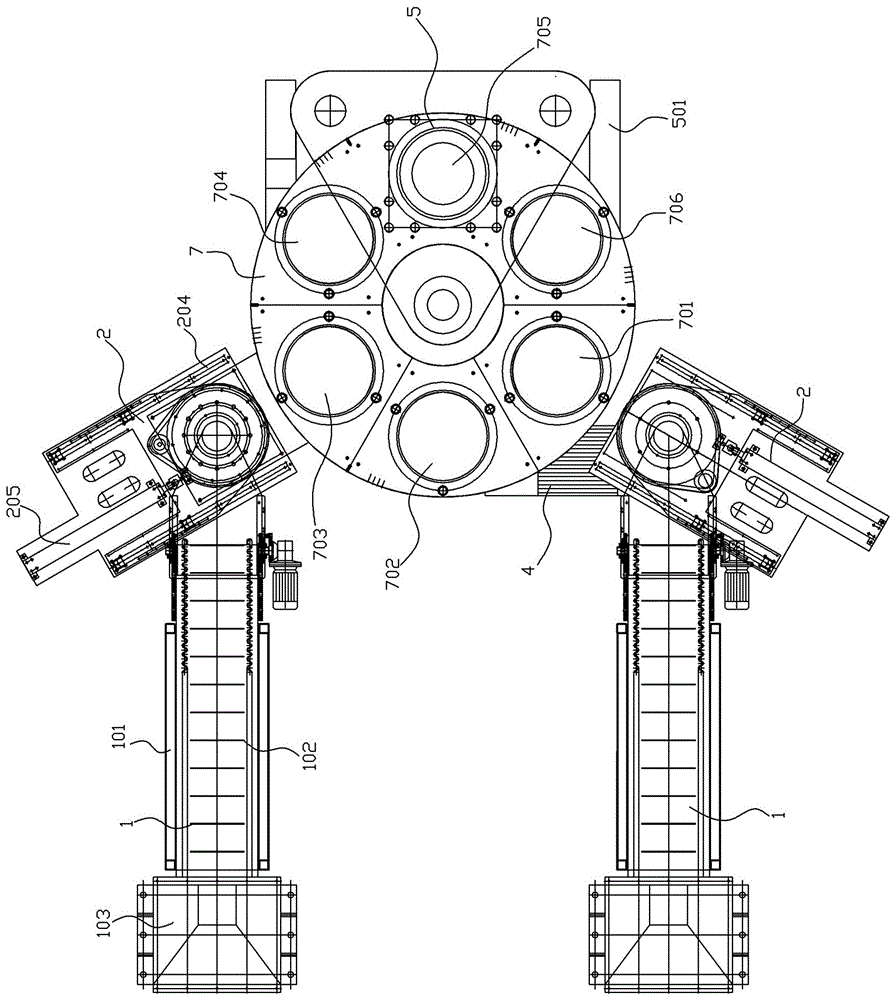

Lifting device

A lifting device comprises a bottom installation frame, a first side supporting column, a second side supporting column, a top supporting frame, idler wheels, an idler wheel rail, a fixed guide rail, sliding blocks, a regulating device, a load containing platform, a top idle pulley installation board and a plurality of idle pulleys, wherein the idle pulleys are arranged on the upper side and the lower side of the bottom installation frame and the lower edge of the top idle pulley installation board; the top supporting frame, the first side supporting column, the second side supporting column and the bottom installation frame are vertically arranged; the top idle pulley installation board is arranged on the lower edge of the top supporting frame; the fixed guide rail and the idler wheel rail are arranged on the first side supporting column and the second side supporting column respectively; one side of each sliding block is connected with the fixed guide rail, and the other side of each sliding block is fixed on the load containing platform; the idler wheels make contact with the idler wheel rail and are fixed on the load containing platform through the regulating device. The lifting device effectively reduces the number of transmission errors, and improves lifting accuracy and load capability.

Owner:SIASUN CO LTD

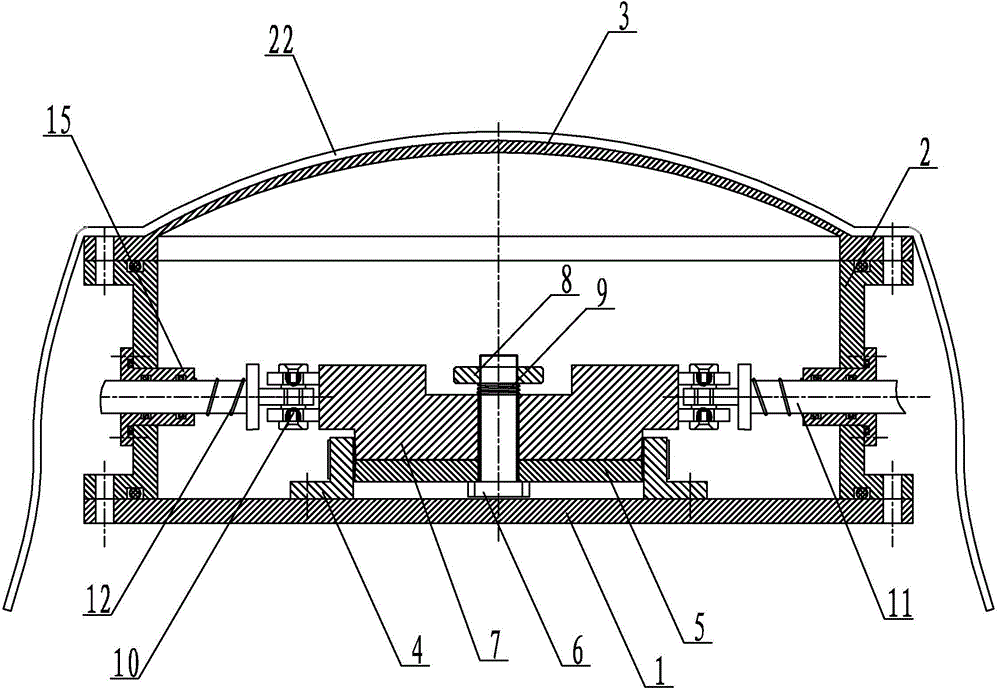

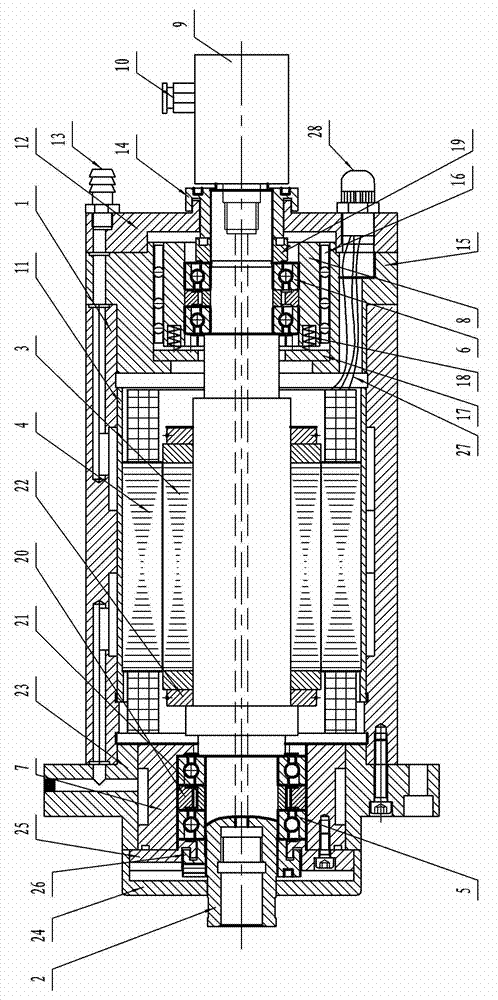

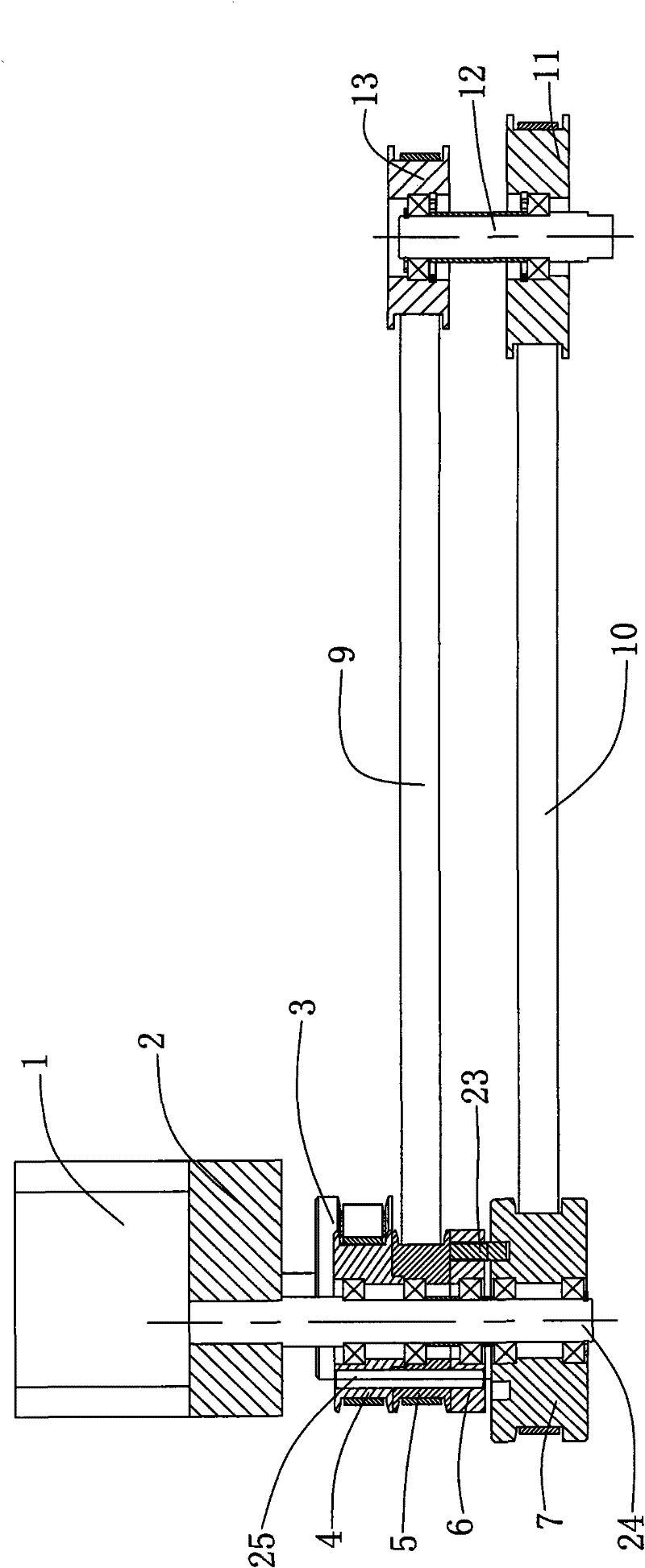

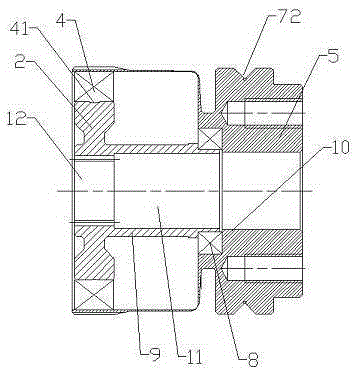

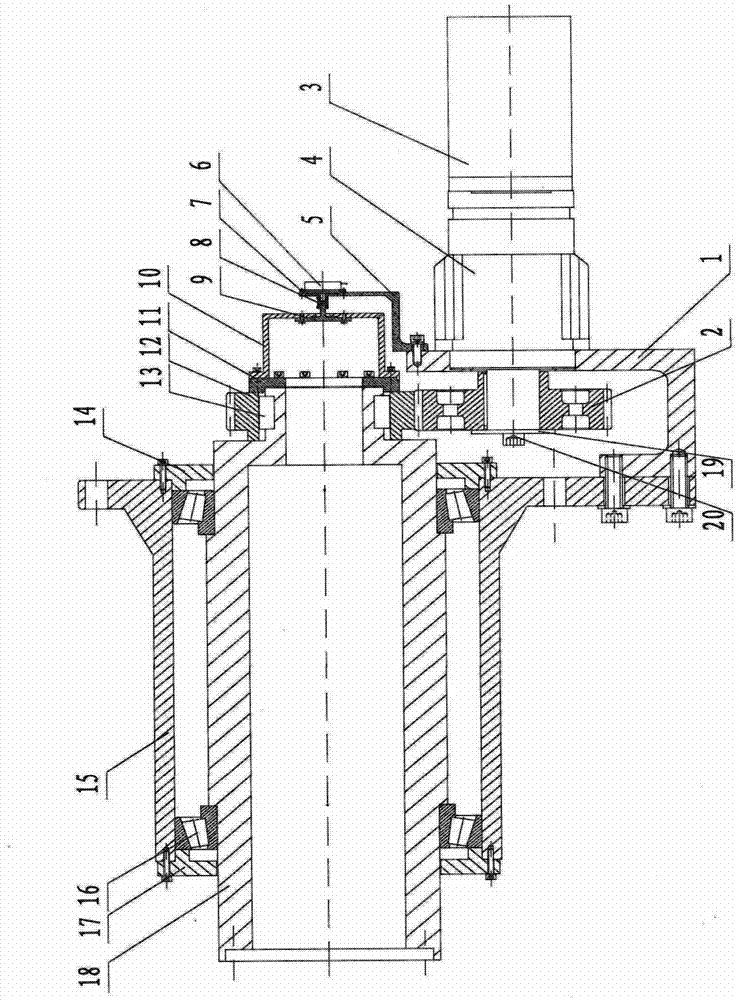

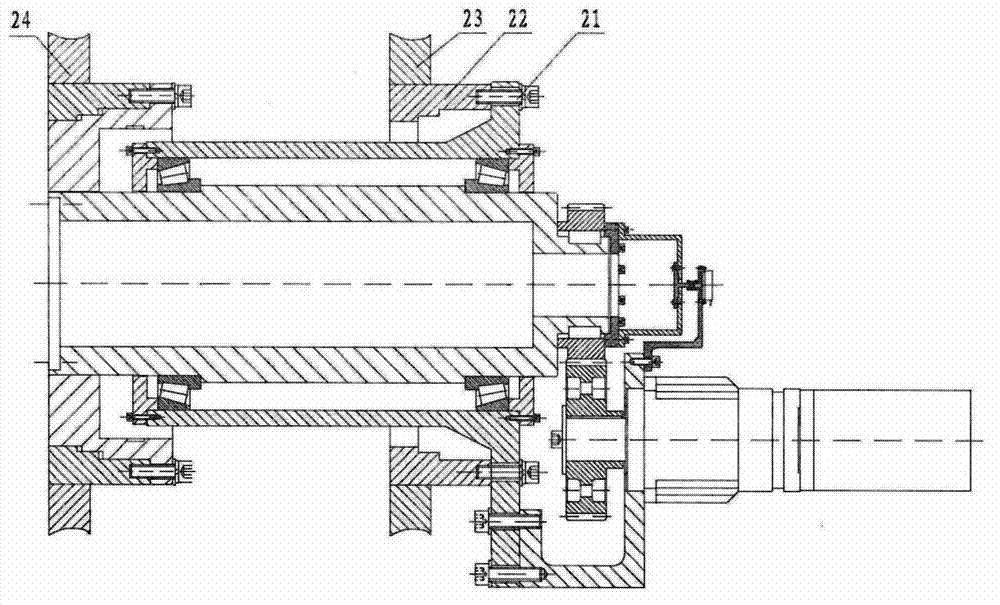

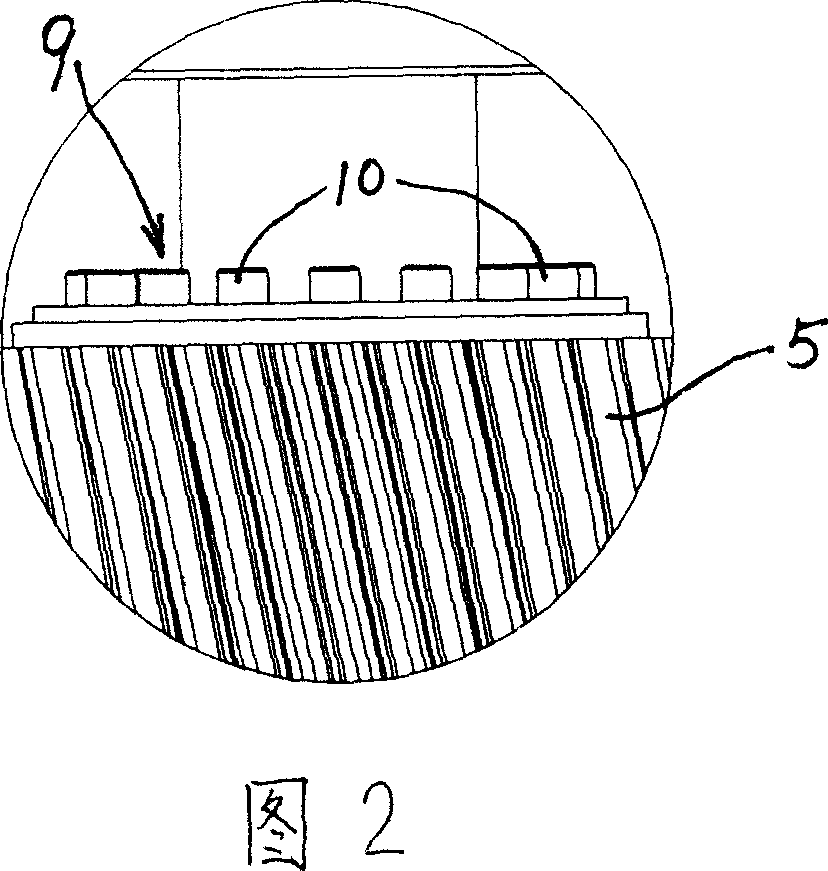

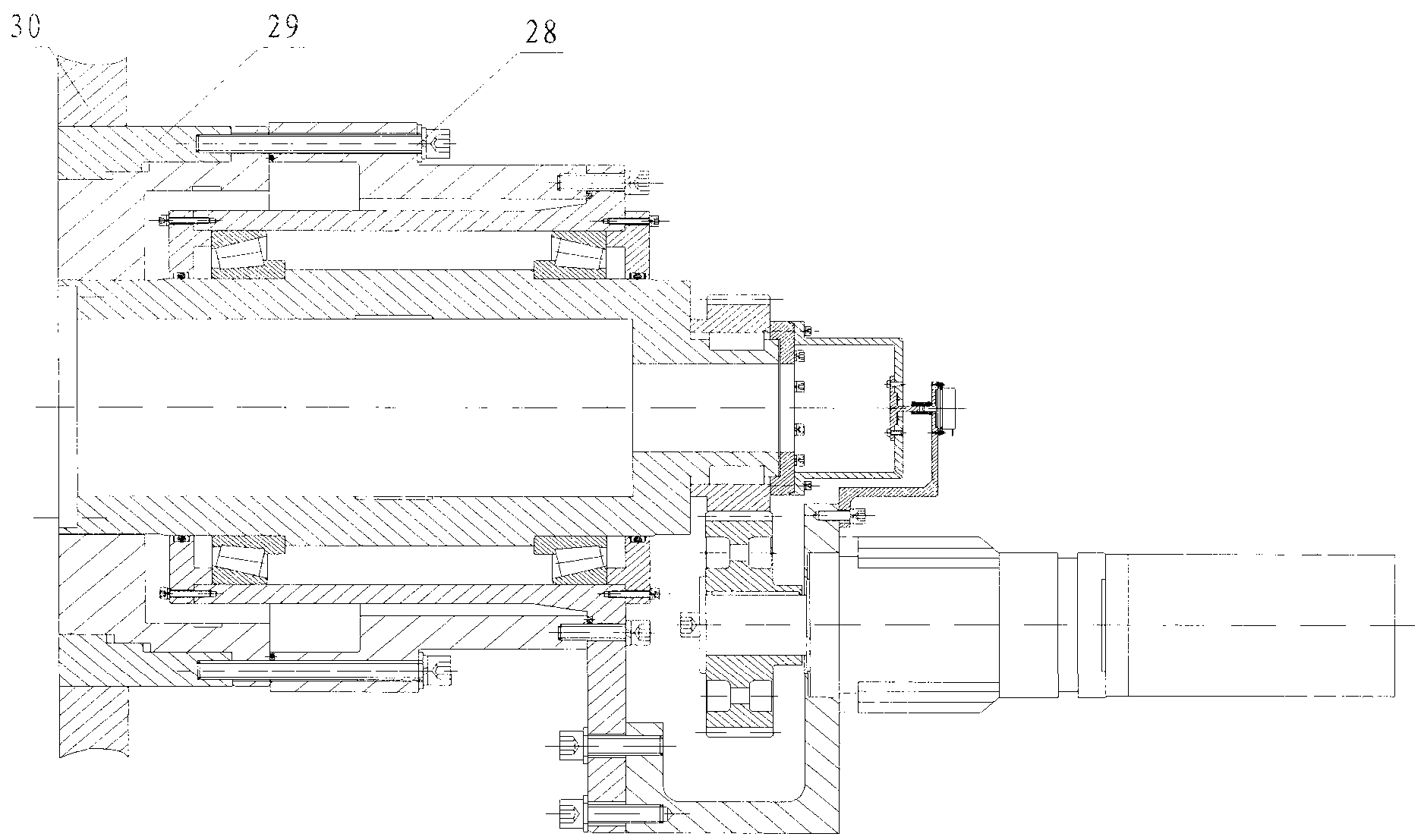

Mesoporous water-through jacking electric spindle

InactiveCN103286331AIncrease speedImprove machining accuracyMaintainance and safety accessoriesElectric machineMachine tool

The invention relates to an electric spindle for a non-traditional machine tool, in particular to a mesoporous water-through jacking electric spindle which comprises a housing, wherein the housing is internally equipped with a motor and a rotor shaft; the motor comprises a stator component and a rotor component which are sleeved together from outside in; the rotor shaft is sleeved with the rotor component; the front end and the rear end of the rotor shaft are fixed on the housing by bearings and bearing supports; a rotating connector is mounted at the rear end of the rotor shaft; a water inlet connector is mounted on the rotating connector; and the water inlet connector is communicated with a water cooling channel in the rotor shaft. The mesoporous water-through jacking electric spindle is compact in structure, small in size, low in inertia, simple and convenient to mount, rapid in response, small in transmission error, low in noise and good in stability, saves time and labor, improves the machining precision and production efficiency, and is suitable for popularization and implementation.

Owner:ANYANG SIPU MACHINERY

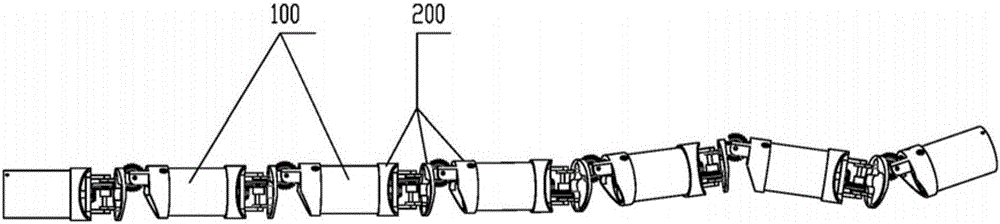

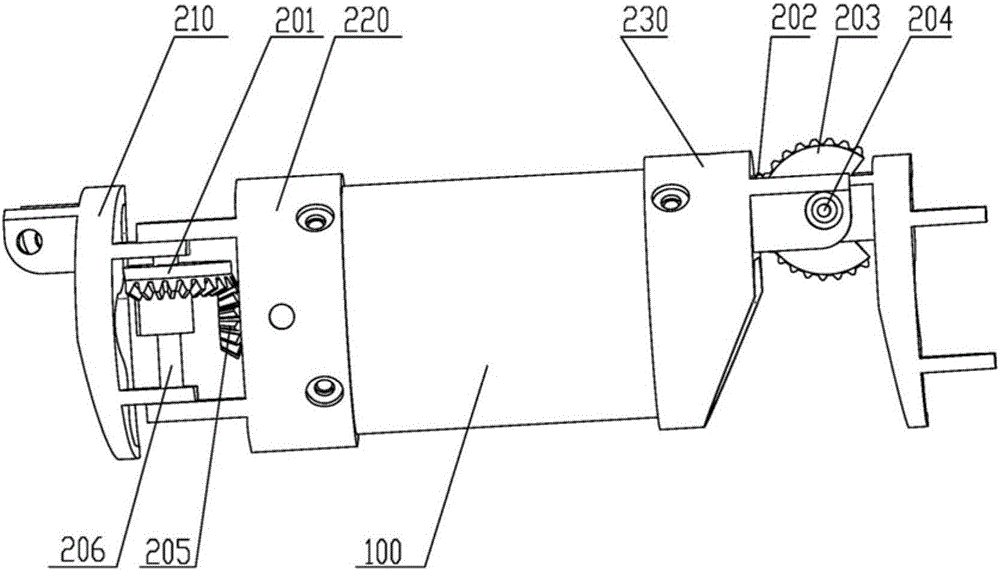

S-shaped robot

ActiveCN106078717ASwing freeReduce complexityProgramme-controlled manipulatorComputer moduleEngineering

An S-shaped robot comprises a plurality of main body modules, a plurality of joint modules and a driving control module. Every two adjacent main body modules are connected through one corresponding joint module. Each joint module comprises a joint swinging arm. The driving control module is used for driving at least one joint swinging arm to swing relative to the former main body module connected with the joint swinging arm, and / or driving at least one joint swinging arm to swing relative to the latter main body module connected with the joint swinging arm. The swinging direction of each joint swinging arm relative to the former main body module connected with the joint swinging arm is perpendicular to the swinging direction of the joint swinging arm relative to the latter main body module connected with the joint swinging arm. By the adoption of the scheme, the complexity of a whole joint steering mechanism is effectively reduced, and meanwhile the transmission accuracy is improved.

