Numerical control point welding machine used for shell rotation reducing sheet

A spot welding machine and cannonball technology, applied in the field of cannonball parts processing machinery, can solve the problems of low production efficiency, high labor intensity of workers, poor welding point position accuracy, etc., and achieve uniform welding points, stable welding process, and stable positive pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings.

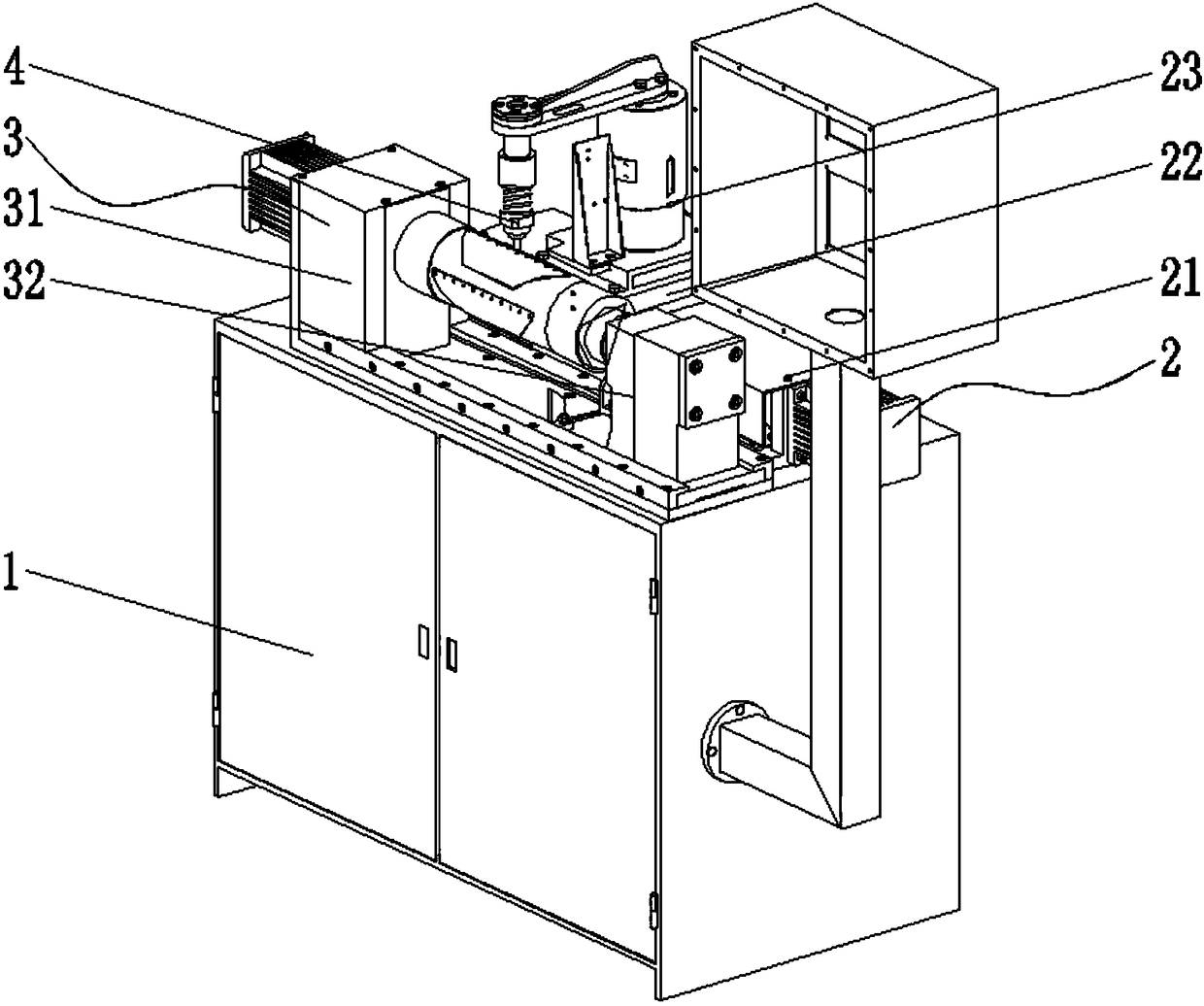

[0035] combine Figure 1-Figure 12 A numerically controlled spot welder for cannonball anti-rotation discs disclosed in this embodiment comprises a bed base 1, a spot welder driving device 2, a spindle drive 3, a spot welder 4 and a numerical control system; the bed base 1, a main shaft driving device 3 is fixedly arranged, and the spot welding machine driving device 2 is arranged on the side of the main shaft driving device 3, and a spot welding machine 4 is fixedly arranged on the spot welding machine driving device 2, and the main shaft driving device 3 , the spot welding machine 4 and the spot welding machine driving device 2 are both connected to the numerical control system.

