Self-toughening substance containing type continuous fiber reinforced thermo-structure composite and preparation method thereof

A continuous fiber and composite material technology, applied in the field of materials, can solve the problems of poor high-temperature structural stability, complex preparation process, limited high-temperature application, etc., and achieve the effects of improving strength, simplifying preparation procedures, and widely available raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

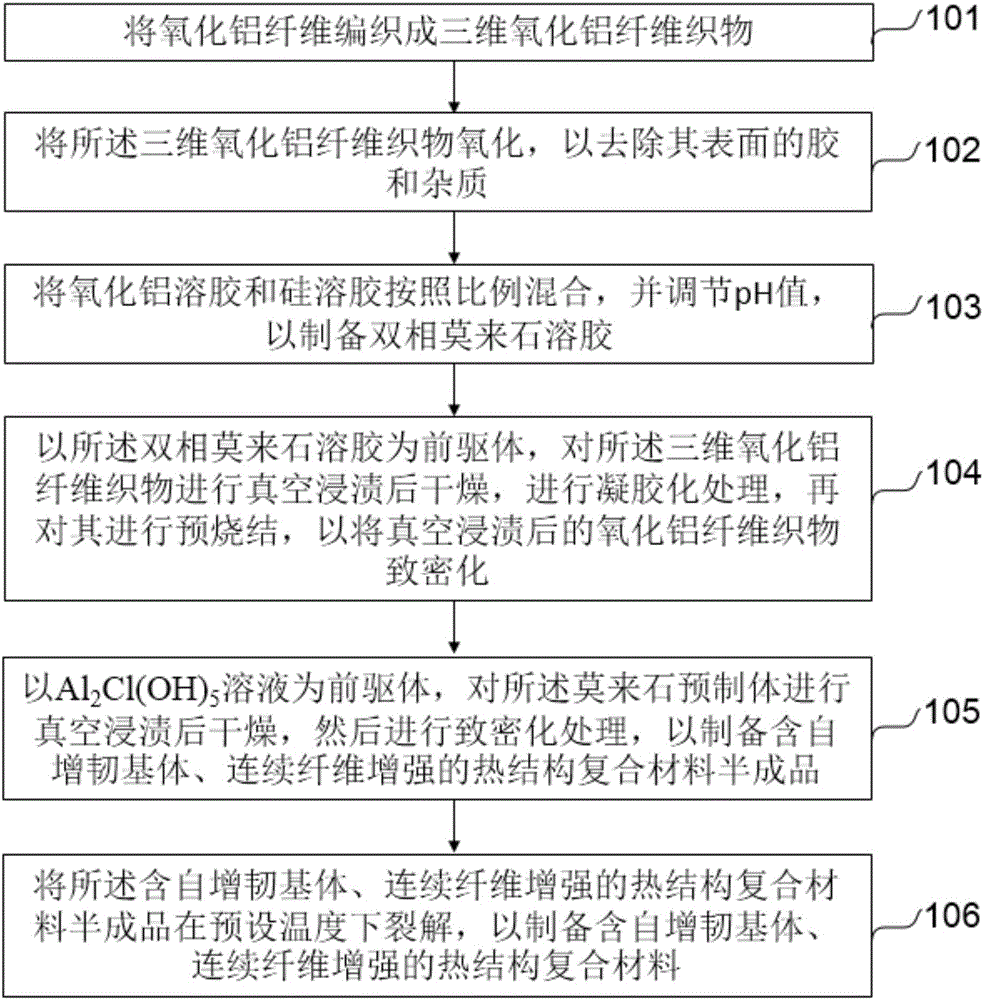

[0032] Such as figure 1 As shown, a method for preparing a self-toughening matrix and continuous fiber-reinforced thermal structural composite material according to an embodiment of the present invention includes the following steps:

[0033] S101: Weaving alumina fibers into a three-dimensional alumina fiber fabric. Specifically, using alumina long fibers as raw materials, alumina fiber fabrics with corresponding structures are prepared by weaving techniques such as three-dimensional four-way, three-dimensional five-way, three-dimensional six-way or three-dimensional orthogonal.

[0034] S102: Oxidizing the three-dimensional alumina fiber fabric to remove glue and impurities on its surface. Specifically, alumina fibers can be placed in a muffle furnace for high-temperature oxidation for a certain period of time, that is, glue and impurities on the surface can be removed.

[0035] S103: Mix the alumina sol and the silica sol in proportion, and adjust the pH value, so as to p...

