Patents

Literature

99 results about "Aluminum Oxide Paste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum Oxide (Alumina) Paste is a screen-printable, high-temperature dielectric coating paste used as an insulator in planar oxygen sensors. We can also manufacture alumina in the form of inks for use in 3D printing and other applications.

Aluminum oxide coated tool

InactiveUSRE41972E1Increase resistancePigmenting treatmentLiquid surface applicatorsHigh resistanceCarbon steel

There is provided a tool at least partly coated with at least two refractory layers of which one of the said layers is a fine-grained α-Al2O3-layer which is the top layer along the cutting edge-line and the other a TiCxNyOz- or a ZrCxNy-layer being the top layer on the clearance face. The coated tool exhibits excellent flank and crater wear and high resistance to flaking, particularly when used for machining of low carbon steel and stainless steel. Used cutting edges can easily be identified by the naked eye.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Method for coating high-nickel ternary material with aluminum oxide and boron oxide

InactiveCN108091830AEfficient removalUniform coverageCell electrodesBoron containingElectrical performance

The invention discloses a method for coating a high-nickel ternary material with aluminum oxide and boron oxide. The method includes the steps: 1) mixing an aluminum oxide precursor and water to prepare aluminum oxide coating liquid; 2) mixing the high-nickel ternary material with the aluminum oxide coating liquid to obtain aluminum oxide coating turbid liquid; 3) performing solid-liquid separation on the aluminum oxide coating turbid liquid, and drying obtained solid materials to obtain dry materials; 4) mixing the dry materials and a boron-containing compound and then sintering the dry materials and the boron-containing compound to obtain the finished high-nickel ternary material coated with the aluminum oxide and the boron oxide. According to the treatment method, washing and coating are combined, surface impurities of the high-nickel ternary material can be more effectively removed, coating is performed in a water phase, a coating can more uniformly cover the surface of the material, and further a positive electrode material with a good electrical performance is obtained. According to the coating method, process steps can be simplified, tempering temperature is reduced, tempering time is shortened, production cycle can be shortened, and production cost is saved.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

Aluminum soldering paste

InactiveCN102764938AEasy to apply and adhereAppropriate viscosityWelding/cutting media/materialsSoldering mediaOrganic solventSolder paste

The invention discloses an aluminum-based alloy soldering paste suitable for an aluminum-stainless steel and aluminum-aluminum alloy soldering connection batch production technology aiming at the requirement of high-efficiency soldering technology. The soldering paste consists of the following components by weight percent: 1) 50-65% of aluminum-based alloy soldering material powder, 2) 10-25% of fluoroaluminate soldering flux, 3) 3-10% of tackifier, 4) 2-10% of thickening agent, 5) 10-30% of organic solvent, and 6) 0.05-0.50% of stabilizing agent. The soldering paste provided by the invention has moderate viscosity and soldering flux which is in accurate proportion, and is extremely suitable for workpieces with irregular weld joint shapes and complex structures; the soldering paste can be very simply and conveniently coated on the part of a welding element, which is required for soldering joint; working procedures such as auxiliary positioning, soldering flux coating and brushing are not required like plate-shaped or silk-shaped soldering materials; the soldering production technology is simplified; the labor cost is lowered; and the product quality and production efficiency are improved.

