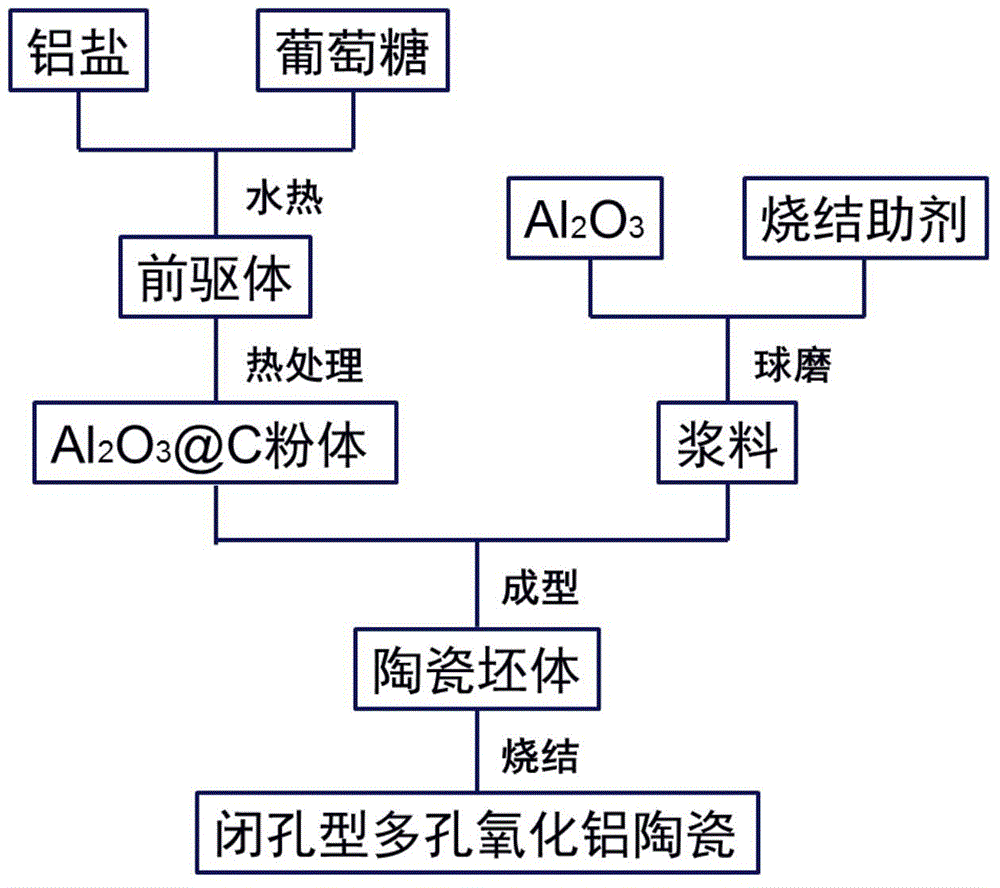

Method for preparing closed-pore porous heat-insulating alumina ceramic

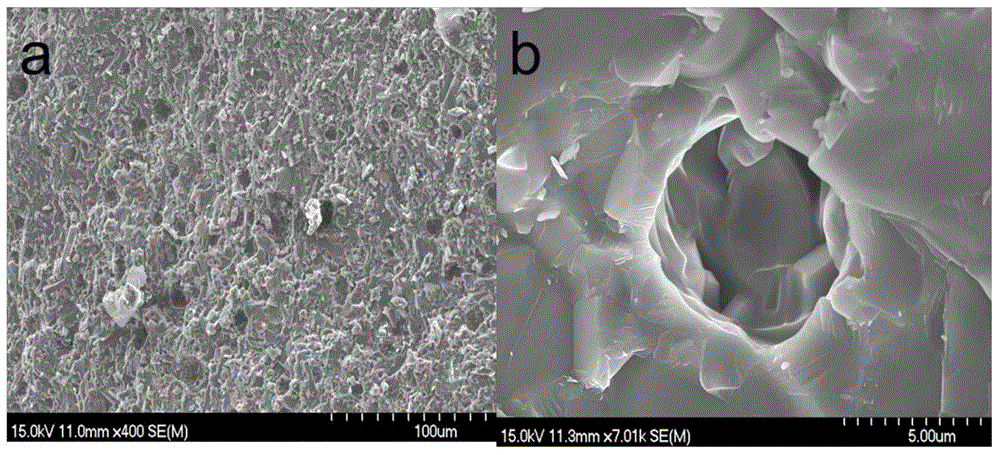

A porous alumina and closed-cell technology, which is applied in ceramic products, applications, household appliances, etc., can solve the problems of excessive additives, easy pulverization of products, complex porous ceramic process, etc., and achieve simple process and excellent heat insulation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) 4g of Al(NO 3 ) 3 9H 2 O and 10 g of glucose were dissolved in 140 mL of deionized water, stirred to a colorless and transparent solution, and placed in a 200 mL hydrothermal reaction kettle.

