Polyvinyl chloride resin composition and insulated wire using the polyvinyl chloride resin composition

A polyvinyl chloride resin, insulated wire technology, applied in the direction of plastic/resin/wax insulators, insulated cables, insulated conductors, etc. Problems such as degradation of properties, etc., to achieve the effects of excellent mechanical properties and cold resistance, good extrusion appearance, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

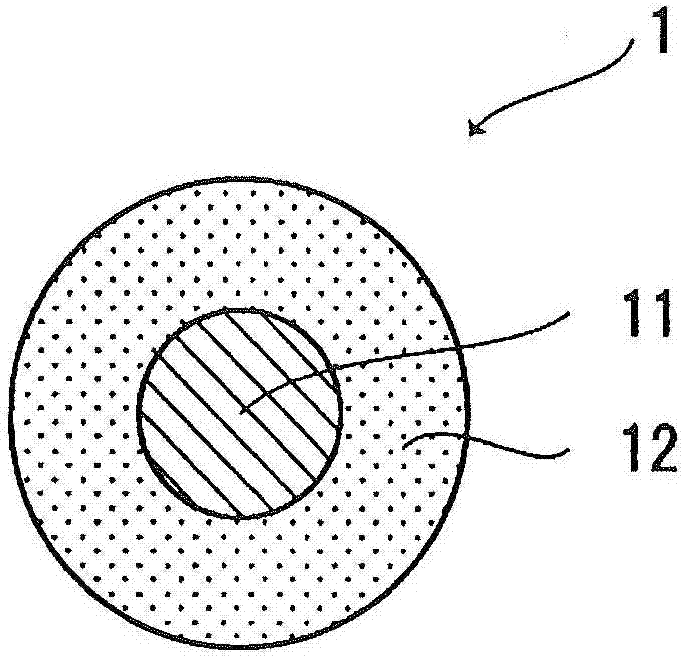

[0047] One embodiment of the present invention will be described below.

[0048] (1) Polyvinyl chloride resin composition

[0049] The polyvinyl chloride resin composition of the present embodiment contains: a polyvinyl chloride resin (A), a plasticizer (B), a non-lead stabilizer (C) including a zinc metal soap (c1) and a hydrotalcite (c2), and not Contains polymethyl methacrylate as a gelling accelerator. Moreover, with respect to 100 mass % of the polyvinyl chloride resin composition, containing 19 mass % to 24 mass % of plasticizer (B), 4 mass % or more of non-lead stabilizer (C), hydrotalcite (c2) relatively The mass ratio (c2 / c1) to the zinc metal soap (c1) is 3.5 or more and 10 or less.

[0050] (polyvinyl chloride resin (A))

[0051] Examples of the polyvinyl chloride resin include copolymers of vinyl chloride and other copolymerizable monomers, and mixtures thereof, in addition to polyvinyl chloride, which is a homopolymer of vinyl chloride. As the polyvinyl chlori...

