Micro-channel plate cladding glass and preparation method thereof

A leather glass and micro-channel plate technology, applied in the direction of electron multiplier details, etc., can solve the problems of high technical risk and high cost of micro-channel plate preparation, and achieve uniform melting, good anti-devitrification performance, and moderate viscosity at high temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

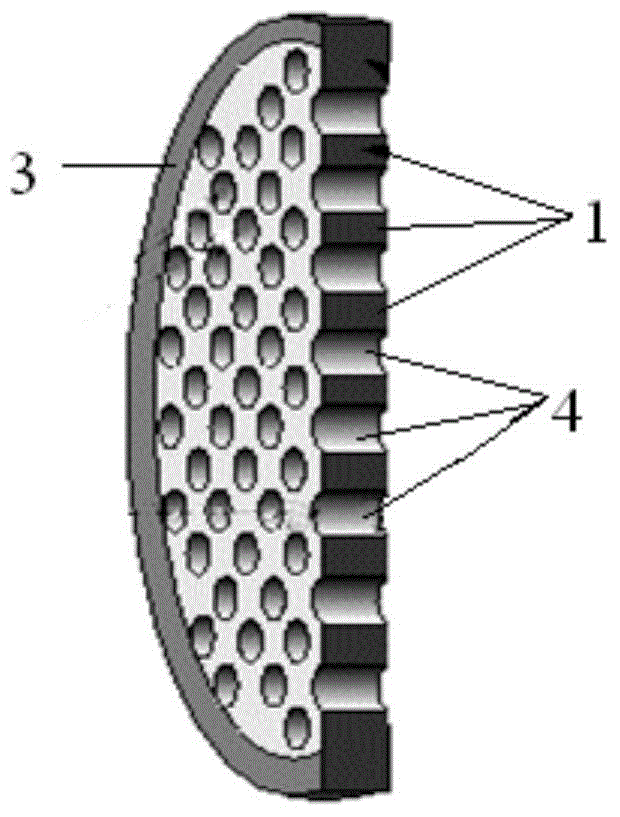

[0042] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0043] Method for preparing leather glass

[0044] Carbonates and / or nitrates of elements such as Si, Al, B, Bi, Sn, In, Sb, Na, Cs, Mg, Ca, Ba are used as raw materials, and leather is prepared by glass preparation methods in the prior art Glass.

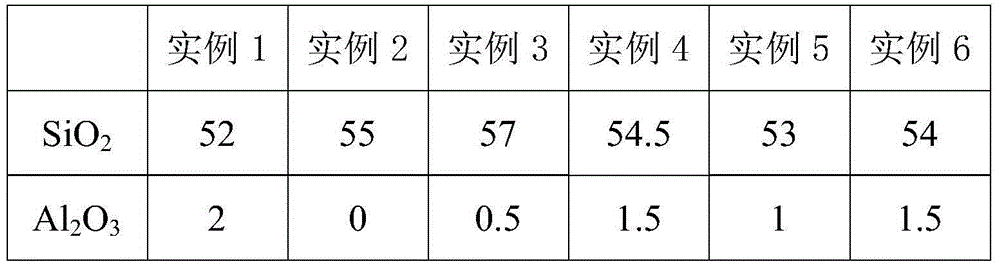

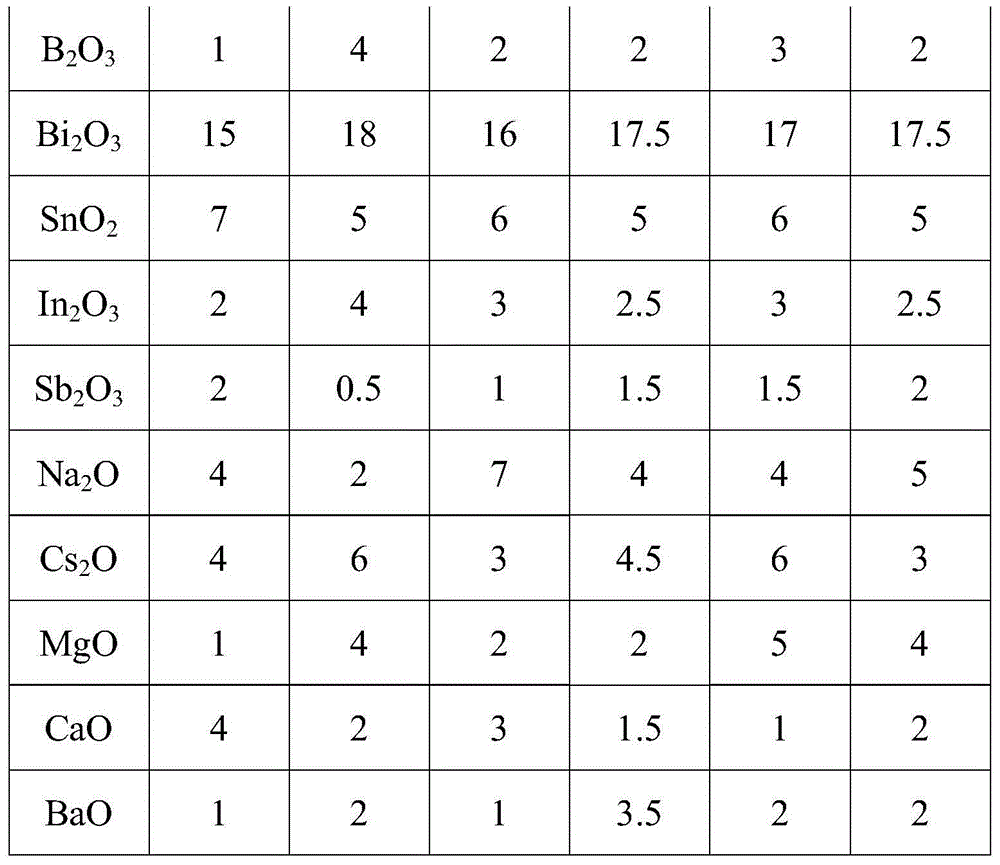

[0045] Examples 1-6, according to the above-mentioned preparation method, by controlling the content of raw materials, the content in parts by weight of metal oxide in the finally obtained leather glass is shown in Table 1 below.

[0046] Table 1

[0047]

[0048]

[0049] In each of the above examples, SiO 2 As a network former of leather glass, it constitutes a glass network skeleton. But th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com