Eu-doped high-silica glass and preparation method thereof

A high-silica glass and high-silica technology, which is applied in the field of Eu-doped high-silica glass and its preparation, can solve the problems of low rare earth ion doping concentration, limited application of quartz glass, and unfavorable device miniaturization, etc. Improve luminous efficiency, avoid concentration quenching effect, and facilitate absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1, use analytical balance to take by weighing 0.0383g of analytically pure yttrium nitrate hexahydrate, 0.0163g of vanadyl sulfate and 0.0045g of analytically pure europium nitrate hexahydrate to be dissolved in 10ml of distilled water, and be formulated to contain 0.01mol / L Y 3+ , 0.01mol / L vanadium ion and 0.001mol / L Eu 3+ soaking solution. Soak the high-silica nano-microporous glass in the soaking solution for 4 hours, take it out, let it dry at room temperature, and then place it in a high-temperature furnace. , then at a speed of 15 °C / min to 900 °C, and then at a speed of 5 °C / min to 1300 °C, heat-preserve and sinter the soaked microporous glass at 1300 °C for 2 hours, and cool the glass to room temperature with the furnace and take it out. After cutting and polishing, the Eu-doped luminescent high-silica glass was prepared.

Embodiment 2

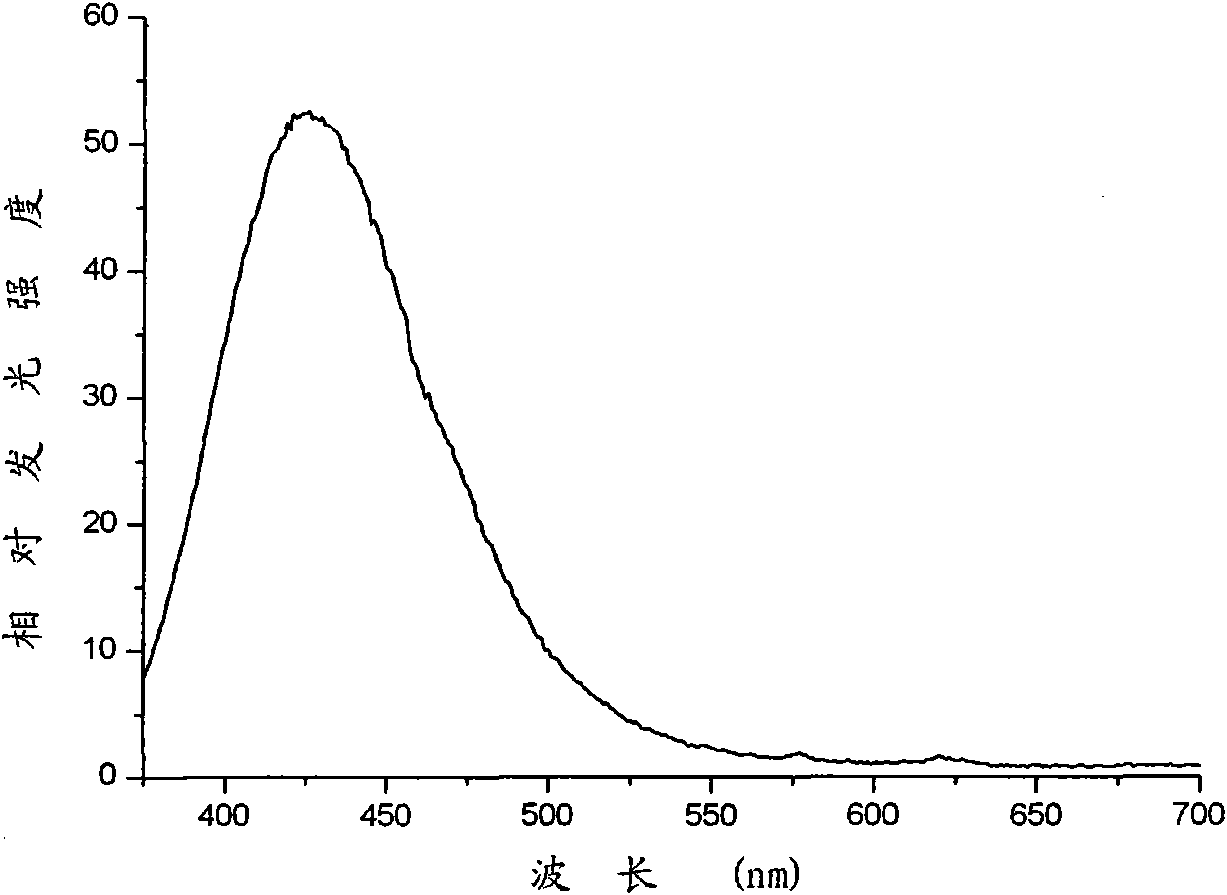

[0038] Example 2, use an analytical balance to weigh 0.0352g of analytically pure europium oxide dissolved in 1mol / L dilute hydrochloric acid, and prepare 10ml containing 0.02mol / L Eu 3+ solution. Soak the high-silica nano-microporous glass in the soaking solution for 30 minutes, take it out, let it dry at room temperature, and then place it in a high-temperature furnace. , and then at a speed of 15 °C / min to 900 °C, and then at a speed of 5 °C / min to 1150 °C, heat-preserve and sinter the soaked microporous glass at 1150 °C for 3 hours, and cool the glass to room temperature with the furnace and take it out. After cutting and polishing, the prepared Eu-doped high-silica glass. The glass can simultaneously generate blue and red light when excited by ultraviolet light. figure 1 The luminescence spectrum of the glass prepared in Example 2 under the excitation of excitation light with a wavelength of 290 nm. Figure 5 The luminous chromaticity of the glass obtained in this embo...

