Ceramic side sealing plate for twin-roll thin-strip continuous casting and preparation method thereof

A twin-roll thin-strip continuous casting and side-sealing technology, which is applied in the field of steel continuous casting, can solve the problems of uniform phase composition and microstructure of the side-sealing plates, mismatch of thermal expansion of the side-sealing plates, and easy generation of cold blocks on the side-sealing plates, etc. problems, to achieve the effect of excellent corrosion resistance to molten steel, good thermal shock resistance, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

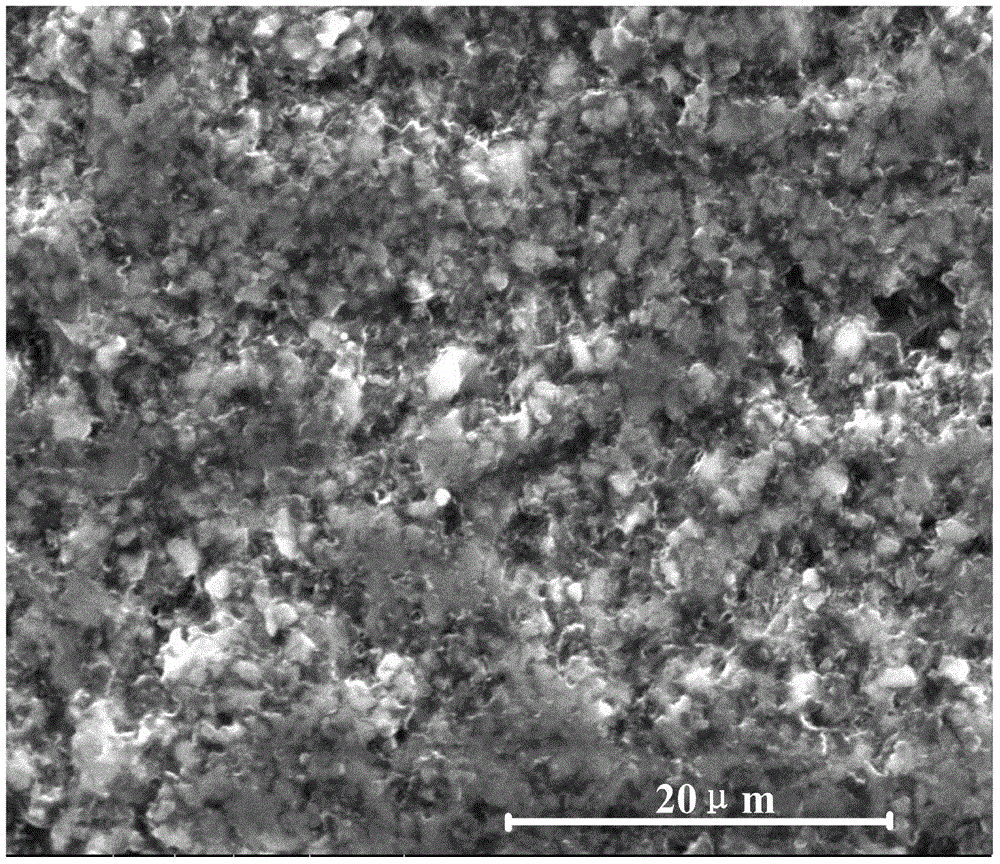

Image

Examples

preparation example Construction

[0026] A preparation method of a ceramic side sealing plate for twin-roll thin strip continuous casting, which comprises the following steps:

[0027] Step 1: Combine hexagonal boron nitride powder, Si 3 N 4 Powder, zirconium mullite powder, TiN powder and additives were ball milled with wet ball milling method for at least 24 hours (enough ball milling time can ensure the particle size, and fine particle size can increase the specific surface area of raw materials, thereby improving The activity of raw materials), the ball milling solvent in the ball milling process is absolute ethanol or industrial alcohol with a purity of more than 95%, respectively forming hexagonal boron nitride slurry, Si 3 N 4 Slurry, zirconium mullite slurry, TiN slurry and additive slurry, the hexagonal boron nitride slurry, Si 3 N 4 The particle size of the solid particles in the slurry, zircon mullite slurry, TiN slurry and additive slurry is 0.1-10 μm, and then the hexagonal boron nitride slu...

Embodiment 1

[0035] Embodiment 1: in step 1, hexagonal boron nitride powder, Si 3 N 4 powder, zircon mullite powder, TiN powder and Y 2 o 3 The powders were milled for 30 hours with a ball mill using a wet ball milling method. The ball milling solvent was absolute ethanol. During the ball milling process, the hexagonal boron nitride slurry, Si 3 N 4 slurry, zircon mullite slurry, TiN slurry and Y 2 o 3 The particle size of the slurry is 2 μm;

[0036] From the powder of step 1 in step 2, by mass percentage: hexagonal boron nitride powder 55%, Si 3 N 4 Powder 15%, Zirconium Mullite Powder 15%, TiN Powder 10%, Y 2 o 3 5% of the powder is selected from the powder to be mixed by wet ball milling, and the time of mixing by wet ball milling is 12 hours;

[0037] In step 3, during the process of granulating the mixed slurry with a spray granulator, 15% of the particle size range of the control powder is below 0.5 mm, and 60% of the particle size range is between 0.5 and 1.5 mm. The ran...

Embodiment 2

[0041] Embodiment 2: in step 1, hexagonal boron nitride powder, Si 3 N 4 powder, zircon mullite powder, TiN powder, Y 2 o 3 Aluminum oxide powder, industrial alumina powder, and MgO powder were milled for 28 hours in a ball mill using a wet ball milling method, and the ball milling solvent was absolute ethanol. 3 N 4 Slurry, Zirconium Mullite Slurry, TiN Slurry, Y 2 o 3 The particle size of slurry, industrial alumina slurry, and MgO slurry is 5 μm;

[0042] From the powder in step 1 in step 2, by mass percentage: hexagonal boron nitride powder 60%, Si 3 N 4 10% powder, 20% zircon mullite powder, 5% TiN powder, Y 2 o 3 Powder 2%, industrial alumina powder 2%, MgO powder 1% choose the powder material to be treated by wet ball milling, and the time of described wet ball milling mixing process is 36 hours;

[0043]In step 3, in the process of granulating the mixed slurry with a spray granulator, 20% of the particle size range of the control powder is below 0.5 mm, and 70...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com