Graphene coating for heat-dissipating copper foils and preparation method and application thereof

A technology for heat dissipation copper foil and graphene, which is applied in epoxy resin coatings, chemical instruments and methods, coatings, etc. Low coefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

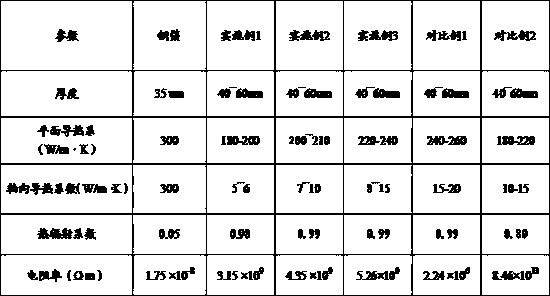

Examples

Embodiment 1

[0045] Embodiment 1: a kind of coating for graphene heat dissipation copper foil, used raw material consumption is as follows:

[0046] 10 parts by weight of graphene slurry, including 25 parts by weight of graphene powder, 6 parts by weight of surface treatment agent (BYK 101), and 60 parts of solvent (propylene glycol methyl ether acetate);

[0047] 30 parts by weight of boron nitride slurry, including 20 parts by weight of boron nitride powder, 6 parts by weight of surface treatment agent, and 80 parts of solvent (propylene glycol methyl ether acetate);

[0048] The binding agent is low hydroxyl value acrylic resin MR-767 and its curing agent amino epoxy resin MR-818, 10 parts by weight;

[0049] Thinner (propylene glycol methyl ether acetate) 50 parts by weight.

[0050] The preparation method is as follows: mix 1-60 parts by weight of diluent and 1-10 parts by weight of surface treatment agent, then add 30-80 parts by weight of graphene powder for mixing and stirring to ...

Embodiment 2

[0056] Embodiment 2: a kind of coating for graphene heat dissipation copper foil, used raw material consumption is as follows:

[0057] Graphene slurry 15 parts by weight, graphene slurry comprises 50 parts by weight of graphene powder, 5 parts by weight of surface treatment agent (BYK 101);

[0058] 45 parts by weight of boron nitride slurry, including 10 parts by weight of boron nitride powder, and 5 parts by weight of surface treatment agent;

[0059] Adhesive (for low hydroxyl value acrylic resin and its curing agent amino epoxy resin) 5 parts by weight;

[0060] The diluent is 35 parts by weight of butyl acetate.

[0061] The preparation method is the same as that of Example 1.

Embodiment 3

[0062] Embodiment 3: a kind of coating for graphene heat dissipation copper foil, used raw material consumption is as follows:

[0063] 20 parts by weight of graphene slurry, the graphene slurry includes 10 parts by weight of graphene powder, and 1 part by weight of surface treatment agent (BYK 101);

[0064] 60 parts by weight of boron nitride slurry, including 30 parts by weight of boron nitride powder, and 9 parts by weight of surface treatment agent;

[0065] Adhesive (for acrylic resin) 10 parts by weight;

[0066] Diluent (for ethylene glycol) 10 parts by weight.

[0067] The preparation method is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com