Single crystal alumina low-temperature brazing method

A sapphire and brazing technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the lack of research on wetting behavior, interfacial reaction connection strength, insufficient interfacial reaction at the interface, and reduce brazing Solve problems such as the performance of welded joints to achieve the effects of increasing mechanical properties, reducing residual stress, and reducing thermal damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Take 0.6 grams of 8-12 μm titanium powder (purity 99.9%), 19.4 grams of 300 mesh (about 48 μm) Sn-3Ag-0.5Cu powder (purity 99.9%) and mix them into a ceramic ball mill jar, introduce 1.6 ml of acetone, put Put in ceramic grinding balls with a total weight of 300 grams, and the diameter of the ceramic balls is 3 to 10 mm. Close the lid and place it in a ball mill with a speed of 250rpm for 8 hours, then take it out and dry it to obtain a Sn-Ag-Cu-Ti alloy powder, wherein the content of Ti is 3wt%, the content of Ag is 2.91wt%, and the content of Cu is 0.485wt%. , the rest are Sn;

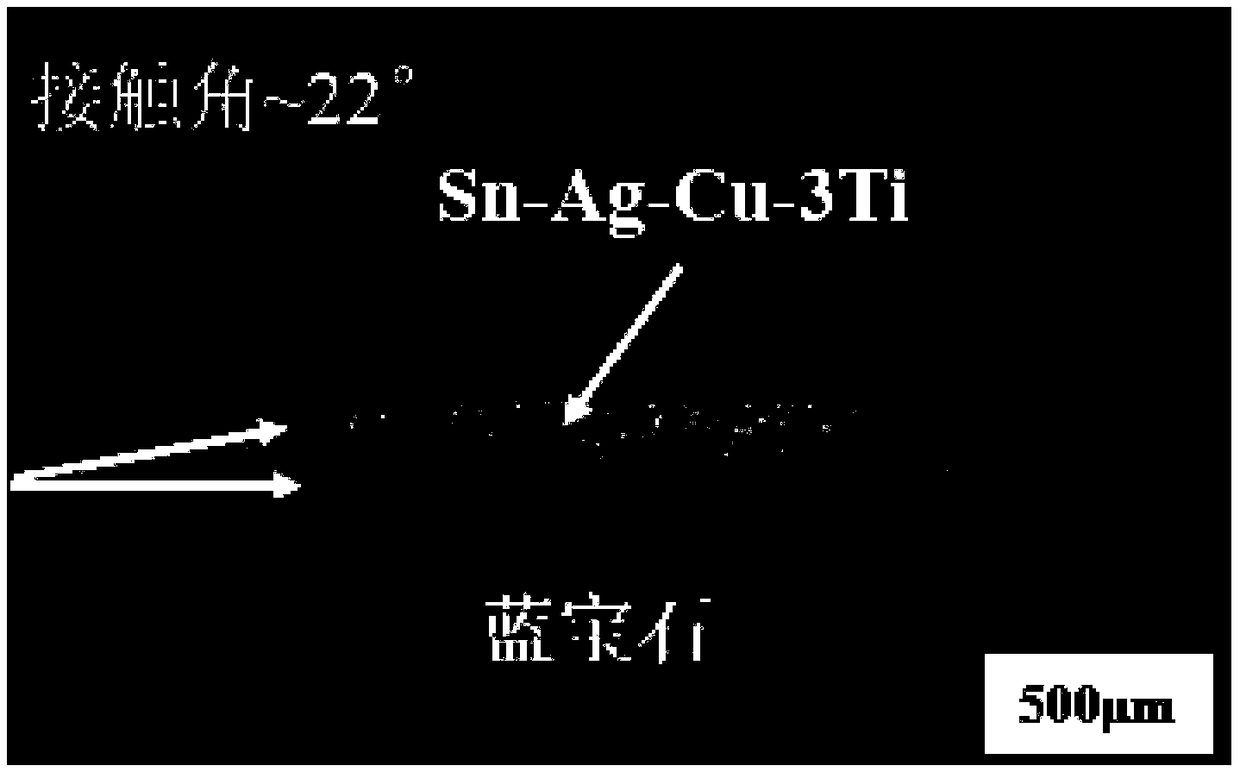

[0024] 2) Brazing sapphire with the Sn-Ag-Cu-Ti alloy powder obtained in step 1) as solder: ultrasonically clean the sapphire substrate with acetone and dry it; then spread Sn-Ag-Cu on the surface of the polished sapphire substrate -Ti alloy powder; then another polished sapphire substrate is placed on the sprinkled Sn-Ag-Cu-Ti alloy powder to form a sapphire / solder / sapphire "sandwich" str...

Embodiment 2

[0026] 1) Take 0.2 grams of 8-12 μm titanium powder (purity 99.9%), 19.8 grams of 300 mesh (about 48 μm) Sn-3Ag-0.5Cu powder (purity 99.9%) and mix them into a ceramic ball mill jar, introduce 1.6 ml of acetone, put Put in ceramic grinding balls with a total weight of 300 grams, and the diameter of the ceramic balls is 3 to 10 mm. Close the lid and place it in a ball mill with a speed of 250rpm for 8 hours, then take it out and dry it to obtain a Sn-Ag-Cu-Ti alloy powder, wherein the content of Ti is 1wt%, the content of Ag is 2.97wt%, and the content of Cu is 0.495wt%. , the rest are Sn;

[0027] 2) Brazing sapphire with the Sn-Ag-Cu-Ti alloy powder obtained in step 1) as solder: ultrasonically clean the sapphire substrate with acetone and dry it; then spread Sn-Ag-Cu on the surface of the polished sapphire substrate -Ti alloy powder; then another polished sapphire substrate is placed on the sprinkled Sn-Ag-Cu-Ti alloy powder to form a sapphire / solder / sapphire "sandwich" str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com