Embodiment 3

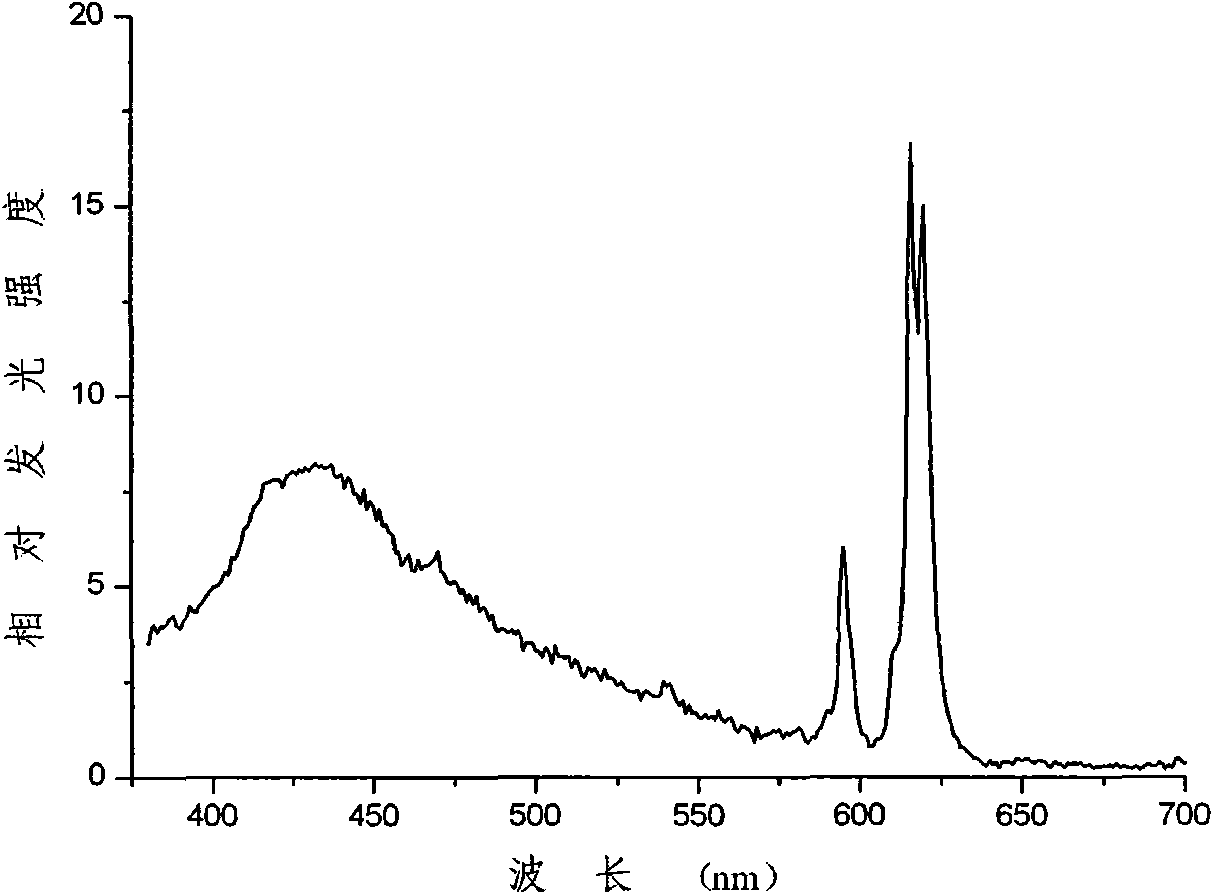

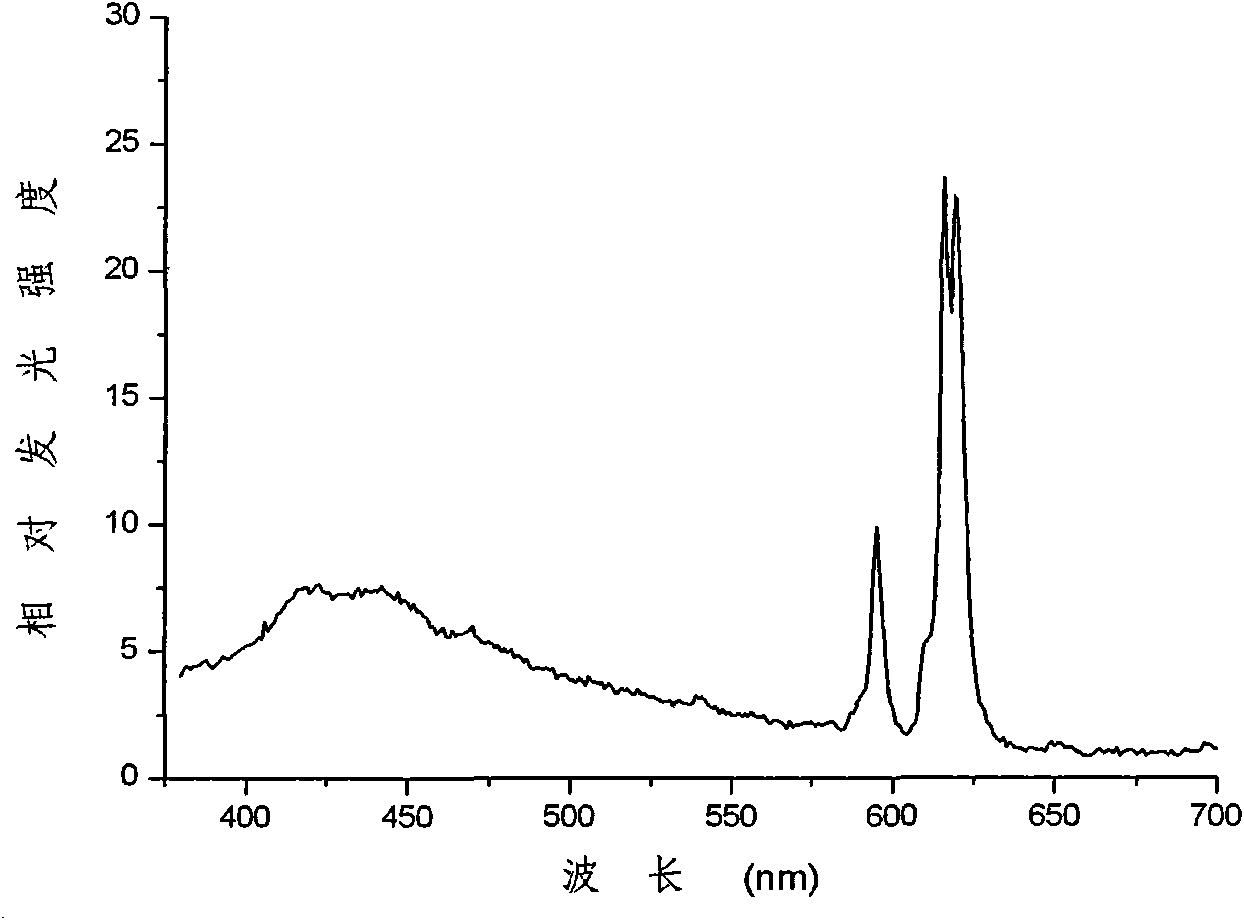

[0039] Example 3, use an analytical balance to weigh 0.0566g of analytically pure yttrium oxide, 0.82g of vanadyl sulfate and 0.0352g of analytically pure europium oxide dissolved in 1mol / L dilute nitric acid, and prepare 10ml containing 0.05mol / L Y 3+ , 0.05mol / L vanadium ion and 0.02mol / L Eu 3+ soaking solution. Soak the high-silica nano-microporous glass in the soaking solution for 3 hours, take it out, let it dry at room temperature, and then place it in a high-temperature furnace. , then at a rate of 15 °C / min to 900 °C, and then at a rate of 5 °C / min to 1200 °C, heat-preserve and sinter the soaked microporous glass at 1200 °C for 3 hours, and cool the glass to room temperature with the furnace and take it out. After cutting and polishing, the prepared Eu-doped luminescent high-silica glass. figure 2 The luminescence spectrum of the glass prepared in Example 3 under the excitation of excitation light with a wavelength of 290 nm. Figure 5 The luminous chromaticity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com