Silicon carbide whisker-toughened aluminum oxide composite ceramic material for bulletproof armor and preparation method thereof

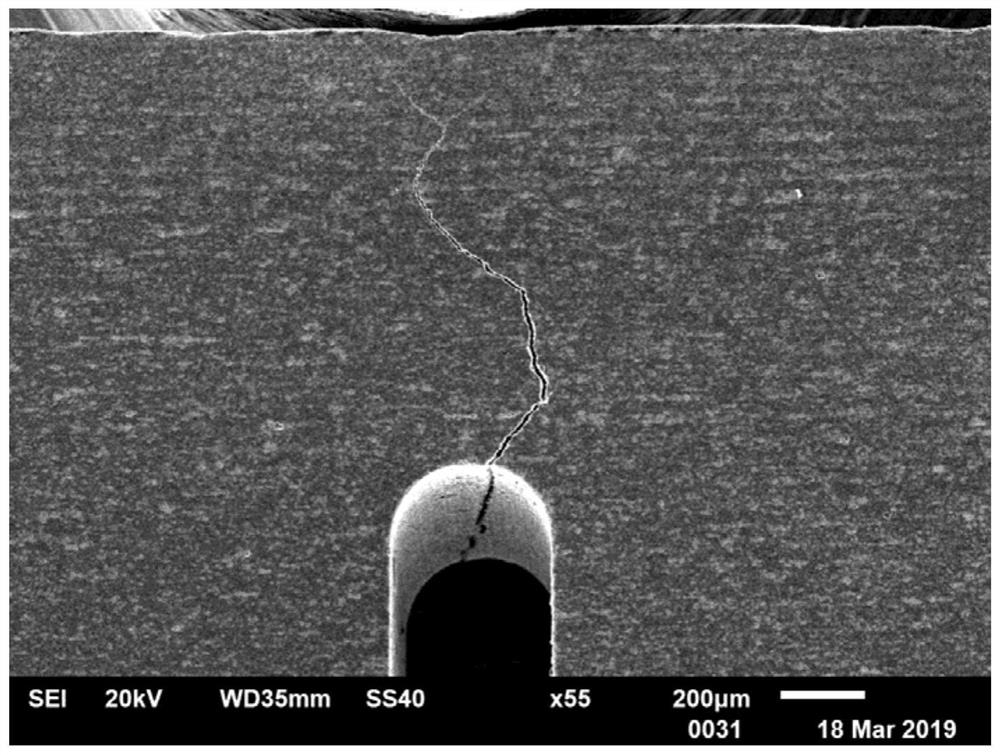

A technology of silicon carbide whiskers and composite ceramics, which is applied to the structure of protective equipment, armor, armor plates, etc., can solve the problems of poor resistance to secondary and multiple impacts, difficult material mechanical properties, and low fracture toughness , to improve the ability to resist multiple impacts, enhance the protective effect and durability, and improve the impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