Owner:SHENZHEN INST OF ADVANCED TECH

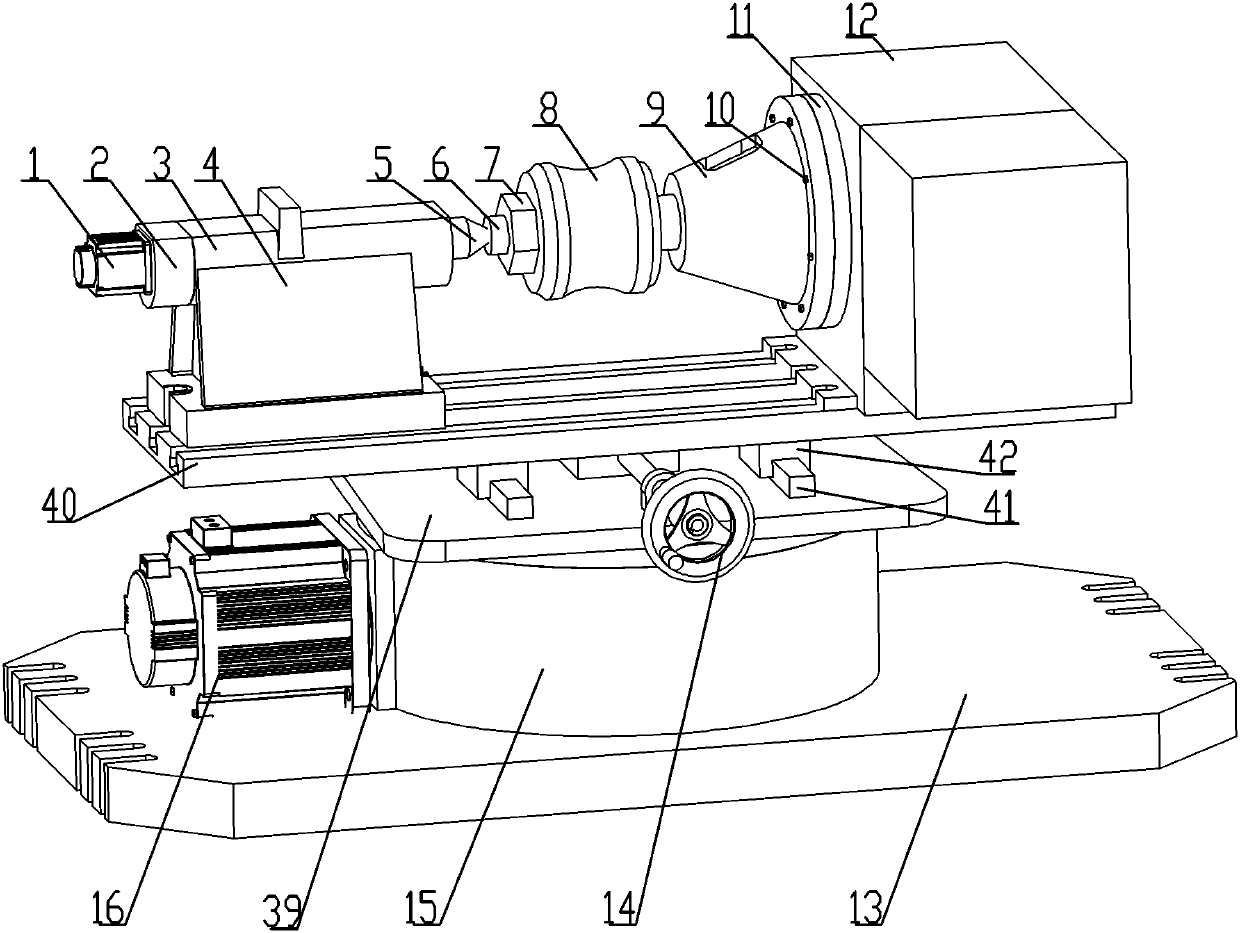

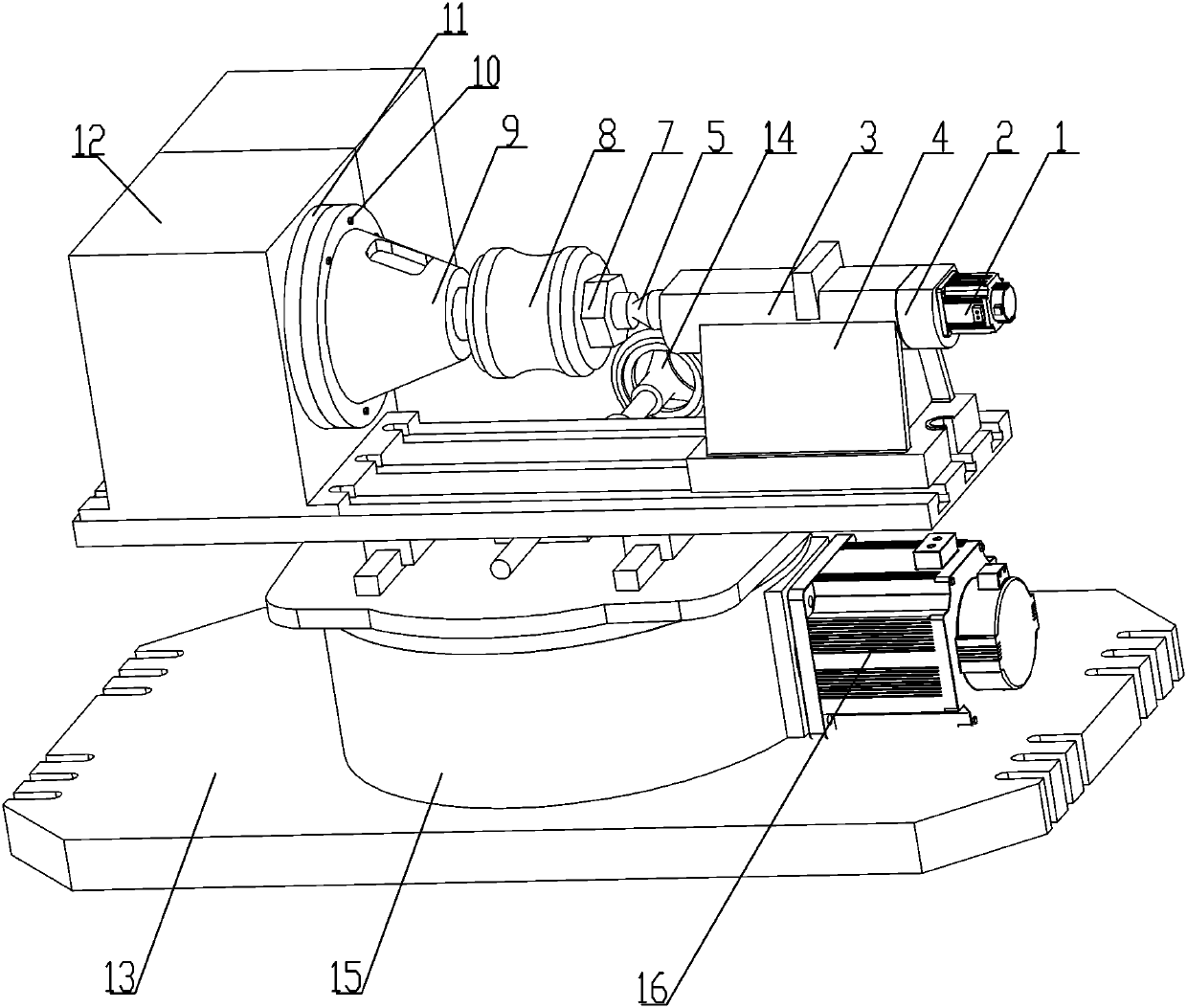

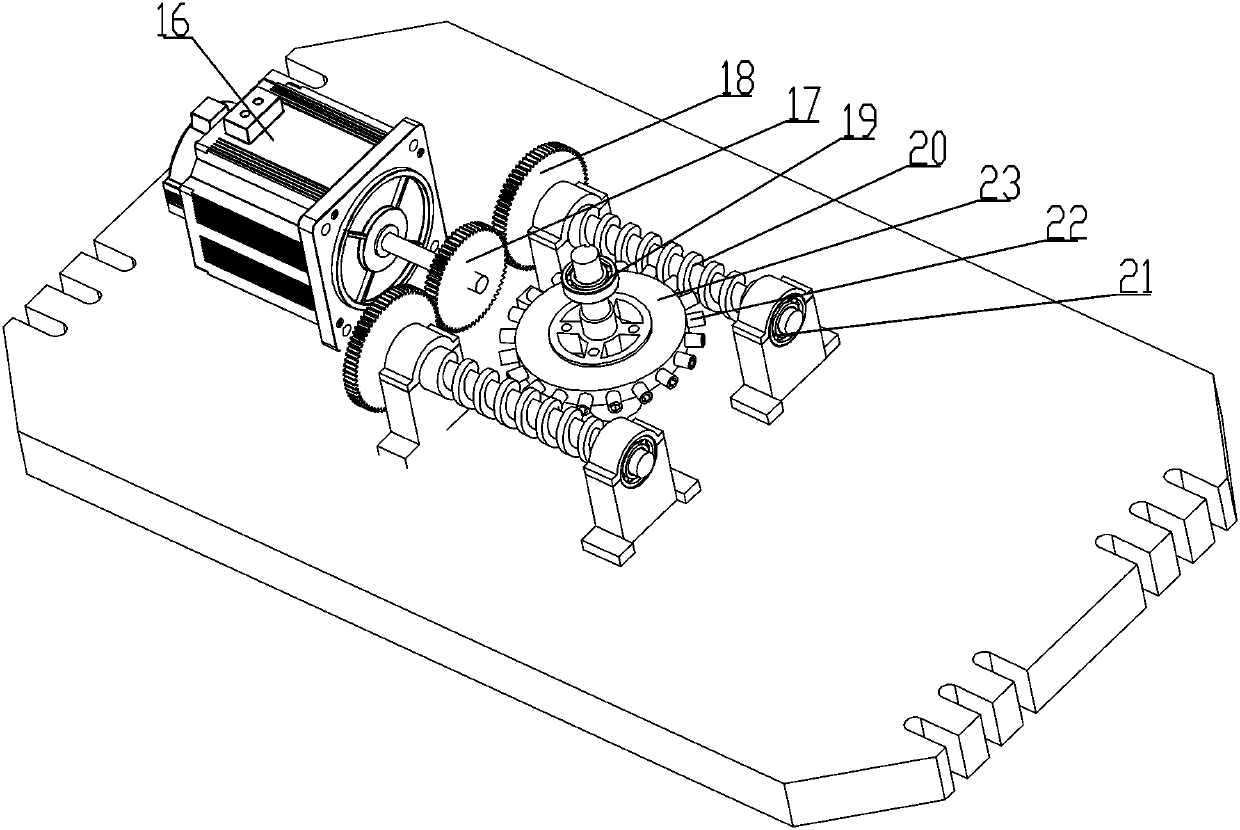

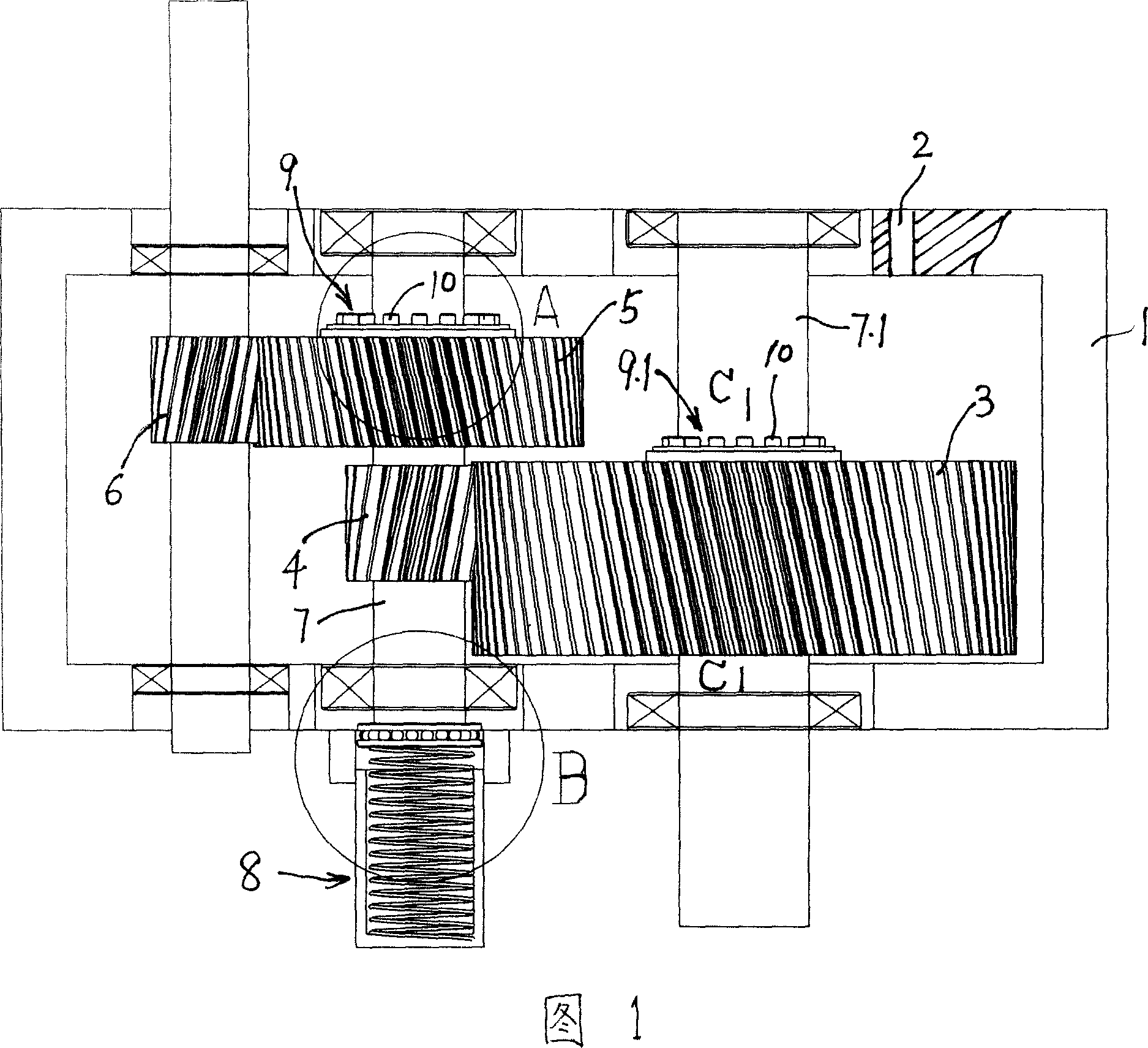

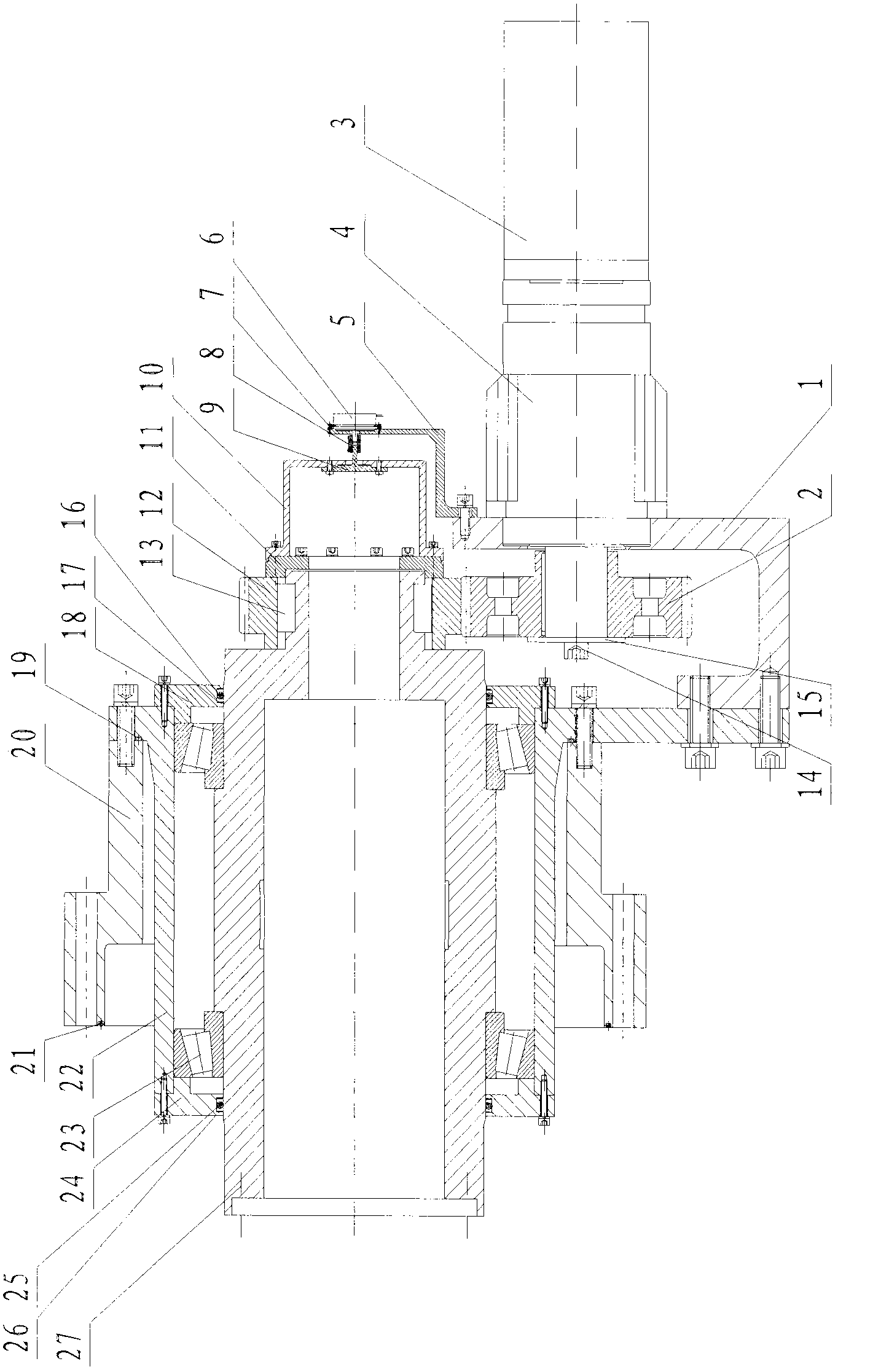

Numerical control double-rotation working table driven by double globoidal cams

PendingCN109940412AIncreased load carrying capacity and stabilityHigh transmission efficiencyLarge fixed membersMetal working apparatusDouble rotationFriction loss

The invention provides a numerical control double-rotation working table driven by double-globoidal cams. A first tank is fixedly arranged on the top part of a bottom plate; a rotation shaft is arranged in the center of the first tank; a first driven plate is arranged on the rotation shaft and is connected with a double-stage driving mechanism for driving the first driven plate to rotate; the double-stage driving mechanism is arranged in the tank and is connected with a first servo motor for providing power; a rotation table is arranged on the top part of the rotation shaft; a top clamping table is adjustably arranged on the top part of the rotation table through a screw rod adjusting mechanism; a workpiece rotation mechanism for driving a workpiece to rotatably index is arranged on one side of the top part of the top clamping table; and a workpiece clamping mechanism is arranged at the power output end of the workpiece rotation mechanism. The rotation working table is provided with double rotation shafts, so that double-rotation-shaft linked space surface milling processing can be realized; and by applying a double-globoidal-cam retarding mechanism, the friction loss during the use of worm-gear mesh transmission is reduced.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

Photoelectric feedback type carpentry milling head device with double swing angles

ActiveCN102019636AIncreased processing flexibilityImprove work efficiencyMulti-purpose machinesShip's carpenterEngineering

The invention provides a photoelectric feedback type carpentry milling head device with double swing angles. The photoelectric feedback type carpentry milling head device with the double swing angles comprises a supporting seat, a main shell, an electric spindle connecting plate, an electric spindle, a shaft C driving mechanism, a shaft A driving mechanism and two rotary photoelectric encoders, wherein the supporting seat is provided with the shaft C driving mechanism which comprises a servo motor and a transmission mechanism, and an output shaft of the shaft C driving mechanism is connected with the main shell; the main shell is provided with the shaft A driving mechanism which comprises a servo motor and a transmission mechanism, and an output shaft of the shaft A driving mechanism is connected with the electric spindle through the electric spindle connecting plate; the shaft C and shaft A driving mechanisms are provided with a travel switch respectively, a positioning block is arranged on a limit belt wheel which is connected to the output shafts of the driving mechanisms, and a corresponding limit switch is arranged on the supporting seat or the main shell; and grating discs in the rotary photoelectric encoders are arranged on the output shafts, and a photoelectric detector and a light source are arranged on the supporting seat or the main shell. The photoelectric feedback type carpentry milling head device with the double swing angles can realize polyhedron carving and milling processing during the processing of wood and artificial boards, and is suitable for carpentry high-accuracy and high-speed multi-axle numerically-controlled machine tool.

