Electronic-control backlash eliminating gear pair with variable tooth thickness

A variable-tooth-thickness gear and electronically controlled technology, which is applied in the field of variable-tooth-thickness gear meshing pairs, can solve problems such as difficult adjustment of spring preload, high requirements for control synchronization, and complex structure and assembly. The effect of reducing backlash and backlash, low synchronization requirements, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

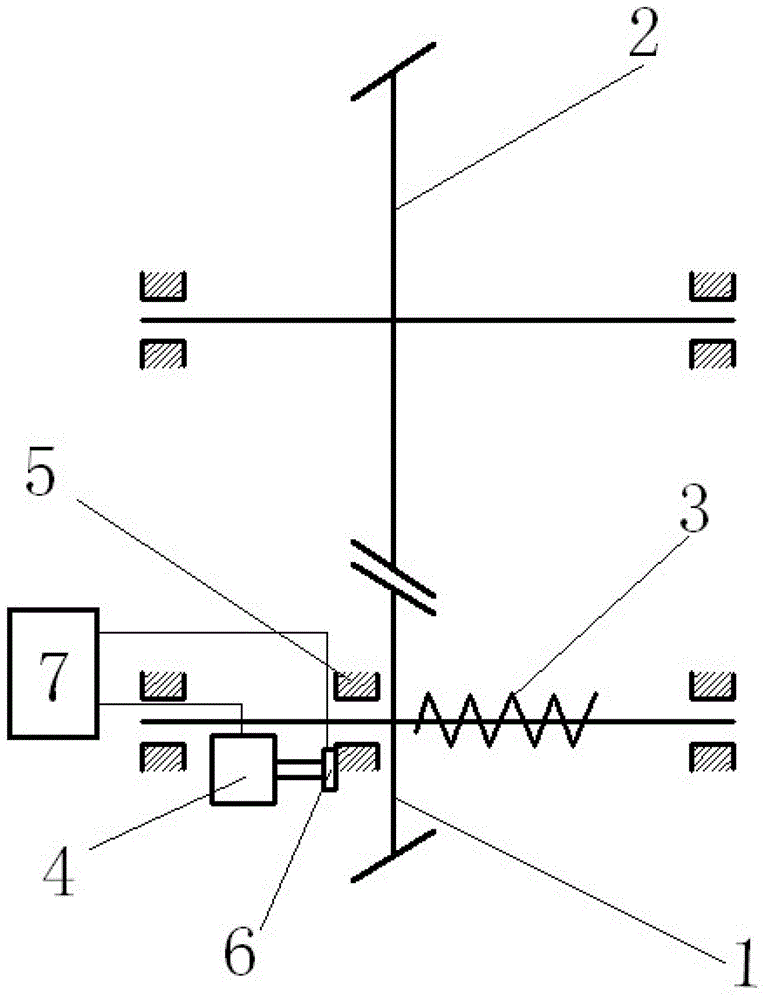

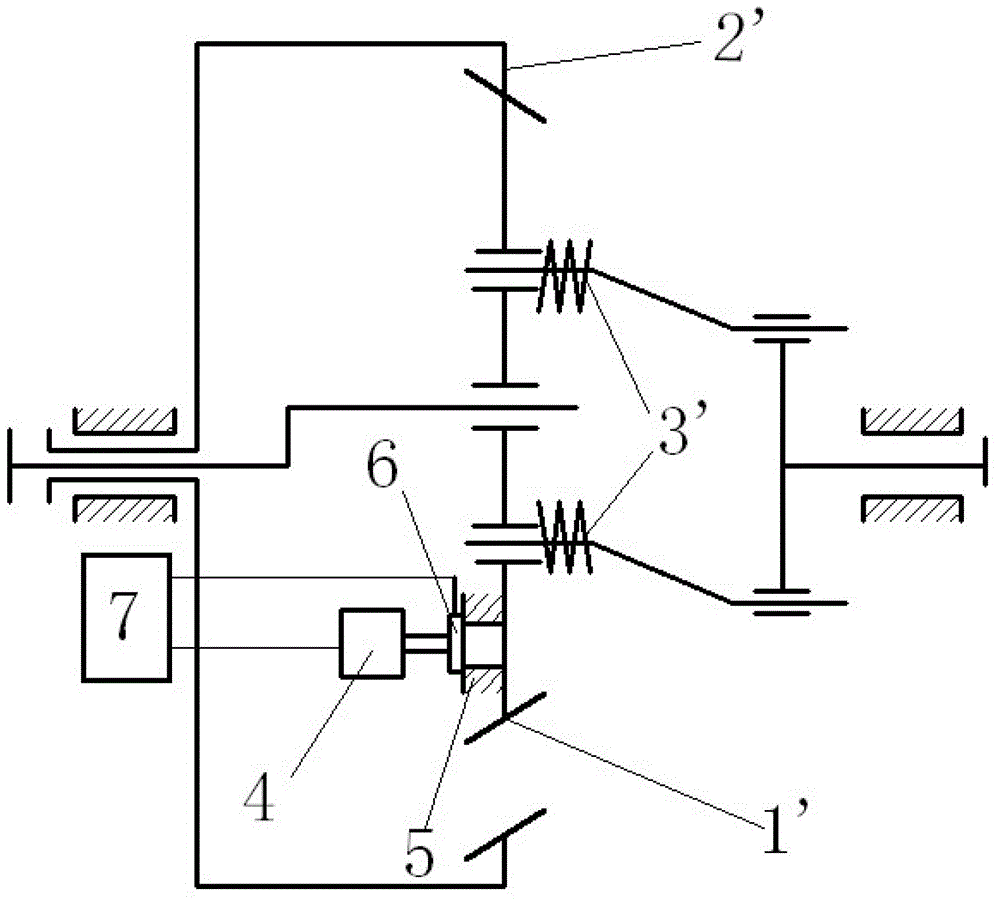

[0024] figure 1 It is the structural principle diagram of the first embodiment of the present invention, as shown in the figure: the electronically controlled anti-backlash variable tooth thickness gear pair in this embodiment includes the variable tooth thickness gear I1 and the variable tooth thickness gear meshed with the variable tooth thickness gear I1 gear II2 and an electronically controlled anti-backlash system, the electronically controlled anti-backlash system at least includes an electronically controlled power device 4 that applies an axial mechanical force for adjusting the backlash to the variable-tooth-thickness gear I1 or / and the variable-tooth-thickness gear II2, and the backlash-adjusting The direction of the axial mechanical force is the direction of eliminating the backlash between the variable tooth thickness gear I1 and the variable tooth thickness gear II2, that is, the direction of the axial mechanical force of the gap adjustment is the direction in whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com