Elevator traction machine

An elevator traction machine and traction sheave technology, applied in the field of elevator traction machines, can solve the problems of deterioration of casting quality, increased material waste, large wall thickness, etc., to reduce processing steps and difficulty, improve casting quality, and ensure operation. safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

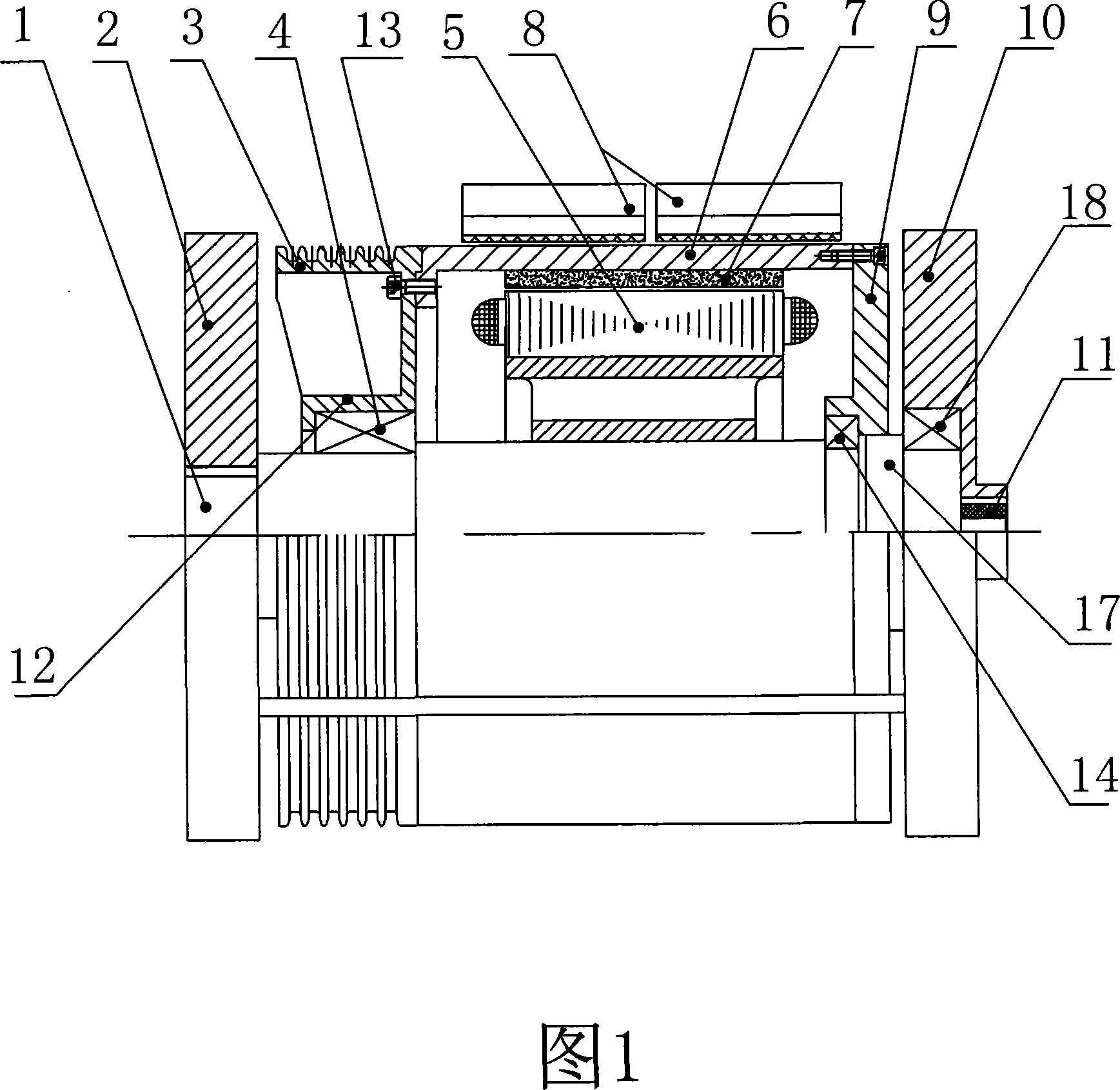

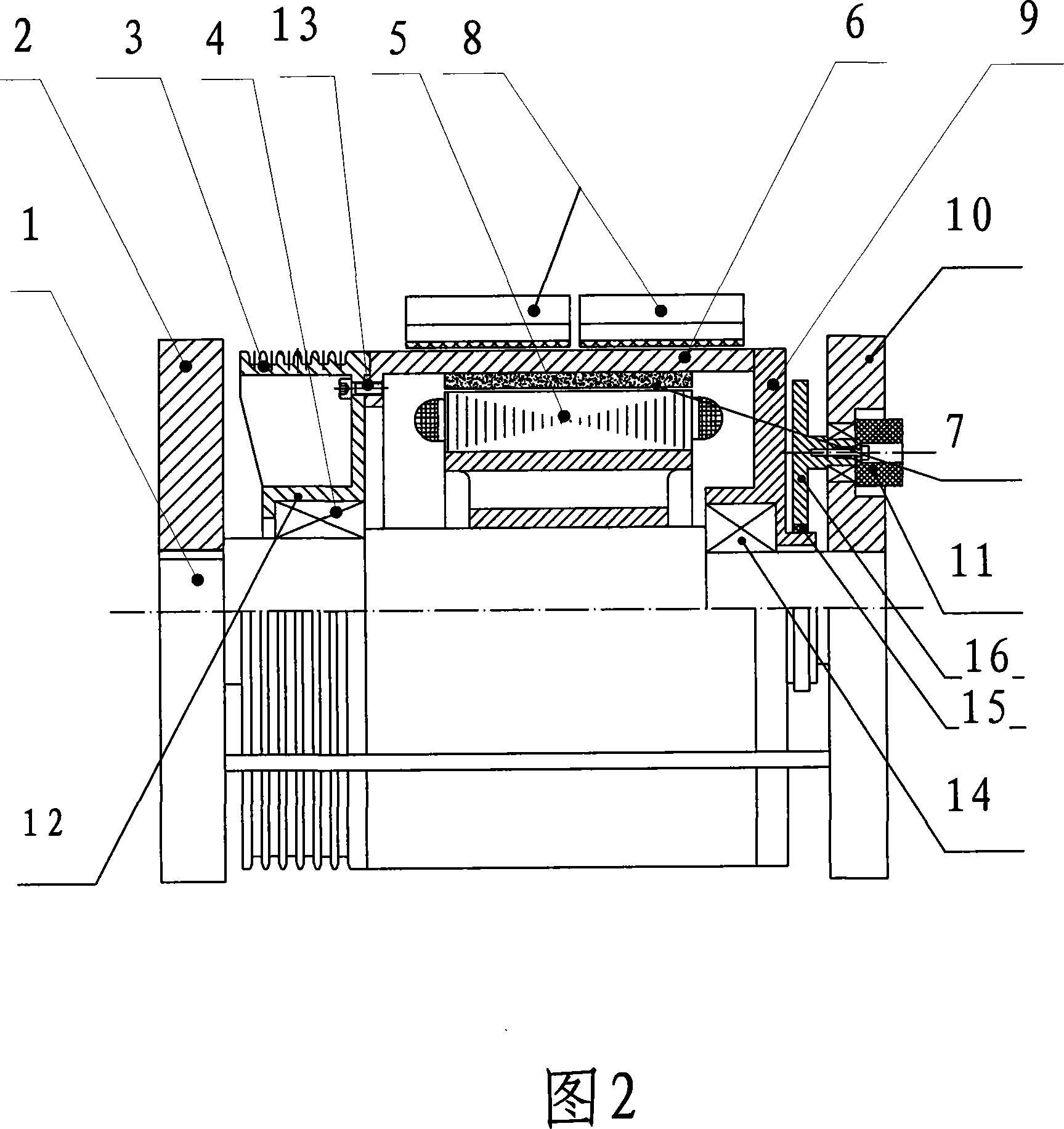

