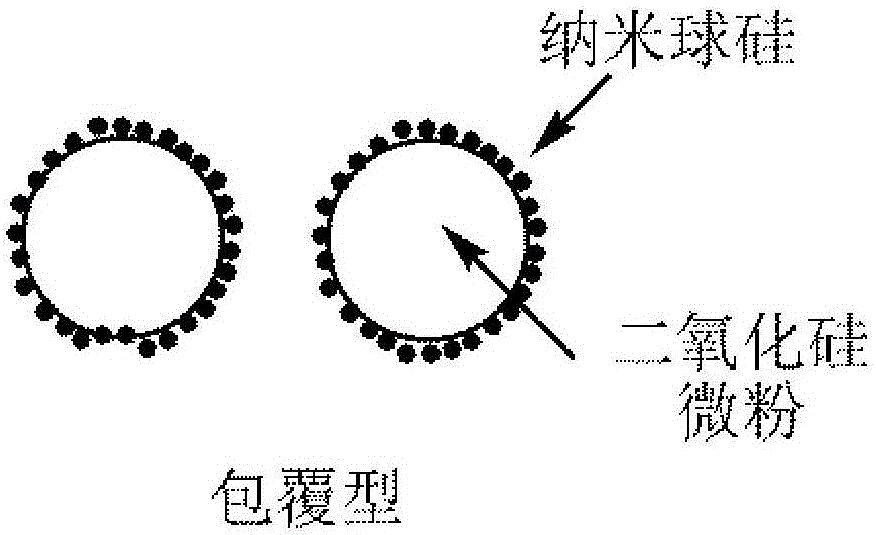

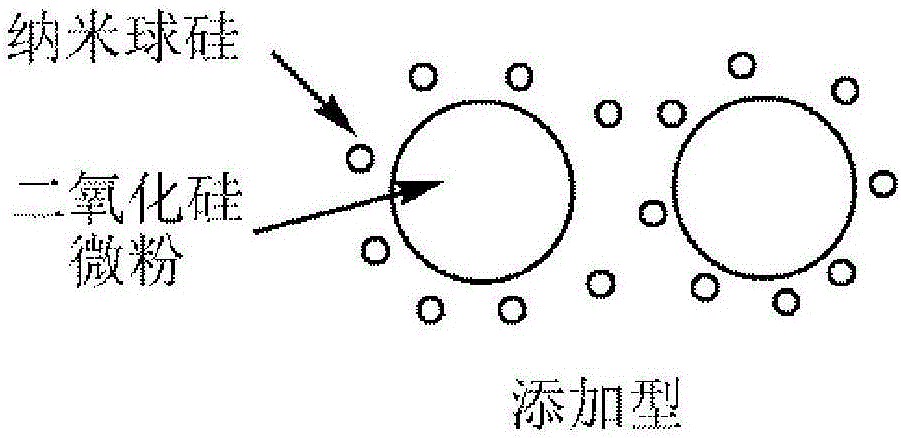

Preparation method of coated filler slurry composition, prepreg comprising slurry composition, laminated board and printed circuit board

A coating type and composition technology, applied in the field of pressing plates, can solve the problems of poor compatibility and affect various properties of cured materials, and achieve the effect of increasing dispersion and fluidity, and increasing solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

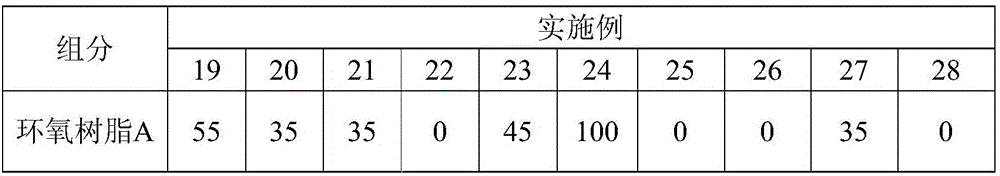

Examples

Embodiment 1

[0068] In this embodiment, the coated filler slurry composition (referred to as slurry A) is prepared by the following method, the specific method is:

[0069] (1) Weigh 100g of master particle filler spherical silica powder (D50 is 0.3μm, D100 is 23μm), 1g butyl stearate (dispersant), 100g methyl ethyl ketone, silica powder, dispersant and butyl Ketone mixing, mechanical stirring to disperse evenly;

[0070] (2) further dispersing the mixed solution obtained in step (1) through a dispersing device to obtain a prefabricated silica slurry;

[0071] (3) Add 0.003g ammoniacal liquor to the prefabricated slurry prepared in step (2), mix well, and record it as liquid A;

[0072] (4) Take by weighing 0.25g methyl orthosilicate, be dissolved in 0.003g butanone, be made into mixed solution;

[0073] (5) Under mechanical stirring, liquid B is added to liquid A, and stirred to react to obtain a reaction mixed solution;

[0074] (6) Store the reaction mixed solution obtained in step (...

Embodiment 2

[0077] In this embodiment, the coated filler slurry composition (referred to as slurry B) is prepared by the following method, the specific method is:

[0078] (1) Take by weighing 100g parent particle filler angular silica micropowder (D50 is 5 μm, D100 is 20 μm), 0.1g sodium lauryl sulfate (dispersant), 70g acetone, silica micropowder, dispersant and acetone are mixed, Mechanical stirring to disperse evenly;

[0079] (2) further dispersing the mixed solution obtained in step (1) through a dispersing device to obtain a prefabricated silica slurry;

[0080] (3) Add 5g tetramethylammonium hydroxide to the prefabricated slurry prepared in step (2), mix homogeneously, and record it as liquid A;

[0081] (4) Take by weighing 17.34g ethyl orthosilicate, be dissolved in 30g acetone, be made into mixed solution;

[0082] (5) Under mechanical stirring, liquid B is added to liquid A, and stirred to react to obtain a reaction mixed solution;

[0083] (6) Store the reaction mixed solu...

Embodiment 3

[0086] In this embodiment, the coated filler slurry composition (referred to as slurry C) is prepared by the following method, the specific method is:

[0087] (1) Weigh 100g master particle filler talc powder (D50 is 10 μm, D100 is 29 μm), 0.12g sodium dodecylbenzenesulfonate (dispersant), 57.14g DMF, mix talc powder, dispersant and DMF, Mechanical stirring to disperse evenly;

[0088] (2) the mixed solution obtained in the step (1) is further dispersed by a dispersing device to obtain a talcum powder prefabricated slurry;

[0089] (3) Add 5g of dilute hydrochloric acid to the prefabricated slurry prepared in step (2), mix well, and record it as liquid A;

[0090] (4) Take by weighing 34.68g ethyl orthosilicate, dissolve in 80g DMF, be made into mixed solution;

[0091] (5) Under mechanical stirring, liquid B is added to liquid A, and stirred to react to obtain a reaction mixed solution;

[0092] (6) Store the reaction mixed solution obtained in step (5) at room temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com