A switchgear valve mechanism

A technology of switch cabinets and valves, which is applied in the direction of switchgear components, etc., can solve the problems of contact arm and base of the handcart and the valve plate, contact between the base of the handcart and the valve plate, and small effective stroke of the valve drive, etc., to achieve Good self-resetting, preventing left and right sliding, small transmission gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

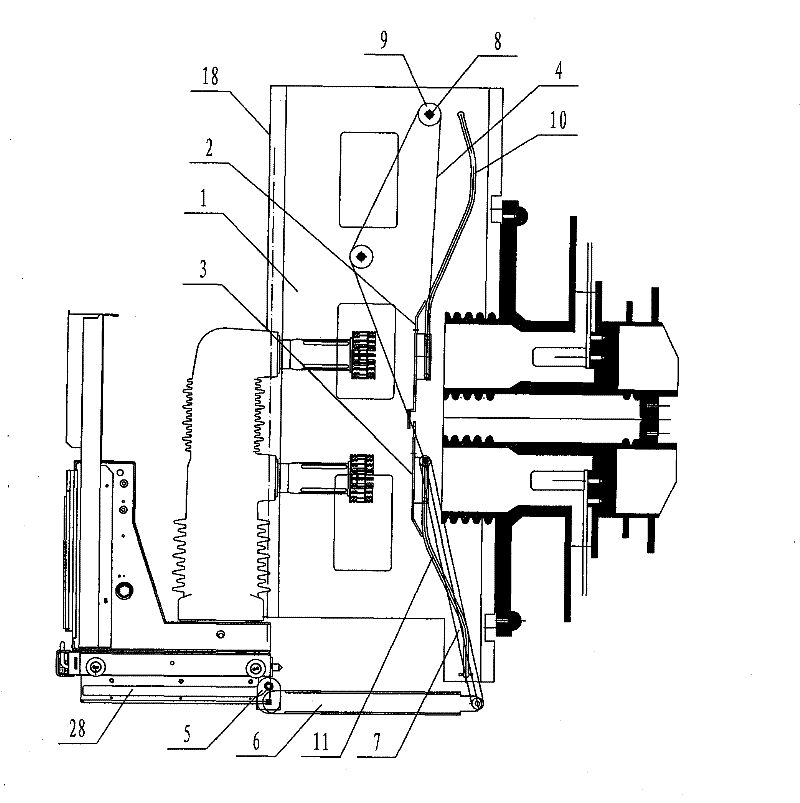

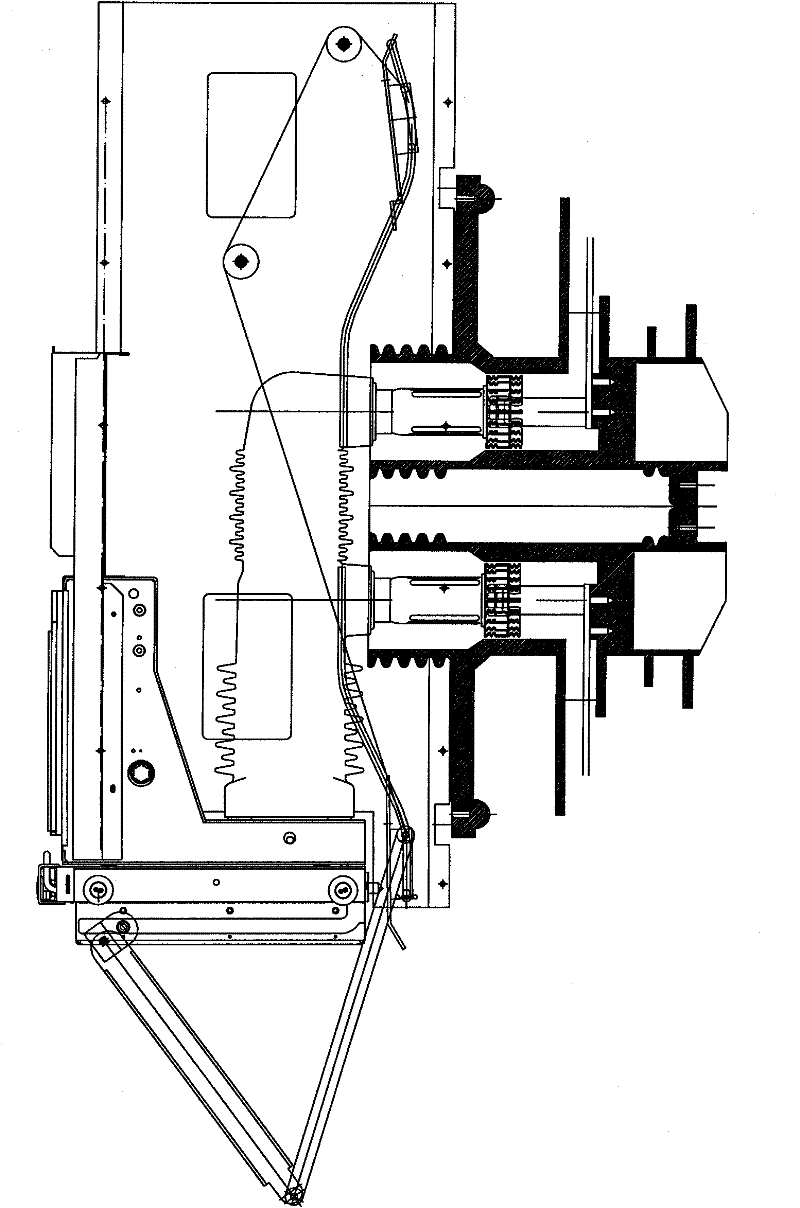

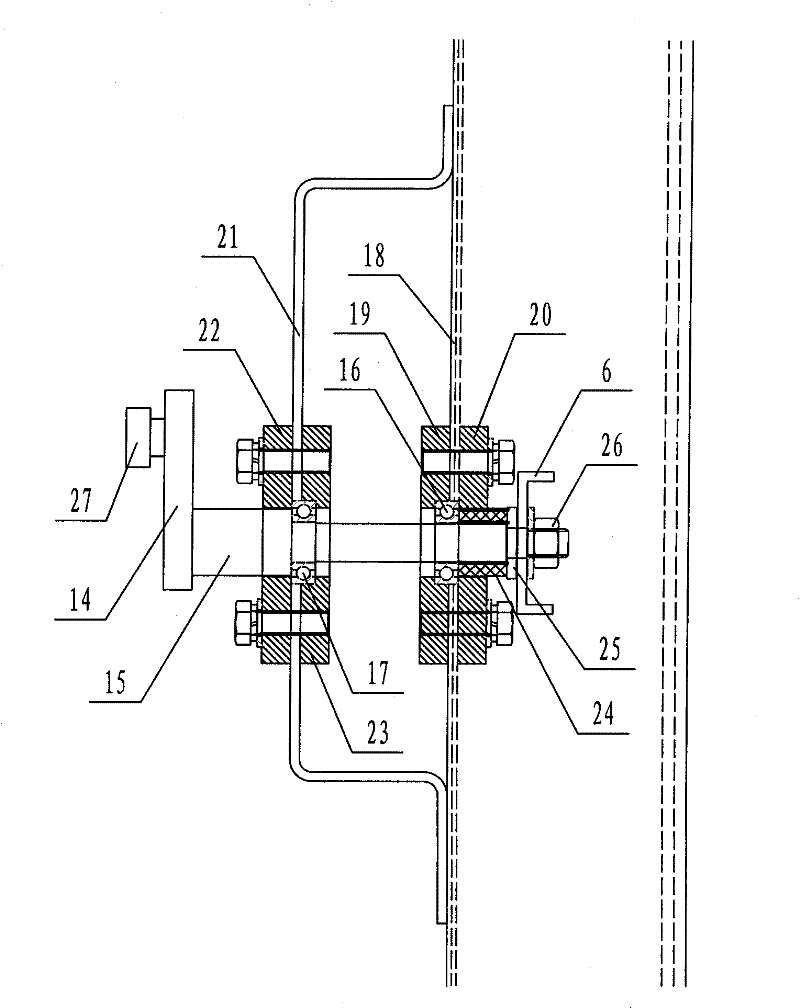

[0015] Such as figure 1 , 2 As shown in and 4, the left end of the valve connecting rod 6 is fixedly connected to the transmission mechanism 5, and its right end is hinged to the lower end of the small connecting rod 7, and the upper end of the small connecting rod 7 is hinged on the top of the lower valve plate 3, and the valve chute plate 1 is fixed on the cabinet body On the side wall 18, the top of the valve chute plate 1 is provided with a fixed shaft 8, the pulley 9 is set on the fixed shaft 8, the upper and lower parts of the valve chute plate 1 are respectively provided with an upper chute 10 and a lower chute 11, and the upper chute The groove width of each part of 10 is the same, the shape of the groove of the lower part is a vertical straight line, and the shape of the groove of the rest part is an arc-shaped curve extending upward, the shape of the lower groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com