Owner:BEIJING FORESTRY MACHINERY RES INST OF STATE FORESTRY ADMINISTRATION

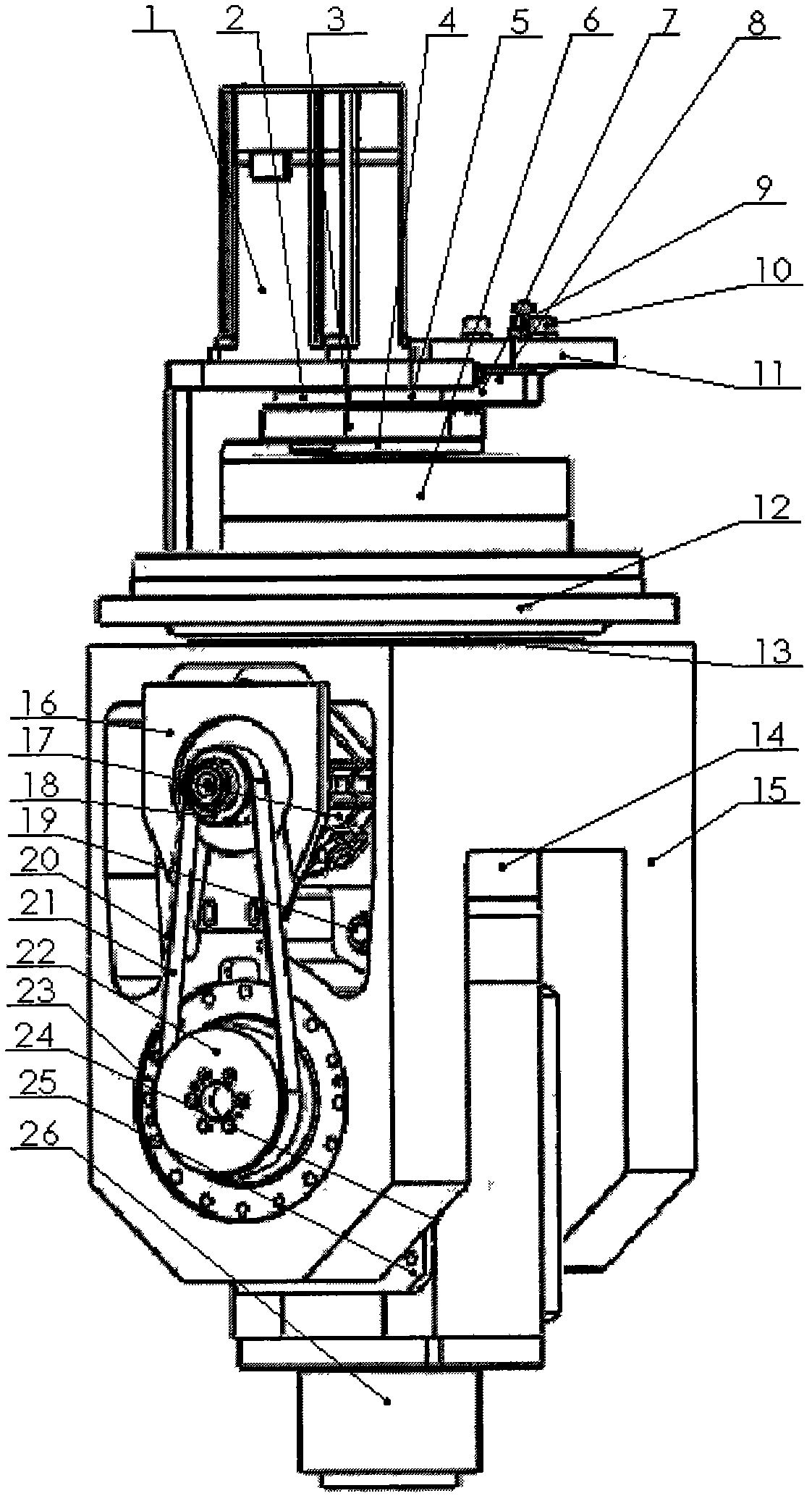

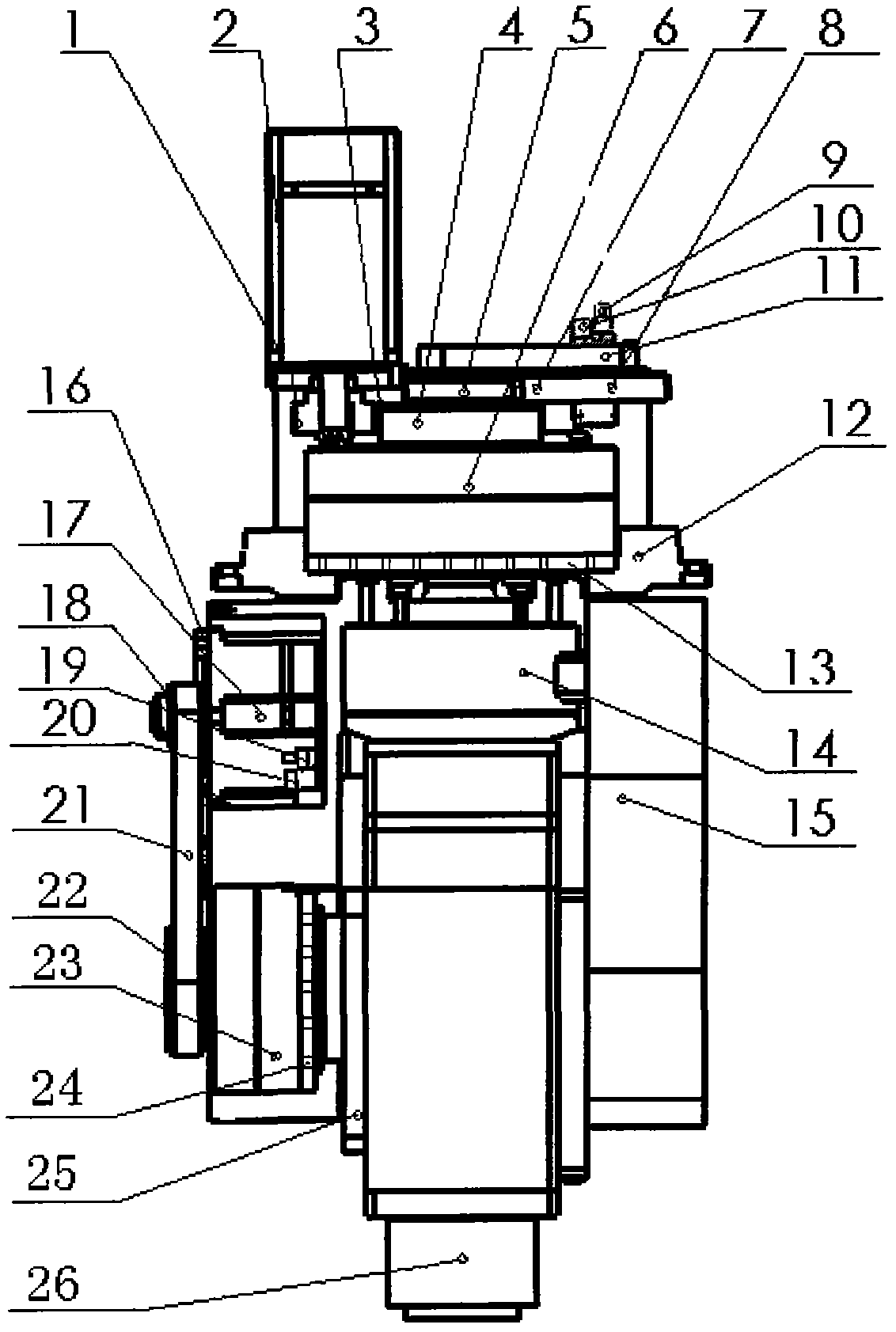

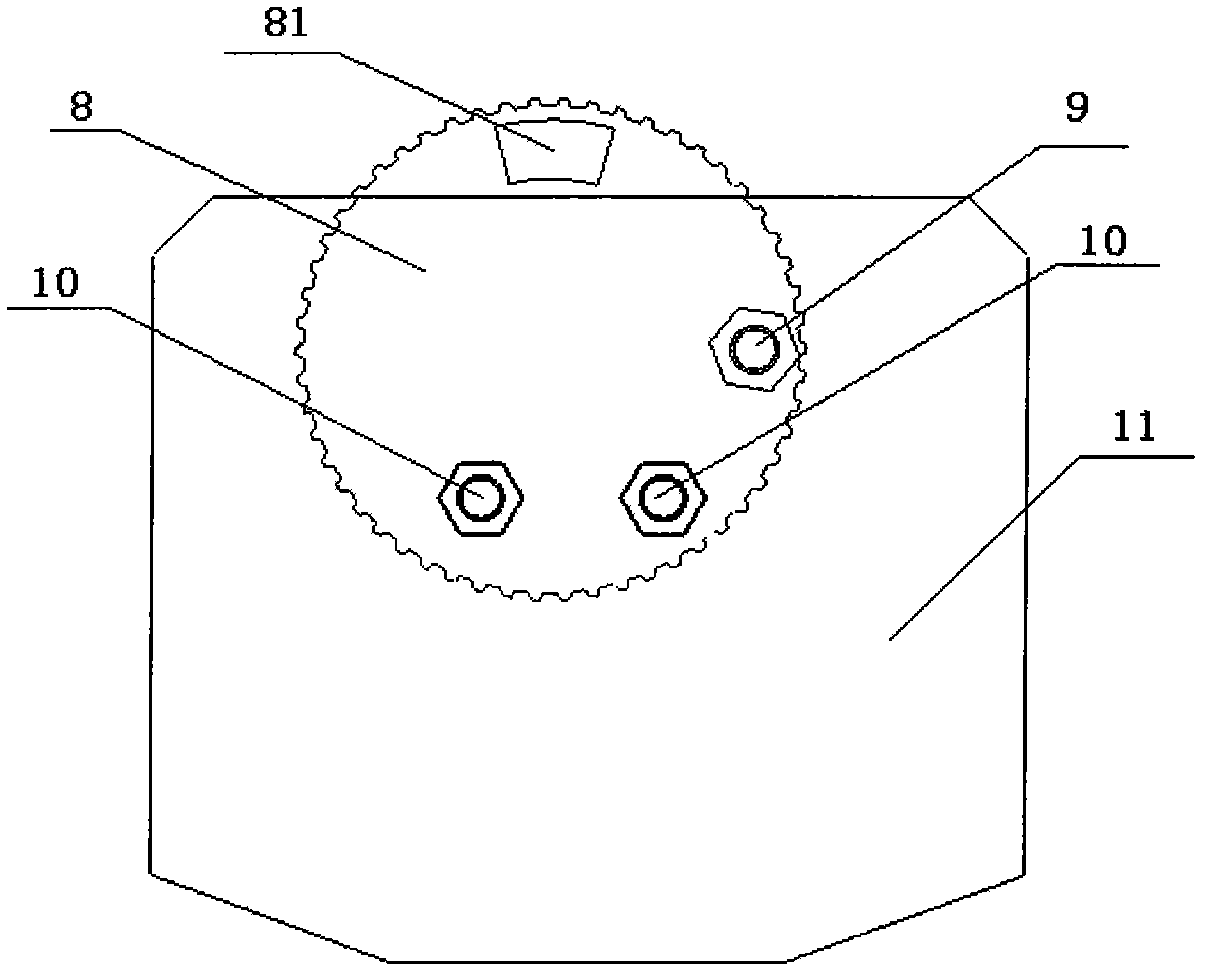

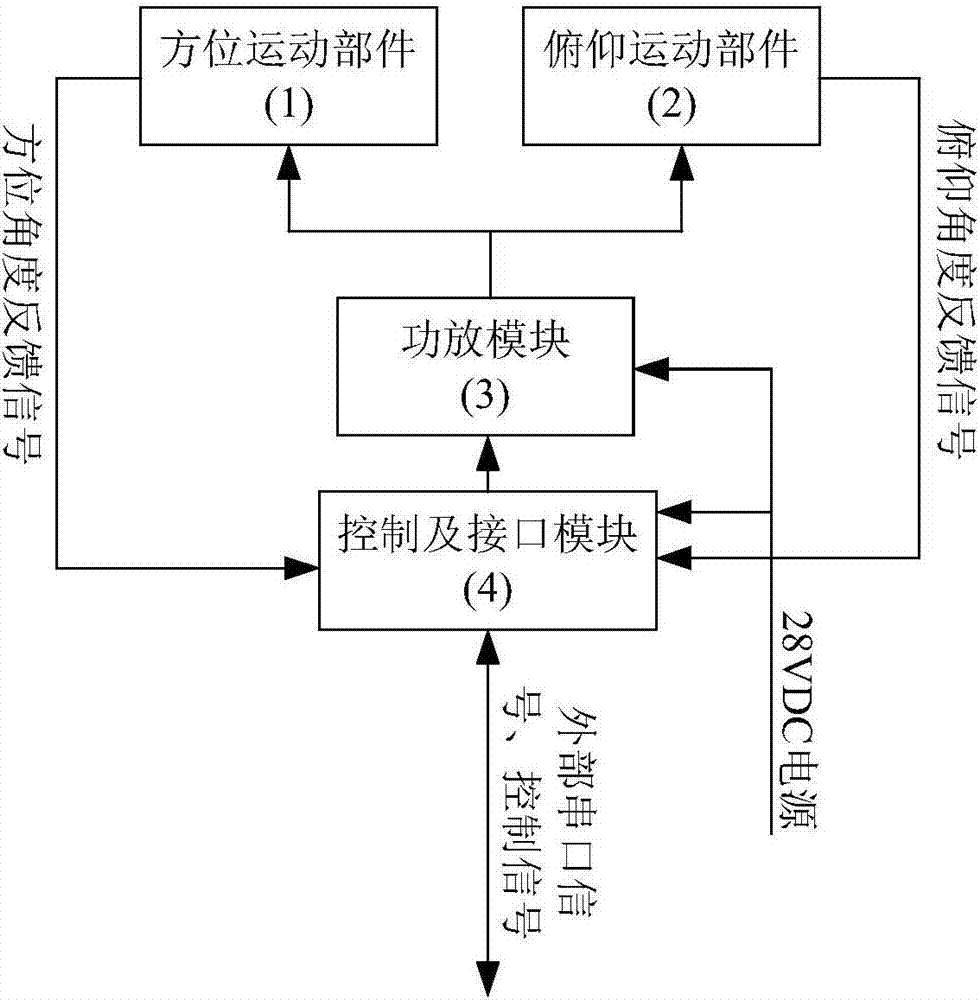

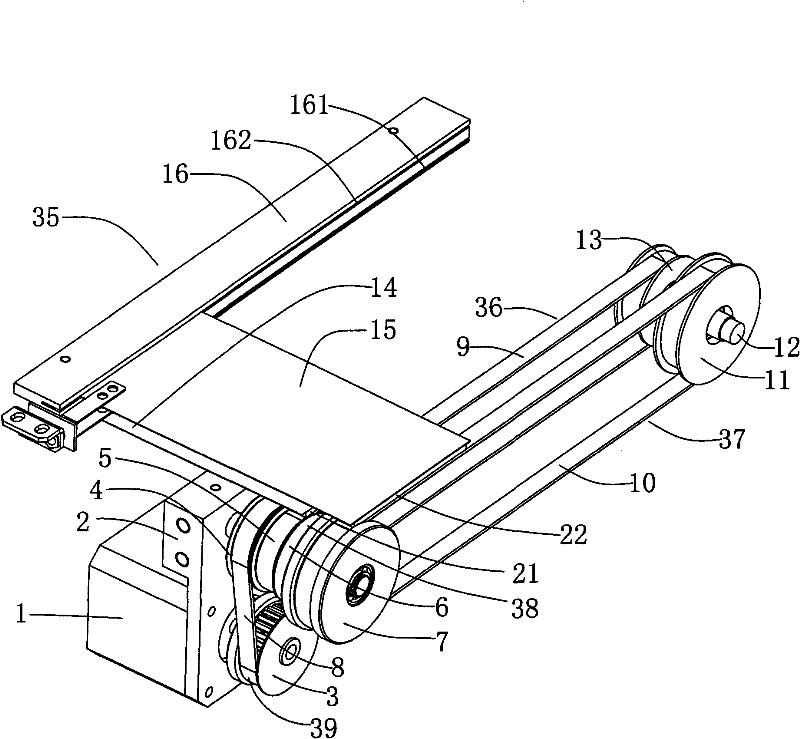

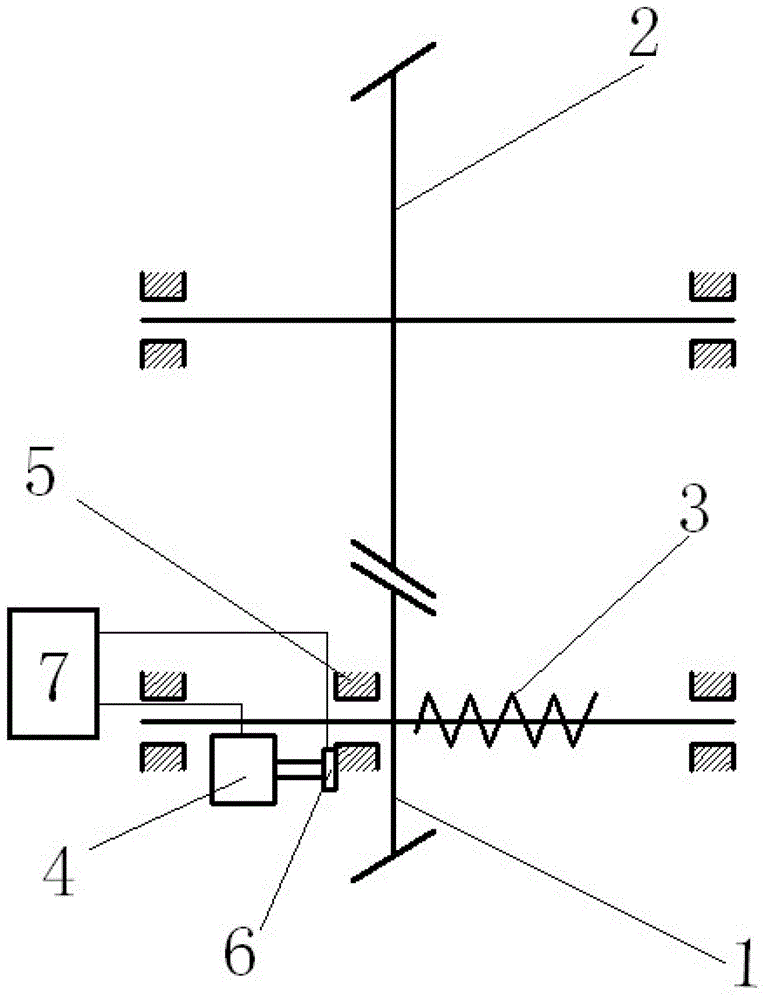

Airborne-antenna high speed servo motion platform

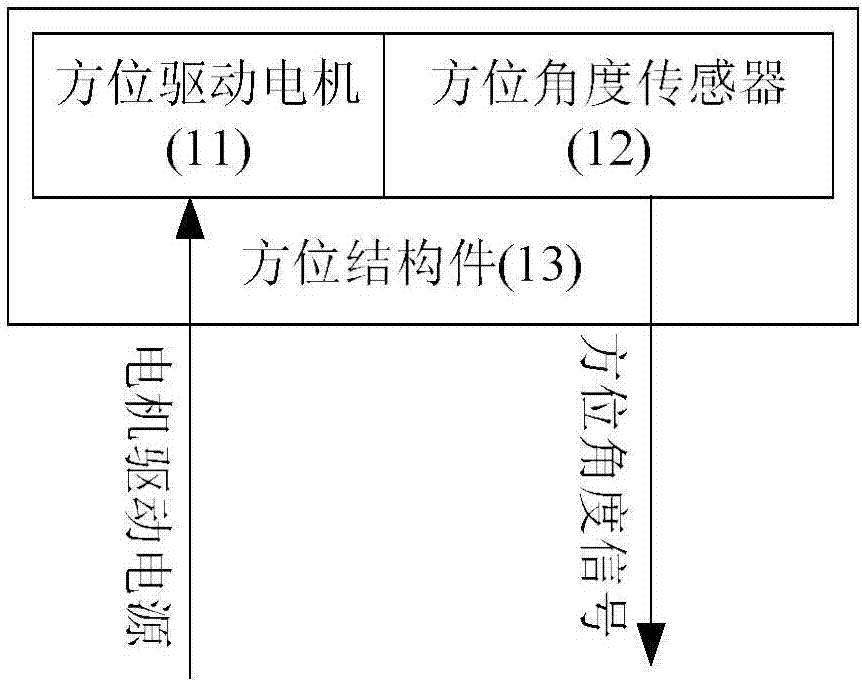

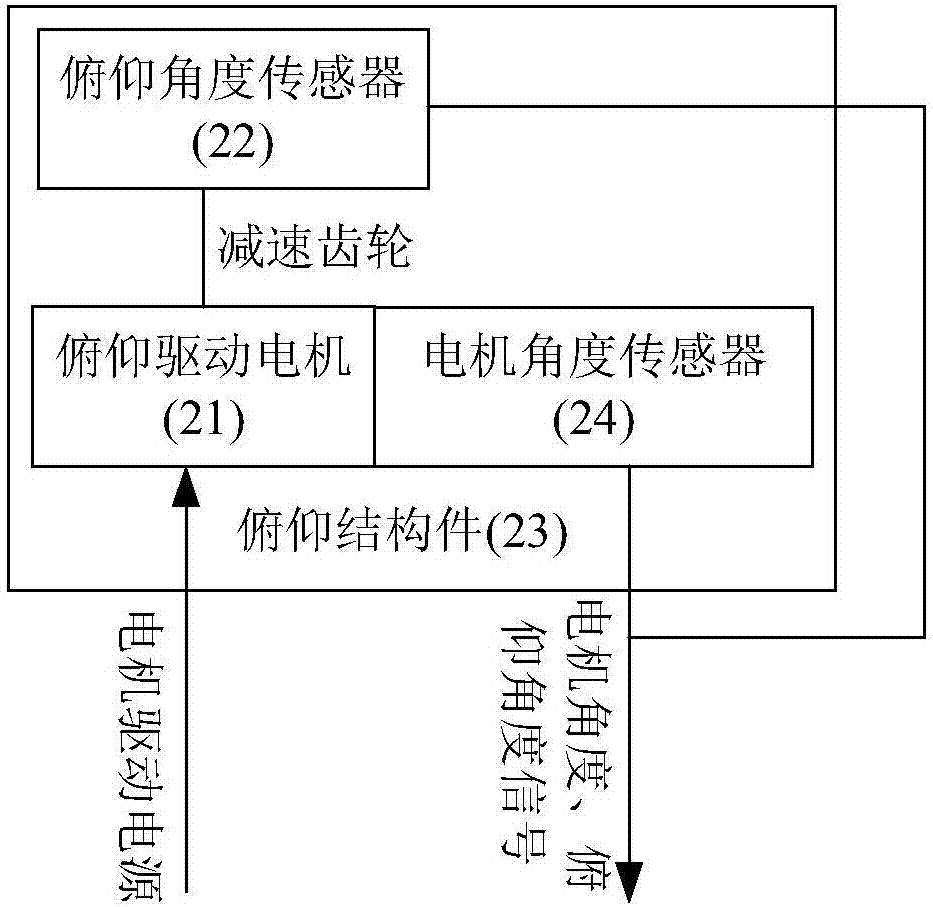

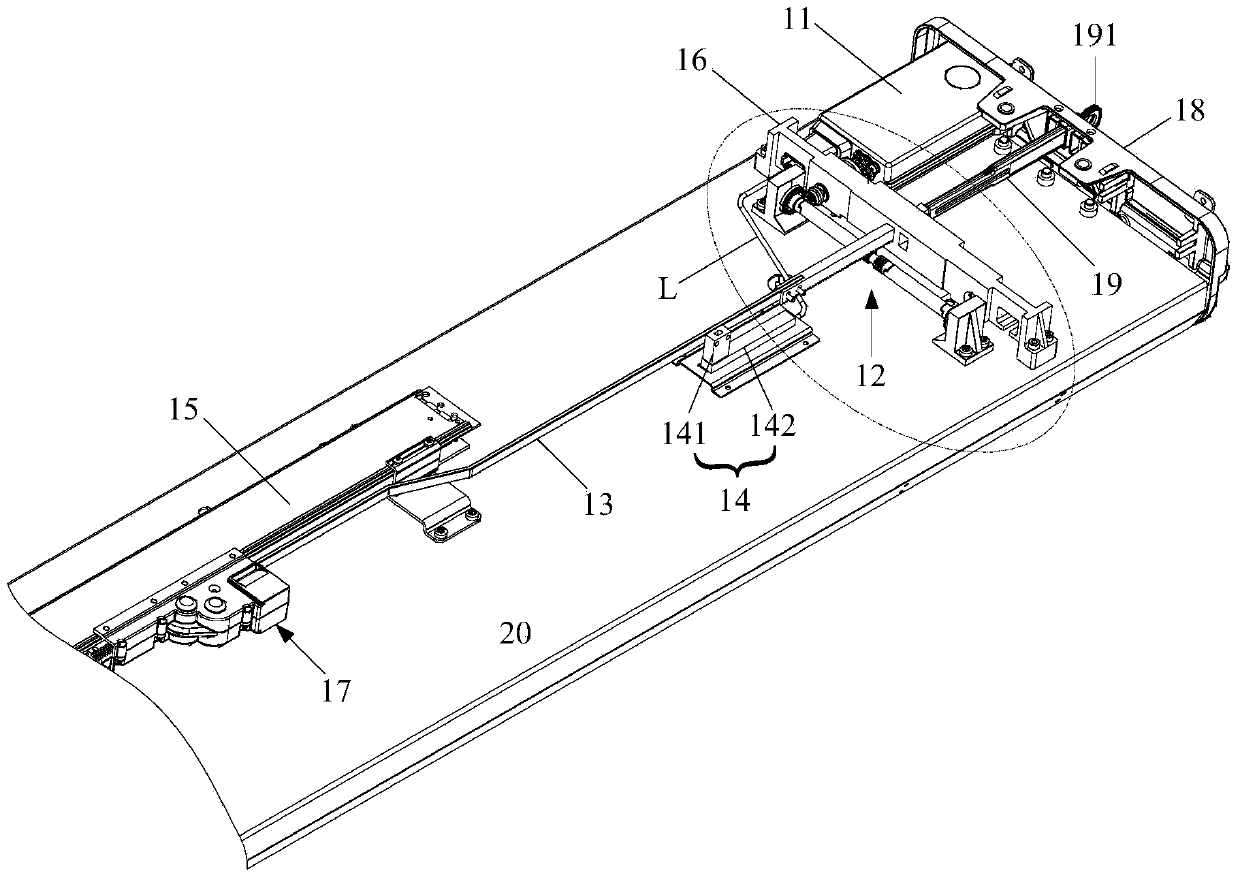

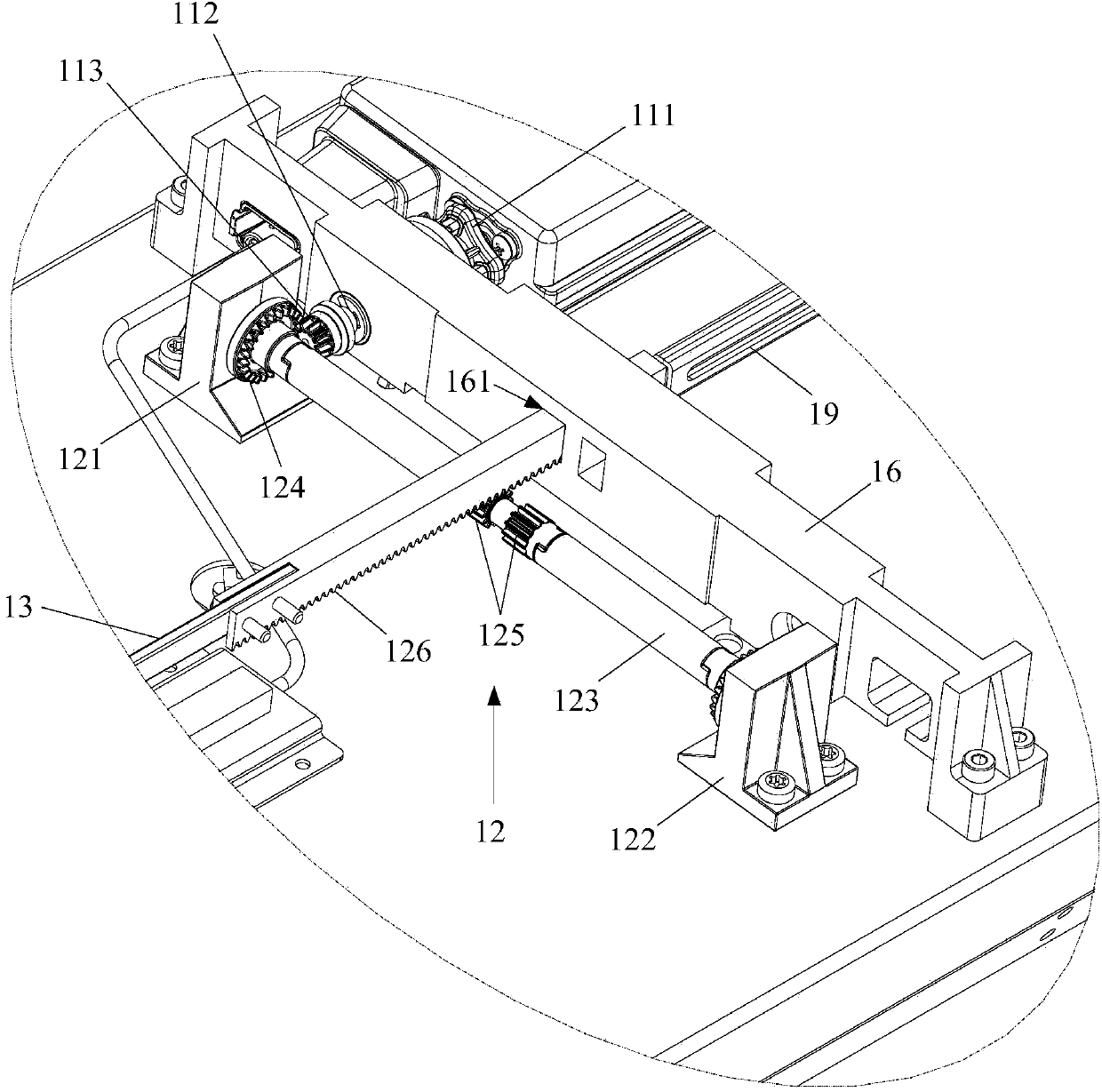

PendingCN107193292AImprove response speedHigh control precisionControl using feedbackControl signalFlight vehicle

The invention discloses an airborne-antenna high speed servo motion platform. By using an existing airborne-antenna servo motion platform, an antenna can not be driven to carry out high-speed and high-precision scanning motion. By using platform of the invention, the above problem is solved. The platform comprises an orientation motion component (1), a pitching motion component (2), a power amplifier module (3) and a control and interface module (4). The control and interface module (4) generates a pulse width modulation signal which is used to control a motor and outputs to the power amplifier module (3) according to a received control instruction, aerial carrier attitude data and feedback signals of orientation and a pitch angle. The power amplifier module generates a motor driving power supply according to a received pulse width modulation control signal, outputs to the orientation motion component (1) and the pitching motion component (2) so as to drive the two components to carry out orientation and pitching motion, and simultaneously feeds back the orientation and the pitch angle to the control and interface module (4) in real time. The platform possesses advantages that a response speed is fast and control precision is high and can be used in various aircrafts which need the antenna to carry out mechanical scanning motion.

