Mesoporous water-through jacking electric spindle

A technology of electric spindle and water passage, which is applied in the direction of metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., which can solve the problems of processing accuracy, efficiency, performance limitation, restricting the superiority of special machine tools, and reducing the use effect of the spindle , to achieve the effect of compact structure, improved processing accuracy and production efficiency, and light volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

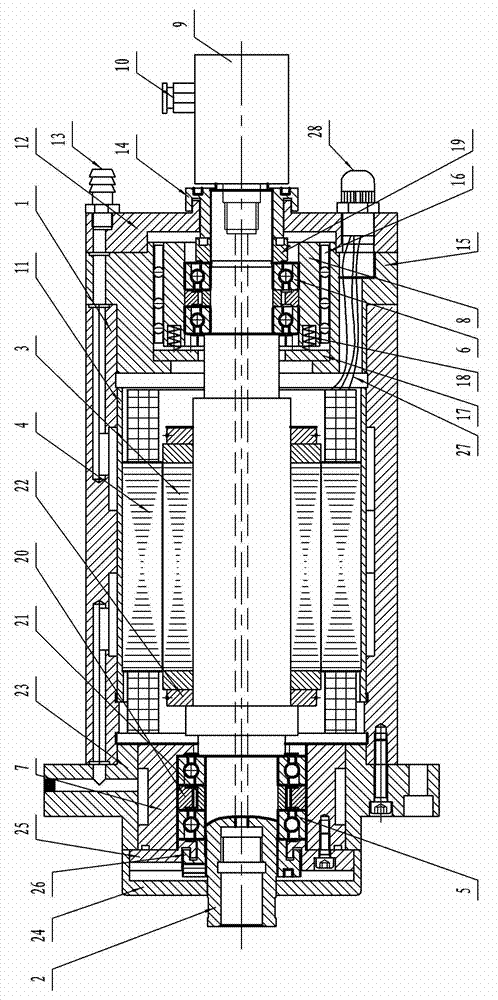

[0024] see figure 1 , in the figure, the electric spindle with middle hole and water passage of the present invention includes a casing 1, and a motor and a rotor shaft 2 are installed in the casing, and the motor includes a stator part 3 and a rotor part 4 that are set together from outside to inside. , the rotor parts are set on the rotor shaft, the front and rear ends of the rotor shaft are respectively fixed on the housing through bearings 5, 6 and bearing seats 7, 8, the rear end of the rotor shaft is equipped with a rotary joint 9, the rotary joint A water inlet joint 10 is installed on it, and the water inlet joint communicates with the water cooling passage in the rotor shaft.

[0025] An inner water jacket 11 is arranged in the cavity between the housing and the stator part, a rear cover 12 is provided at the rear end of the housing, and a water inlet and outlet nozzle 13 is arranged on the outer end surface of the rear cover. The inner water jackets are connected. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com