Owner:江门市盈盛焊接材料科技有限公司

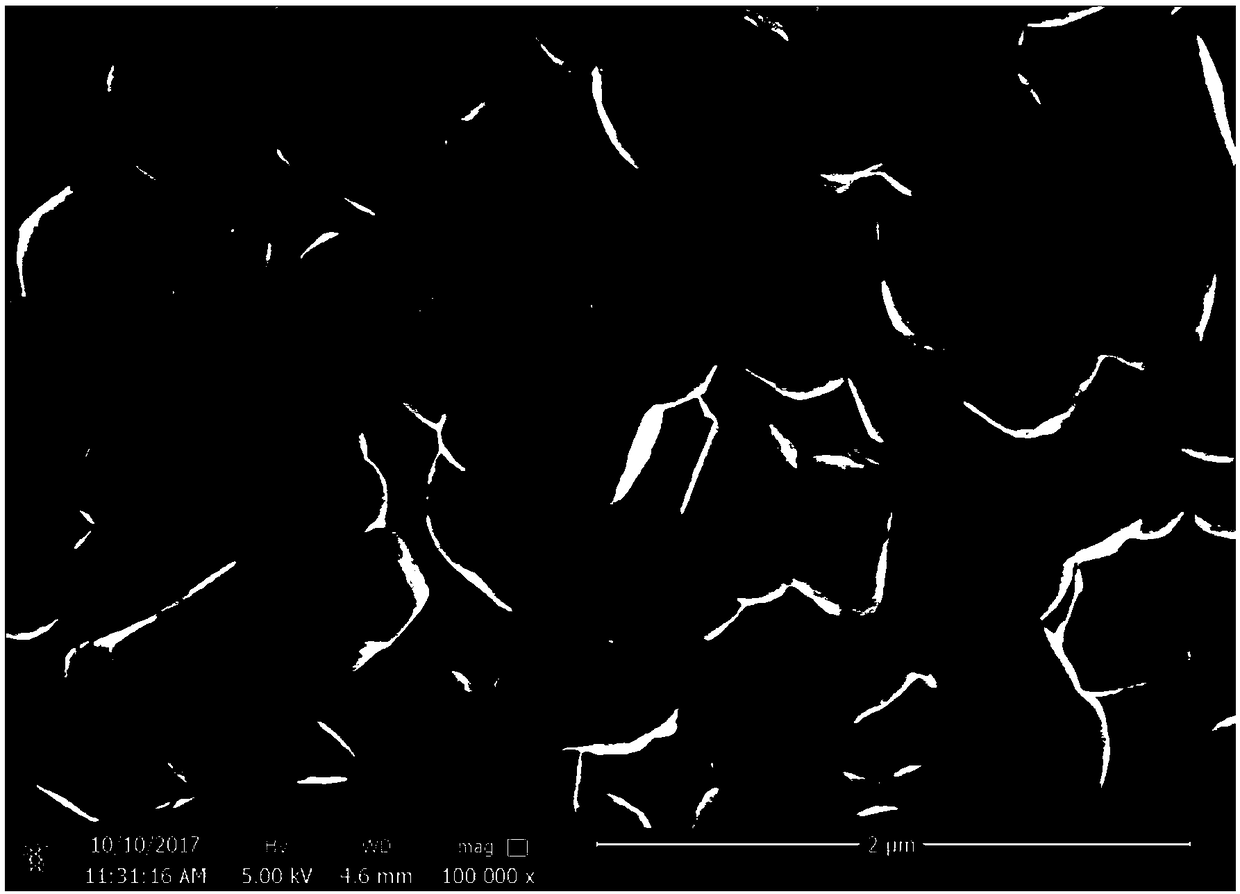

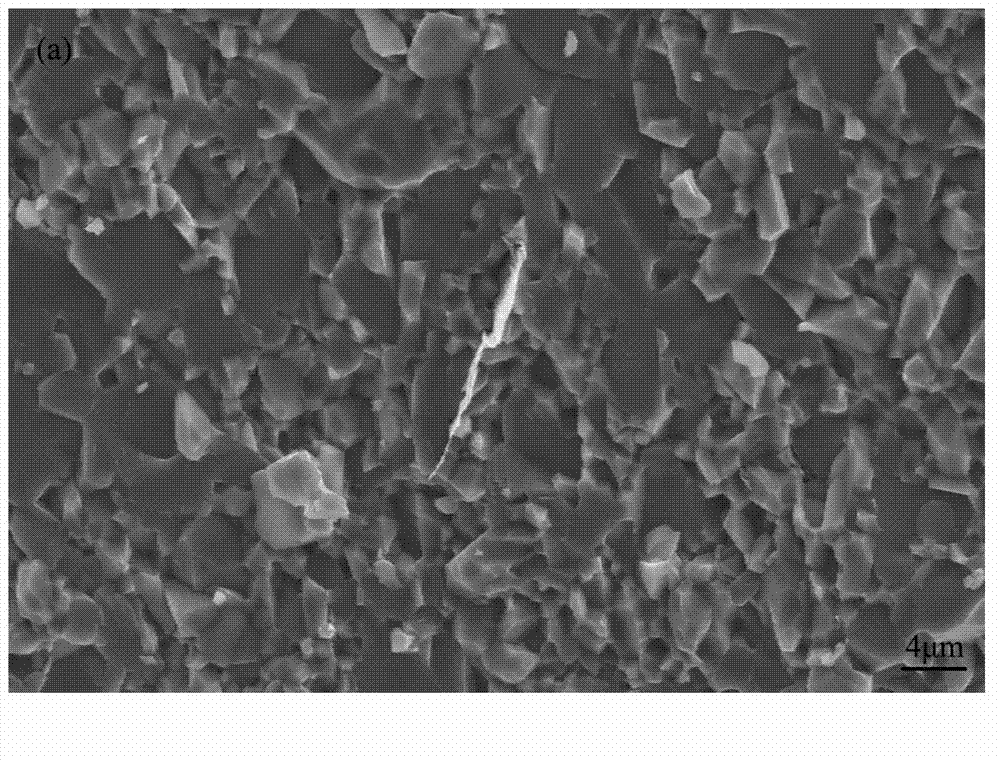

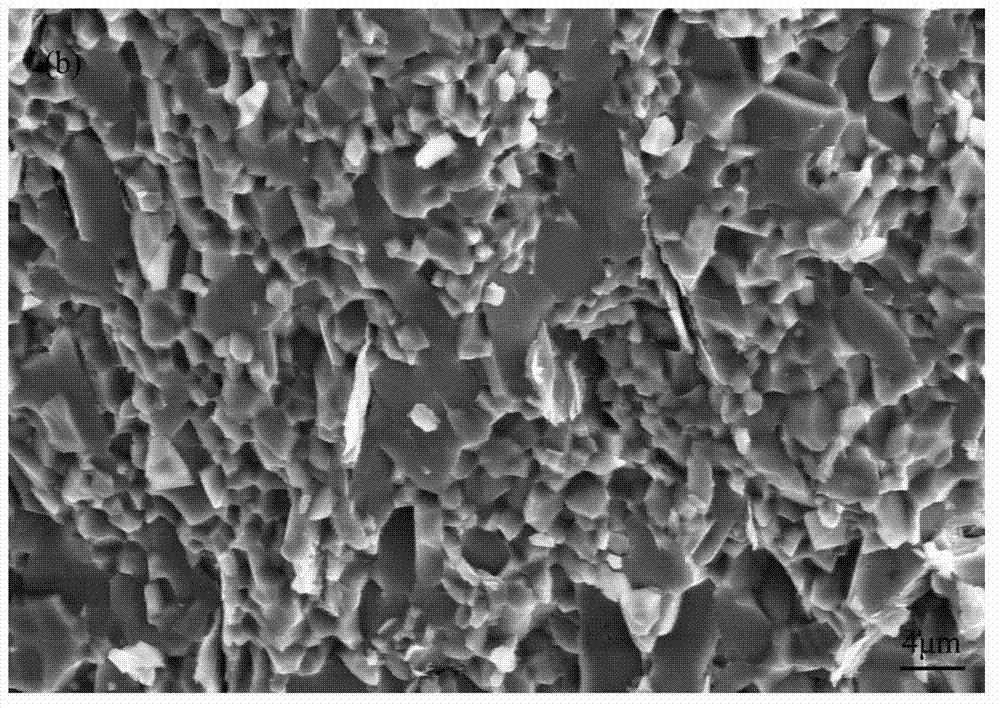

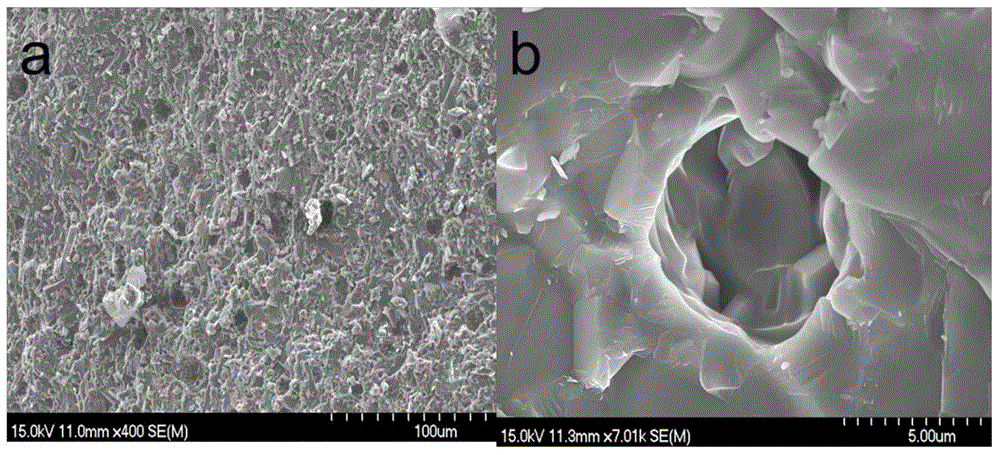

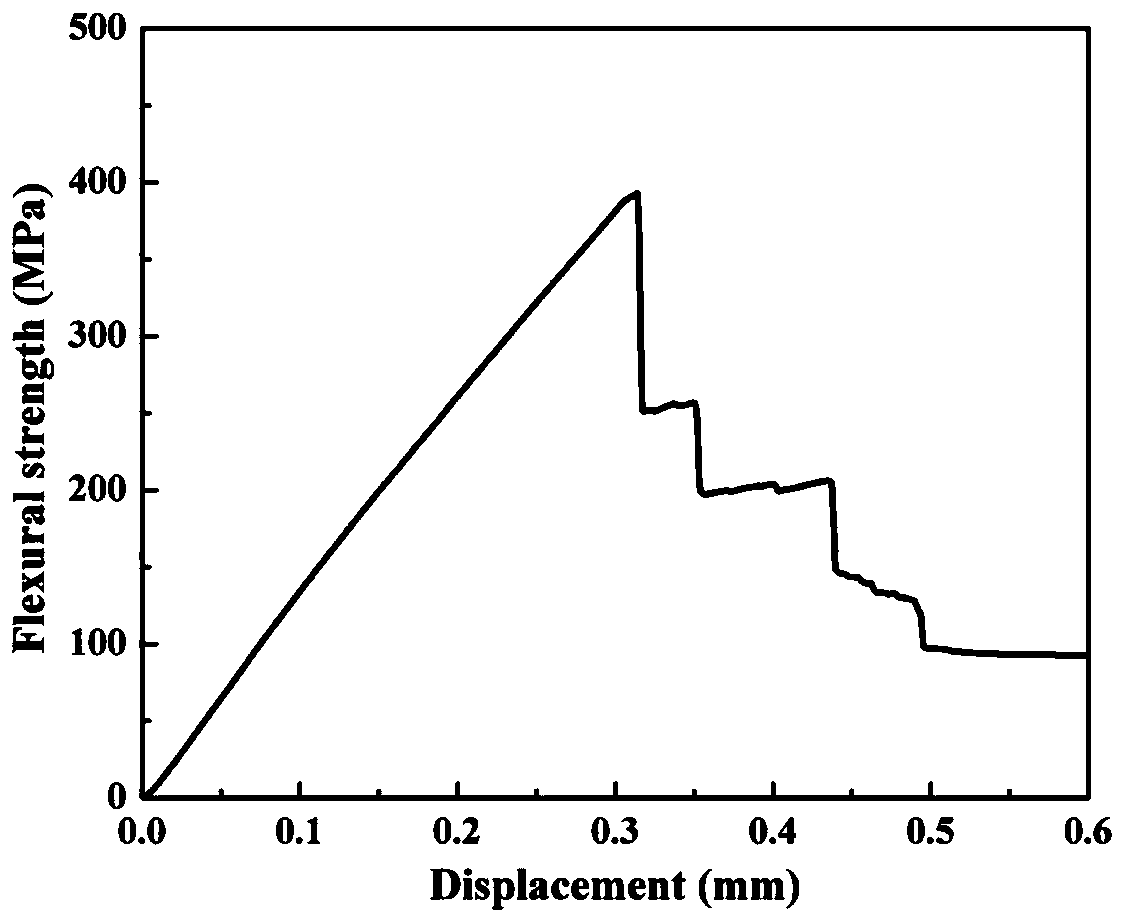

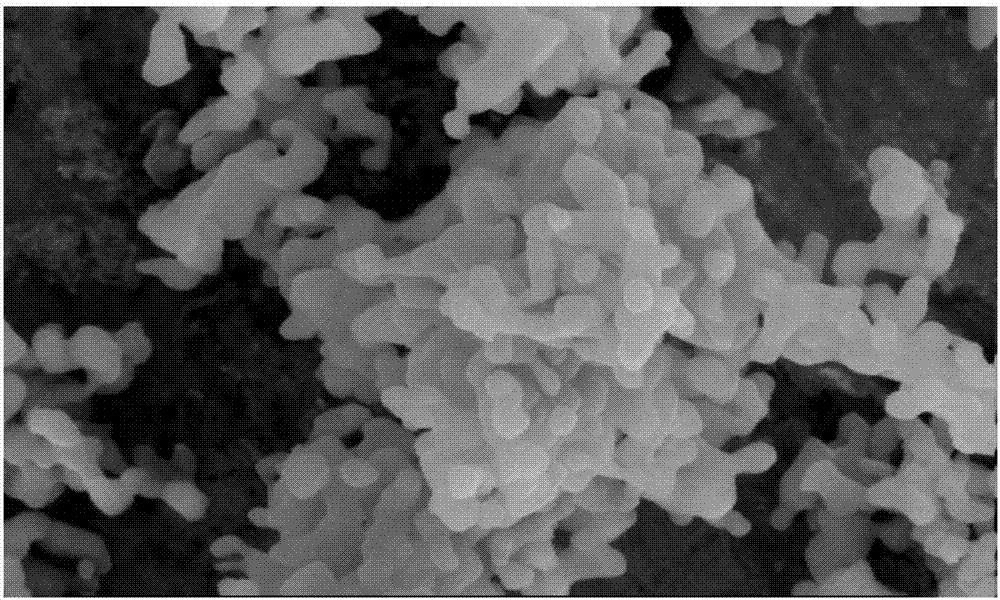

Preparation method of graphene-nanosheet-reinforced alumina ceramic

The invention discloses a preparation method of graphene-nanosheet-reinforced alumina ceramic, which uses graphene nanosheets as a reinforcing phase and alumina as a substrate. The method comprises the following steps: filling alumina powder into a planetary ball mill tank using alumina balls as milling balls, thereby obtaining required alumina slurry; dissolving graphene nanosheets and a dispersing agent sodium naphthalene sulfonate in alkaline distilled water to form a water solution, applying ultrasonic in a ultrasonic cleaning instrument, pouring into the alumina slurry, mixing and carrying out ball milling; and putting the powder mixture of the two substances in a graphite mold, carrying out hot pressed sintering in a multifunctional sintering furnace, keeping the temperature for some time, stopping heating, and naturally cooling to room temperature to obtain the finished product. The method disclosed by the invention is simple, and can easily implement large-scale production; and the product has the advantages of high strength, high toughness and lower cost.

