Solar cell module

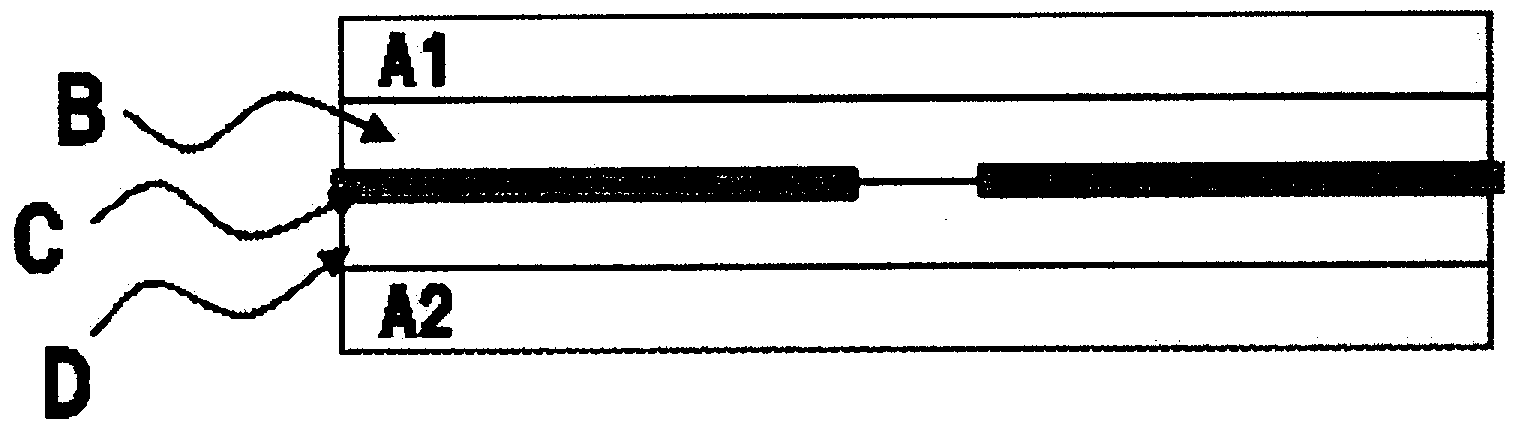

一种太阳能电池、反应型的技术,应用在光伏模块、光伏模块的支撑结构、电路等方向,能够解决无法利用紫外光能量、变色、背面保护片劣化等问题,达到输出难以降低、挤出成型性优异、交联特性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] As a composition for the light-receiving side sealing sheet (B), 2,5-dimethyl-2,5-bis 0.1 parts by mass of (tert-butyl peroxy)hexane, 0.4 parts by mass of tert-butyl peroxy-2-ethylhexyl carbonate, 1.0 parts by mass of triallyl isocyanurate, γ-methacryloyloxy 0.2 parts by mass of propyltrimethoxysilane was used to obtain a resin composition.

[0079] The obtained resin composition was extruded into a sheet (also called "precursor sheet for light-receiving side sealing) having a thickness of about 600 μm through an extruder equipped with a T-die. "). The transmittance of the sheet body of the composition for light-receiving side sealing sheet (B) at a wavelength of 300 nm was 67%.

[0080] As the composition for the back side sealing sheet (D), 2,5-dimethyl-2,5-bis 0.1 parts by mass of (tert-butyl peroxy)hexane, 0.4 parts by mass of tert-butyl peroxy-2-ethylhexyl carbonate, 1.0 parts by mass of triallyl isocyanurate, γ-methacryloyloxy 0.2 parts by mass of propyltrimet...

Embodiment 2

[0087] Except that the ultraviolet absorber was replaced with 2-(4-allyloxy-2-hydroxyphenyl)-2H-benzotriazole, the same procedure as in Example 1 was carried out to produce a back side sealing sheet (D) Tablets of the composition. Table 1 shows the evaluation results of the diffusion of the ultraviolet absorber similar to Example 1 using the sheet body of the composition for the sheet (D) for back side sealing.

Embodiment 3

[0089] Except that the ultraviolet absorber was replaced with 2-(4-acryloyloxy-2-hydroxyphenyl)-2H-benzotriazole, the back side sealing sheet (D) was produced in the same manner as in Example 1. Tablets of the composition. Table 1 shows the evaluation results of the diffusion of the ultraviolet absorber similar to Example 1 using the sheet body of the composition for the sheet (D) for back side sealing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com