Preparation method of silicon carbide ceramic tubular product

A technology of silicon carbide ceramics and tubular products, which is applied in the field of silicon carbide ceramic materials and its preparation, to achieve the effects of long life, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

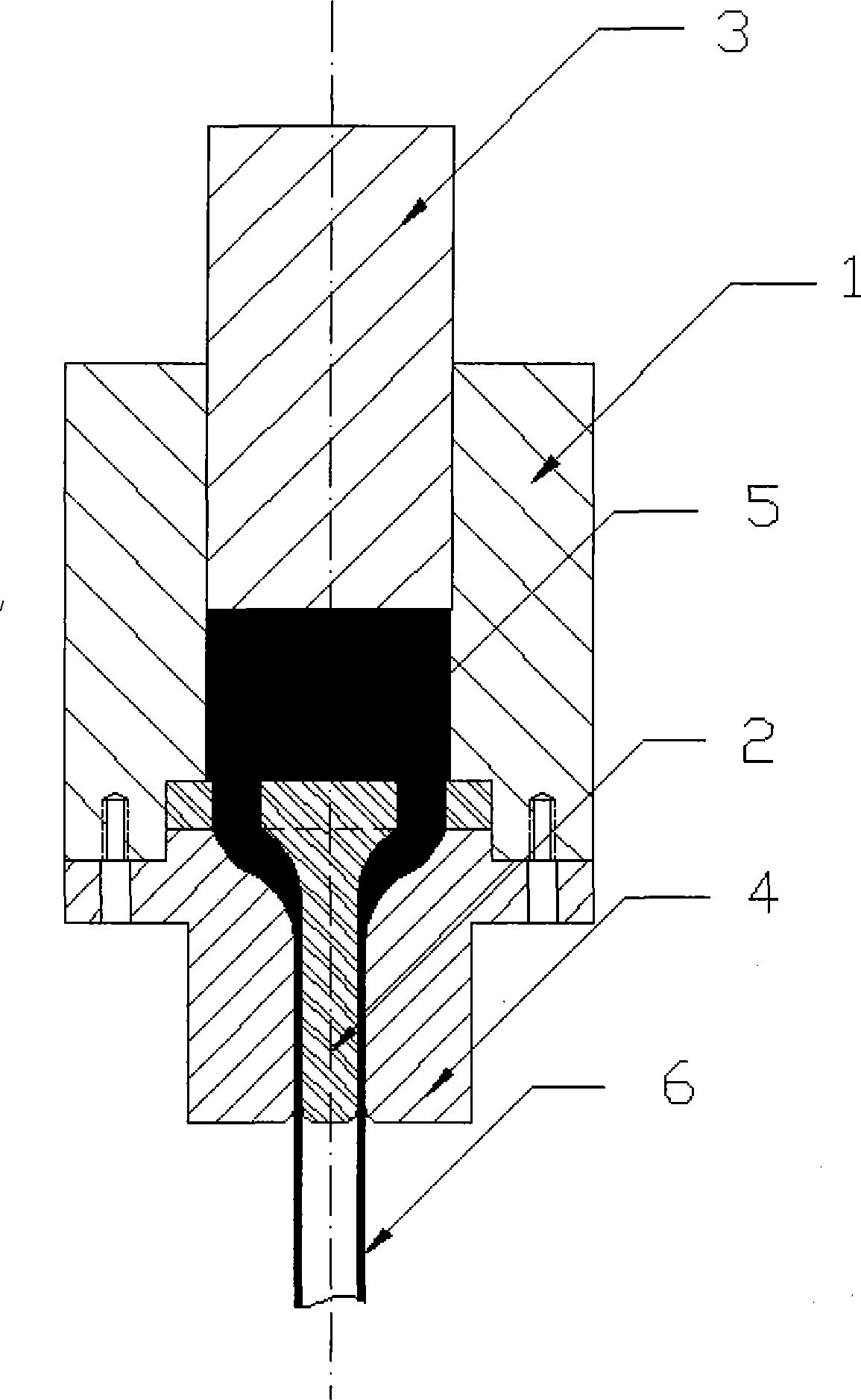

[0046] The preparation method uses solid particle powder and high-molecular materials with high carbon yield as raw materials. After air-drying and aging treatment, a tubular prefabricated body is prepared in an extrusion molding die, and then a high-pressure compaction is carried out in a hot isostatic press. After melting, pyrolysis and sintering, the specific preparation process is as follows:

[0047] (1) Mix solid particle powder (silicon carbide powder, silicon powder or both mixed powder), polymer material, curing agent and organic solvent in a certain proportion, ball mill after mechanical stirring, and filter to obtain slurry. Slurry solution solute is 5~70% (preferably range is 40~70%) of total mass; After air-drying, remove a certain amount of organic solvent in the slurry, make the organic solvent mass content after air-drying be 1~5%, again through Curing in the air not higher than 40°C for 20 hours, it becomes a raw material that can be used for extrusion molding...

Embodiment 1

[0061] The technical indicators of the silicon carbide ceramic tube gained in the present embodiment are as follows:

[0062] Dimensions: outer diameter 10mm, wall thickness 1mm, length 1000mm; density 100%; composition 98% SiC, 2% Si; compressive strength not less than 800MPa, material thermal conductivity 140W / (m K); thermal expansion coefficient 4.6ppm, 400 cycles of air cooling at 1400°C without any damage.

[0063] Example 2

Embodiment 2

[0065] The technical indicators of the SiC honeycomb ceramic material obtained in the present embodiment are as follows:

[0066] Dimensions: outer diameter 50mm, wall thickness 5mm, length 500mm; density 70%; composition 99% SiC, 1% Si; compressive strength not less than 200MPa, material thermal conductivity 60W / (m K); thermal expansion coefficient 4.6ppm, 1400℃ cycle air cooling 300 times without any damage.

[0067] Example 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com