Owner:SHANDONG UNIV

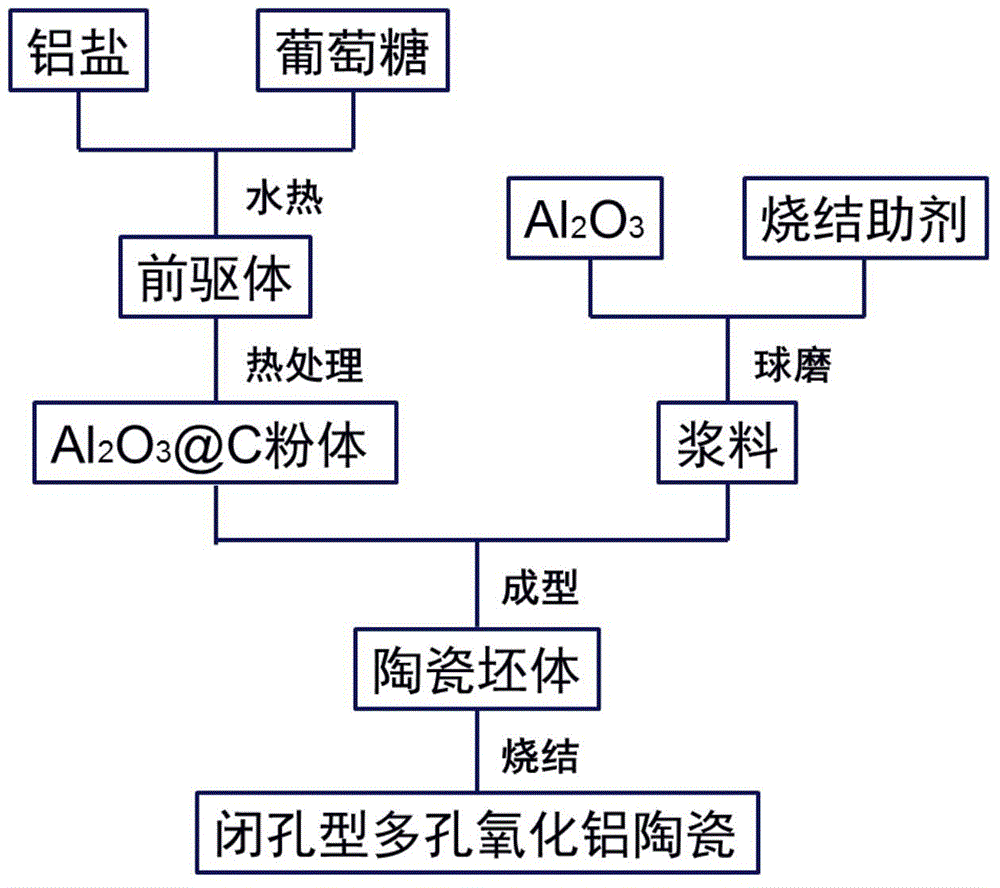

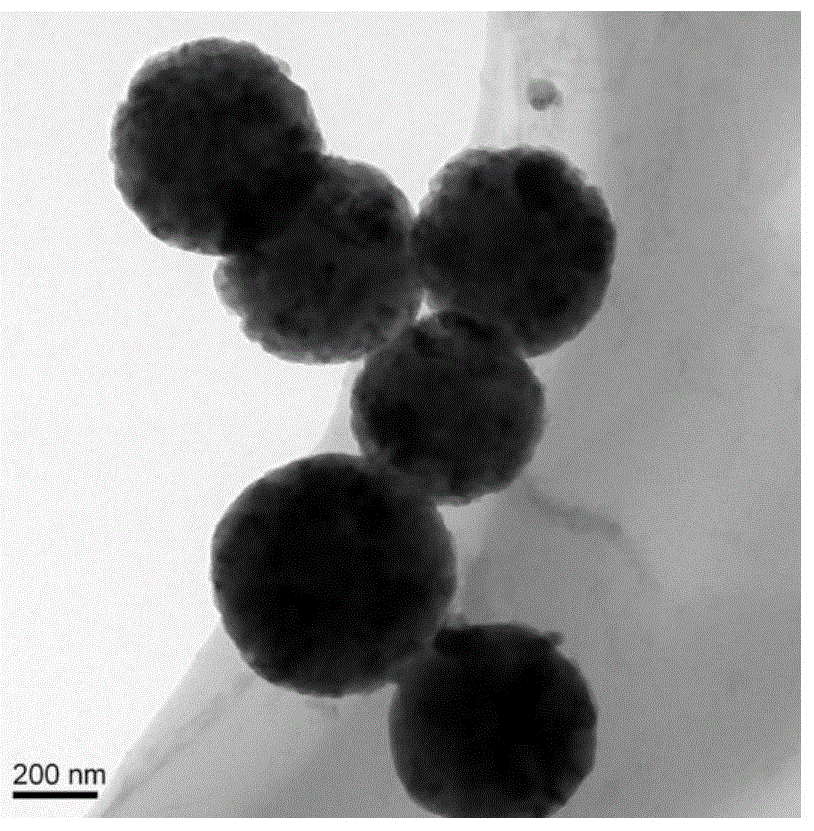

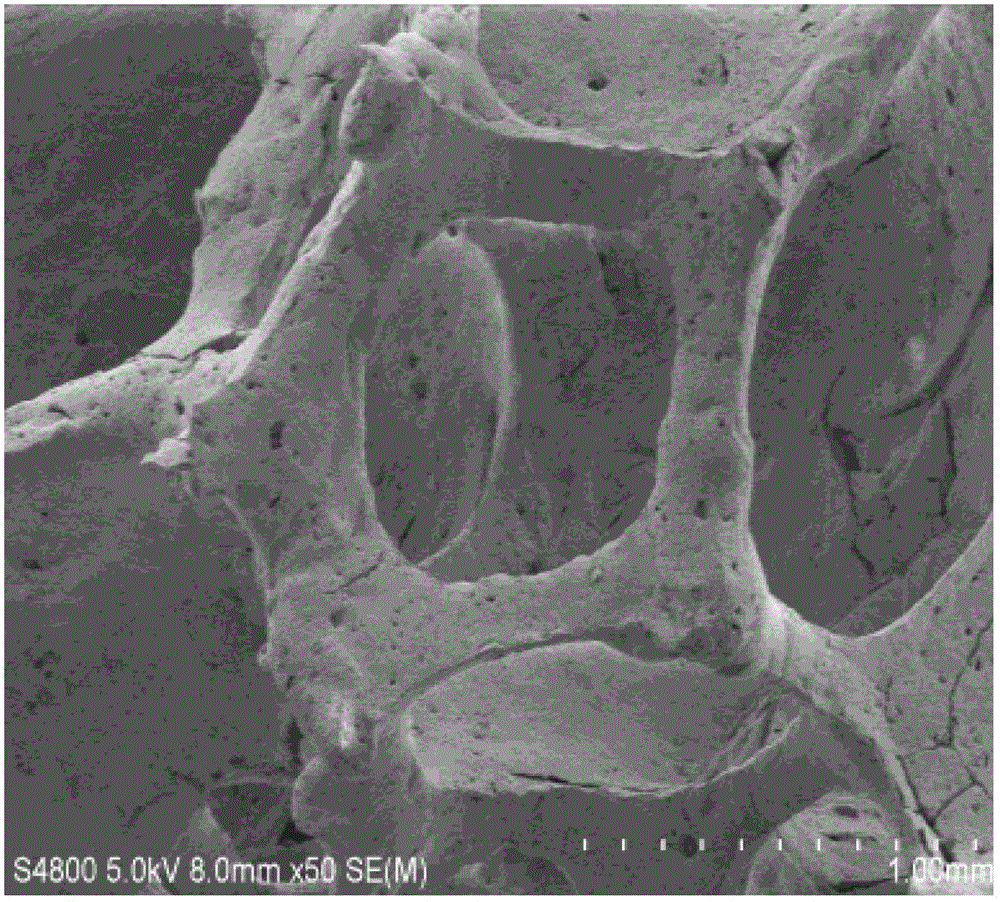

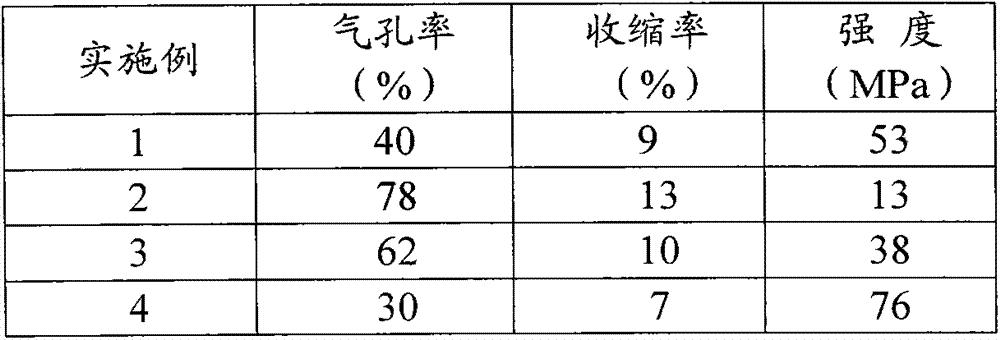

Method for preparing closed-pore porous heat-insulating alumina ceramic

The invention relates to a method for preparing a closed-pore porous heat-insulating alumina ceramic. According to the method, a powder which is prepared by adopting a hydrothermal synthesis method and is in a core-shell structure is added into alumina slurry as a pore forming agent to prepare an alumina ceramic, in the process of sintering an alumina ceramic blank, the carbon sphere as a core is removed under oxidization, the alumina layer as a shell and the alumina substrate are sintered compactly to form a magnesium-aluminium spinel together with a sintering additive, and the magnesium-aluminium spinel is pined into the grain boundary. Closed pores are introduced into the prepared alumina ceramic successfully, the rate of closed pores of the alumina ceramic is up to10-60%, and the rate of open pores is less than 5%. The thermal conductivity of the alumina ceramic is 0.1W / (m.K), and the usage temperature is over 1,400 DEG C. The method provided by the invention can be used for overcoming the defects that the existing process for preparing the porous ceramic by foaming is complex, too many additives are added, and the product is easy to powderize.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Prepn process of thermally conductive and electrically insulating silicone rubber composite material