Owner:SHAANXI CHANGLING ELECTRONICS TECH

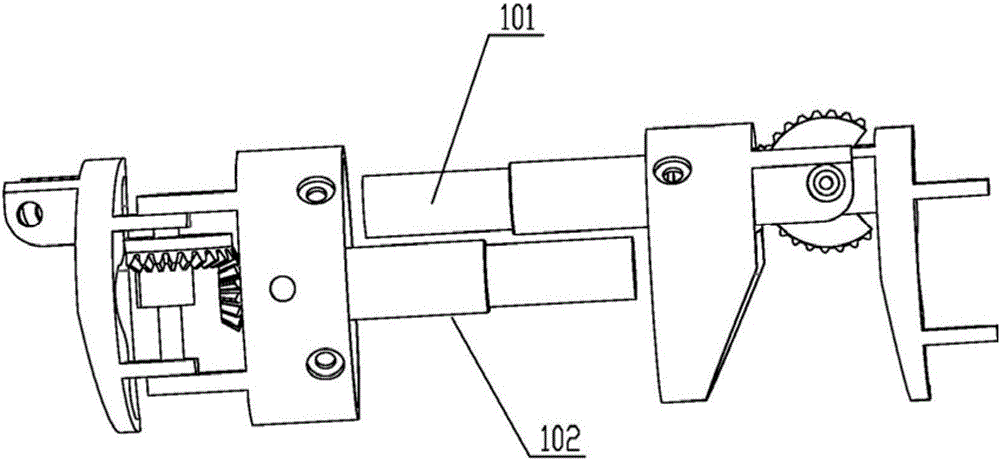

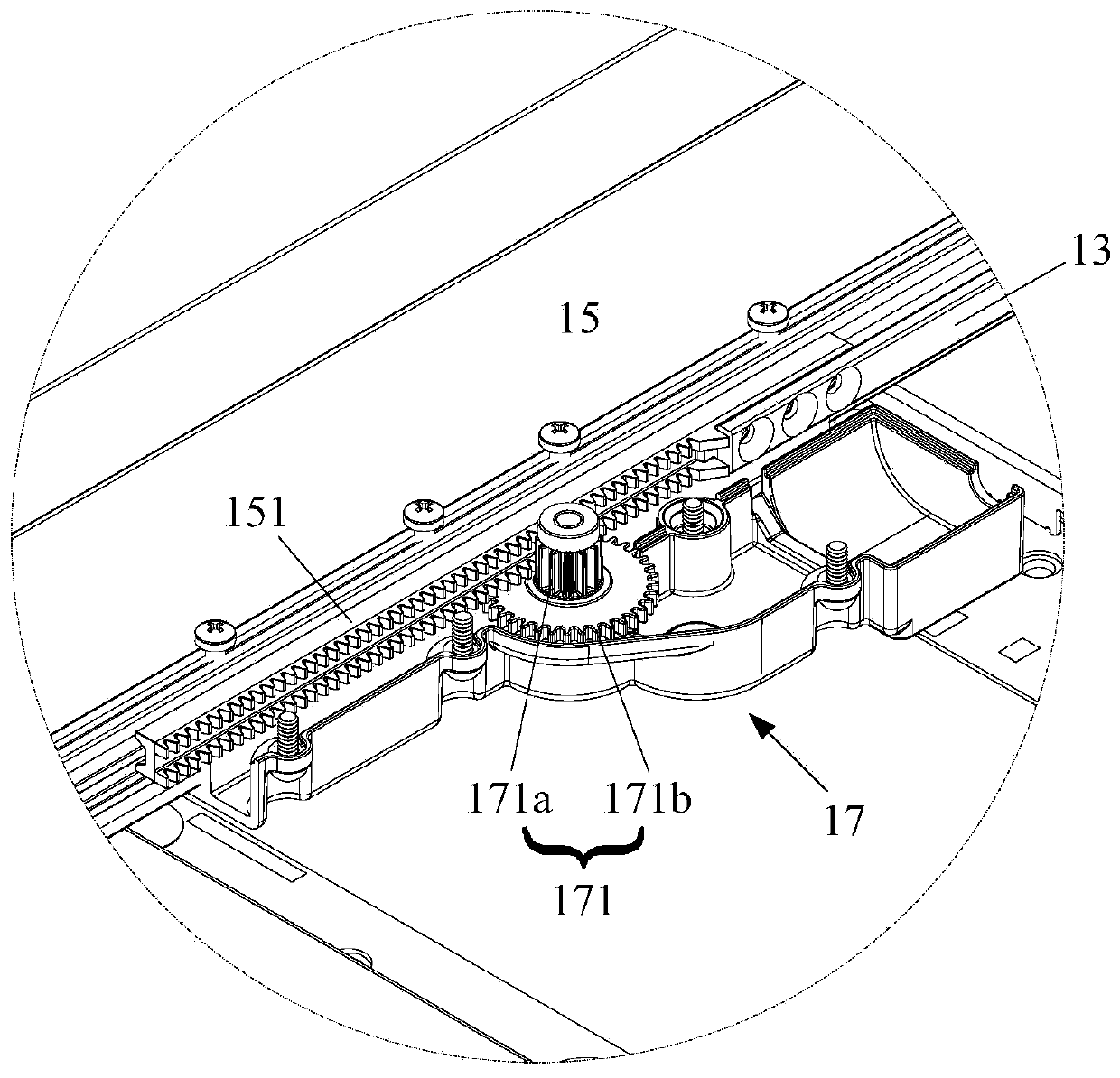

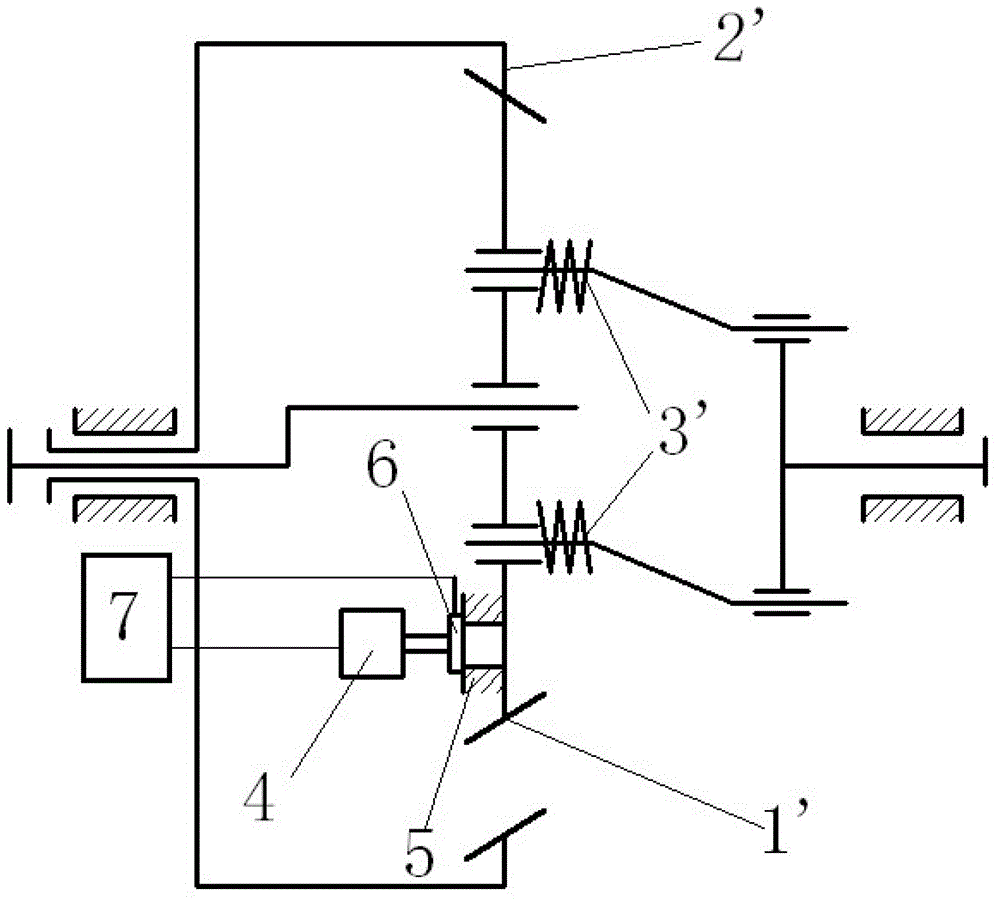

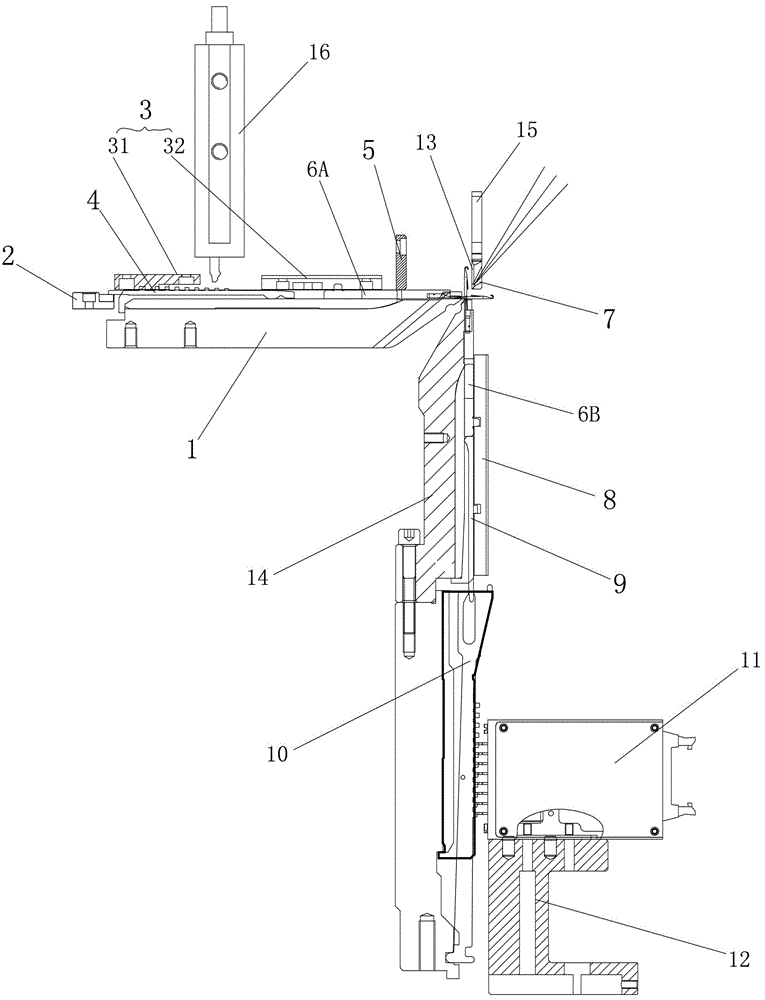

Antenna and adjusting device for electrical downtilt of antenna

ActiveCN103700944AHigh adjustment accuracyThe resistance value is accurateAntennasElectrical tuningElectrical connection

The invention provides an antenna and an adjusting device for the electrical downtilt of the antenna. The adjusting device comprises an electric tuning unit, a first transmission mechanism, a pull rod, a second transmission mechanism, a potentiometer and a phase shifter, wherein the first transmission mechanism is respectively and mechanically connected with the electric tuning unit and the pull rod for converting rotary movement output by the electric tuning unit into linear movement of the pull rod, the second transmission mechanism is respectively and mechanically connected with the pull rod and the phase shifter for transmitting the linear movement of the pull rod to the phase shifter, the potentiometer is directly and mechanically connected with the pull rod, and is also electrically connected with the electric tuning unit for enabling the electric tuning unit to receive a resistance value measured by the potentiometer and to adjust the rotating angle of the electric tuning unit according to the relationship between the resistance value and the electrical downtilt of the antenna. Through the above manner, adjustment for the electrical downtilt of the antenna can be realized by the adjusting device with a simpler structure, the cost is relatively low, the transmission error during adjustment can be reduced, and the adjusting precision of the electrical downtilt of the antenna is improved.

Owner:ANHUI TATFOOK TECH CO LTD

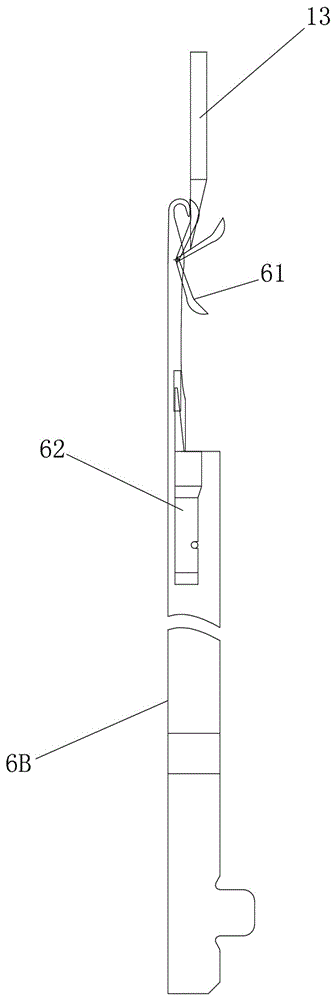

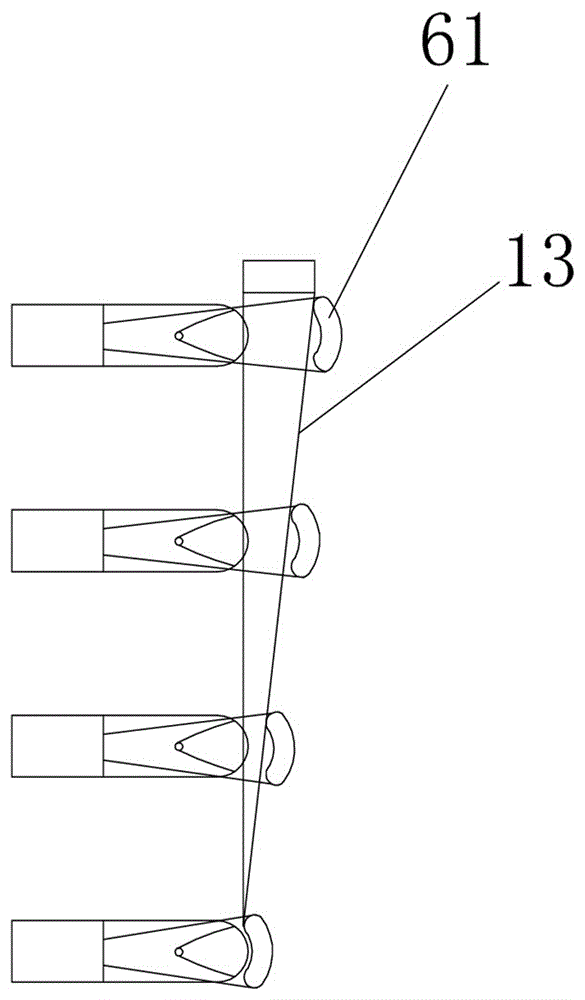

Dielectric phase shifter of base station electric tunable antenna

InactiveCN104201440AGood intermodulation characteristicsPrecise structural designWaveguide type devicesAntennasElectricityPhase shifted

The invention applies to the mobile communication base station antenna and radio frequency field, and provides a dielectric phase shifter of a base station electric tunable antenna. The dielectric phase shifter of the base station electric tunable antenna comprises a cover plate, a bottom plate, a slide mechanism, at least one guide pillar and a feed network, wherein the slide mechanism comprises a slide plate and a phase shifting piece, the phase shifting piece comprises an upper phase shifting piece and a lower phase shifting piece, the slide plate is provided with at least two slide grooves, the phase shifting piece penetrates through and slides in the slide groove, at least two fixing pieces penetrate through the slide plate, the at least one guide pillar is fixed on the bottom plate, the lower phase shifting piece is provided with a guiding groove, the at least one guide pillar penetrates through the guiding groove in the lower phase shifting piece, the feed network is arranged on the bottom plate, and the phase shifting piece moves in a plane space on the surface of the feed network. Accordingly, the dielectric phase shifter of the base station electric tunable antenna achieves phase shifting effects in a large range.

Owner:MOBILE ANTENNA TECH SHENZHEN +2

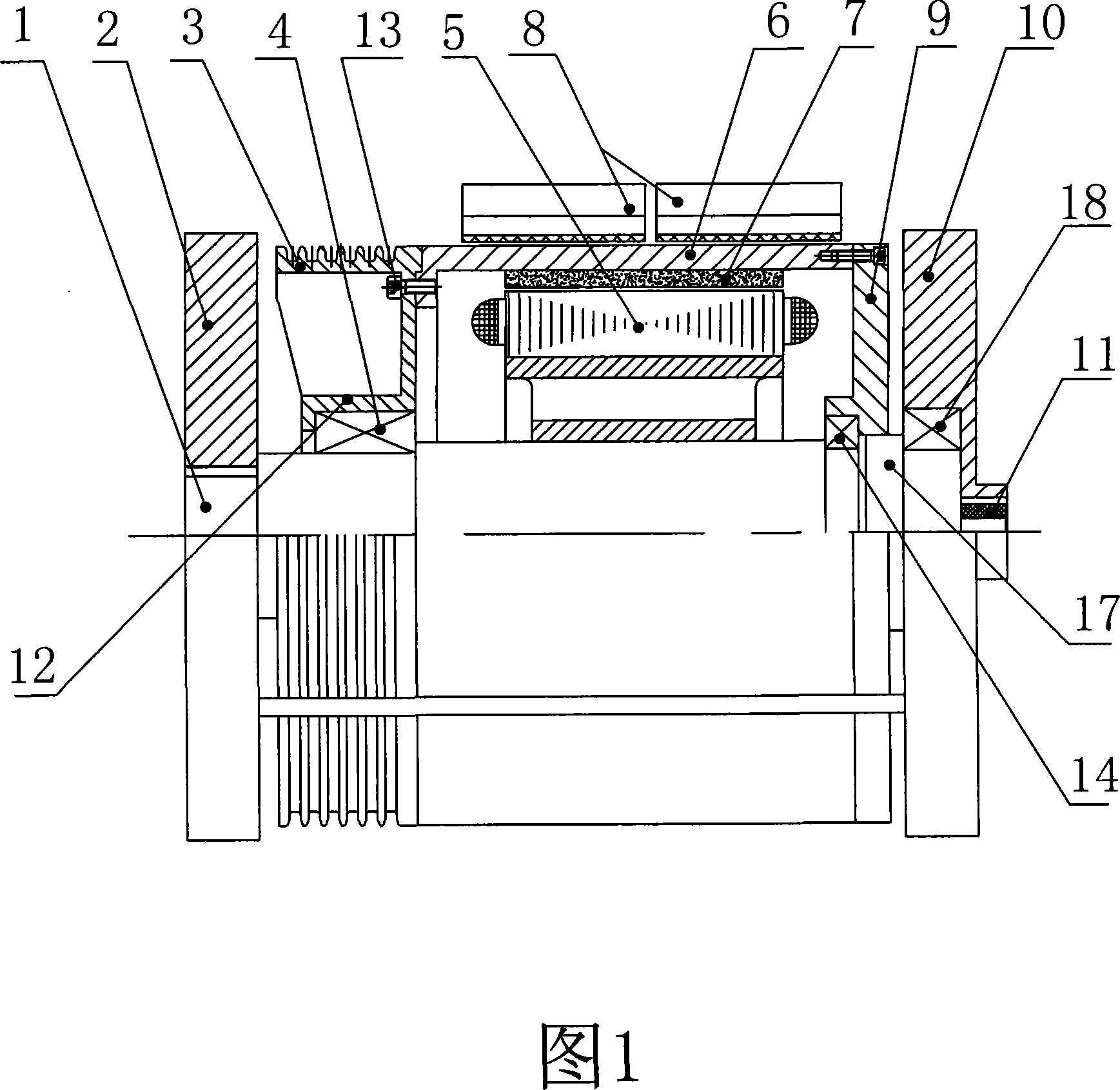

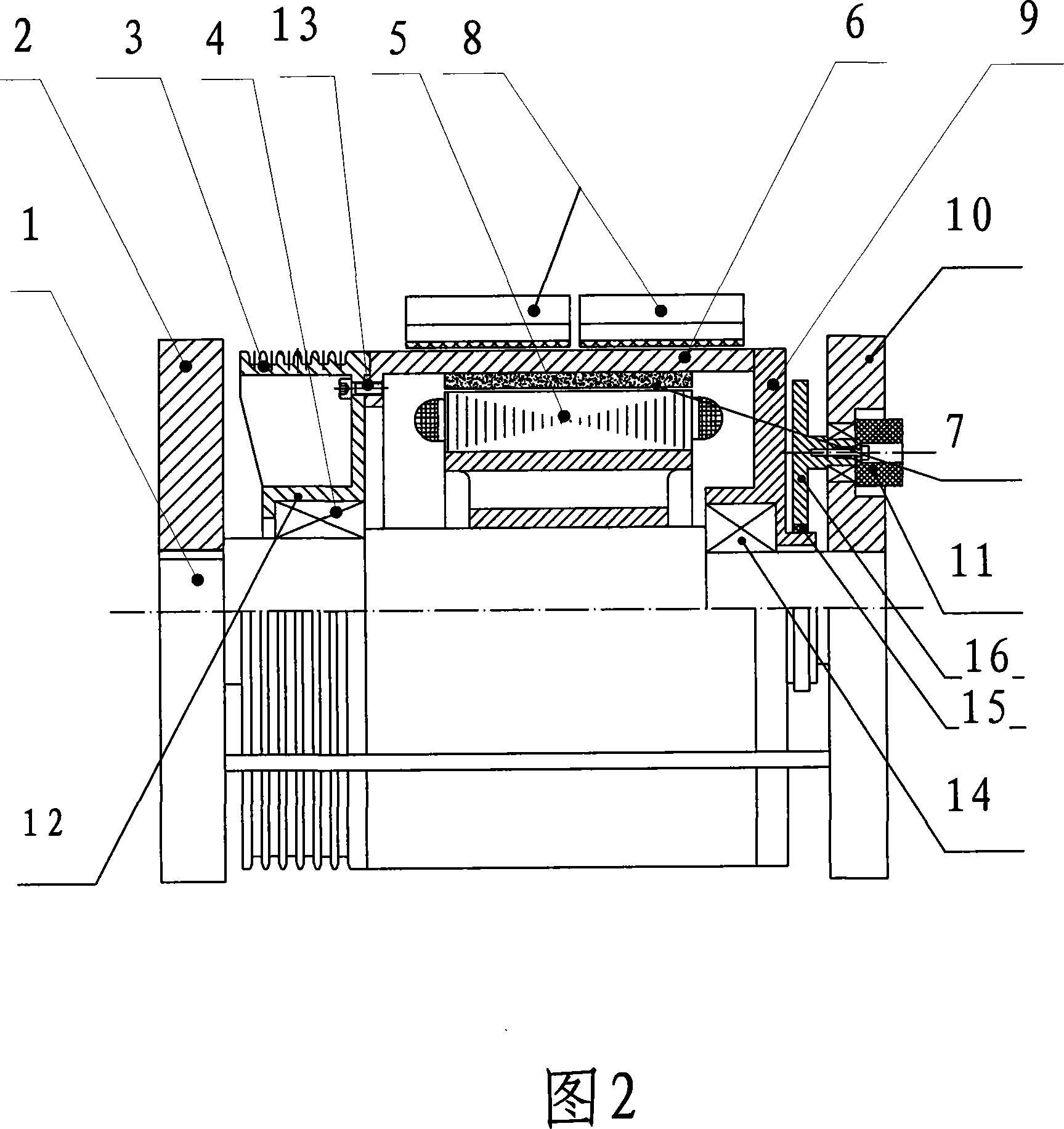

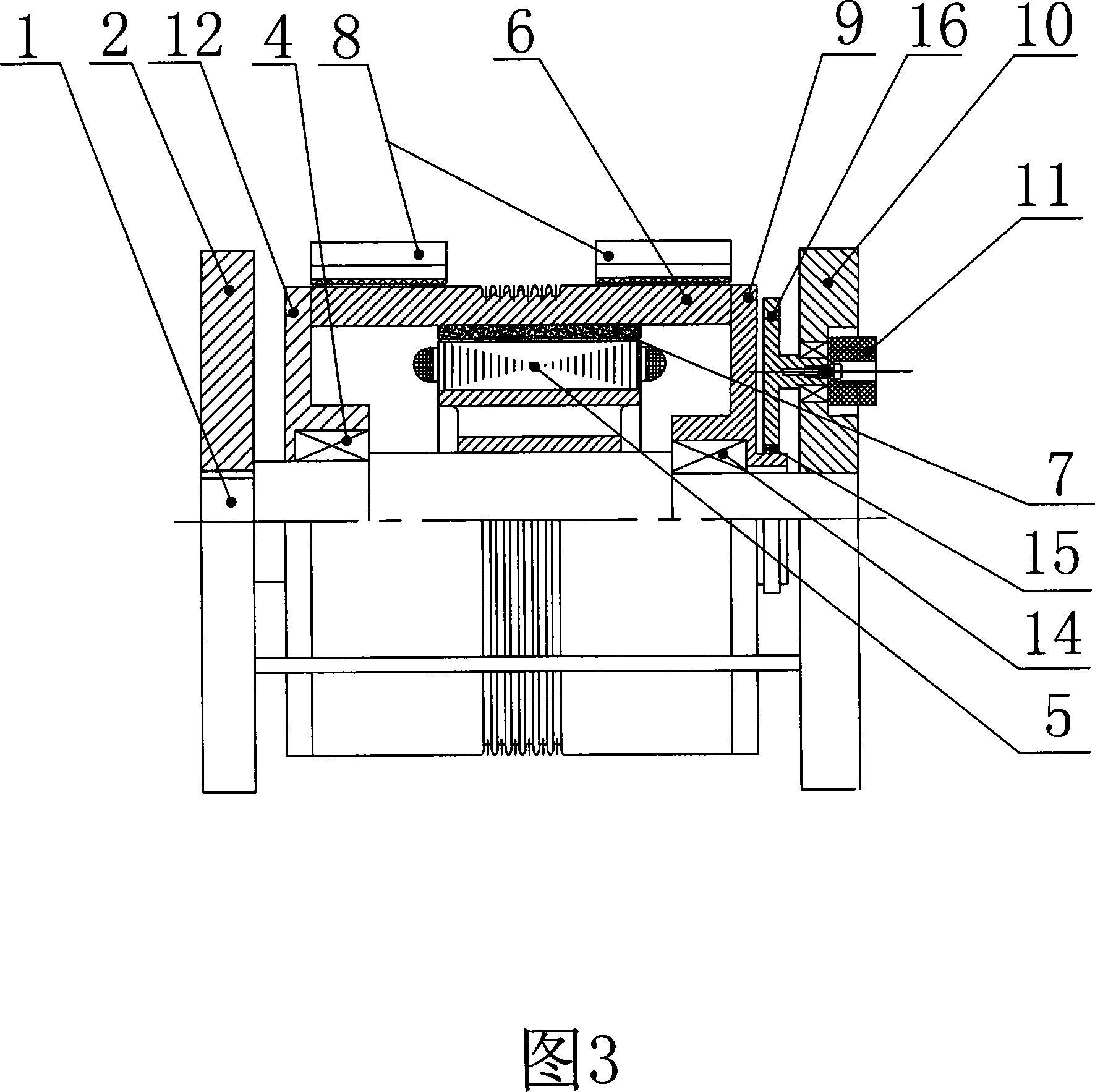

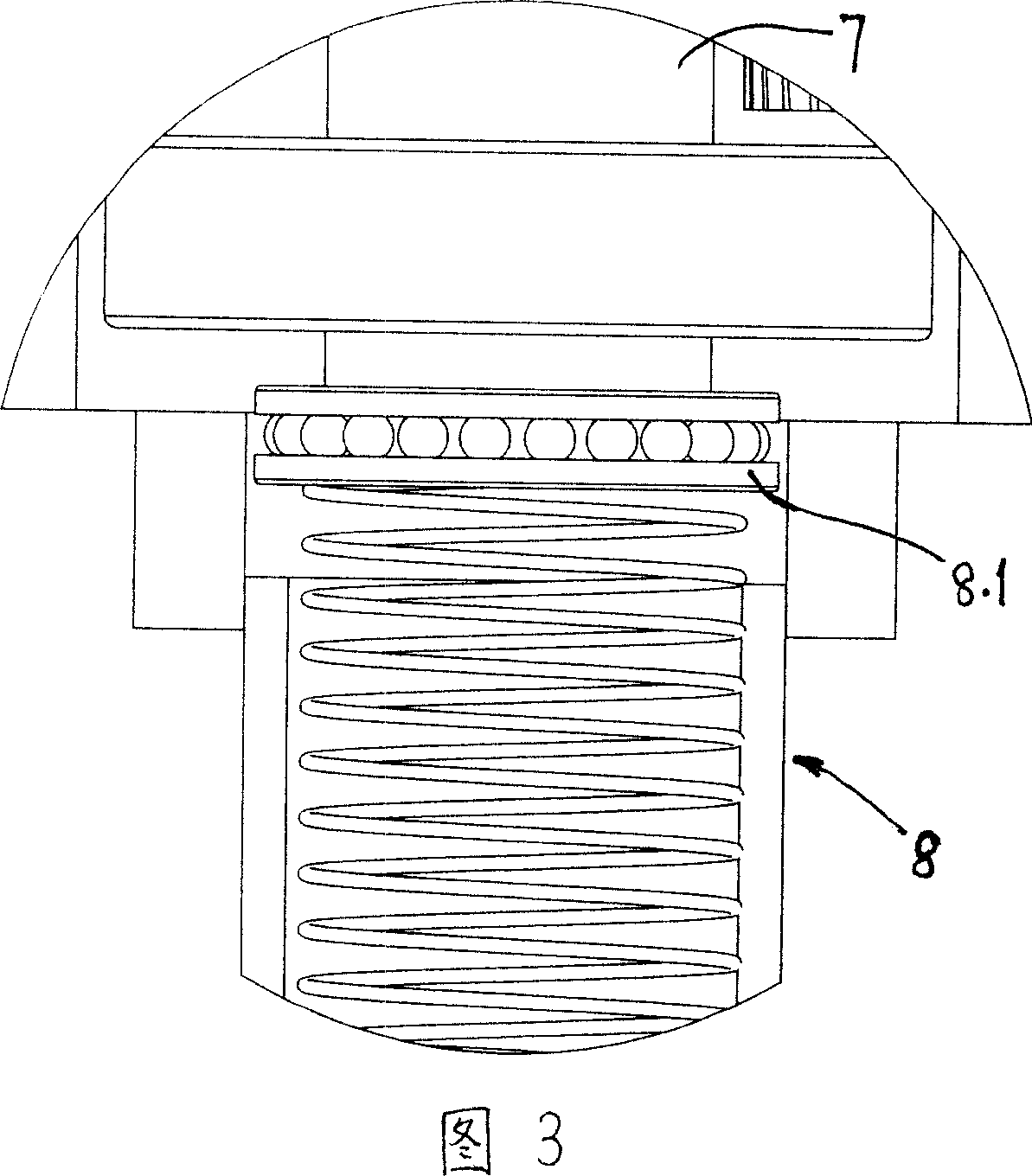

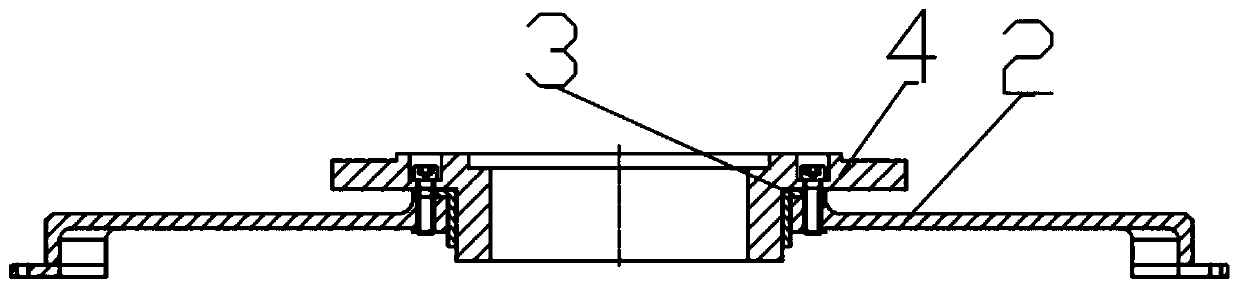

Elevator traction machine

The invention discloses an elevator traction device, which includes a detachable load-bearing wall frame body that consists of a front support (2) and a rear support (10), a supporting shaft (1), a stator (5) fixedly arranged on the supporting shaft (1), an outer rotor cylinder (6) sheathed outside the stator (5), a permanent magnetic piece (7)and an encoder (11); a traction wheel (3) is separably connected with the end of the outer rotor cylinder (6) and is arranged on the support shaft (1) by a bearing, one end of the supporting shaft is fixed on the front support (2) and the other end supports on a rear end cover (9) by a bearing (14), a rotation shaft (17) is tightly fitted in a central hole that is on the rear end cover and is coaxial with the support shaft (1), and the other end of the rotation shaft (17) is arranged on the rear support (10) by a bearing (18) and is connected with the encoder (11). The invention is low in manufacturing cost and maintenance cost, safe in operation, and good in maintainability and a cage almost has no vibration.

