Micro-gap transmission

A technology of transmission and micro-gap, which is applied in the direction of transmission, transmission parts, gear transmission, etc., can solve the problems of high processing precision of gears and shafts, transmission angle error, etc., and achieve small transmission error, simple structure, and easy manufacturing and the effect of simple assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

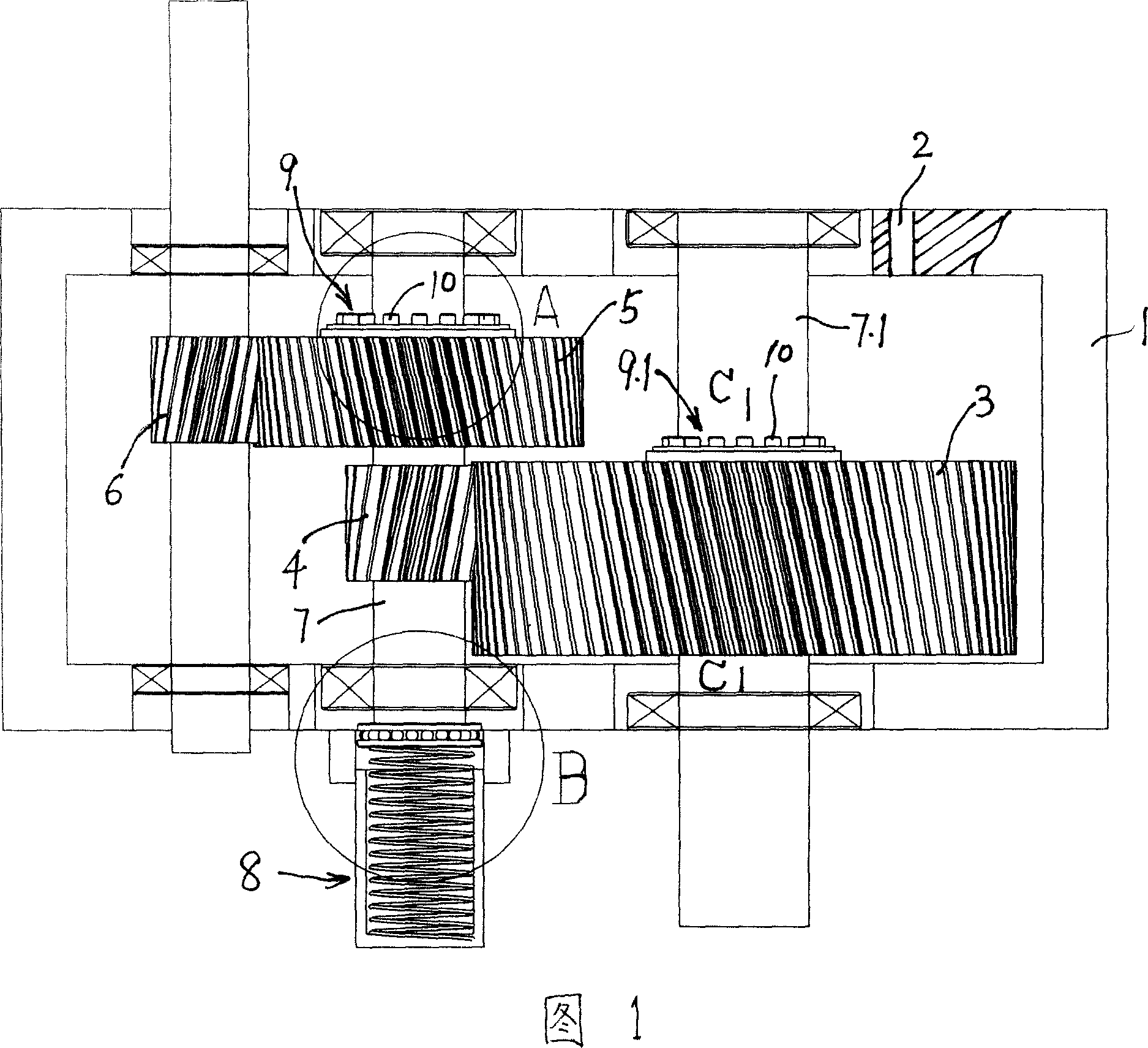

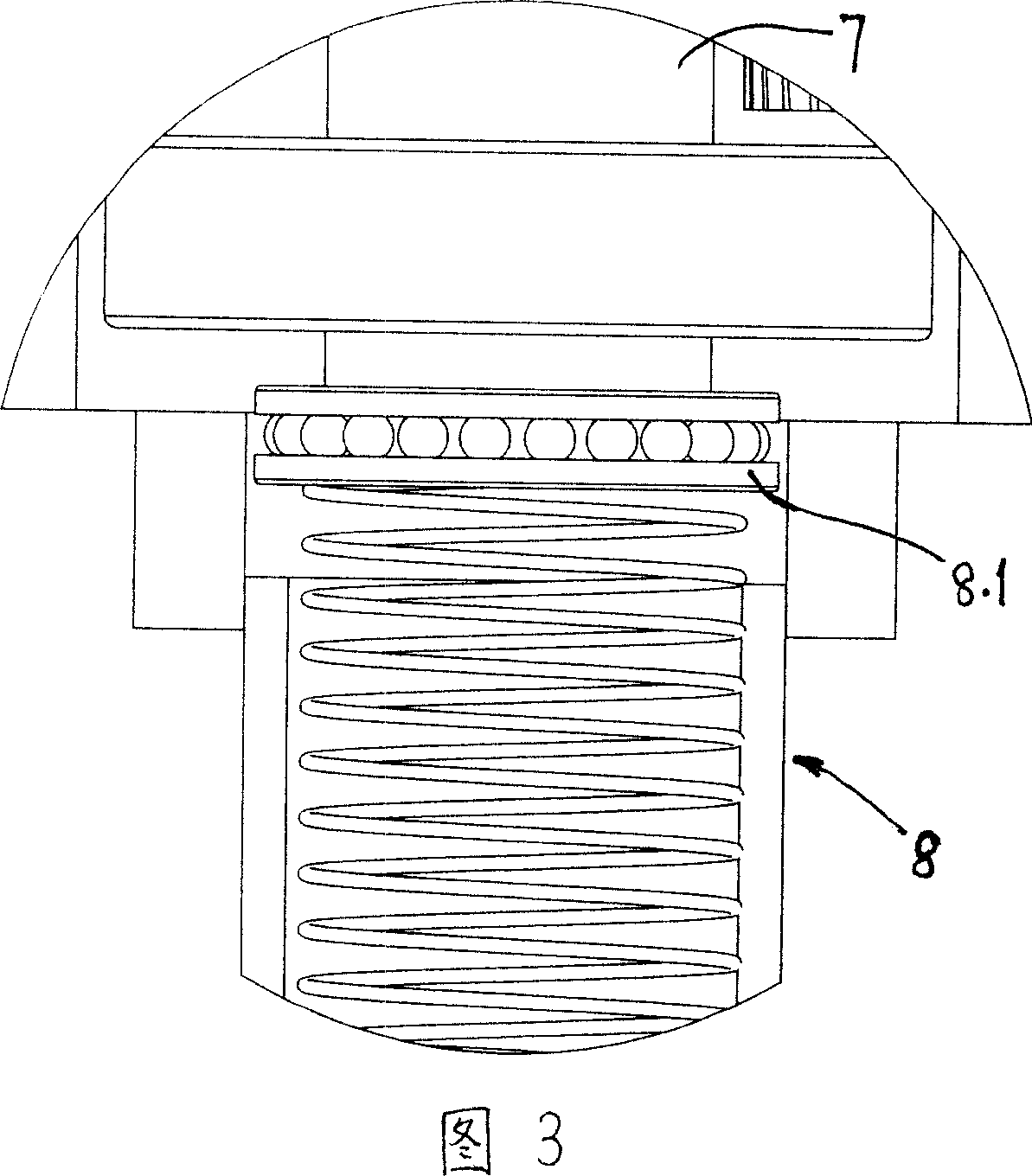

[0015] Referring to FIG. 1 to FIG. 4 , the present invention will be further described in detail below in conjunction with embodiments. The micro-gap transmission device of the present invention includes: a box body 1 and gears 3, 4, 5, 6 that mesh with each other, and its unique