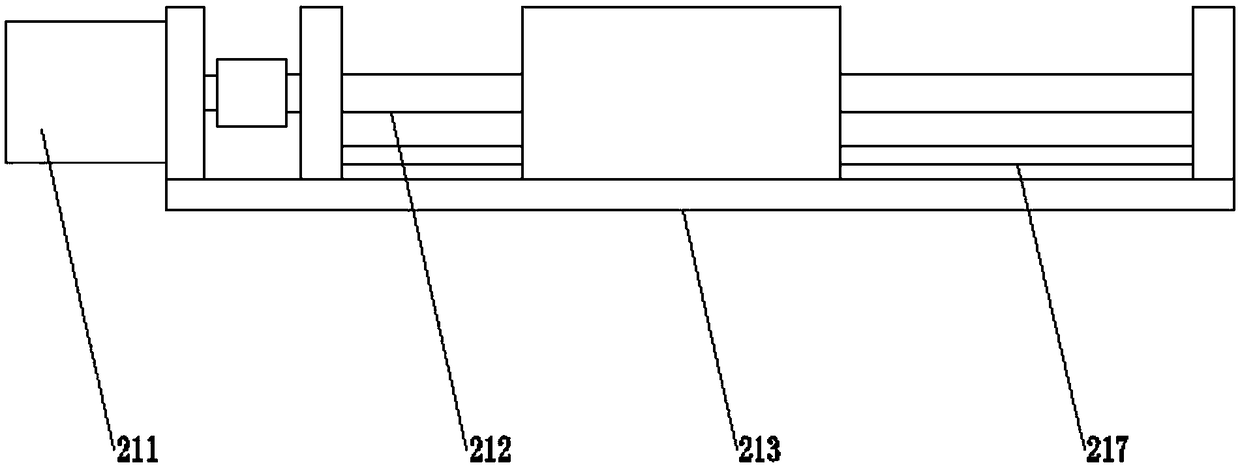

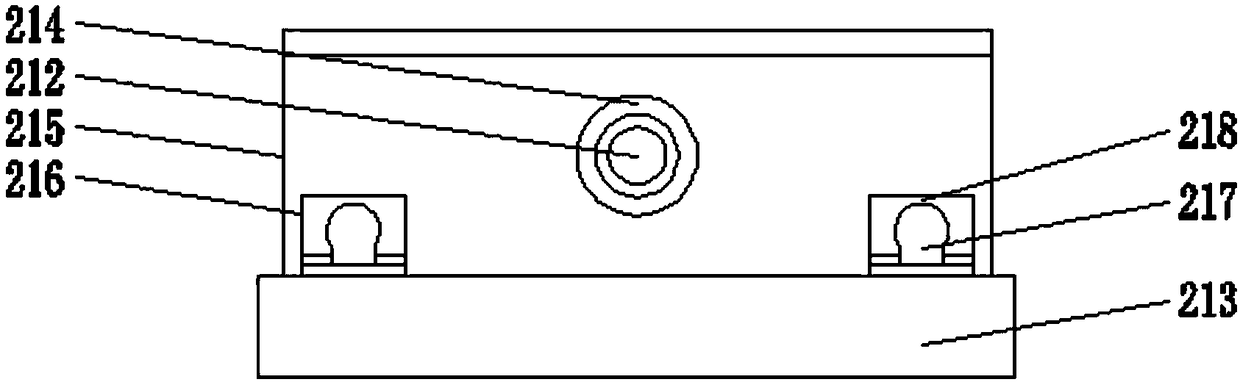

[0036] Specifically, the spot welding machine driving device 2 includes an X-axis driving device 21, a Y-axis driving device 22 and a Z-axis driving device 23, and the X-axis driving dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com