Owner:NINGBO HONGDA ELEVATOR

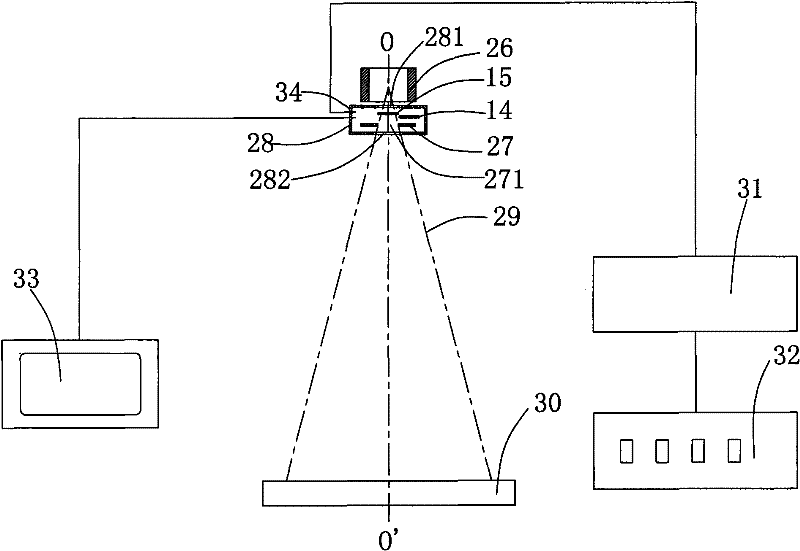

X-ray beam filtering device, beam limiter and medical diagnosis X-ray apparatus

ActiveCN102125437ASmall transmission errorHigh transmission precisionRadiation diagnosticsSoft x rayX-ray

The invention discloses an X-ray beam filtering device, a beam limiter and a medical diagnosis X-ray apparatus. The X-ray beam filtering device comprises a power source, a first linear transmission device, a second linear transmission device, a linkage device, a first filtering sheet and a second filtering sheet, wherein the power source drives the first linear transmission device to move; the first linear transmission device drives the first filtering sheet as well as the linkage device; the linkage device is connected with the second linear transmission device; the second linear transmission device drives the second filtering sheet; and the linkage device has a load travel driving the second linear transmission device to move and a no-load travel free from drive. By controlling the first and second filtering sheets to change between the position in an X-ray beam range and the position outside an X-ray range, the filtering combinations with different filtering thickness can be realized and can not only filter unnecessary radioactive rays in the X-ray beam, but also can meet different filtering requirements as well as different using requirements of medical workers to a relatively large degree.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

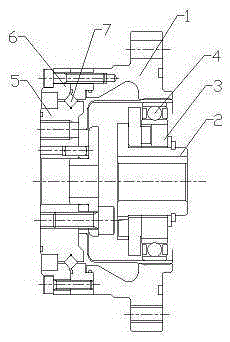

Robot harmonic reducer device

InactiveCN105387159AAvoid separate processingSave raw materialsFriction gearingsHarmonicReduction drive

The invention discloses a robot harmonic reducer device. The robot harmonic reducer device comprises a rigid gear, a flexible gear and a wave generator which are assembled together. A coaxial positioning device is arranged between the flexible gear and the wave generator. The assembly accuracy between the wave generator and the flexible gear is reduced to be less than 2 microns through the coaxial positioning device, and the radial run-out error between the wave generator and the flexible gear is reduced to be less than 5 microns. According to the robot harmonic reducer device, an inner ring and an outer ring of a cross roller bearing are integrally machined on the rigid gear and the flexible gear respectively, roller pins are directly assembled, the inner ring and the outer ring are omitted, and raw materials are saved; moreover, the situation that multiple assembly errors are generated due to the fact that an inner ring, an outer ring and roller pins of a cross roller bearing are machined respectively and then assembled and finally are assembled between a rigid gear and a flexible gear is avoided. The overall assembly error is reduced to be less than 2 microns.

Owner:SHANDONG SHKE MACHINERY MFG

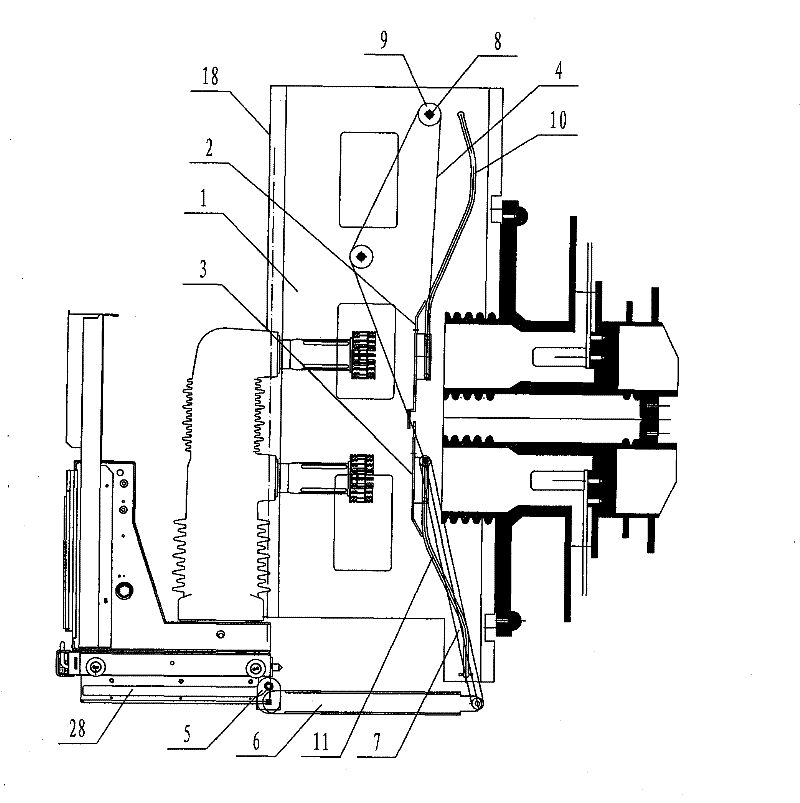

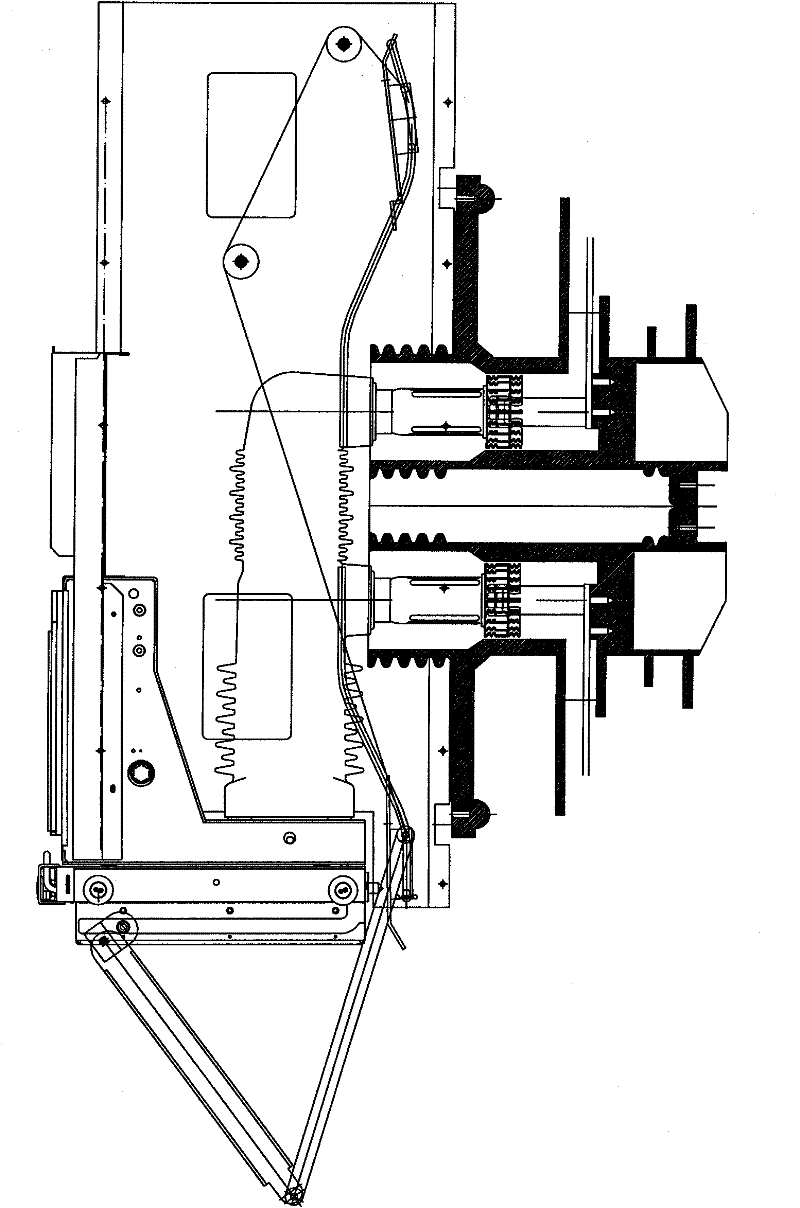

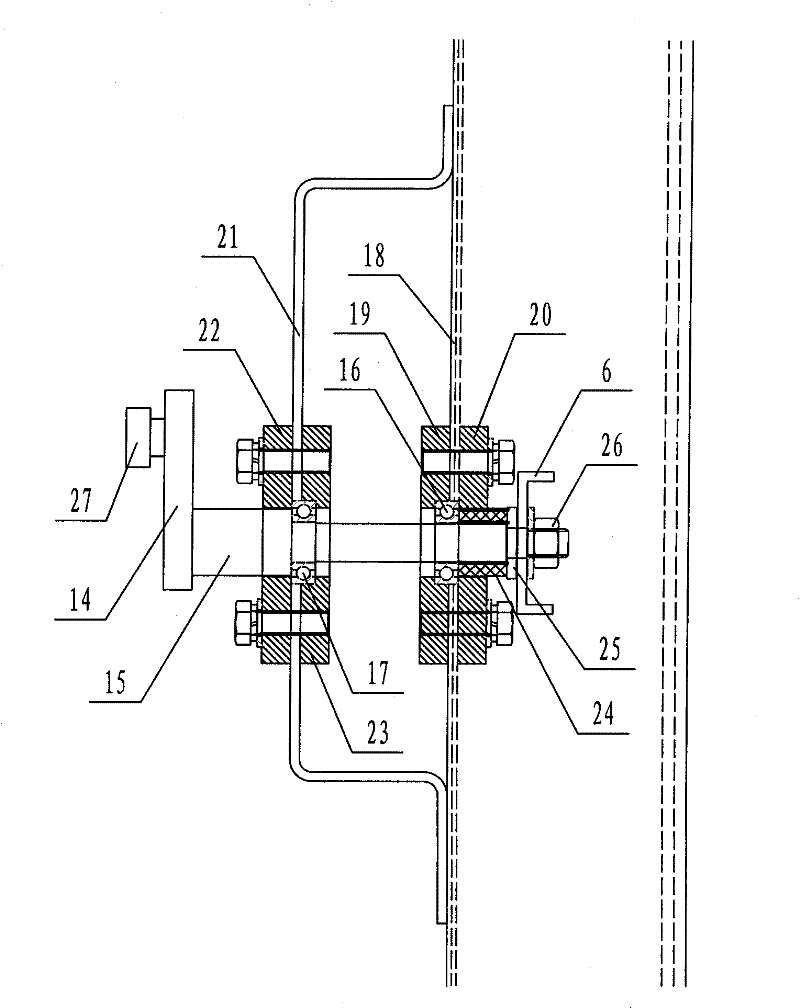

A switchgear valve mechanism

ActiveCN102290721APrevent sliding left and rightSmall activity gapSwitchgear detailsEngineeringPulley

The invention discloses a switch cabinet valve mechanism. The left end of a valve connecting rod is fixedly connected with a drive mechanism. The right end of the valve connecting rod is hinged with the lower end of a small connecting rod. The upper end of the small connecting rod is hinged at the upper part of a lower valve plate. A valve sliding groove plate is fixed on the side wall of a cabinet body. A fixing shaft is arranged at the upper part of the valve sliding groove plate. A fixed pulley is arranged on the fixing shaft. An upper sliding groove and a lower sliding groove are respectively arranged at the upper part and the lower part of the valve sliding groove plate. One ends of pins are respectively hinged at the upper part and the lower part of the external side surface of an upper valve plate. One ends of pins are also respectively hinged at the upper part and the lower part of the external side surface of the lower valve plate. The other ends of the pins are socket-connected into corresponding rollers. One end of a steel wire rope is fixed at the upper end of the small connecting rod and the other end of the steel wire rope is wound through the fixed pulley and is fixed at the upper part of the upper valve plate. The switch cabinet valve mechanism has the characteristics of convenience in installation, firm fixation, high structural strength, good drive performance and the like, and is suitable for all kinds of switch cabinets.

Owner:SHANDONG TAIKAI COMPLETE ELECTRIC APPLIANCE

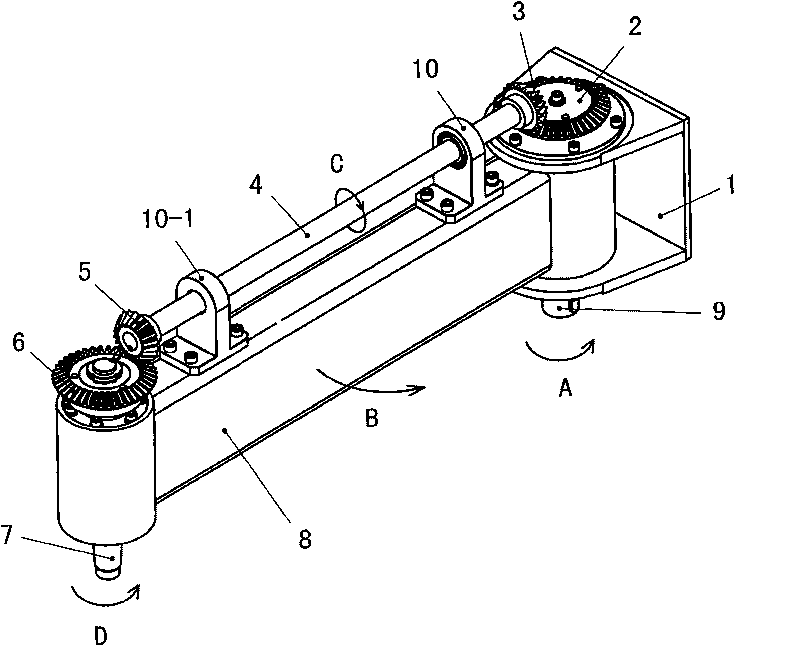

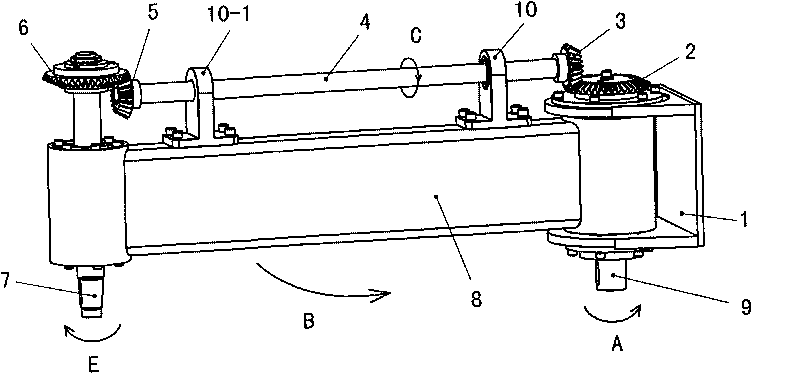

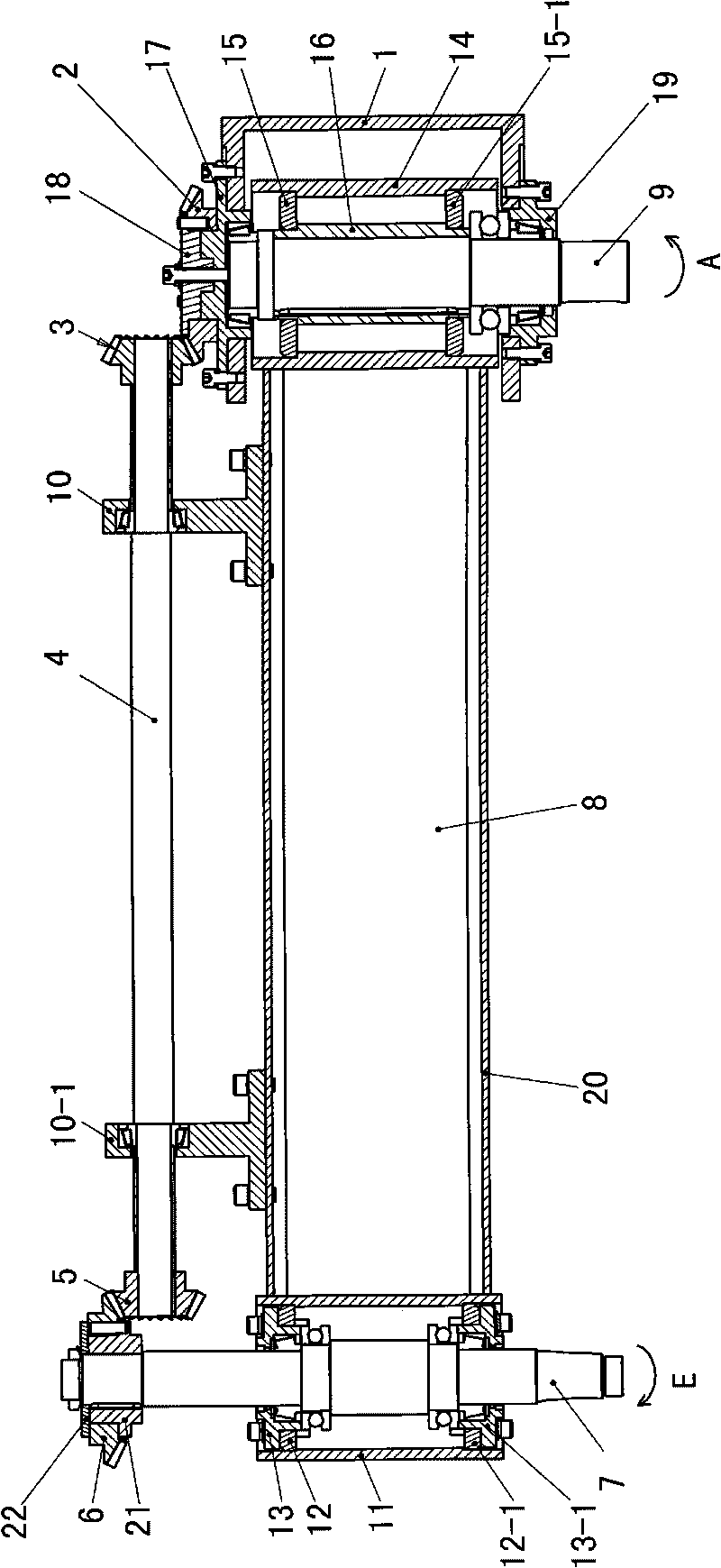

Wrist transmission mechanism of stacking robots

The invention relates to the field of mechanical transmission, and discloses a wrist transmission mechanism of stacking robots. In order to solve the problems such as complex structure, high cost and the like, the wrist transmission mechanism provides the following technical scheme which is characterized in that the right part of a swing arm (8) is in rotary connection with a bracket (1); a driving rotor (9) is fixedly connected with the right part of the swing arm (8); the right part of a transmission shaft passes through and is in rotary connection with a first bearing pedestal (10), while the left part passes through and is in rotary connection with a second bearing pedestal (10-1); the bottoms of the bearing pedestals are fixedly connected with the swing arm (8); a wrist rotor (7) is in rotary connection with the left end of the swing arm (8); the top of the wrist rotor (7) is fixedly connected with a fourth bevel gear (6), a first bevel gear (2) and the bracket (1); a second bevel gear (3) is fixedly connected with the right end of the transmission shaft (4) and is in meshed connection with the first bevel gear (2); and a third bevel gear (5) is fixedly connected with the left end of the transmission shaft (4) and is in meshed connection with the fourth bevel gear (6). The wrist transmission mechanism has the advantages of simple structure and low cost.