The present invention discloses preparation process of thermally conductive and electrically insulating silicone rubber composite material. The preparation process includes the following steps: 1. mixing tabular alumina and alcohol solution of polyglycol to prepare alumina slurry or powder; 2. mixing high temperature sulfurized silicone rubber, alumina slurry, hydroxyl silicone oil and vulcanizer in certain weight proportion; 3. sulfurizing and forming through molding at certain temperature to form required product; and 4. the secondary sulfurizing of the product in a forced air drying tank. The composite material of the present invention has raised thermal conductivity coefficient, high compatibility between alumina and silicone rubber, and low cost.

Owner:LIANYUNGANG LIANLIAN CHEM CO LTD

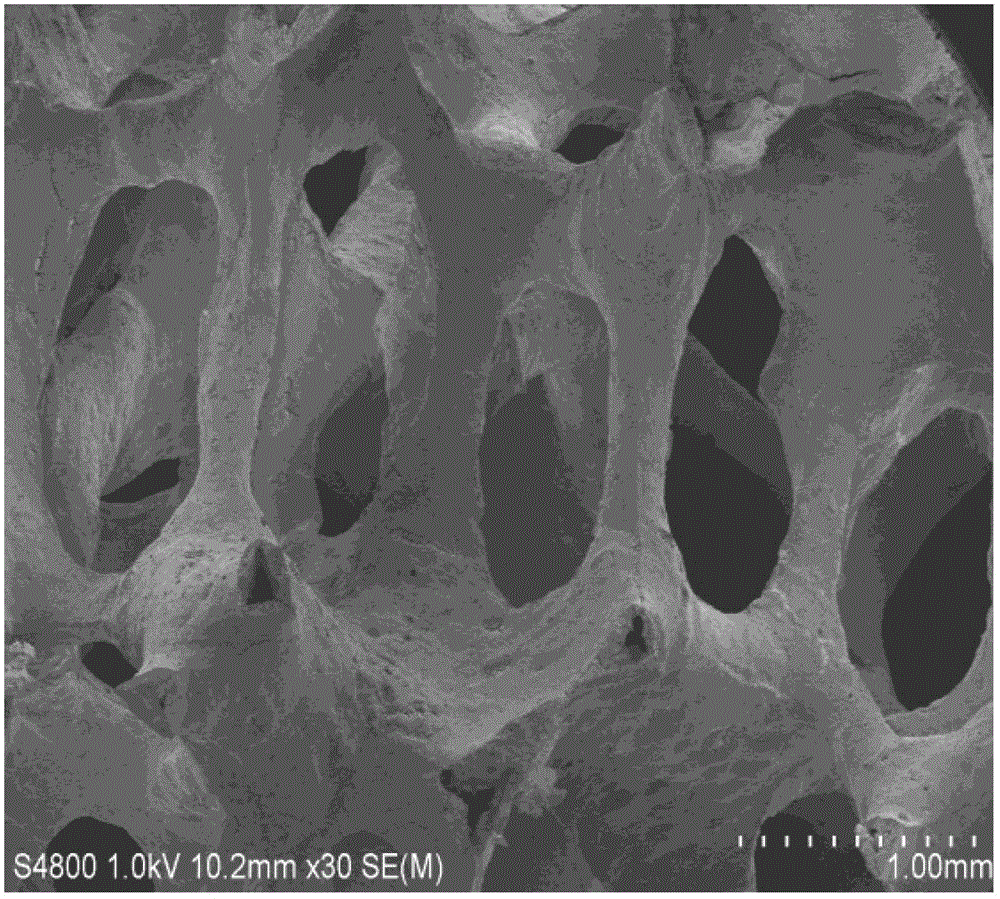

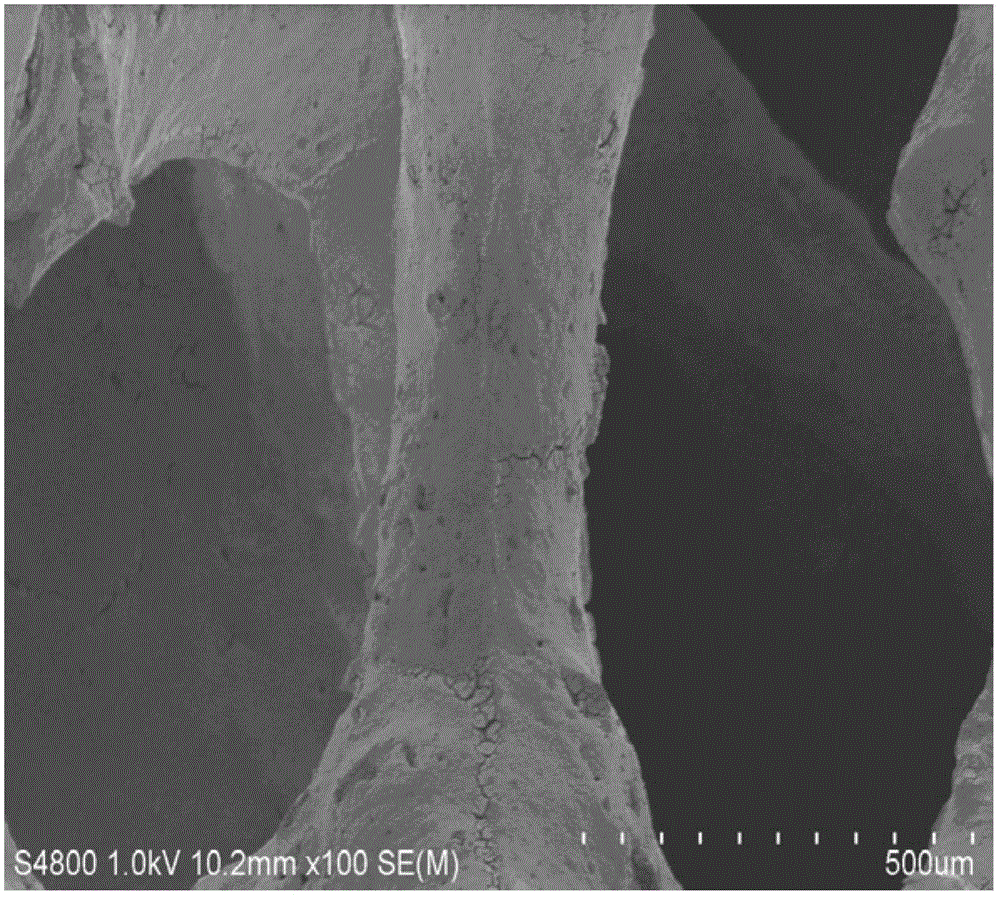

Process for preparing TiO2 (titanium dioxide) film on aluminum-oxide foamed ceramic