feature is that the elastic member 8 pushes the gear shaft 7 from one axial end to the other end shaft shoulder or shaft end.

[0016] There is preferably a bearing 8.1 between the elastic member 8 and the shaft shoulder or shaft end.

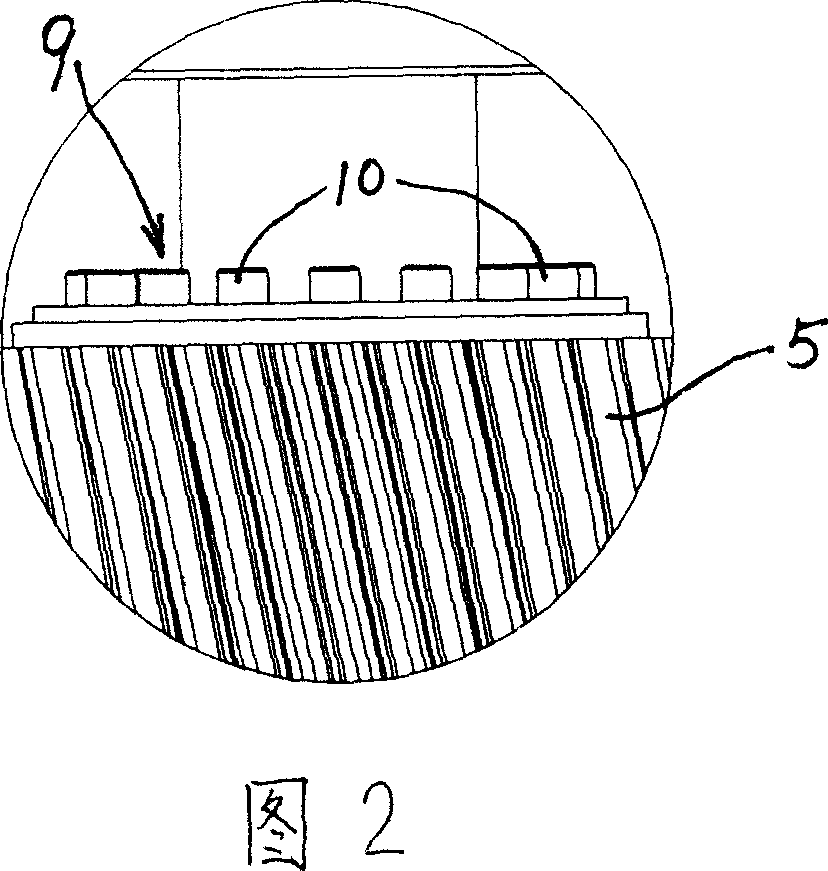

[0017] A further technical solution may be: the gear shafts 7, 7.1 are connected to the gears 5, 3 through tension couplings 9, 9.1. Specifically, between the gears 5, 3 and the gear shafts 7, 7.1, the bolts 10 tighten the conical tension rings 11 located on both sides, and the gears are squeezed under the extrusion of their mutually matching conical surfaces. 5 and 3 are fastened together with the gear shafts 7 and 7.1 respectively.

[0018] When assembling, in ord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com