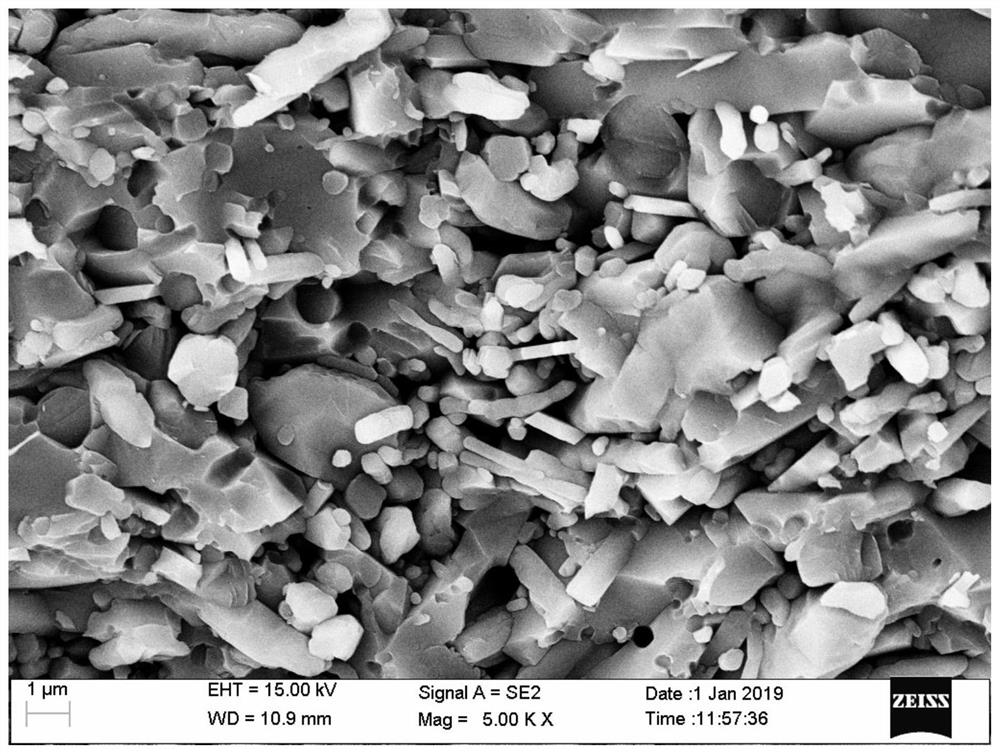

[0027] In this example, an alumina composite ceramic material for bulletproof armor toughened by silicon carbide whiskers with a volume fraction of silicon carbide whiskers of 30% was prepared. The raw materials used mainly include silicon carbide whiskers (average diameter 1μm, length range 10-100μm), alumina powder (average particle size 20nm), yttrium oxide powder (average particle size 30nm), deionized water, hydroxypropyl methyl Base cellulose powder (average particle size 180 μ m), polyvinyl alcohol, sodium lauryl sulfate and DarvanCN dispersant, Darvan CN dispersant is the slurry dispersant produced by U.S. Vanderbilt Company (R.T.Vanderbilt). Concrete preparation process is as follows:

[0028]1) Weigh 768g of deionized water, 13g of silicon carbide whiskers and 35g of alumina powder into a 1L ball mill jar in sequence, and after stirring evenly, add 3.8g of hydroxypropyl methylcellulose powder and 7.7g of polyethylene Alcohol and 2.4g of DarvanCN dispersant, then add...

Embodiment 2

[0033] In this example, an alumina composite ceramic material for bulletproof armor toughened by silicon carbide whiskers with a volume fraction of silicon carbide whiskers of 10% was prepared. The raw material used is identical with embodiment 1. Concrete preparation process is as follows:

[0034] 1) The difference between this step and step 1) in Example 1 is that the amount of deionized water used is 701g, the amount of silicon carbide whiskers added is 3.8g, the amount of aluminum oxide powder added is 40g, and the amount of hydroxypropyl The amount of methylcellulose powder added was 3.5 g, the amount of polyvinyl alcohol added was 7 g, and the amount of Darvan CN dispersant added was 5.8 g.

[0035] 2) This step is the same as step 2) in Example 1.

[0036] 3) This step is the same as step 3) in Example 1.

[0037] The aluminum oxide composite ceramic material for bulletproof armor toughened by silicon carbide whiskers with a volume fraction of silicon carbide whiske...

Embodiment 3

[0039] In this embodiment, the volume fraction of silicon carbide whiskers is 50% and the alumina composite ceramic material for bulletproof armor is toughened with silicon carbide whiskers. The raw material used is identical with embodiment 1. Concrete preparation process is as follows:

[0040] 1) The difference between this step and step 1) in Example 1 is that the amount of deionized water used is 896g, the amount of silicon carbide whiskers added is 26g, the amount of aluminum oxide powder added is 30g, and the amount of hydroxypropyl methyl The added amount of base cellulose powder is 4.5g, the added amount of polyvinyl alcohol is 9g, and the added amount of Darvan CN dispersant is 2.8g.

[0041] 2) This step is the same as step 2) in Example 1.

[0042] 3) This step is the same as step 3) in Example 1.

[0043] The aluminum oxide composite ceramic material for bulletproof armor toughened by silicon carbide whiskers with a volume fraction of silicon carbide whiskers o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com