Preparation method of oriented graphene/alumina composite ceramic

A graphene composite and directional arrangement technology, applied in the field of preparation of alumina-based composite ceramic materials, can solve the problems of poor electrical and thermal conductivity, low safety in use, and brittle fracture of alumina ceramics, and achieve obvious electrical conductivity and Anisotropic thermal conductivity, low cost, and excellent electrical and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

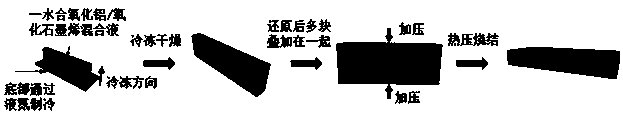

[0038] Such as figure 1 As shown, the present embodiment prepares aligned graphene / alumina composite ceramics according to the following steps:

[0039] 1: Preparation of graphene oxide: Prepare graphene oxide by chemical method: weigh 4 g flake graphite and put it in a beaker, pour 450 ml of concentrated sulfuric acid and 50 ml of phosphoric acid into the beaker to prepare a mixed solution, and stir at room temperature for 50 min. Place the beaker in a water bath for heating, add 18 g of potassium permanganate to the solution in 8 times, and heat the solution at 70 °C, take it out after 16 h and cool it at room temperature. After cooling to room temperature, slowly pour the mixed solution into 700 ml of ice water containing 6 ml of hydrogen peroxide with a mass fraction of 30%, let it stand for 24 hours, filter off the supernatant, and take the lower solution for centrifugal washing and washing. After drying, graphene oxide is obtained.

[0040] 2. Preparation of graphene o...

Embodiment 2

[0048] Such as figure 1 As shown, the present embodiment prepares aligned graphene / alumina composite ceramics according to the following steps:

[0049] 1: Preparation of graphene oxide: Prepare graphene oxide by chemical method: weigh 4 g flake graphite and put it in a beaker, pour 450 ml of concentrated sulfuric acid and 50 ml of phosphoric acid into the beaker to prepare a mixed solution, and stir at room temperature for 50 min. Place the beaker in a water bath for heating, add 18 g of potassium permanganate to the solution in 8 times, and heat the solution at 70 °C, take it out after 16 h and cool it at room temperature. After cooling to room temperature, slowly pour the mixed solution into 700 ml of ice water containing 6 ml of hydrogen peroxide with a mass fraction of 30%, let it stand for 24 hours, filter off the supernatant, and take the lower solution for centrifugal washing and washing. After drying, graphene oxide is obtained.

[0050] 2. Preparation of graphene o...

Embodiment 3

[0055] Such as figure 1 As shown, the present embodiment prepares aligned graphene / alumina composite ceramics according to the following steps:

[0056] 1: Preparation of graphene oxide: Prepare graphene oxide by chemical method: weigh 4 g flake graphite and put it in a beaker, pour 450 ml of concentrated sulfuric acid and 50 ml of phosphoric acid into the beaker to prepare a mixed solution, and stir at room temperature for 50 min. Place the beaker in a water bath for heating, add 18 g of potassium permanganate to the solution in 8 times, and heat the solution at 70 °C, take it out after 16 h and cool it at room temperature. After cooling to room temperature, slowly pour the mixed solution into 700 ml of ice water containing 6 ml of hydrogen peroxide with a mass fraction of 30%, let it stand for 24 hours, filter off the supernatant, and take the lower solution for centrifugal washing and washing. After drying, graphene oxide is obtained.

[0057] 2. Preparation of graphene o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com