Owner:DONGHUA UNIV

Half-module pivoted window mechanism applied to sub transonic speed wind tunnel

The invention relates to a half-module pivoted window mechanism applied to a sub transonic speed wind tunnel. The half-module pivoted window mechanism comprises a driving transmission module, a feedback and measurement module and a rotating module, wherein the driving transmission module consists of a support seat, a large cylindrical straight gear, an alternating current servo motor, a speed reducer, a gear press cover, a small cylindrical straight gear, a compression cover and a compression screw, the feedback and measurement module consists of a potentiometer support seat, a potentiometer, a press sheet, a shaft coupler, a small shaft and a connecting cover, and the rotating module consists of a right bearing cover, a bearing seat, a pair of precise conical roller bearings, a left bearing cover and a main shaft. Through the adoption of a cylindrical straight gear group, the half-module pivoted window mechanism can realize the movement for positive 360 degrees and negative 360 degrees, in addition, the integral hosting of the mechanism can be realized, a measurement part adopting the potentiometer as the core is adopted for the transmission matching of the cylindrical straight gear group, and the attack angle control precision being + / -3' can be realized.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

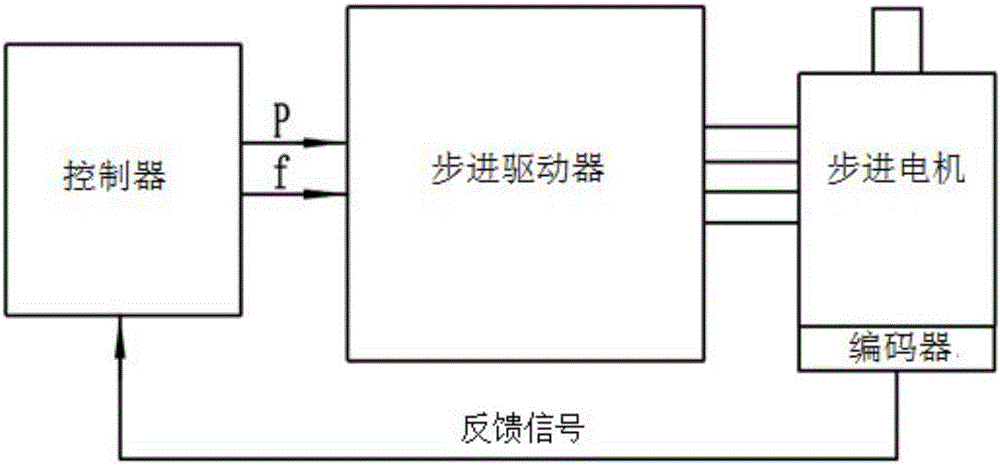

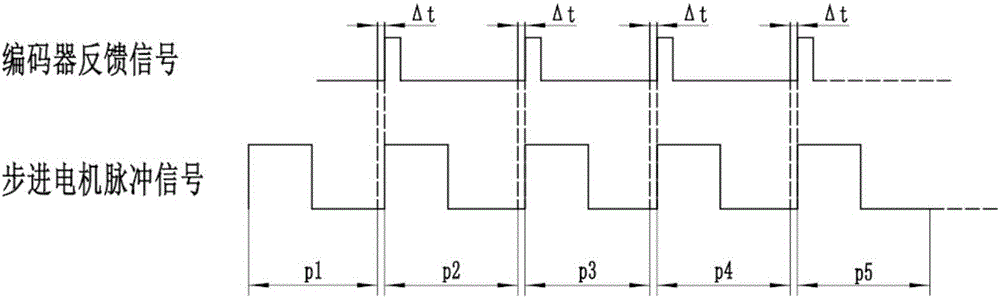

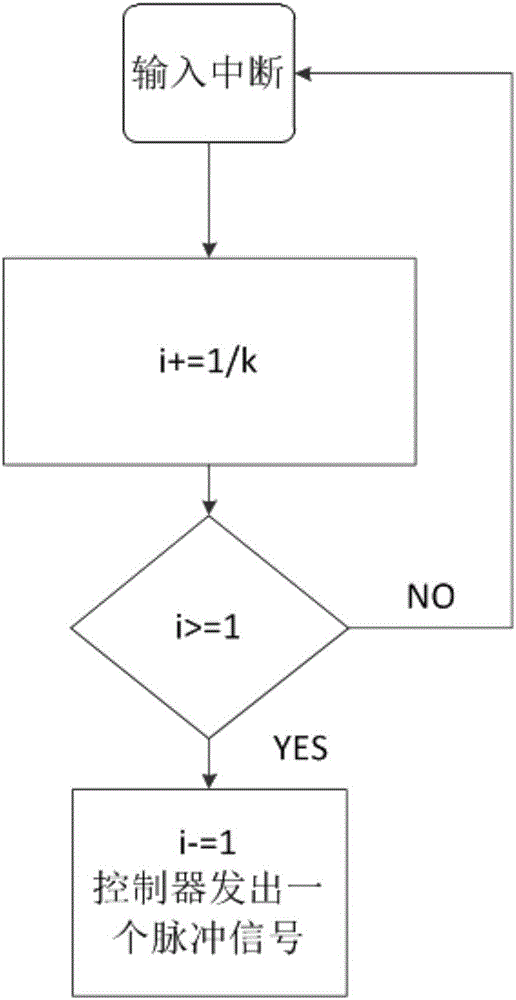

Quick-response stepping motor pole speed drive system and method

InactiveCN106712612AIncrease profitSmall transmission errorDynamo-electric converter controlNumerical controlControl theory

The invention relates to a quick-response stepping motor pole speed drive system and method. A stepping motor is connected to an incremental encoder through a synchronous rotation mechanism, and the incremental encoder is connected with a controller. When the stepping motor rotates one step angle, the incremental encoder feeds back one or more signals to the controller correspondingly, and the controller takes the feedback signal as a signal that the stepping motor rotates a next step angle. Because the encoder is high in speed of feeding back the signal, the motor nearly can receive feedback signals of a plurality of encoders at the same time after the motor rotates one step angle, thereby driving the next step angle. The method can enable the stepping motor not to lose a step during high-frequency operation, greatly reduces the transmission error of the industrial control field, improves the utilization rate of the stepping motor, guarantees the control precision, enlarges the control range of the rotating speed of the motor, is quick in response speed, facilitates the precise positioning, can be widely used in the numerical control machining, and effectively improves the machining precision.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

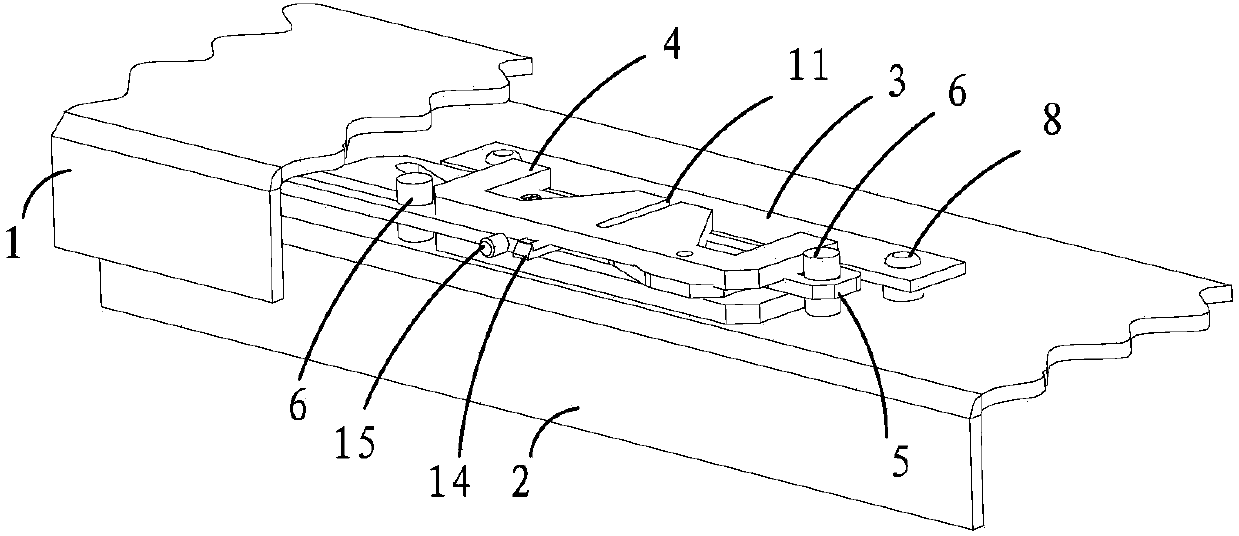

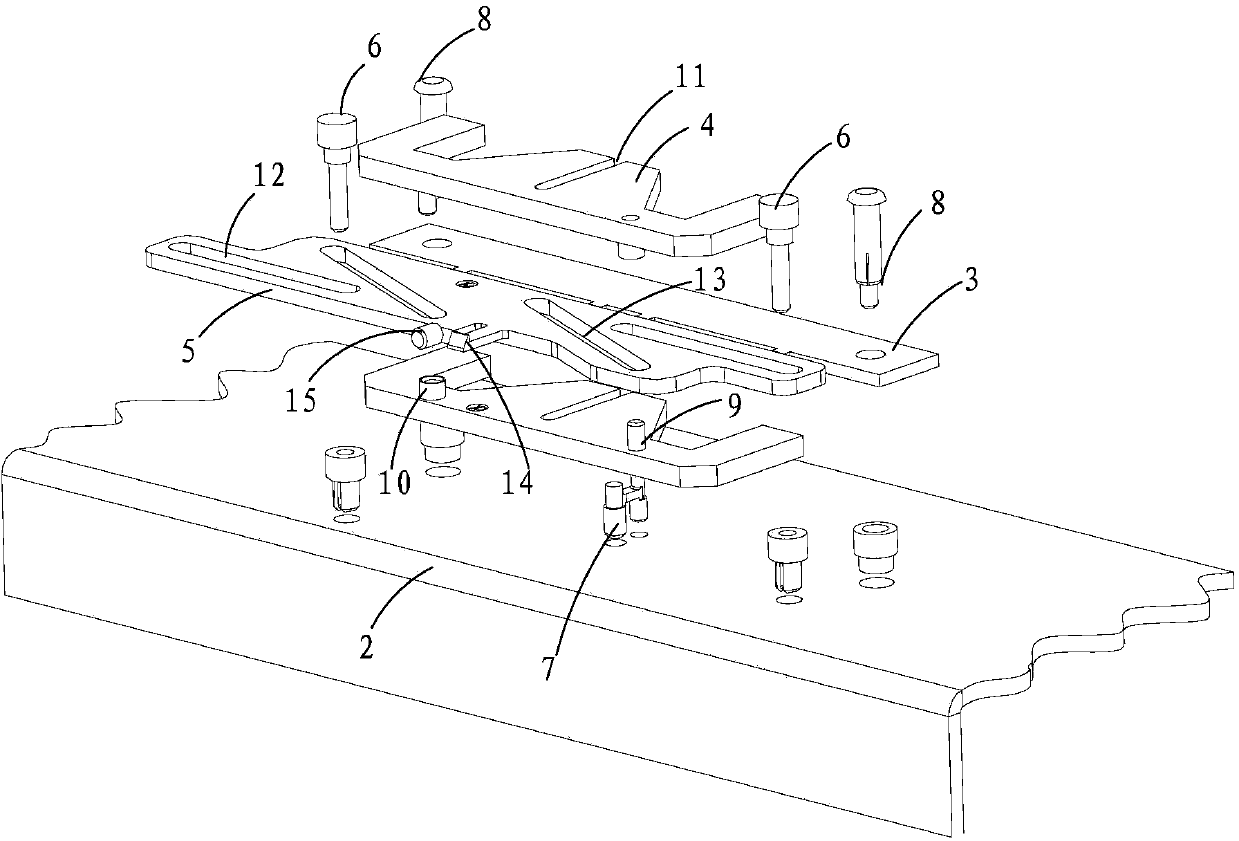

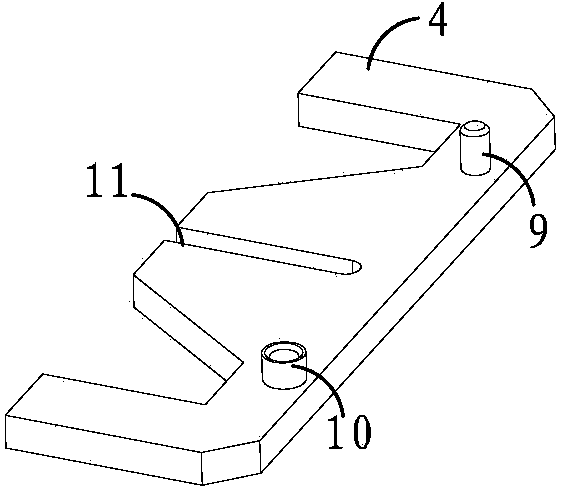

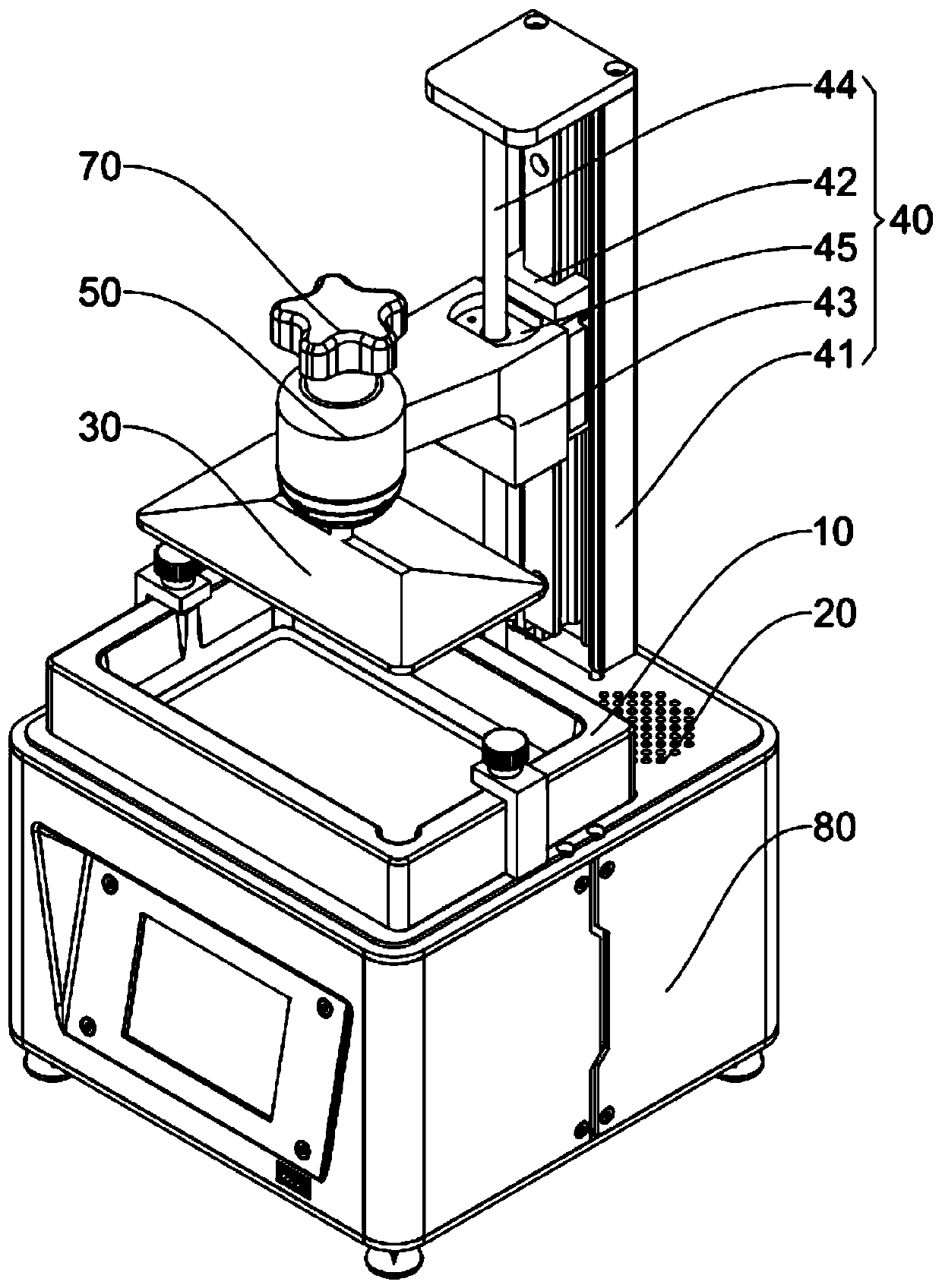

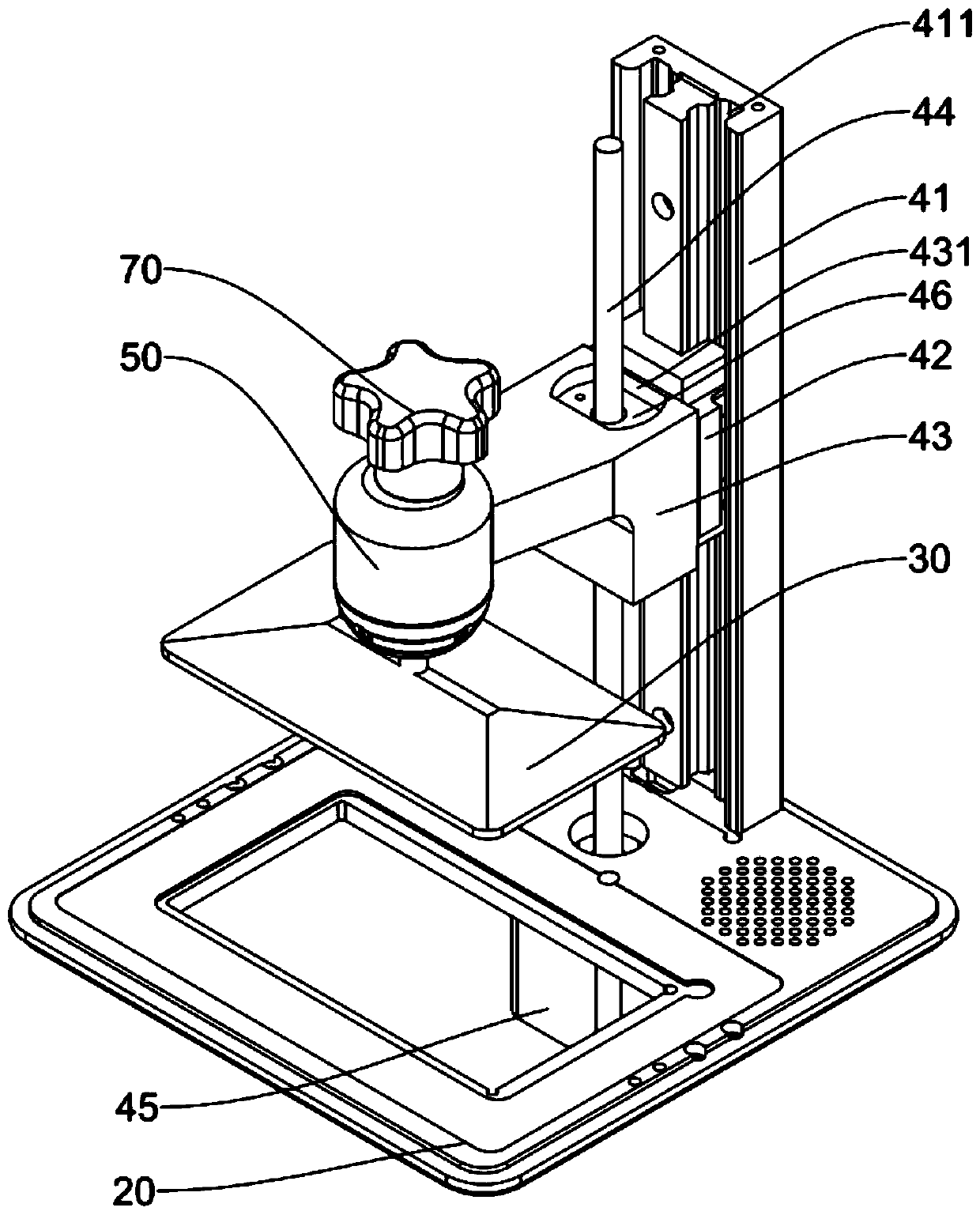

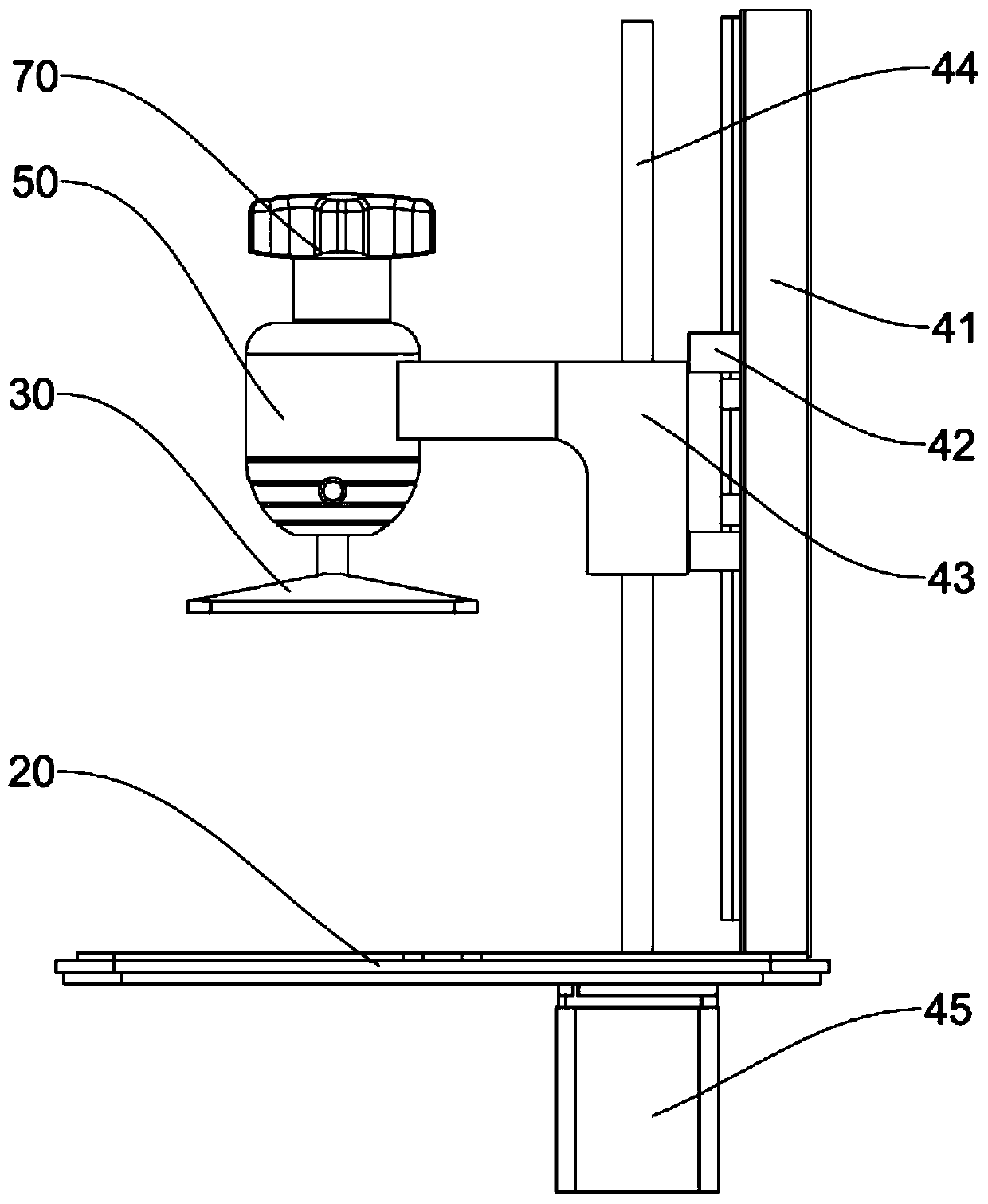

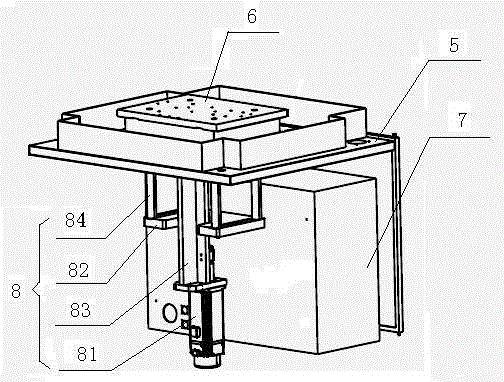

Platform adjustment mechanism of photocuring 3D printer, and photocuring 3D printer

PendingCN110884131AEasy levelingImprove surface accuracyManufacturing platforms/substrates3D object support structuresEngineeringComputer printing

The invention discloses a platform adjustment mechanism of a photocuring 3D printer, and the photocuring 3D printer. The platform adjustment mechanism comprises a base plate, a forming platform plate,a vertical moving assembly, a connecting piece and a platform adjusting assembly; a resin groove is formed in the base plate; the plane, facing the resin groove, of the forming platform plate is a forming face; the vertical moving assembly is connected with the forming platform plate and controls the forming platform plate to move in the vertical direction; the connecting piece is connected withthe vertical moving assembly and the forming platform plate; the platform adjusting assembly is arranged between the connecting piece and the forming platform plate, used for adjusting the forming platform plate to be parallel to the bottom face of the resin groove, and comprises a positioning ball head, a positioning compression piece, a fastening piece and a connecting rod, the side face, facingthe forming platform plate, of the connecting piece is provided with a first groove part, and the positioning ball head and the positioning compression piece are both arranged in the first groove part; and the positioning compression piece sleeves the positioning ball head, the connecting rod is connected with the positioning ball head and the forming platform plate, a through hole is formed in the connecting piece, and the fastening piece penetrates through the through hole to compress the positioning compression piece so as to compress the positioning ball head.

Owner:SHENZHEN ELEGOO TECH CO LTD

Electronic-control backlash eliminating gear pair with variable tooth thickness

InactiveCN102878279AQuick responseHigh transmission precisionToothed gearingsGearing detailsAxial displacementControl power

The invention discloses an electronic-control backlash eliminating gear pair with variable tooth thickness. The gear pair comprises a tooth thickness variable gear I, a tooth thickness variable gear II and an electronic-control backlash eliminating system, wherein the tooth thickness variable gear II is meshed with the tooth thickness variable gear I, the electronic-control backlash eliminating system comprises at least an electronic-control power device used for exerting backlash-regulating axial mechanical force on the tooth thickness variable gear I and the tooth thickness variable gear II, and the direction of the backlash-regulating axial mechanical force is a direction for backlash elimination between the tooth thickness variable gear I and the tooth thickness variable gear II. According to the gear pair, real-time control of axial displacement is achieved through electronic control, then the tooth backlash can be regulated in real time according to backlash regulation requirements, the response is rapid, the transmission accuracy is improved, the volume is small, the structure is simple, the synchronism requirement for control is low, the cost is low, the assembling requirements are easy to satisfy, the tooth backlash and the return difference can be eliminated or reduced timely, the transmission error during reversing can be reduced, therefore the operation and the control are simple and fast, and high adaptability is provided at occasions with high requirements for the integral structure.

Owner:CHONGQING UNIV

Electronic-control anti-backlash gear pair

ActiveCN104295708AEliminate backlashEliminate hysteresisPortable liftingGearing elementsElectricityGear wheel

The invention discloses an electronic-control anti-backlash gear pair. The electronic-control anti-backlash gear pair comprises a first gear, a second gear and a third gear. The second gear and the third gear are coaxial and parallel and are meshed with the first gear, and the freedom degree of relative rotation in the circumferential direction exists between the second gear and the third gear. The electronic-control anti-backlash gear pair further comprises an electronic-control anti-backlash system composed of an electronic driving block and a control unit, wherein the electronic driving block is used for driving the second gear and the third gear to relatively rotate to eliminate meshed backlash between the second gear and the first gear and between the third gear and the first gear during electronic deformation. According to the electronic-control anti-backlash gear pair, when the backlash needs to be adjusted, electronic deformation materials are electrified to be deformed, a double gear formed by the second gear and the third gear relatively rotates to eliminate the backlash between the second gear and the first gear meshed with the second gear and between the third gear and the first gear meshed with the third gear, the gear backlash and the return difference can be accordingly eliminated or reduced in real time, cost is low, the structure is simple, accessory equipment such as a motor is not needed, the occupied space is small, driving energy is reduced, the transmission error during direction changing is reduced, and operation and control are simpler and more convenient; as the original mode that the backlash is eliminated through mechanical force of a power source is not adopted, controllability and accuracy are high, and the electronic-control anti-backlash gear pair is suitable for occasions with the requirements for the high accuracy.

