Slide block mechanism for reducing transmission backlash of rack and pinion

A technology of rack and pinion and carriage, which is applied to transmission parts, belts/chains/gears, mechanical equipment, etc., and can solve the problems of increasing processing costs and installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

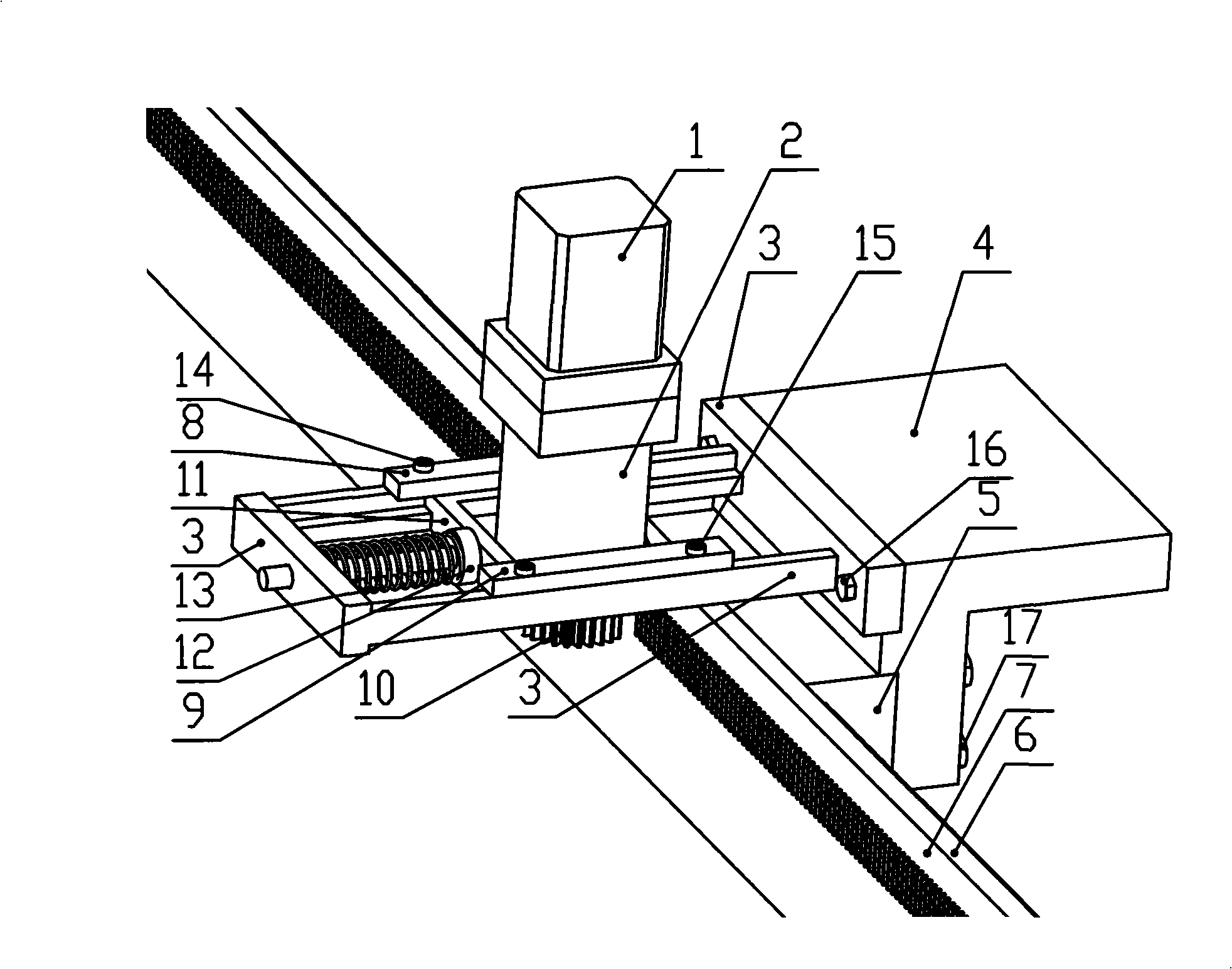

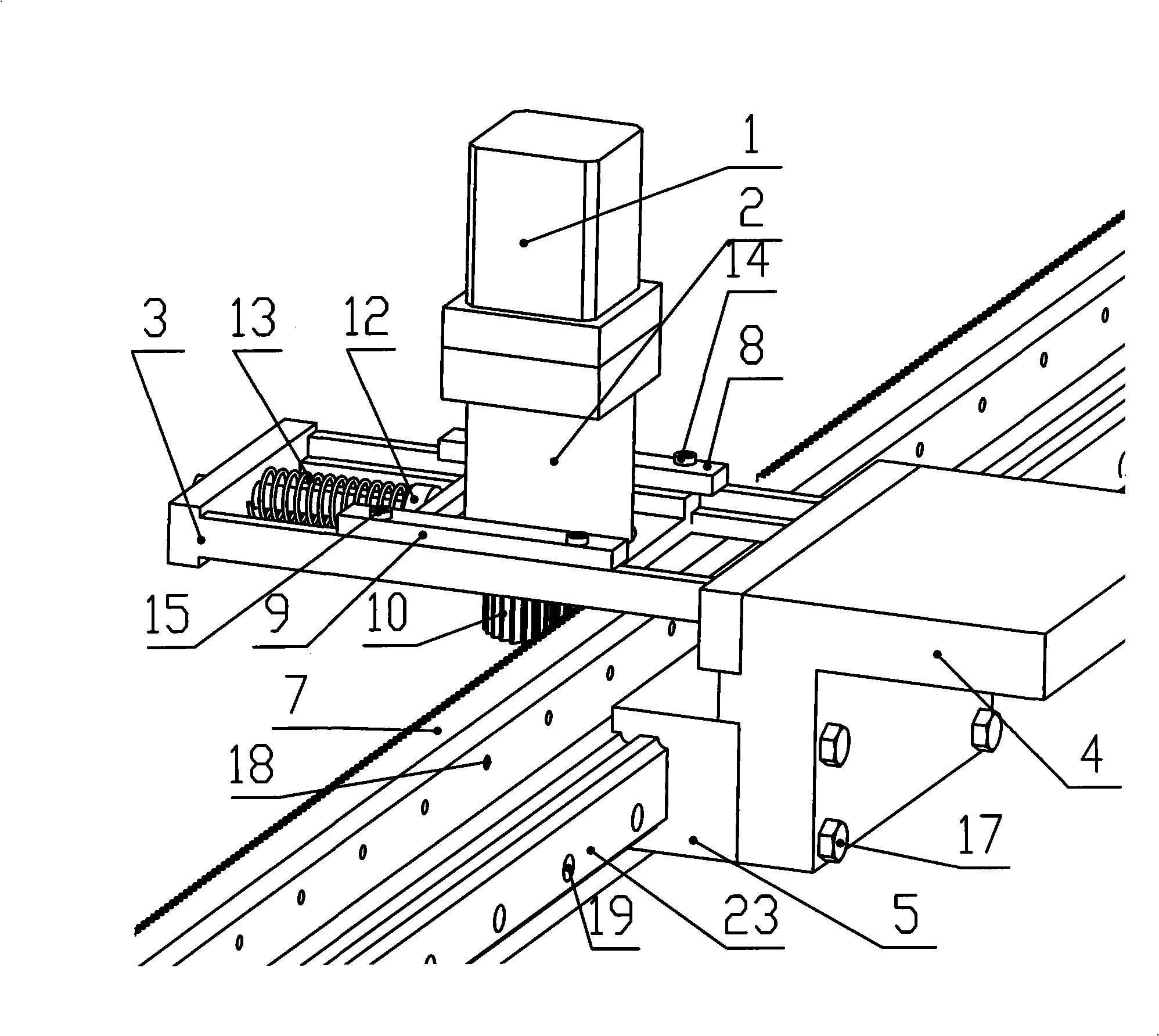

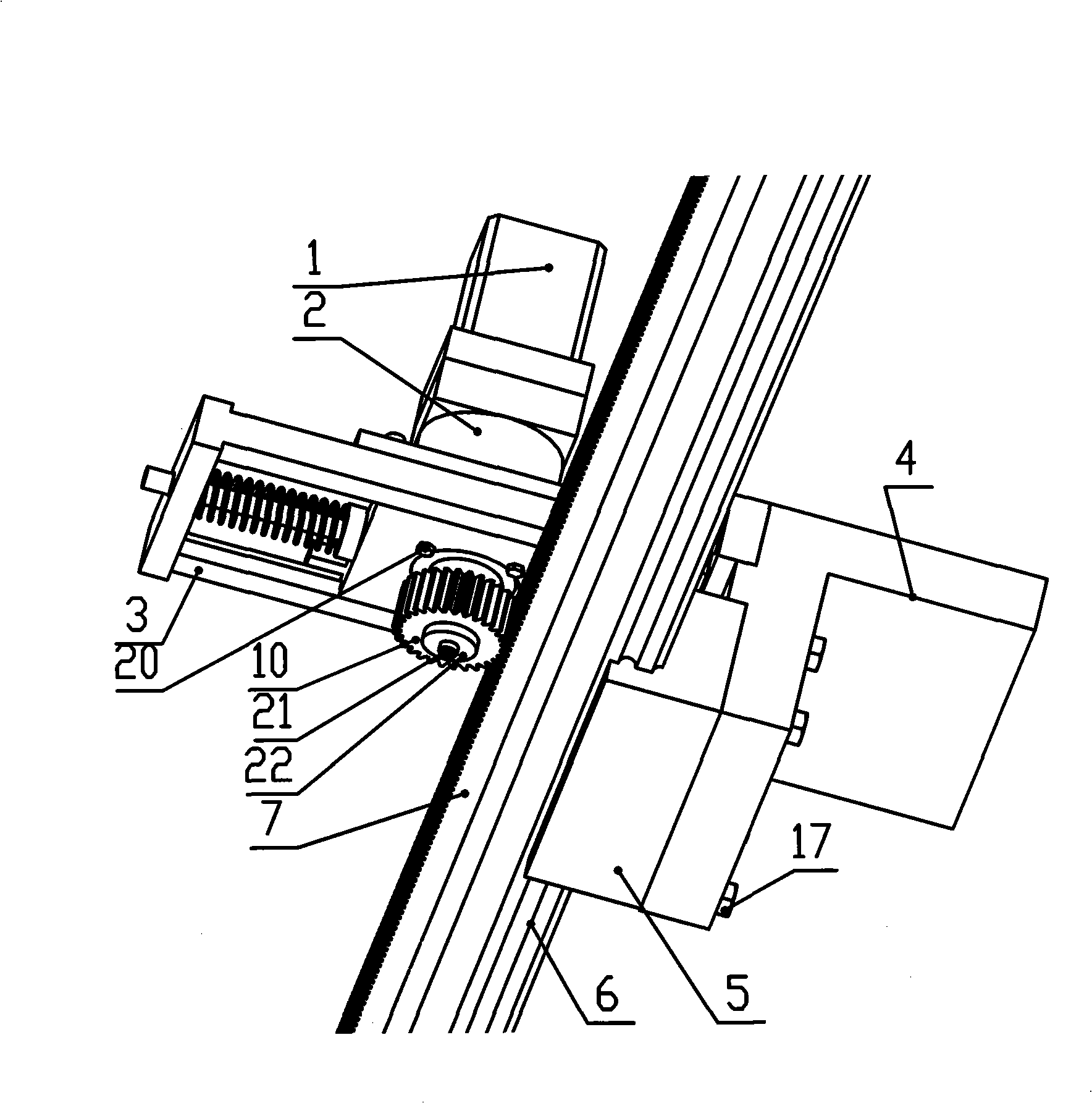

[0011] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0012] combine Figure 1-Figure 3 , the main components of the present invention include: motor 1, reducer 2, bracket 3, moving body 4, slider 5, rack mounting body 6, rack 7, pressing plate 8, pressing plate 9, gear 10, carriage 11, guide Rod 12, compression spring 13, screw group 14, screw group 15, screw group 16, screw group 17, screw group 18, screw group 19, screw group 20, screw 21, pressure piece 22 and slide rail 23.

[0013] Install the pressure piece 22 on the output shaft of the reducer 2 through the screw 21, fix the gear 10 on the output shaft of the reducer 2 through the key and the pressure piece 22, install the gear 10 on the output shaft of the reducer 2, and make the gear 10 opposite The speed reducer has only one degree of freedom of rotation around its axis of rotation; the speed reducer 2 is fixed on the carriage 11 through the screw group 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com