Ceramic grinding segment for cement grinder and preparation method of ceramic grinding segment

A grinding machine and grinding segment technology, applied in the field of cement processing, can solve the problems of poor high temperature resistance, insufficient strength, low grinding body hardness, etc., and achieve the effects of long replacement period, good bonding force and high melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

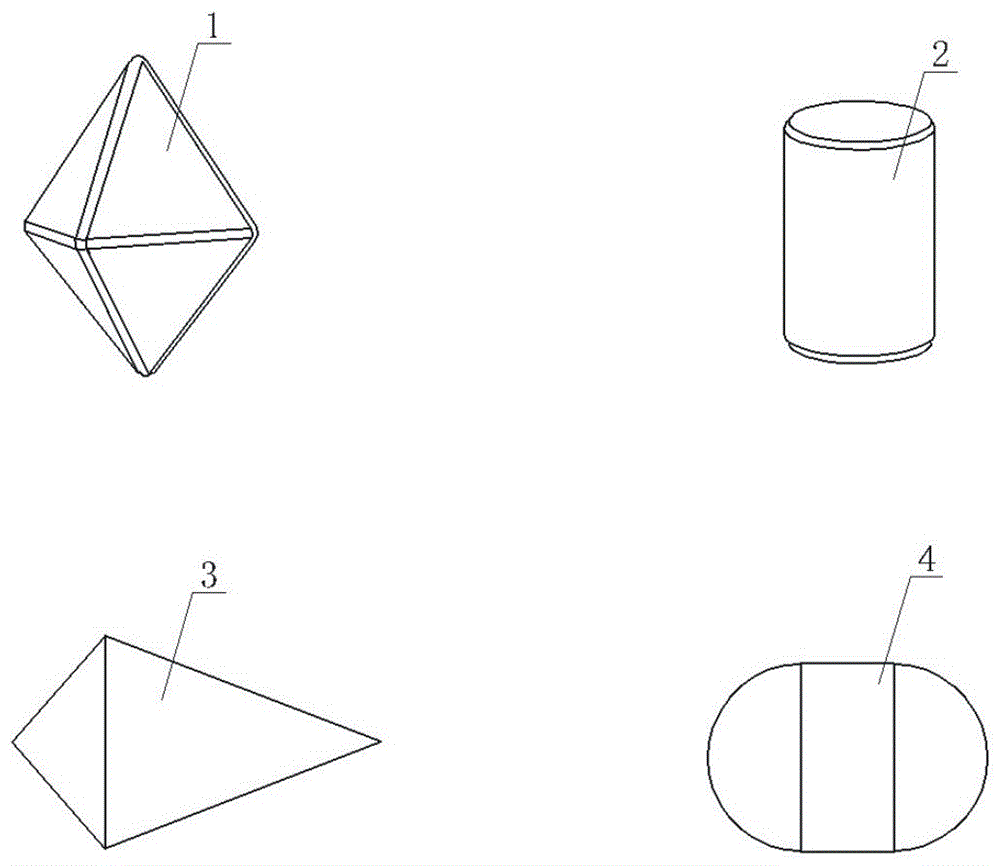

Image

Examples

Embodiment 1

[0034]The ceramic grinding section of the cement grinder contains 92% of alumina, 0.5% of tungsten carbide, 0.8% of calcium carbonate, 1.2% of magnesium carbonate, 2% of titanium nitride, 2.5% of silicon dioxide and 1% of zirconia by weight percentage. Prepared as follows:

[0035] (a) Batching: get all ingredients by weight percentage; configure PVA solution simultaneously, proportioning is PVA:water=8:100;

[0036] (b) Ball milling:

[0037] (b1) Primary grinding: Add the ingredients calculated in step (a) to the primary grinding equipment, and add ball stones and water (the primary grinding balls can be Φ30-Φ50mm 92-high alumina isostatic balls, the same below) , the ratio is material: ball: water=1:2.5:0.7, stop grinding to slurry fineness D90≤8 micron, cross 40 mesh sieves and go out grinding;

[0038] (b2) Fine grinding: Add the slurry obtained in step (b1) into the fine grinding equipment, and add ball stones and water (fine grinding ball stones can be 92-high alumina...

Embodiment 2

[0047] The ceramic grinding section of the cement grinder contains 95% of alumina, 0.5% of tungsten carbide, 0.8% of calcium carbonate, 1.2% of magnesium carbonate, 0.5% of titanium nitride, 1% of silicon dioxide and 1% of zirconia by weight percentage. Prepared as follows:

[0048] (a) Batching: get all ingredients by weight percentage; configure PVA solution simultaneously, proportioning is PVA:water=7:100;

[0049] (b) Ball milling:

[0050] (b1) Primary grinding: Add the ingredients calculated in step (a) to the primary grinding equipment, and add ball stones and water in a ratio of material: ball: water = 1:2.5:0.75, until the slurry fineness D90≤8 Micron stop grinding, pass through a 40-mesh sieve for grinding;

[0051] (b2) Fine grinding: Add the slurry obtained in step (b1) to the fine grinding equipment, and add ball stones and water in a ratio of material: ball: water = 1:3:0.75, until the fineness of the slurry is D50≤1.5 microns 、Stop grinding after D90≤3.2 micr...

Embodiment 3

[0060] The ceramic grinding section of the cement grinder contains 92% of alumina, 2% of tungsten carbide, 1.7% of calcium carbonate, 1% of magnesium carbonate, 0.5% of titanium nitride, 2% of silicon dioxide, and 0.8% of zirconia by weight percentage. Prepared as follows:

[0061] (a) Batching: get all ingredients by weight percentage; configure PVA solution simultaneously, proportioning is PVA:water=10:100;

[0062] (b) Ball milling:

[0063] (b1) Primary grinding: Add the ingredients calculated in step (a) to the primary grinding equipment, and add ball stones and water in a ratio of material: ball: water = 1:2.5:0.72, until the slurry fineness D90≤8 Micron stop grinding, pass through a 40-mesh sieve for grinding;

[0064] (b2) fine grinding: add the slurry obtained in step (b1) to the fine grinding equipment, and add ball stones and water in a ratio of material: ball: water = 1:2.5:0.75, until the fineness of the slurry is D50≤1.5 microns 、Stop grinding after D90≤3.2 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com