Owner:CHONGQING UNIV

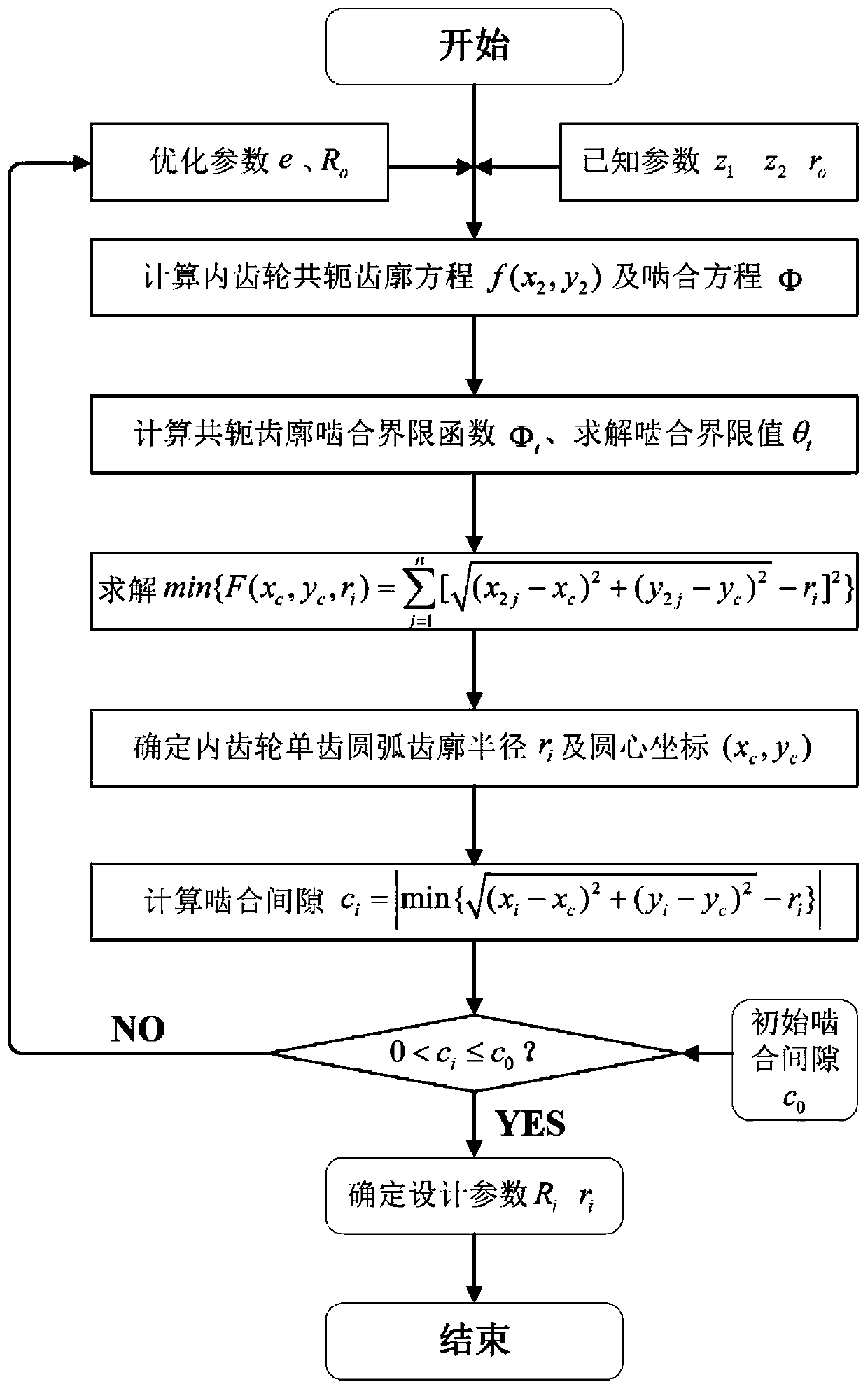

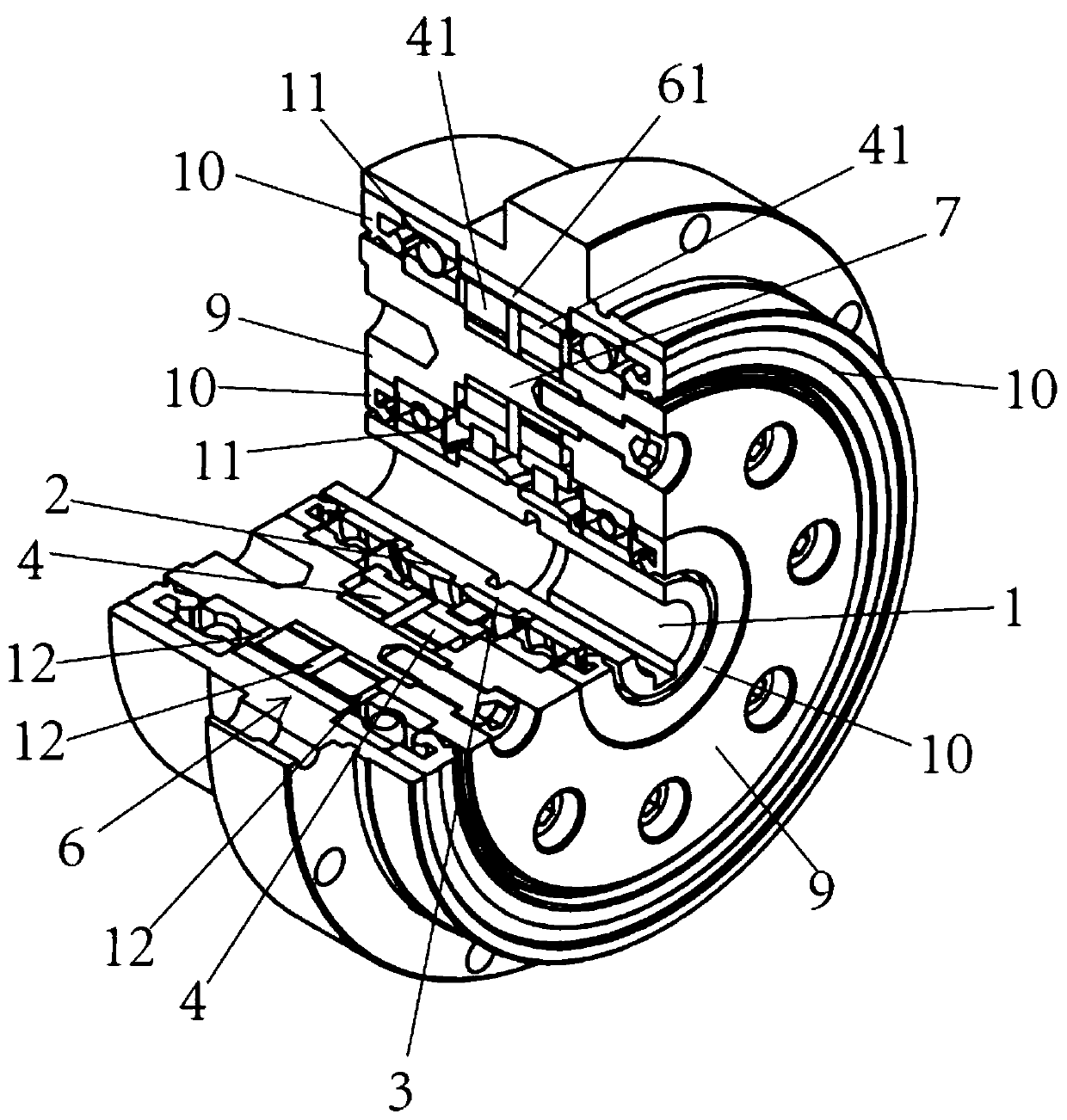

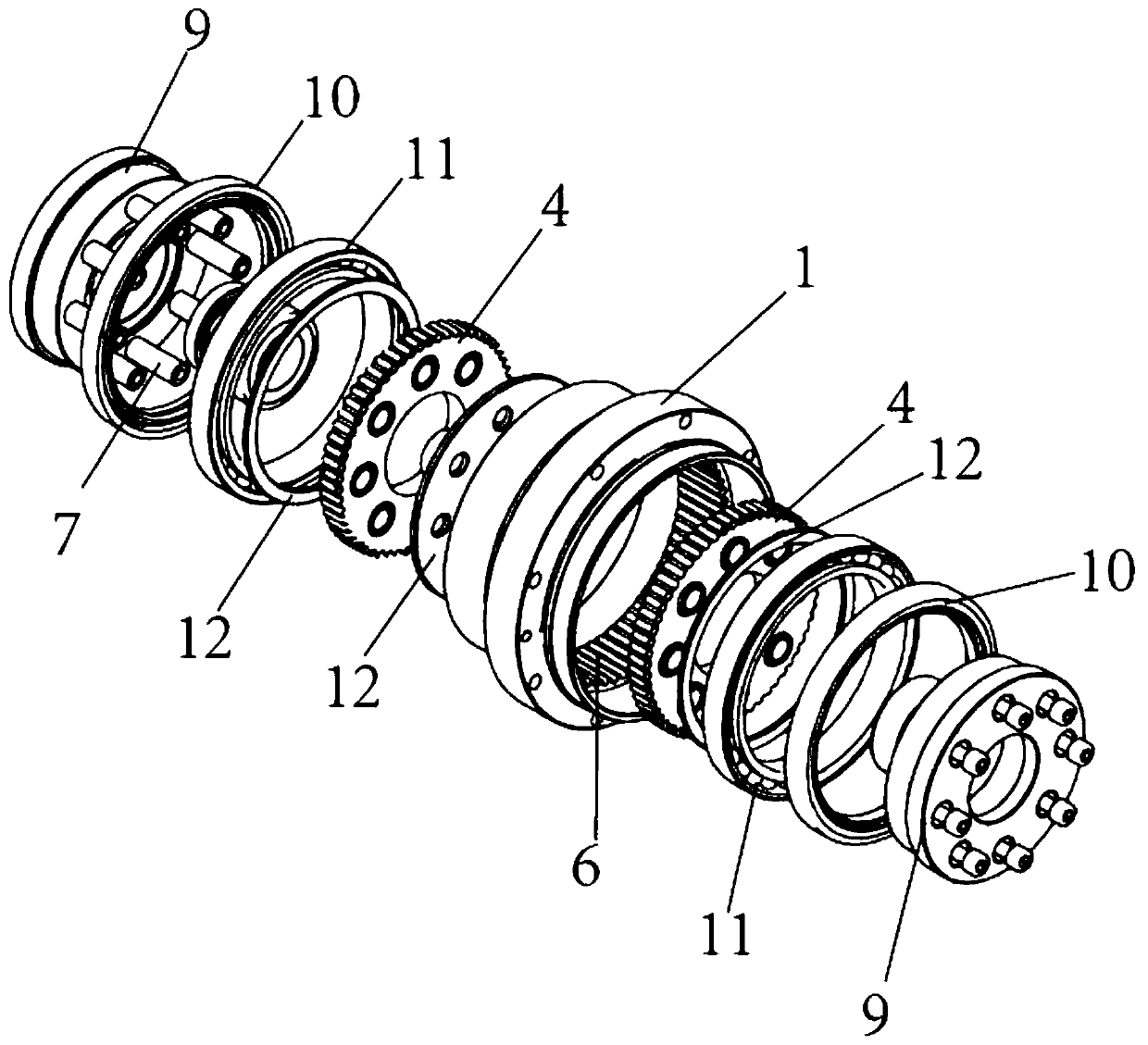

Double-arc gapped meshing few tooth difference planet transmission device

PendingCN110067833AReduce processing stepsArc machining is less difficultGear lubrication/coolingPortable liftingGear wheelEngineering

The invention discloses a double-arc gapped meshing few tooth difference planet transmission device. A box and an eccentric shaft arranged in the box are included. A first eccentric part and a secondeccentric part of the eccentric shaft are provided with two outer gears correspondingly. The box inner walls corresponding to the outer gears are provided with inner gears, and the inner gears and theouter gears are matched for meshing. A plurality of drive pins are further arranged between the two outer gears. The two ends of the multiple drive pins are connected and matched with two end discs,a planet carrier structure is formed, and power is output. Tooth profiles of the inner gears and tooth profiles of the outer gears are arcs. Initial meshing gaps exist in the inner gears and the outergears. The double-arc gapped meshing few tooth difference planet transmission device solves the problems about complex curve high-precision machining and tooth profile shape correcting, and a good precision running effect is kept.

Owner:SUZHOU BIO ENGIN ROBOTIC TECH CO LTD

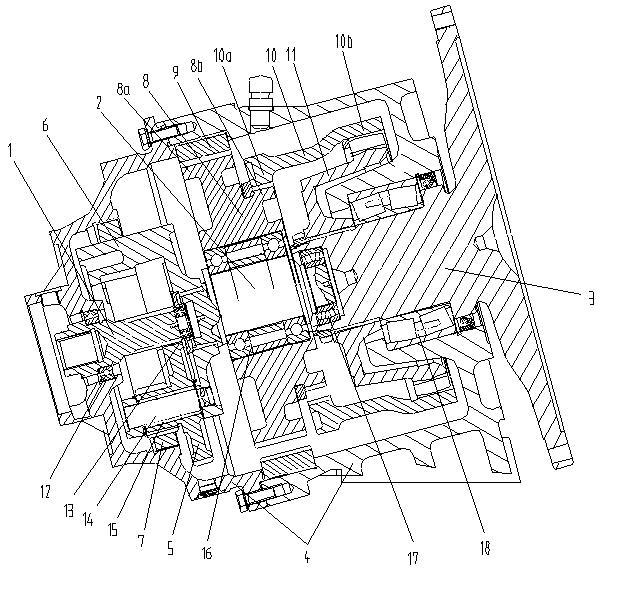

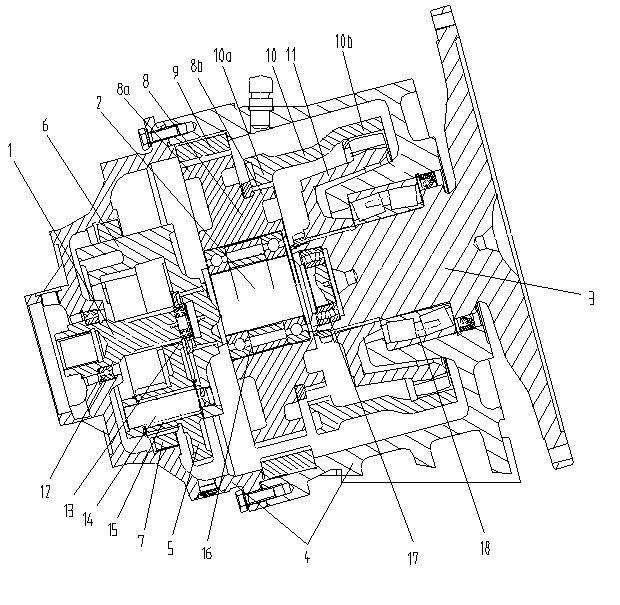

Speed reducer

InactiveCN102062176ACompact structureSmall transmission errorToothed gearingsReduction driveDifferential transmission

The invention discloses a speed reducer, which comprises a power input gear shaft, a first-level planet gear transmission component, an eccentric shaft of which the axis is deflected to the axis of the power input gear shaft in parallel, a second-level planet gear transmission component, a power output gear shaft and a speed reducer shell. The speed reducer employs the planet gear transmission mechanism, so the structure is compact; the floating planet gear transmission mechanism can adaptively compensate manufacturing and assembling errors and abnormal abrasion, and has small transmission error and high precision. In the transmission process, the differential transmission way of the rare-tooth planet gear of the speed reducer increases the number of meshed teeth in a transmission process, ensures strong bearing capability, stable transmission, low transmission noise and high transmission efficiency, and solves the nonlinear coupling problem of the speed reducer under an extreme working condition. In the transmission process, cambered drum teeth of the speed reducer can filter fluctuations caused by processing and installation errors and the bad working condition, so the abrasion is lowered, the transmission is more stable, the noise is lower, and the service life is longer.

Owner:CHONGQING AEROSPACE POLYTECHNIC COLLEGE

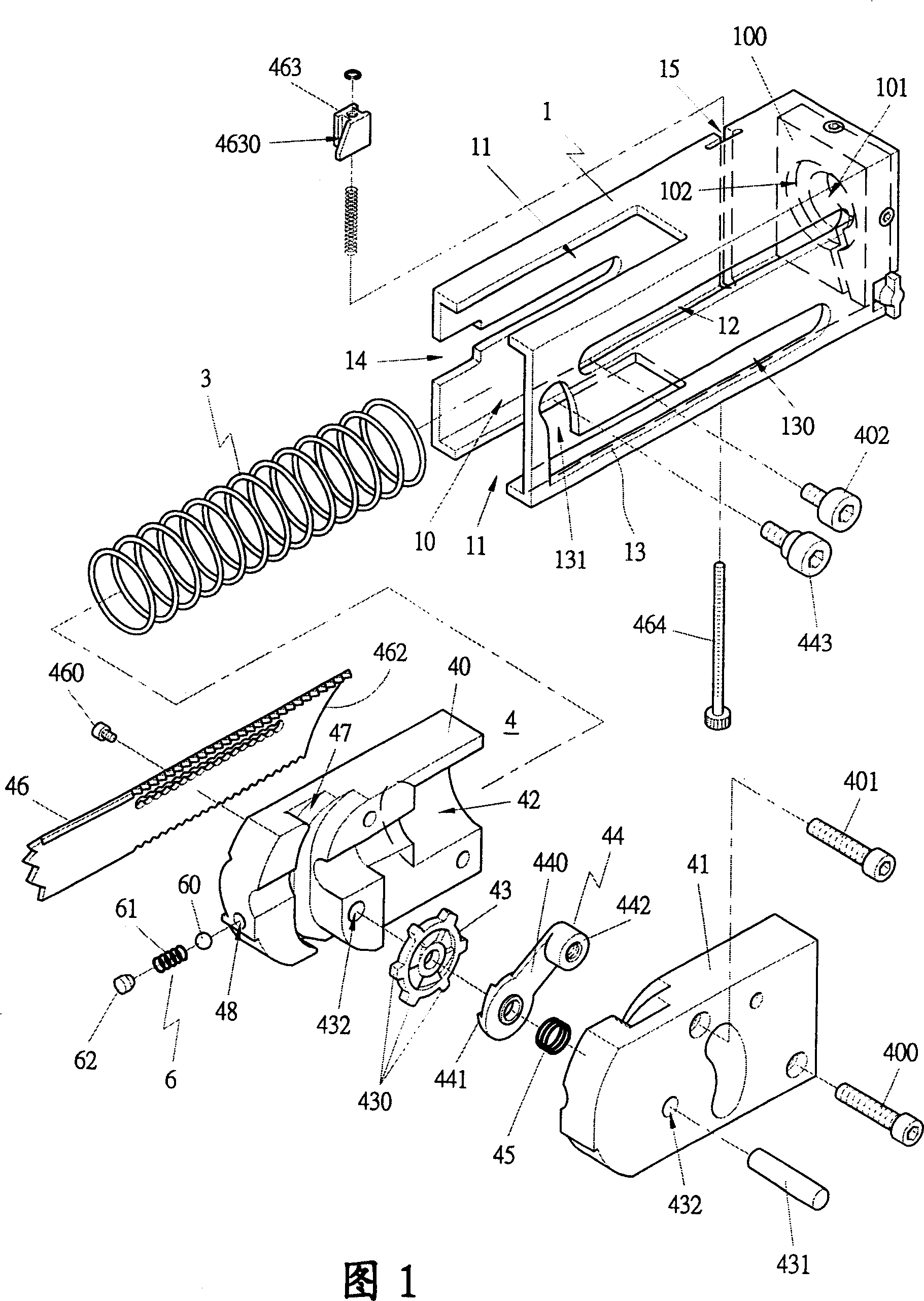

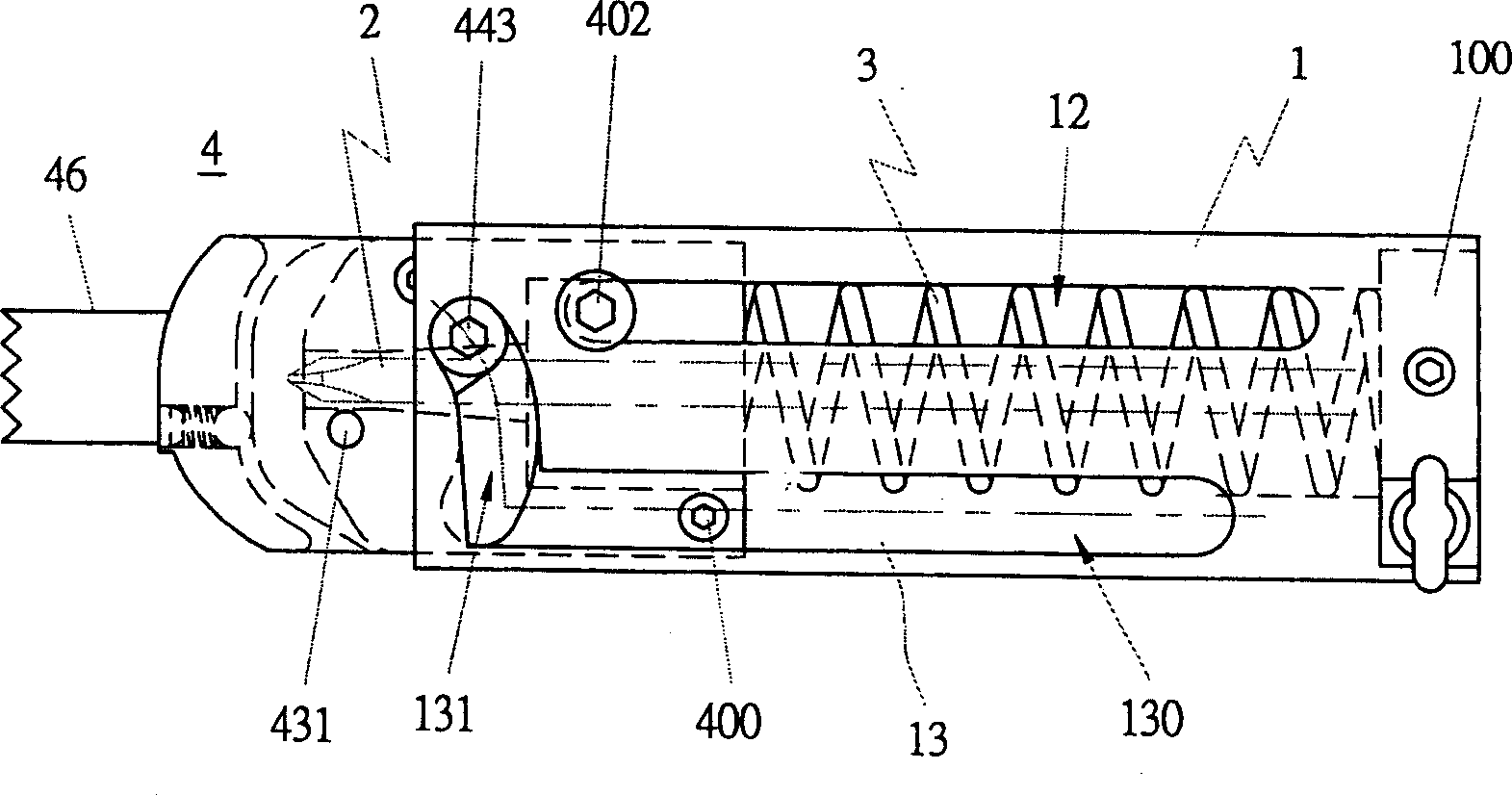

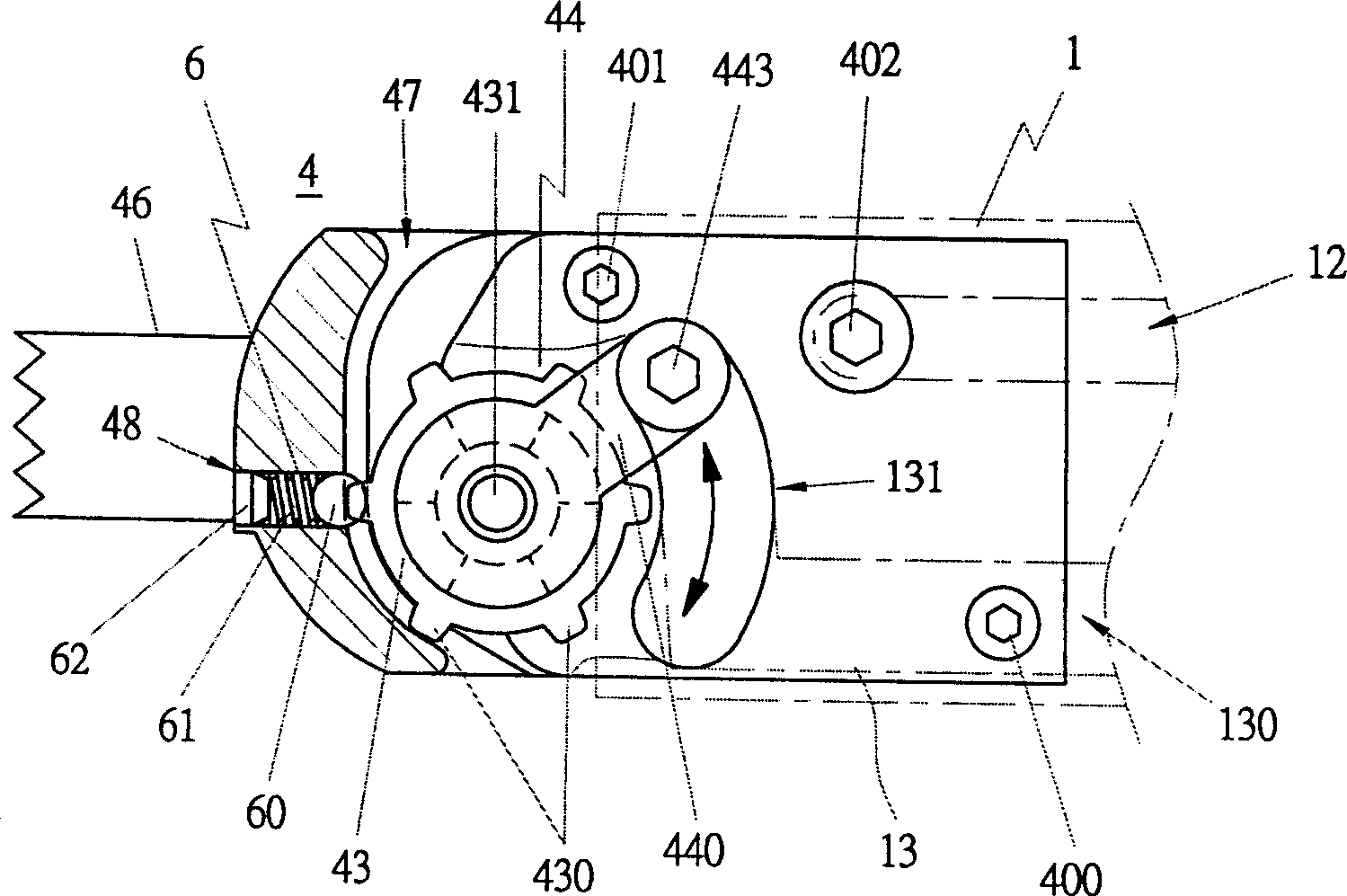

Micro-gap transmission

InactiveCN1924396ASmall backlashSmall transmission errorToothed gearingsPortable liftingEngineeringMicro gap

This invention relates to micro gap drive device, which comprises case and meshed gear and is characterized by spring parts with one end push other end along gear axis. This invention has the following advantages as a, micro gap between motor switch with high accuracy; b, simple process and matching for widely application.