InactiveCN102744049AIncrease the effective areaImprove acid and alkali corrosion resistancePhysical/chemical process catalystsIndustrial waste waterPtru catalyst

The invention discloses a process for preparing a TiO2 (titanium dioxide) film on aluminum-oxide foamed ceramic. The process adopts a concrete implementation scheme that coating aluminum oxide slurry is coated on a foam rib by dipping and extruding, then foam is burned up, and finally, the aluminum-oxide foamed ceramic with high porosity is obtained in a high-temperature sintering manner; Ti collosol is uniformly coated on a pore wall of an aluminum-oxide foamed ceramic carrier by negative-pressure infiltration; and the TiO2 film which is uniformly and continuously distributed on the pore wall of the aluminum-oxide foamed ceramic is prepared by drying and thermal treatment. According to materials disclosed by the invention, the porous aluminum-oxide foamed ceramic serves as a base body; meanwhile, the base body has good resistance to acid and alkali corrosion due to the stable chemical properties of the Al2O3 (aluminum oxide) ceramic; in addition, the carrier material has good high-temperature resistance and oxidation resistance by virtue of a high-melting point of the Al2O3 ceramic. These properties of the materials well meet the requirements on properties of catalysts and the carrier which are used for purifying industrial wastewater, domestic sewage and toxic waste gas in extremely serious corrosive environments.

Owner:CHANGAN UNIV

Preparation method of low-cost and high-efficiency aluminum oxide fiber reinforced aluminum oxide composite material

The invention belongs to the technical field of preparation of continuous fiber reinforced ceramic based composite materials, and particularly discloses a preparation method of a low-cost and high-efficiency aluminum oxide fiber reinforced aluminum oxide composite material. The method comprises the following specific steps: firstly, preparing a stable aluminum oxide slurry, then brushing the aluminum oxide slurry on degummed aluminum oxide fiber cloth, molding after mould pressing, drying to obtain an aluminum oxide fiber reinforced aluminum oxide composite material rough blank, and finally, sintering to obtain the aluminum oxide fiber reinforced aluminum oxide composite material. The preparation method provided by the invention has the characteristics of simple process and short preparation period, and the prepared aluminum oxide fiber reinforced aluminum oxide composite material has excellent high-temperature mechanical properties and thermal stability.

Owner:NAT UNIV OF DEFENSE TECH

Method for preparing slurry containing aluminum oxide

ActiveCN101209425AGuaranteed solid contentLow viscosityCatalyst carriersCatalyst protectionSlurryBinding force

The invention provides a preparation method used for preparing sizing agent containing alumina of auto-exhaust purification catalyst, which comprises that pseudo-boehmite, TiO2, oxygen storage materials, active metal nitrate and surfactant are mixed evenly with water, thus obtaining the sizing agent containing the alumina; wherein, the method also comprises that acetate solution is added into the sizing agent containing the alumina so as to adjust viscosity of the sizing agent. The preparation method provided by the invention used for preparing the sizing agent containing the alumina of auto-exhaust purification catalyst has good effect of coating and more one-time loading weight, and a coating layer made of the prepared sizing agent has good binding force with matrix and good resistance to heat shocks, and crazes and drops off uneasily.

Owner:BYD CO LTD

Preparation method of alumina pellets through hot oil column moulding

ActiveCN105502447AMeet strength requirementsSimplified post-processing stepsCatalyst carriersAluminium oxides/hydroxidesSlurryStone dust

The invention provides a preparation method of alumina pellets through hot oil column moulding. The preparation method comprises the following steps: preparing an alumina suspension liquid from pseudo-boehmite powder, which is produced by an alkoxyl aluminium hydrolysis method, a first gelatinizing agent, and water, then adding an acid solution into the alumina suspension liquid to obtain alumina slurry, adding a second gelatinizing agent into the alumina slurry, evenly mixing, then dropwise adding alumina slurry into a hot oil column so as to form alumina pellets, directly collecting alumina pellets from the bottom end of the hot oil column, washing the collecting aluminum pellets by water, drying, and burning. The provided method has the advantages that the post treatment technology is simplified and the method can be applied to large scale industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

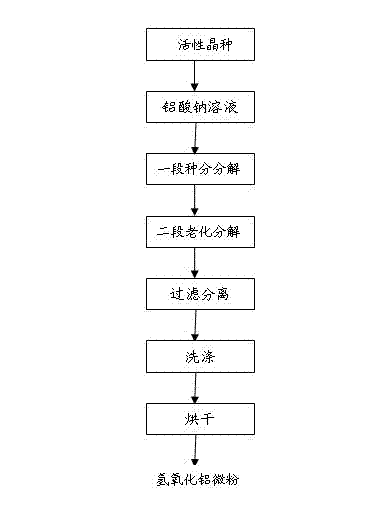

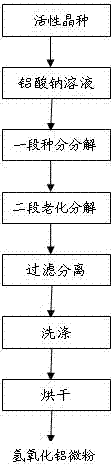

Method for preparing aluminum hydroxide micro-powder with low oil absorption rate

InactiveCN102336425ALow extrusion rateIncrease extrusion rateAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationDecompositionSodium aluminate

The invention provides a method for preparing aluminum hydroxide micro-powder with a low oil absorption rate, which comprises the following steps of: taking a sodium aluminate solution as a raw material, adding a ground active seed crystal to the raw material, sorting and decomposing ultrathin aluminum hydroxide pulp, continuously heating the ultrathin aluminum hydroxide pulp for aging and decomposition, and then drying to obtain the aluminum hydroxide micro-powder with a low oil absorption rate. Sequential decomposition and aging are increased on the basis of the original technical processes for preparing the aluminum hydroxide micro-powder with the sodium aluminate solution, and the prepared aluminum hydroxide micro-powder has a low oil absorption rate and a high extrusion speed. The operation process is simple and feasible, and the product quality is obviously improved.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

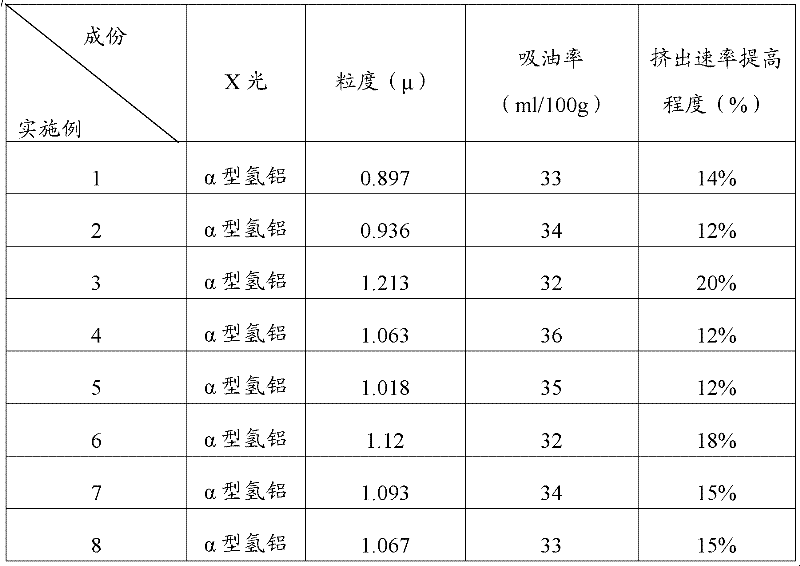

Oxide ceramic material, ceramic substrate employing the same, ceramic laminate device, and power amplifier module

An oxide ceramic material is provided to contain aluminum oxide as a principal component, and at least one selected from A and B shown below as an auxiliary component: A: niobium oxide and copper oxide B: copper oxide, titanium oxide, and silver oxide. With this, it is possible to provide an oxide ceramic material having sinterability at a low temperature and a high heat conductivity, as well as a ceramic substrate, a ceramic laminate device, and a power amplifier module employing the same.