Embodiment

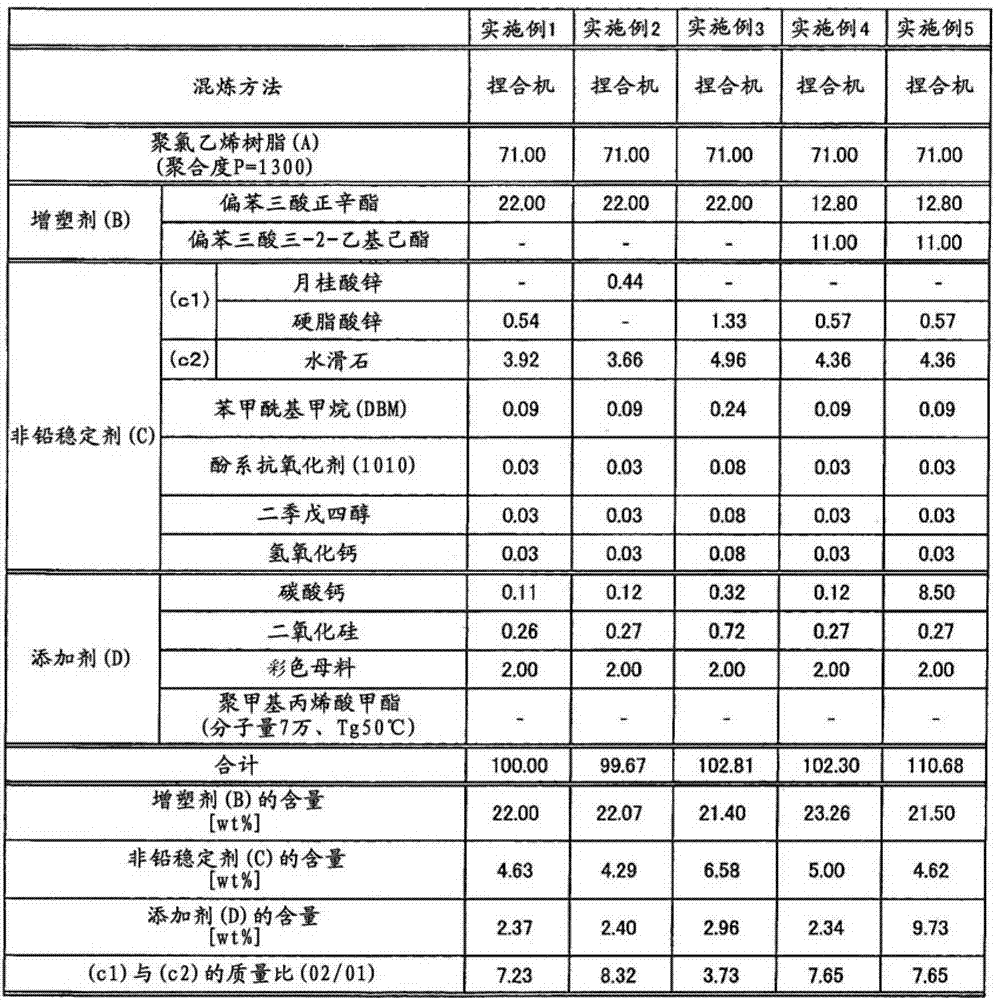

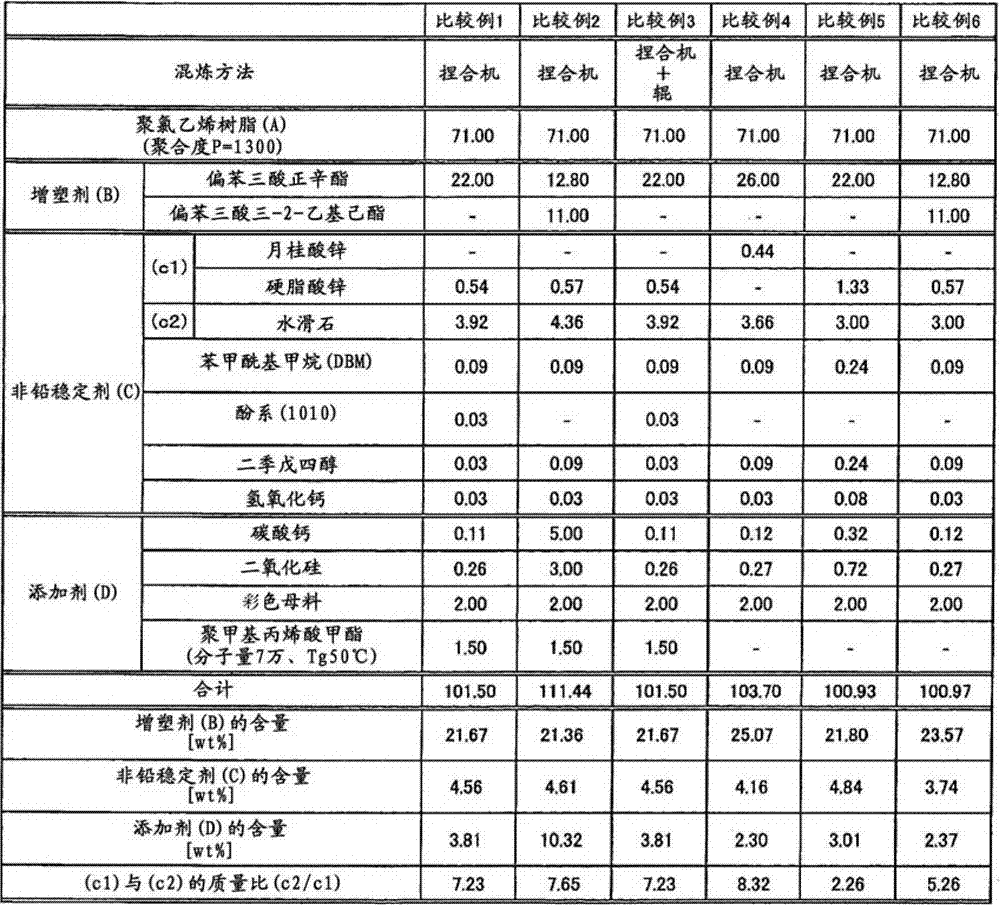

[0095] Embodiments of the present invention will be described below. In this example, a polyvinyl chloride resin composition was prepared, and an insulated wire was produced using it. And the polyvinyl chloride resin composition was evaluated by measuring the cold resistance of the obtained insulated wire, extruded appearance, and the crimping property of an insulated wire. These Examples are one example of the present invention, and the present invention is not limited by these Examples.

[0096] Materials used in the following examples and comparative examples are summarized below.

[0097] As the polyvinyl chloride resin (A), the following were used.

[0098] Polyvinyl chloride resin: "TK-1300" manufactured by Shin-Etsu Chemical (average degree of polymerization 1300)

[0099] As the plasticizer (B), the following substances were used.

[0100] Tri-n-octyl trimellitate: "N-08" manufactured by Kao

[0101] Tri-2-ethylhexyl trimellitate: "T-08" manufactured by Kao

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com