Embodiment 1

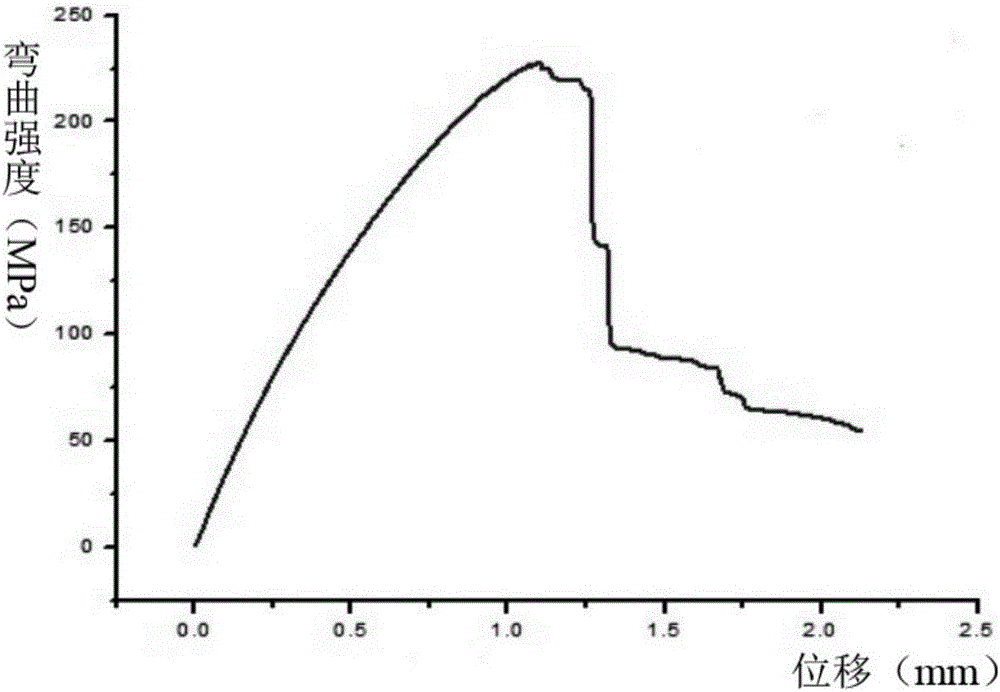

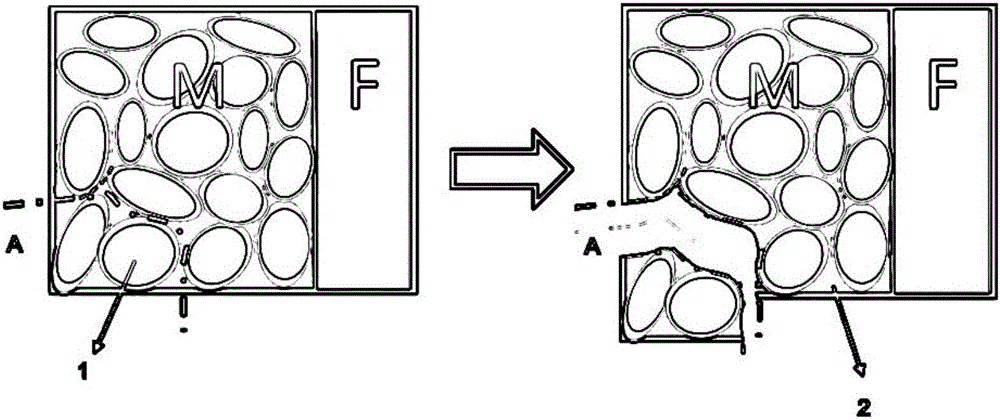

[0041] Example 1 provides a preparation process of a self-toughening matrix and continuous fiber-reinforced thermal structural composite material. The composite material uses 42% three-dimensional alumina fiber fabric as reinforcement, and porous mullite + alumina as reinforcement. The matrix is mainly composed of a mullite phase with a porous skeleton and a bonding phase and a dense alumina phase. Wherein in the matrix, the solid content of the porous mullite matrix is 60%, and the solid content of the alumina matrix is 40%. Specific steps are as follows:

[0042] (1) Preparation of fiber fabric: Alumina fiber fabric is used as raw material, and a three-dimensional orthogonal structure alumina fiber fabric is prepared by weaving process, and the volume fraction of alumina fiber fabric is controlled to be 42%.

[0043] (2) Pretreatment of alumina fiber fabric: put the alumina fiber fabric in step (1) into a muffle furnace, heat up to 550°C at 5°C / min in an air atmospher...

Embodiment 2

[0050] Example 2 provides a preparation process of a self-toughening matrix and continuous fiber-reinforced thermal structural composite material. The composite material uses 40% three-dimensional alumina fiber fabric as a reinforcement, and porous mullite + alumina as a The matrix is mainly composed of a mullite phase with a porous skeleton and a bonding phase and a dense alumina phase. Wherein in the matrix, the solid content of the porous mullite matrix is 75%, and the solid content of the alumina matrix is 25%. Specific steps are as follows:

[0051] (1) Preparation of fiber fabric: Alumina fiber fabric is used as raw material to prepare three-dimensional five-directional structure alumina fiber fabric by weaving process, and the volume fraction of alumina fiber fabric is controlled to be 40%.

[0052] (2) Pretreatment of alumina fiber fabric: put the alumina fiber fabric in step (1) into a muffle furnace, raise the temperature to 500°C at 5°C / min in an air atmosphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com