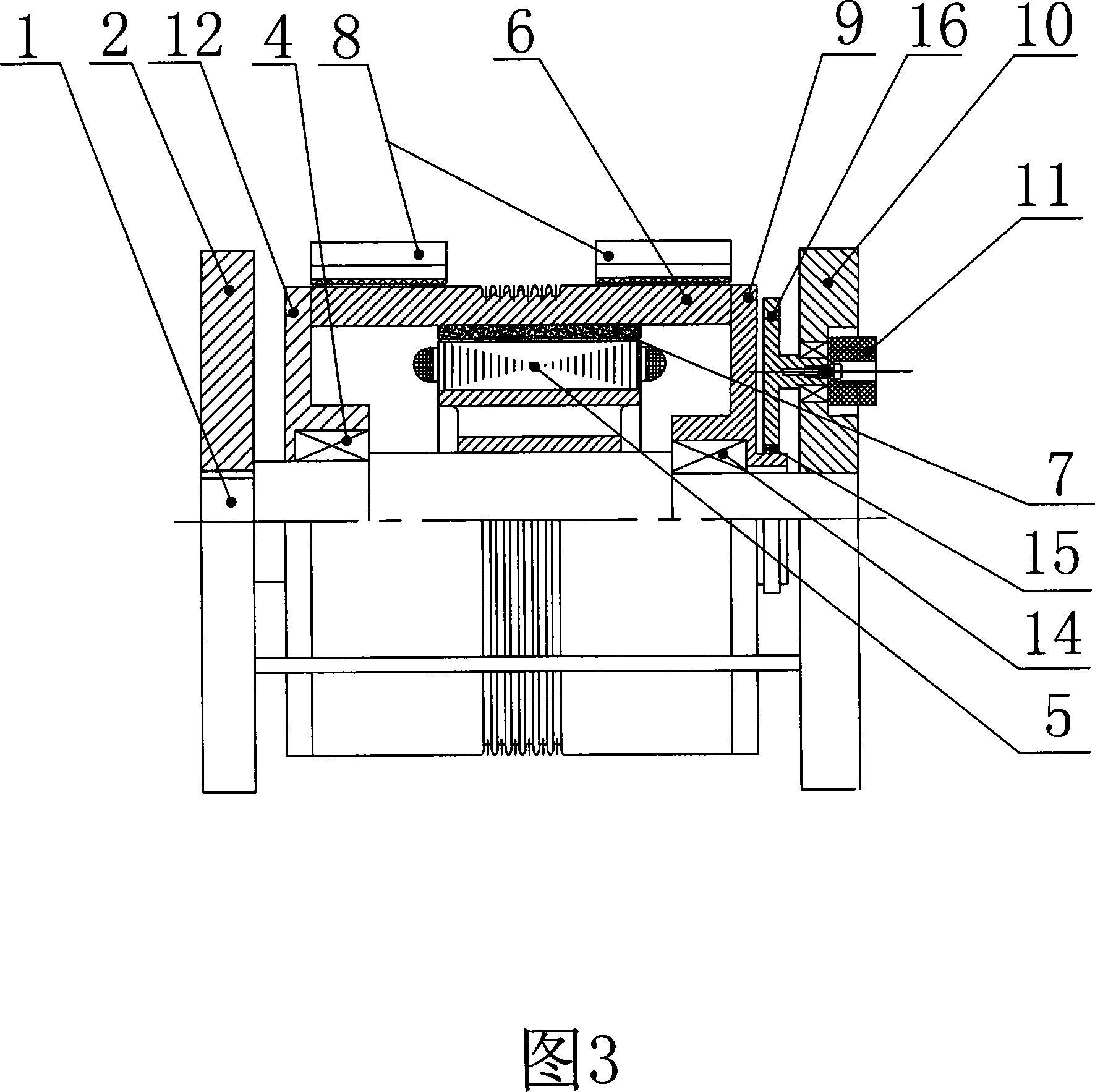

[0026]Figure 2 shows an embodiment of the elevator traction machine of the present invention, including a detachable load-bearing wallboard frame composed of a front support 2 and a rear support 10, a support shaft 1, a stator 5 fixed on the support shaft 1, The outer rotor cylinder 6, which rotates outside the stator 5 and doubles as a brake wheel, and the encoder 11 for measuring the speed and the relative position of the stator and rotor magnetic fields. The inner surface of the outer rotor cylinder 6 is mounted with a permanent magnet 7, and the two ends of the outer rotor cylinder 6 are respectively fixed with a front end cover 12 and a rear end cover 9, and the front end cover 12 and the rear end cover 9 are supported by bearings. On the support shaft 1, the front end of the support shaft 1 is fixed on the front support 2, and the rear en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com