Owner:PANASONIC CORP

Imitating metal fluorocarbon coatings using aluminium powder slurry after surface treatment

InactiveCN101397434AExcellent pinking and discolorationSolve the phenomenon of blackening and powder loss due to insufficient alkali resistanceInorganic pigment treatmentCoatingsSlurrySolvent

A pseudo-metallic fluorocarbon paint adopts polymer or inorganic substance-coated aluminum paste, solving the problems of darkening and peeling caused by insufficiency of alkali resistance of untreated aluminum powder paste used in the prior art. The pseudo-metallic fluorocarbon paint comprises composition I including hydroxyl fluorocarbon resin, the polymer or inorganic substance-coated aluminum paste, wetting and dispersing agent, cellulose acetate butyrate, anti-settling sagging agent and solvent; and composition II, hexamethylene diisocyanate (HDI) trimer, wherein, the proportion of composition I to composition II is 16-19:1. The pseudo-metallic fluorocarbon paint prepared by using such compositions including polymer or inorganic substance-coated aluminum paste, in such a proportion, has the advantages of extraordinary alkali and color-changing resistance, so in alkaline environment, aluminum powder erosion changes seldom occur. When being applied to building walls for coating protection, the paint has excellent color retention performance.

Owner:SKSHU PAINT

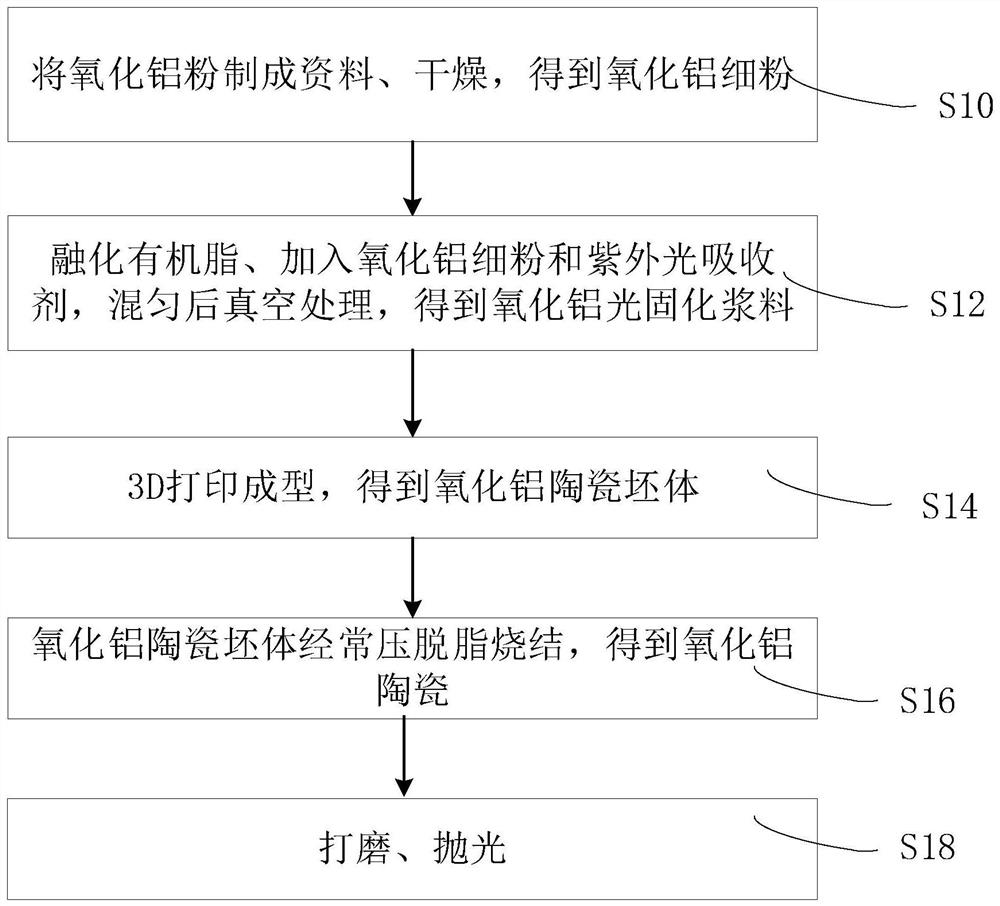

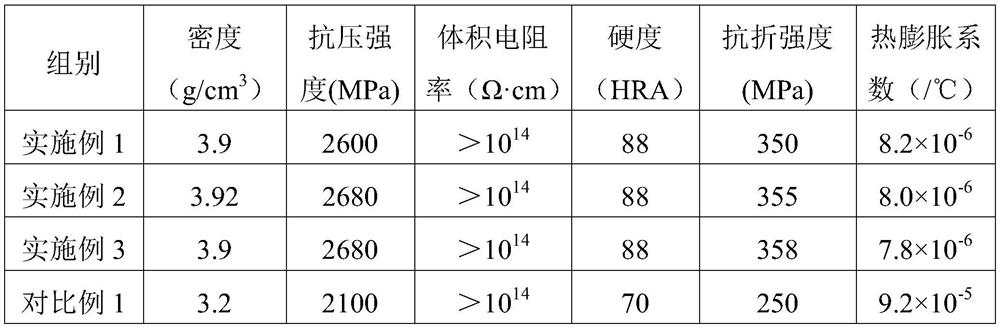

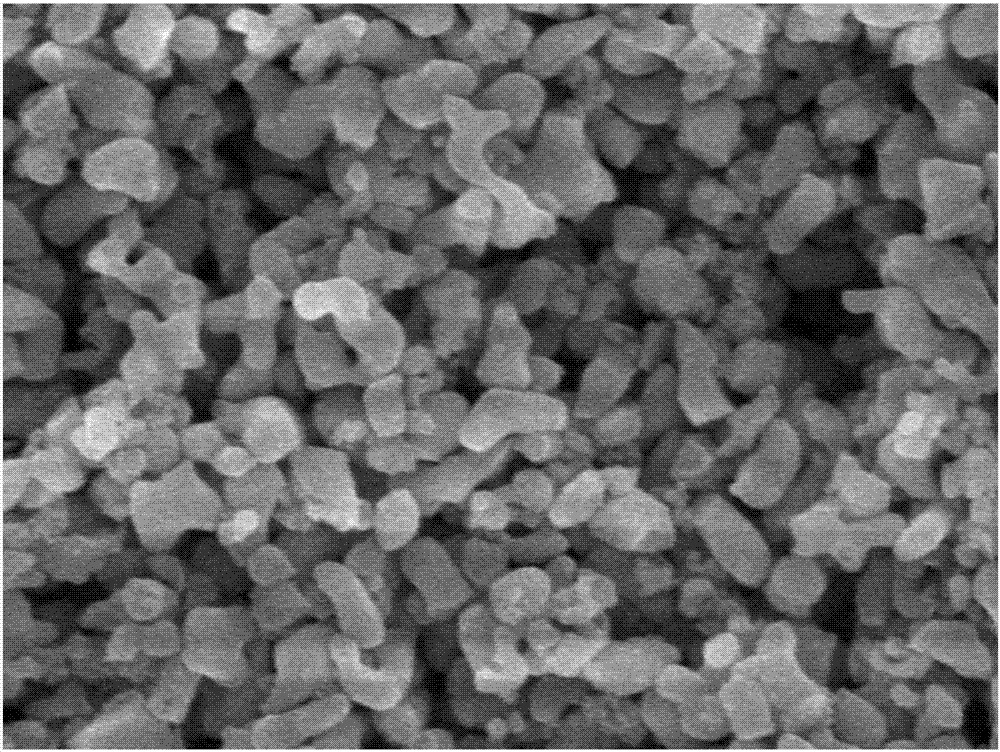

Aluminum oxide ceramic and preparation method thereof