[0030] (2) Put the three sets of sealed hydrothermal reaction kettles in a blast drying oven, raise the temperature to 160°C, hold the heat for 16h, 20h and 24h respectively, and cool down to room temperature naturally after the reaction.

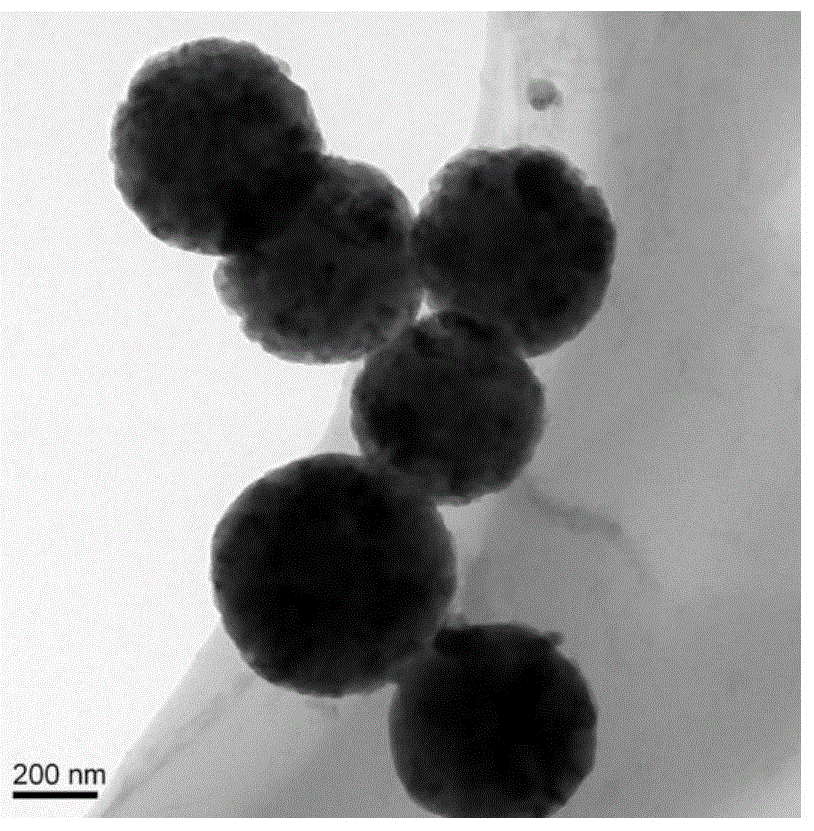

[0031] (3) Open the hydrothermal reaction kettle, the product is collected by suction filtration, and then washed several times with deionized water and absolute ethanol; the collected precipitate is dried in a drying oven at 60°C, and the black precipitate is placed in a muffle furnace for 900 ℃ heat treatment for 2h (argon atmosphere), to obtain the precursor A. The shape of the precursor is as figure 2 shown.

[0032] (4) Al 2 o 3 The Al 2 o 3 Slurry B.

[0033] (5) Place precursor A in slurry B (mass ratio A:B=1:99), mechani...

Embodiment 2

[0037] (1) 3g of Al 2 (SO 4 ) 3 18H 2 O and 5g of glucose were dissolved in 80mL of deionized water, stirred to a colorless and transparent solution, and placed in a 100mL hydrothermal reaction kettle.

[0038] (2) Put the three sets of sealed hydrothermal reaction kettles in a blast drying oven, raise the temperature to 180°C, hold the heat for 16h, 20h and 24h respectively, and cool down to room temperature naturally after the reaction.

[0039] (3) Open the hydrothermal reaction kettle, collect the product by suction filtration, and then wash several times with deionized water and absolute ethanol; dry the collected product in a drying oven at 60°C to obtain precursor A.

[0040] (4) Al 2 o 3 Powder, MgO and TiO 2 Mix in absolute ethanol at a mass ratio of 95:4:1 and place it in a planetary ball mill for 10 hours to prepare Al 2 o 3 Slurry B.

[0041] (5) Place precursor A in slurry B (mass ratio A:B=1:99), mechanically stir for 5 hours after ultrasonication for 30 m...

Embodiment 3

[0044] (1) 2g of Al(NO 3 ) 3 9H 2 O and 5g of glucose were dissolved in 60mL of deionized water, stirred to a colorless and transparent solution, and placed in a 100mL hydrothermal reaction kettle.

[0045] (2) Place the sealed hydrothermal reaction kettle in a blast drying oven, heat up to 160° C., keep it warm for 24 hours, and cool down to room temperature naturally after the reaction.

[0046] (3) Open the hydrothermal reaction kettle, the product is collected by suction filtration, and then washed several times with deionized water and absolute ethanol; the collected product is dried in a drying oven at 60°C to obtain a black precipitate; the black precipitate is placed in a muffle Precursor A was obtained by heat treatment at 1200° C. for 2 hours in a furnace (argon atmosphere).

[0047] (4) Al 2 o 3 Powder, MgO and TiO 2 Mix in absolute ethanol at a mass ratio of 90:9:1 and place it in a planetary ball mill for 10 hours to prepare Al 2 o 3 Slurry B.

[0048] (5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com