High-thermal-conductivity particle reinforcement Al-based composite and preparing method thereof

A particle-reinforced aluminum and composite material technology, which is applied in the field of metal matrix composite materials, can solve the problem of insufficient thermal conductivity and comprehensive mechanical properties, and cannot meet the needs of high thermal conductivity and comprehensive mechanical properties of die-casting aluminum alloy materials. and other problems, achieving obvious thermal conductivity, overcoming the floating of strengthening particles, and solving the problems of hardness and machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

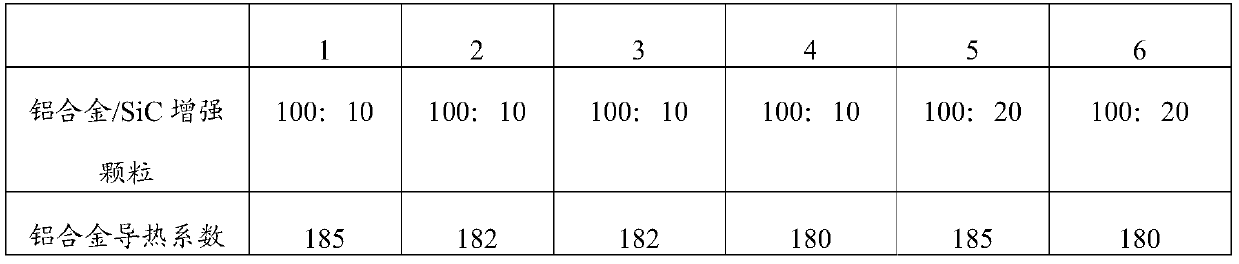

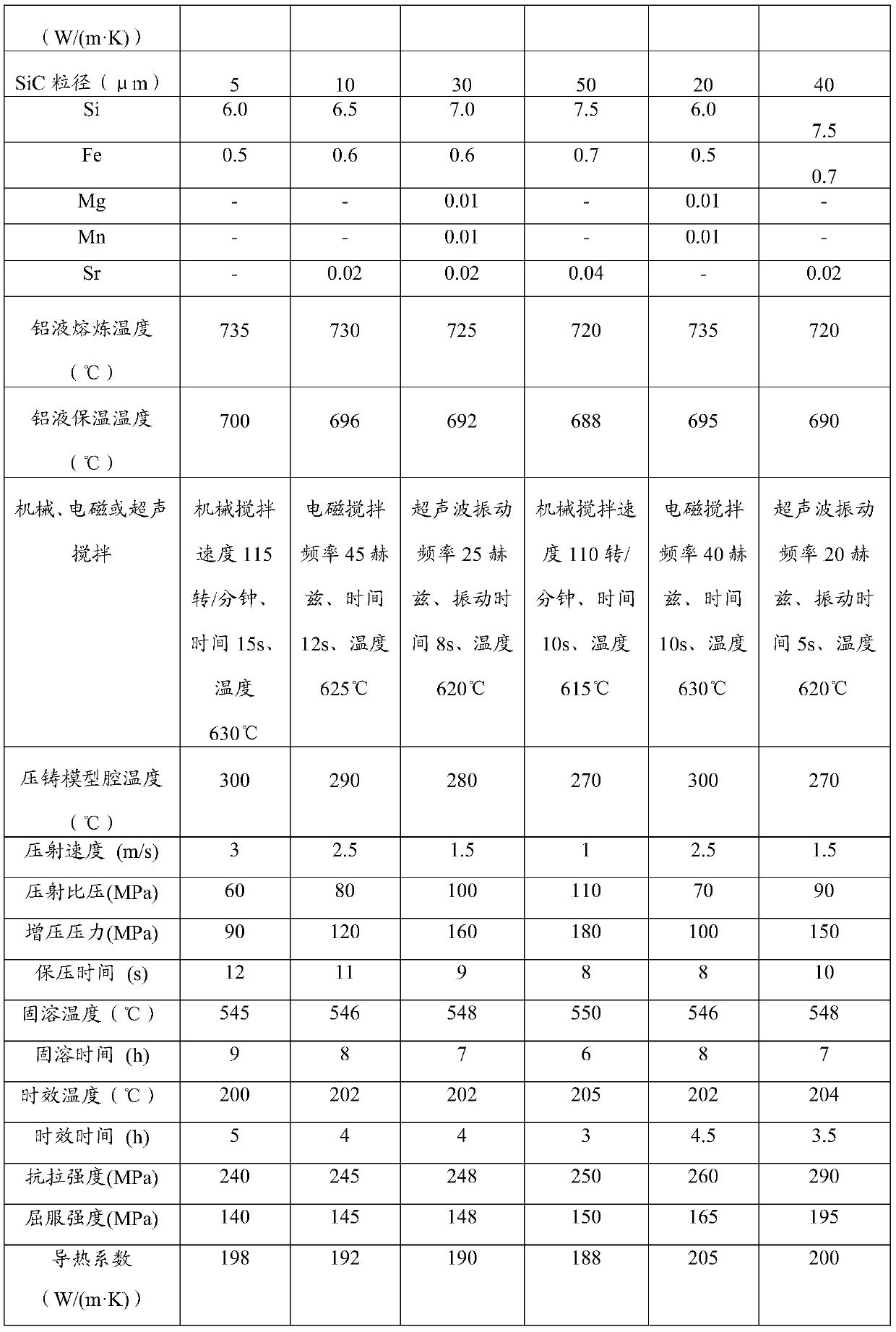

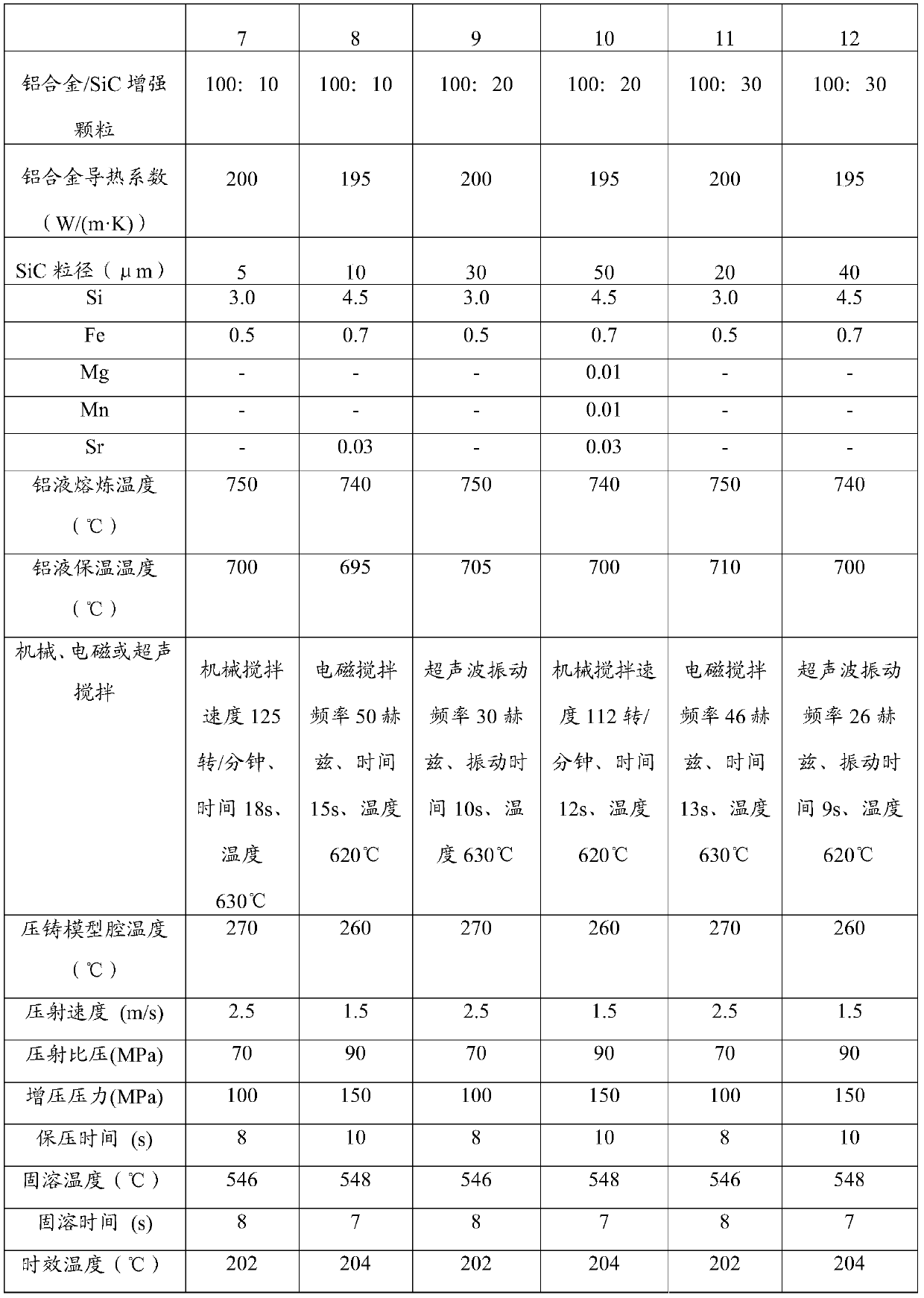

Embodiment 1

[0084] Mass ratio: aluminum alloy: SiC solid particles = 100:10.

[0085] Aluminum alloy: Si 6.0%, Fe 0.5%, the rest Al, thermal conductivity 185W / (m·K).

[0086] Solid particles: SiC particle size 5μm, thermal conductivity 290W / (m·K).

[0087] The preparation method of the high thermal conductivity particle reinforced aluminum matrix composite material specifically includes the following steps:

[0088] 1S batching and smelting: distributing the aluminum alloy raw materials according to the group; heating and smelting the prepared aluminum alloy raw materials to obtain aluminum alloy liquid, wherein the melting temperature is 735°C;

[0089] Preparation of 2S semi-solid slurry: Stir the aluminum alloy liquid obtained in step 1S, and at the same time add the reinforcing particles evenly according to the above-mentioned appropriate mass ratio to prepare a high thermal conductivity particle-reinforced aluminum-based semi-solid slurry at a temperature of 630°C ;

[0090]3S die...

Embodiment 2

[0094] Mass ratio: aluminum alloy: SiC solid particles = 100:10.

[0095] Aluminum alloy: Si 6.5%, Fe 0.6%, Sr 0.02%, the rest Al, thermal conductivity 182W / (m·K).

[0096] Solid particles: SiC particle size 10μm, thermal conductivity 290W / (m·K).

[0097] The preparation method of the high thermal conductivity particle reinforced aluminum matrix composite material specifically includes the following steps:

[0098] 1S batching and smelting: distributing the aluminum alloy raw materials according to the group; heating and smelting the prepared aluminum alloy raw materials to obtain aluminum alloy liquid, wherein the melting temperature is 730°C;

[0099] Preparation of 2S semi-solid slurry: Stir the aluminum alloy solution obtained in step 1S, and at the same time add the reinforcing particles uniformly according to the above-mentioned appropriate mass ratio to prepare a high thermal conductivity particle-reinforced aluminum-based semi-solid slurry at a temperature of 625°C ;...

Embodiment 3

[0104] Mass ratio: aluminum alloy: SiC solid particles = 100:10.

[0105] Aluminum alloy: Si 7.0%, Fe 0.6%, Mg 0.01%, Mn 0.01%, Sr 0.02%, the rest Al, thermal conductivity 182W / (m·K).

[0106] Solid particles: SiC particle size 30μm, thermal conductivity 290W / (m·K).

[0107] The preparation method of the high thermal conductivity particle reinforced aluminum matrix composite material specifically includes the following steps:

[0108] 1S batching and smelting: distributing the aluminum alloy raw materials according to the group; heating and melting the prepared aluminum alloy raw materials to obtain aluminum alloy liquid, wherein the melting temperature is 725°C;

[0109] 2S semi-solid slurry preparation: Stir the aluminum alloy liquid obtained in step 1S, and at the same time add the reinforcing particles evenly according to the above-mentioned appropriate mass ratio, and prepare a high thermal conductivity particle-reinforced aluminum-based semi-solid slurry at a temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com