Owner:吴琼海

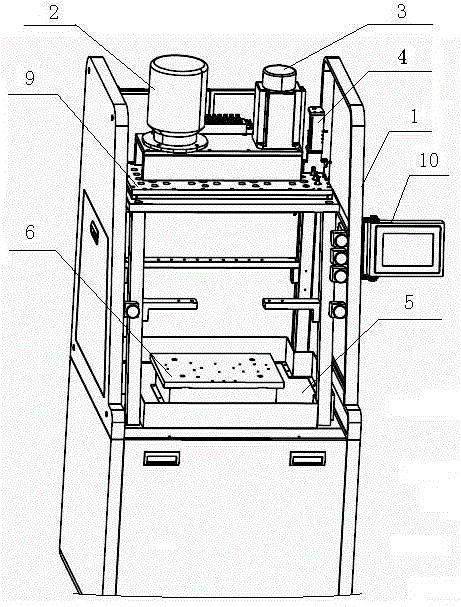

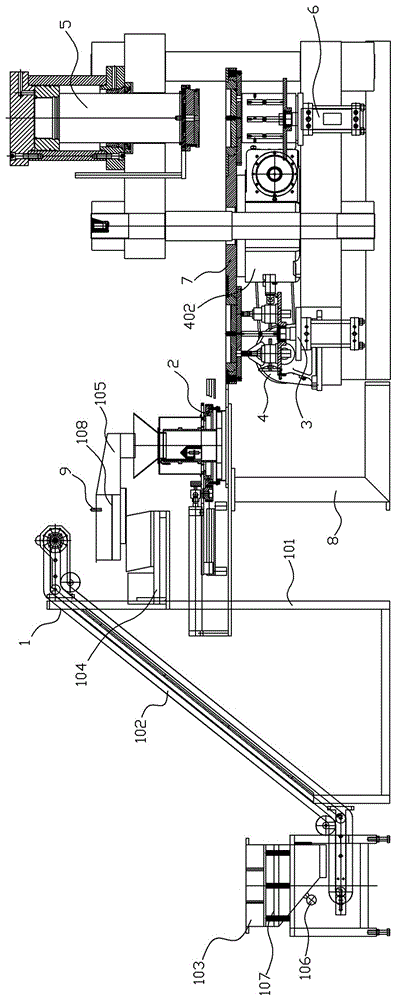

Multi-shaft automatic drilling and tapping machine

ActiveCN105397489ASmall footprintHighly integratedFeeding apparatusOther manufacturing equipments/toolsGear wheelElectric machinery

The invention discloses a multi-shaft automatic drilling and tapping machine. The multi-shaft automatic drilling and tapping machine comprises a machine body. A drilling motor, a tapping motor and a switching clutch are arranged at the upper part of the machine body. A worktable and a work-piece clamping device are arranged in the middle of the machine body. A main control unit and a lifting mechanism are arranged at the lower part of the machine body. A gearbox is arranged below an output shaft of the drilling motor and an output shaft of the tapping motor and is provided with a first driving gear connected to the output shaft of the drilling motor, a second driving gear connected to the output shaft of the tapping motor, work gears and transmission gears, output shafts of the work gears are connected to cutters, and the transmission gears are connected to the first driving gear and the work gears or the second driving gear and the work gears. The lifting mechanism is connected to the work-piece clamping device and the main control unit. According to the machine, the drilling process and the tapping process are integrated on one machine, so that the occupied area is small and the integration level is high; the gearbox is compact in layout, and each transmission gear is provided with multiple work gears, so that the transmission error is small; multi-shaft output is adopted, so that the machining efficiency is improved, and the cost is lowered.

Owner:深圳市耐恩科技有限公司

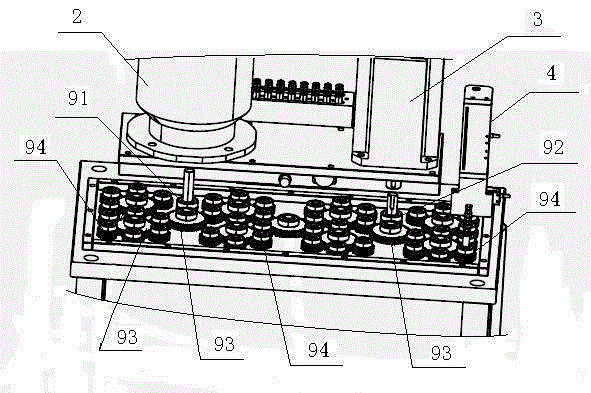

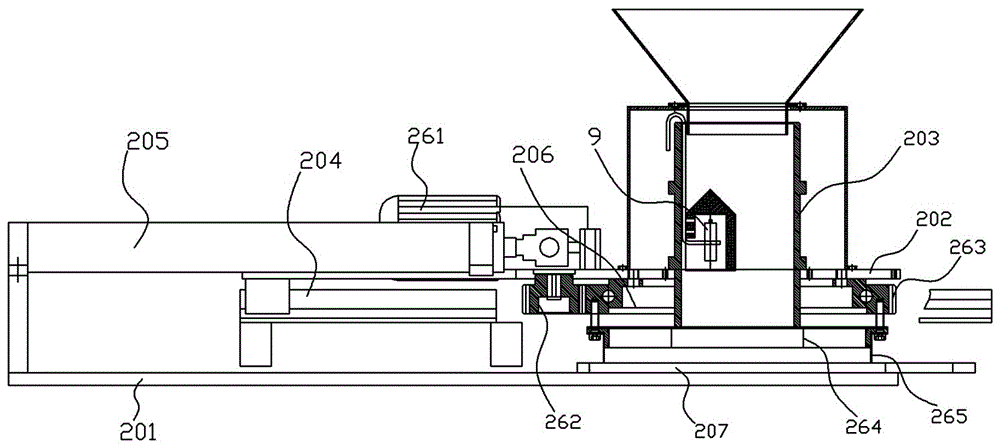

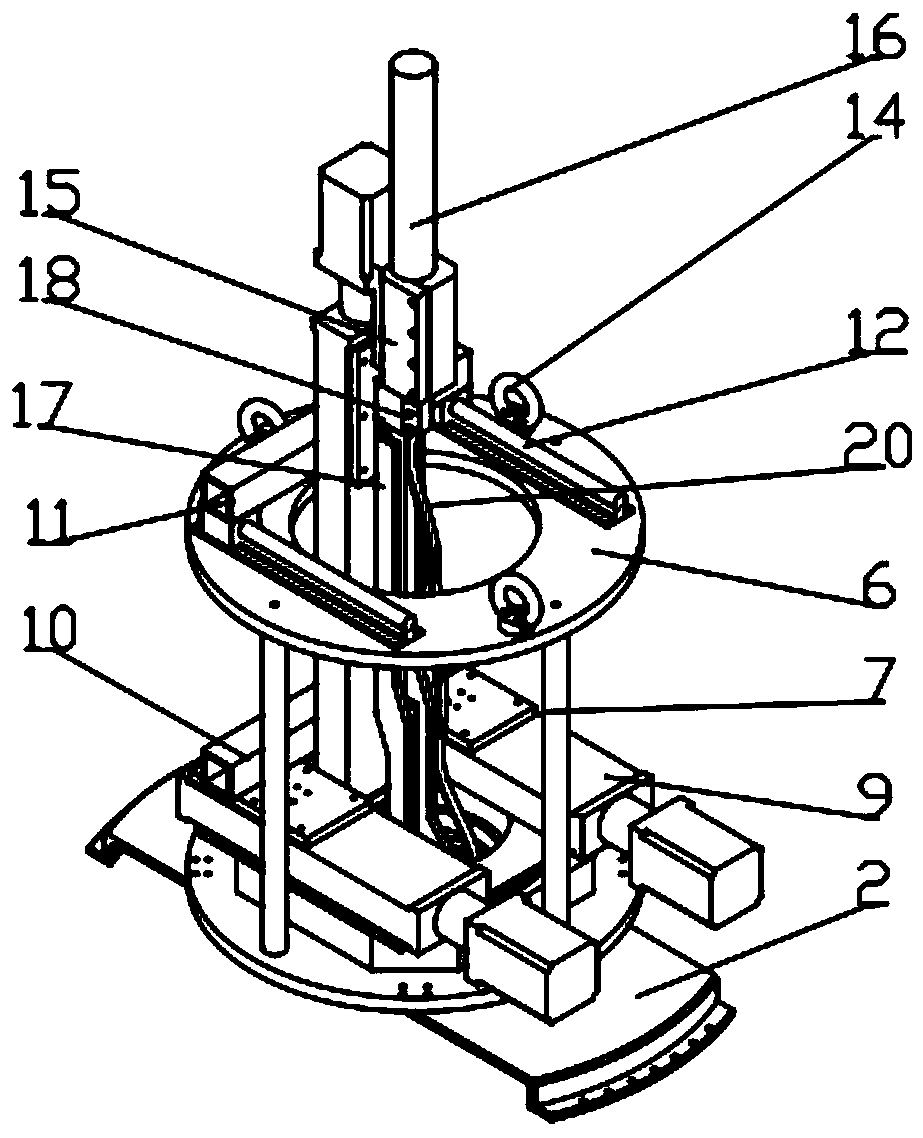

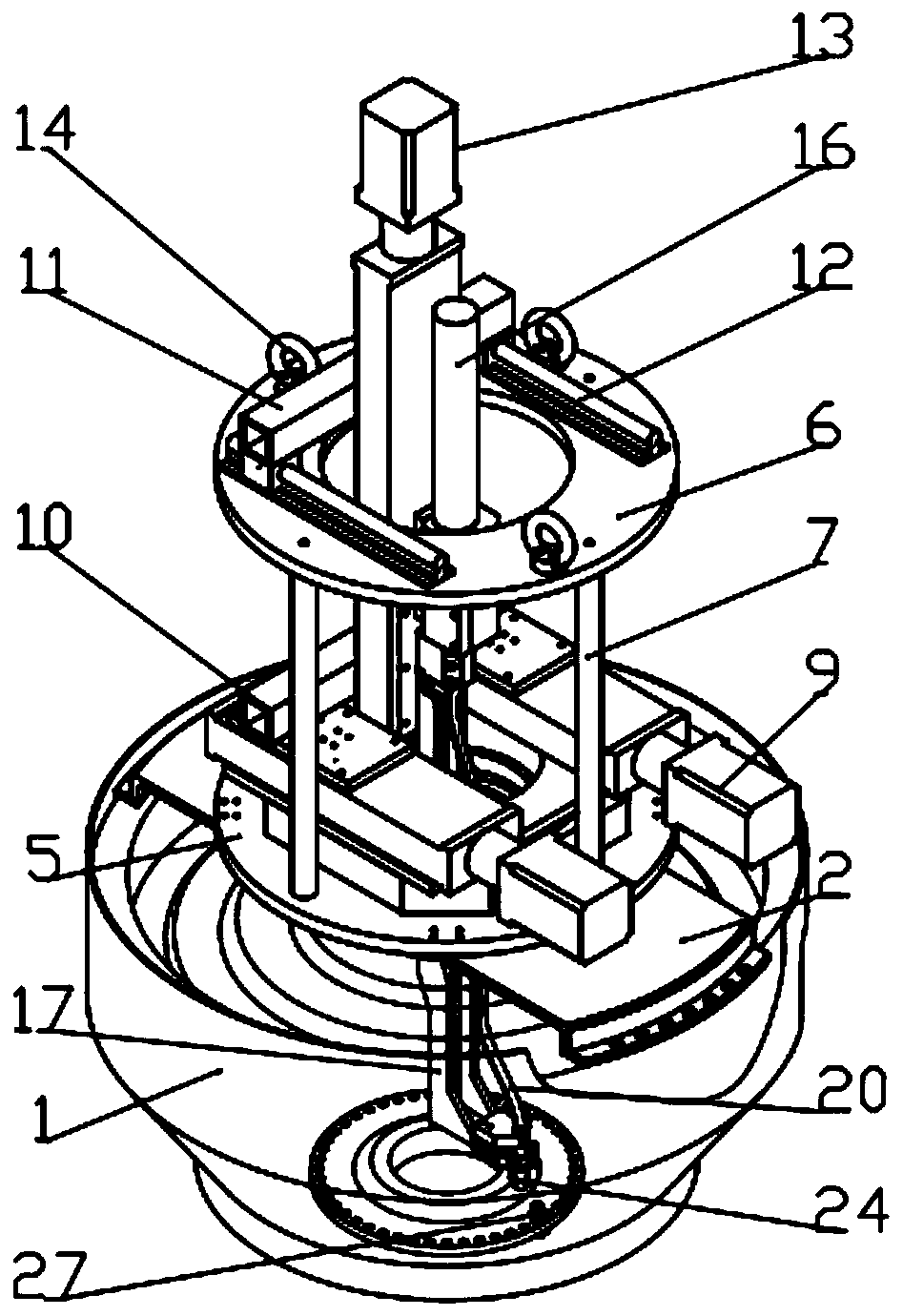

Full-automatic rotary multi-station grinding wheel forming machine

ActiveCN106041770AHigh purityQuality improvementGrinding devicesNumerical controlUltimate tensile strength

The invention relates to the technical field of grinding materials, grinding tools and grinding wheels, particularly to a full-automatic rotary multi-station grinding wheel forming machine which comprises lifting conveying mechanisms, pushing and scraping mechanisms, a constant-volume adjusting mechanism, a worktable transmission power mechanism, a compression forming mechanism, a demoulding ejection mechanism, a mould mounting frame and a numerical control unit, wherein a plurality of mould cavities are uniformly distributed on the mould mounting frame in a circumferential direction; each mould cavity correspond to one station, and the mould cavities correspond to a primary scraping station, a screen piece placing station, a secondary scraping station, a core ring placing station, a compression station and a demoulding station in sequence; and any one of the six stations is controlled to open or close according to needs. According to the full-automatic rotary multi-station grinding wheel forming machine, feeding, pushing and scraping, adjusting, compression and finished product ejection are all completed automatically, so that the equipment reliability and the degree of automation are greatly improved, and meanwhile the labor intensity of workers is lowered; and owing to automatic production the production efficiency, the product quality and the product conformity are all improved remarkably.

Owner:ZHENGZHOU HONGYI MACHINERY

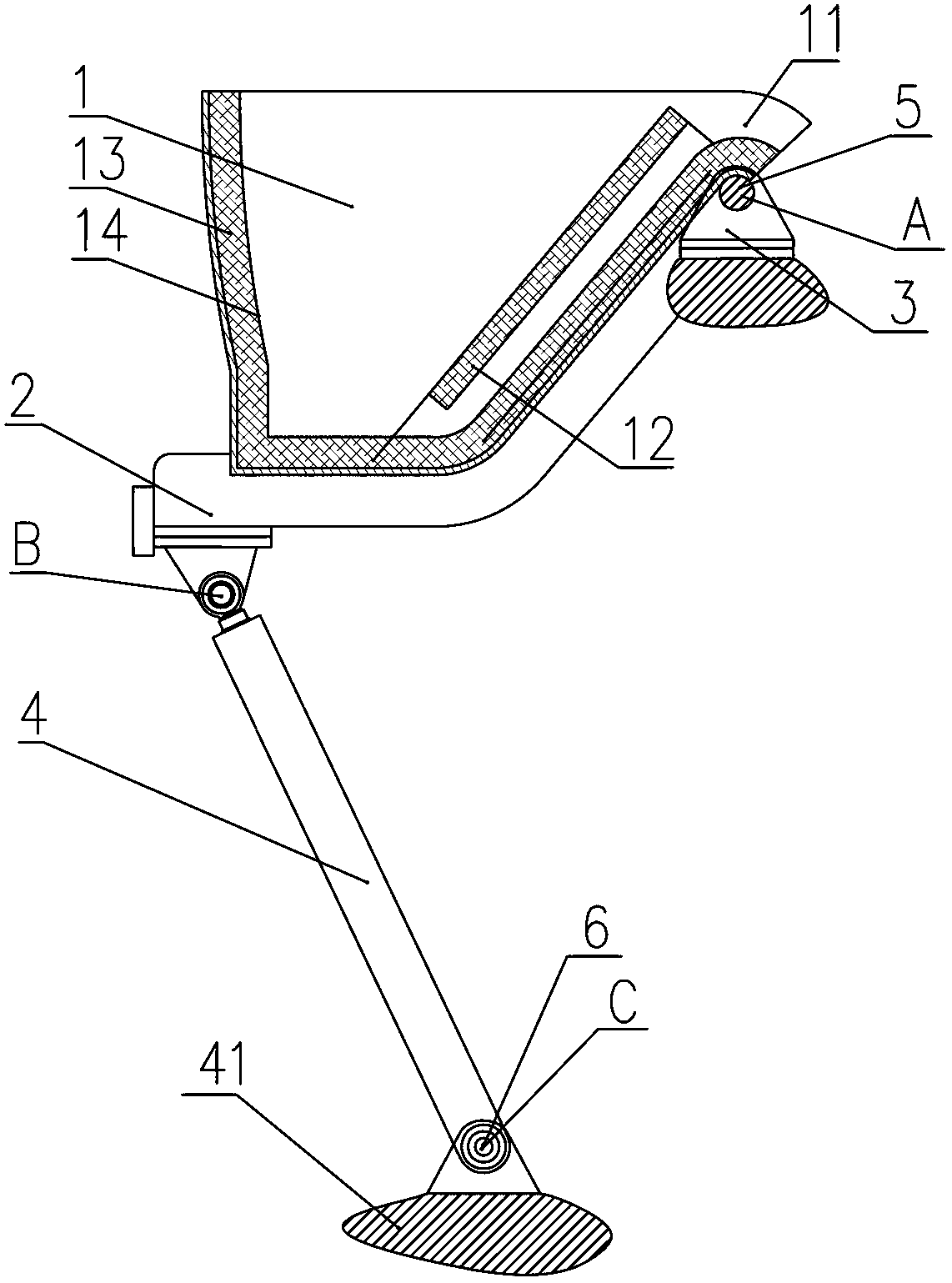

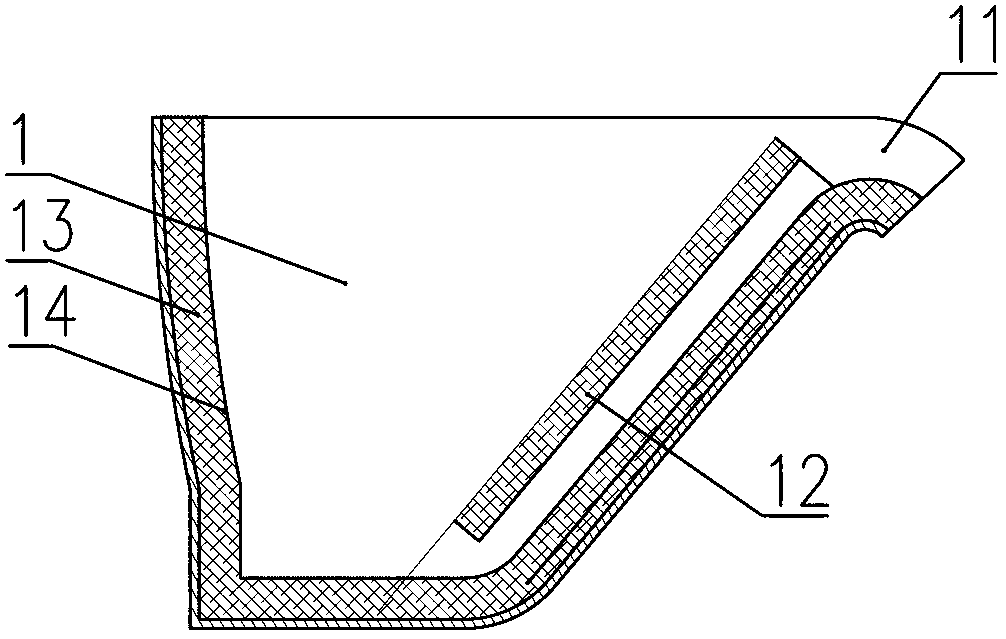

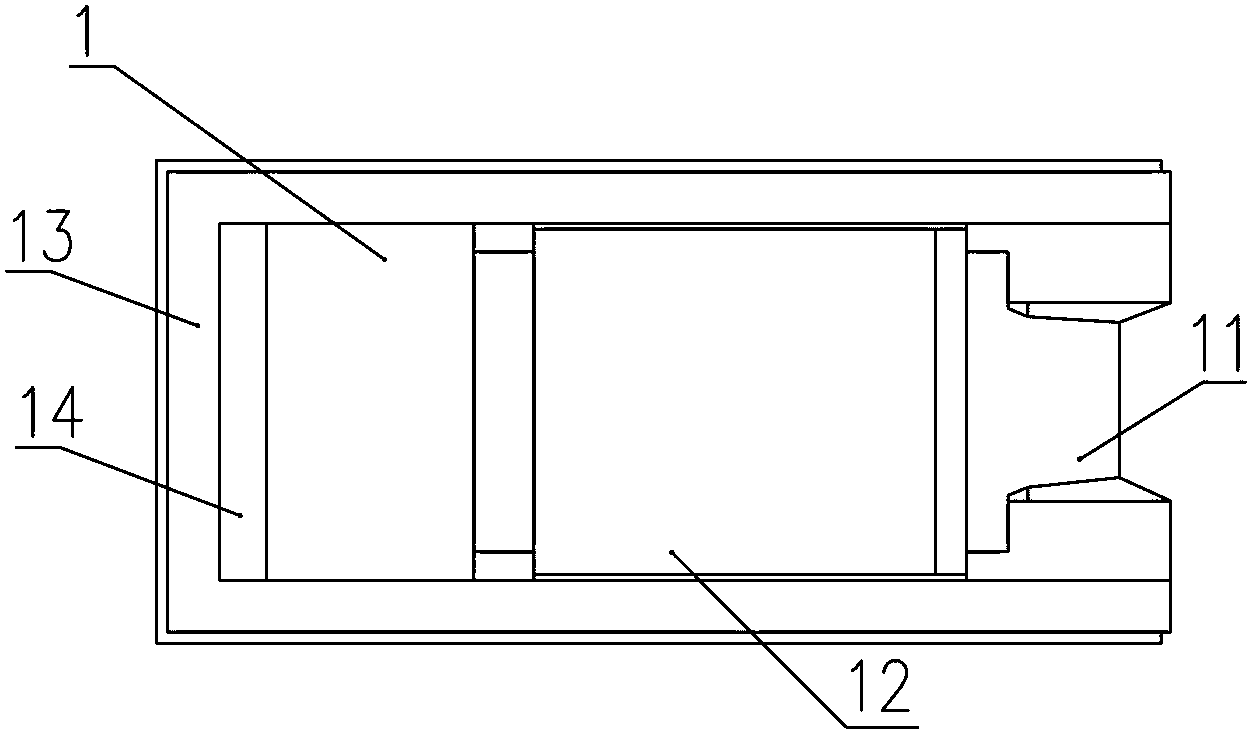

Pouring equipment and pouring ladle

ActiveCN102699303AQuality assuranceSimple structureMelt-holding vesselsHydraulic cylinderAngular velocity

The invention provides pouring equipment and a pouring ladle. The pouring equipment comprises the pouring ladle, a pouring ladle frame, a fixed supporting body, a hydraulic cylinder and a hydraulic cylinder base, wherein the pouring ladle is fixed on the pouring ladle frame; one end of the hydraulic cylinder is hinged on the pouring ladle frame; and the other end of the hydraulic cylinder is hinged on the hydraulic cylinder base, wherein one end of the pouring ladle frame is arranged on the fixed supporting body; the right end of the pouring ladle is provided with a pouring gate; the width of an upper opening of the pouring ladle is a fixed value; the internal side of the left side wall of the pouring ladle, which is far away from the pouring gate, is provided with a compensating curved plane; the hydraulic cylinder moves at a constant speed; and in the pouring process, the compensating curved plane can be used for compensating angular velocity variation of the pouring ladle, so that the pouring flow speed of the pouring ladle is constant. According to the pouring equipment provided by the invention, when the hydraulic cylinder moves at the constant speed, the final pouring flow speed of the pouring ladle, which is invariable at the fixed value, is ensured; the quality of a cast is effectively guaranteed; and meanwhile, as a driving device has a simple structure and less transmission parts, lower fault rate is achieved and the production efficiency is effectively increased.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Half-module window rotating mechanism applied to supersonic wind tunnel

ActiveCN102840962AHigh rotation accuracyImprove transmission efficiencyAerodynamic testingReducerAlternating current

Provided is a half-module window rotating mechanism applied to a supersonic wind tunnel. The half-module window rotating mechanism comprises a drive transmission module, a feedback and measurement module and a rotation module, wherein the drive transmission module is composed of a support, a large cylindrical straight gear, an alternating current servo motor, a reducer, a gear pressing cover, a small cylindrical straight gear, a pressing cover and pressing screws. The feedback and measurement module is composed of a potentionmeter support, a potentionmeter, a pressing sheet, a coupler, a small shaft and a connecting cover. The rotation module is composed of an O-shaped seal ring, a baffle ring, a right bearing cover, a connecting seat, a bearing seat, a conical roller bearing, a left bearing cover and a main shaft. Through adoption of a cylindrical straight gear set, the half-module window rotating mechanism can achieve rotating at + / -360 degrees. The mechanism can be installed integrally in hanging mode. Control accuracy of an attacking angle within a + / -3 deviation range can be achieved due to the fact that the cylindrical straight gear set is matched with a measurement portion with the potentionmeter as the center in drive mode.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Flexible-shaft transmission-type tightening device and method for internal nuts of aero-engine

InactiveCN110561098AGuaranteed accuracySmall space impactMetal working apparatusOperation modePositioning system

The invention discloses a flexible-shaft transmission-type tightening device and method for internal nuts of an aero-engine, and belongs to the technical field of automated assembly. The flexible-shaft transmission-type tightening device for the internal nuts of the aero-engine comprises a tooling pre-positioning system, a nut aligning and positioning system and a flexible-shaft transmission-typetightening execution system. Through the nut aligning and positioning system, a tightening sleeve is mounted on a to-be-tightened nut in a sleeving manner and driven by a tightening motor to completethe tightening work; by the adoption of the automated operation mode, the flexible-shaft transmission-type tightening device disclosed by the invention has the characteristics of being high in degreeof automation, high in motion precision and high in tightening precision; the manual operation task is relieved; the operation process is greatly simplified; errors introduced by the manual operationare avoided; the tightening consistency of the internal nuts is guaranteed; and the whole machine assembly work efficiency is improved.

Owner:DALIAN UNIV OF TECH

Vertical loop-transferring jacquard control mechanism of round knitting machine

ActiveCN106637649AGuaranteed uptimeSmall transmission errorWeft knittingTextile/flexible product manufactureBiomedical engineeringNozzle

The invention discloses a vertical loop-transferring jacquard control mechanism of a round knitting machine. The vertical transferring jacquard control mechanism comprises an upper needle dial, a reset triangular component, an upper loop-transferring working triangular component, an upper jacquard sheet, knitting needles, a weft nozzle, a lower loop-transferring working triangular component, a middle needle, a lower jacquard sheet, a needle selector, a lower needle dial, needle protecting plates and two groups of needle opening tongue pieces; the knitting needles include an upper knitting needle and a lower knitting needle; the needle protecting plates are arranged on the outer edge of the upper needle dial and the lower needle dial so as to ensure stable sliding of the knitting needle; two groups of needle opening tongue pieces are located at the needle lifting place of the weft nozzle, and a group of needle opening tongue pieces are used for opening the needle tongue of the upper knitting needle to perform the next turn of weaving; the other group of needle opening tongue pieces are used for opening the needle tongue of the lower knitting needle to perform the next turn of weaving. The knitting needle is stable and smooth in running, small in transfer bias, long in service life, suitable for many patterns, accurate in needle selection, high in output, and good in textile quality.

Owner:福建佰源智能装备股份有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com