ActiveCN111807823AReduce cost inputLower sintering temperatureAdditive manufacturing apparatusOxide ceramicHigh density

The invention discloses aluminum oxide ceramic and a preparation method thereof. The method comprises the following steps that preparing aluminum oxide powder into a slurry to obtain an aluminum oxideslurry with the particle size D90 smaller than or equal to 0.8 micrometer; drying the aluminum oxide slurry to obtain aluminum oxide fine powder; wherein the content of aluminum oxide in the aluminumoxide powder is greater than or equal to 99wt%; heating and melting a photosensitive resin, a first dispersing agent and a lubricating agent, adding the aluminum oxide fine powder and an ultravioletlight absorber, uniformly mixing, and vacuumizing to obtain an aluminum oxide photocuring slurry; carrying out 3D printing molding on the aluminum oxide photocuring slurry to obtain an aluminum oxideceramic green body; degreasing and sintering the aluminum oxide ceramic green body under normal pressure to obtain aluminum oxide ceramic; wherein the normal-pressure degreasing and sintering conditions are as follows: the temperature is increased to 550-650 DEG C at the rate of (0.2-1) DEG C / min, the temperature is kept for 6-10 hours, then the temperature is increased to 1200-1400 DEG C at the rate of (1-5) DEG C / min, and the temperature is kept for 5-8 hours. The aluminum oxide ceramic prepared by the method has high density and good mechanical properties, and can meet the requirements of semiconductor equipment on ceramic materials.

Owner:GEMCH MATERIAL TECH SUZHOU

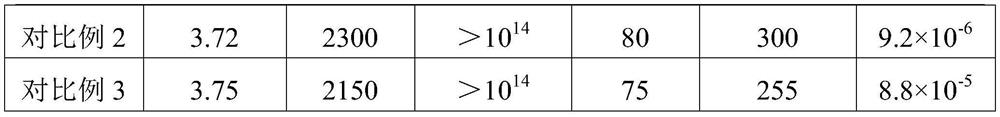

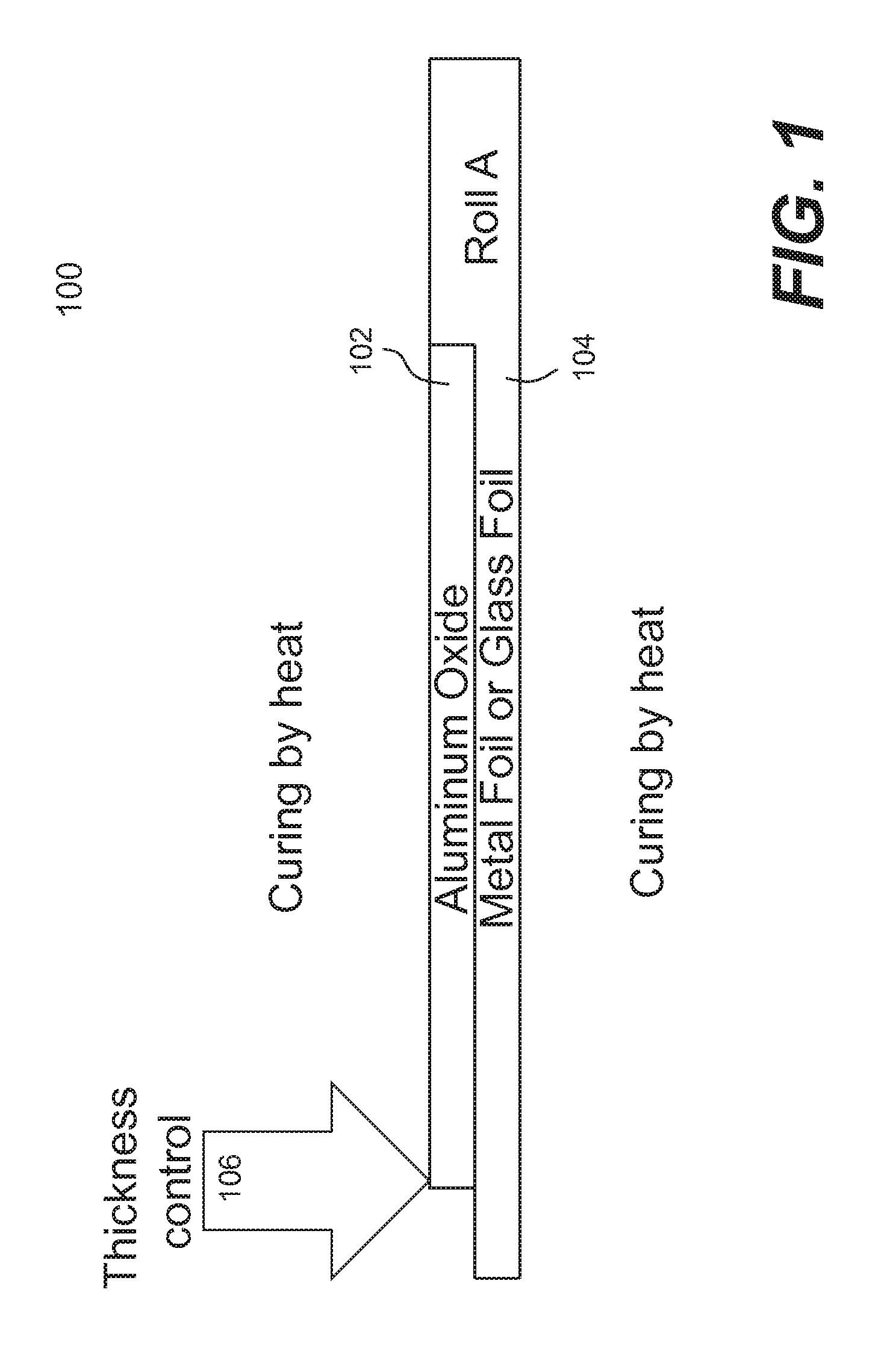

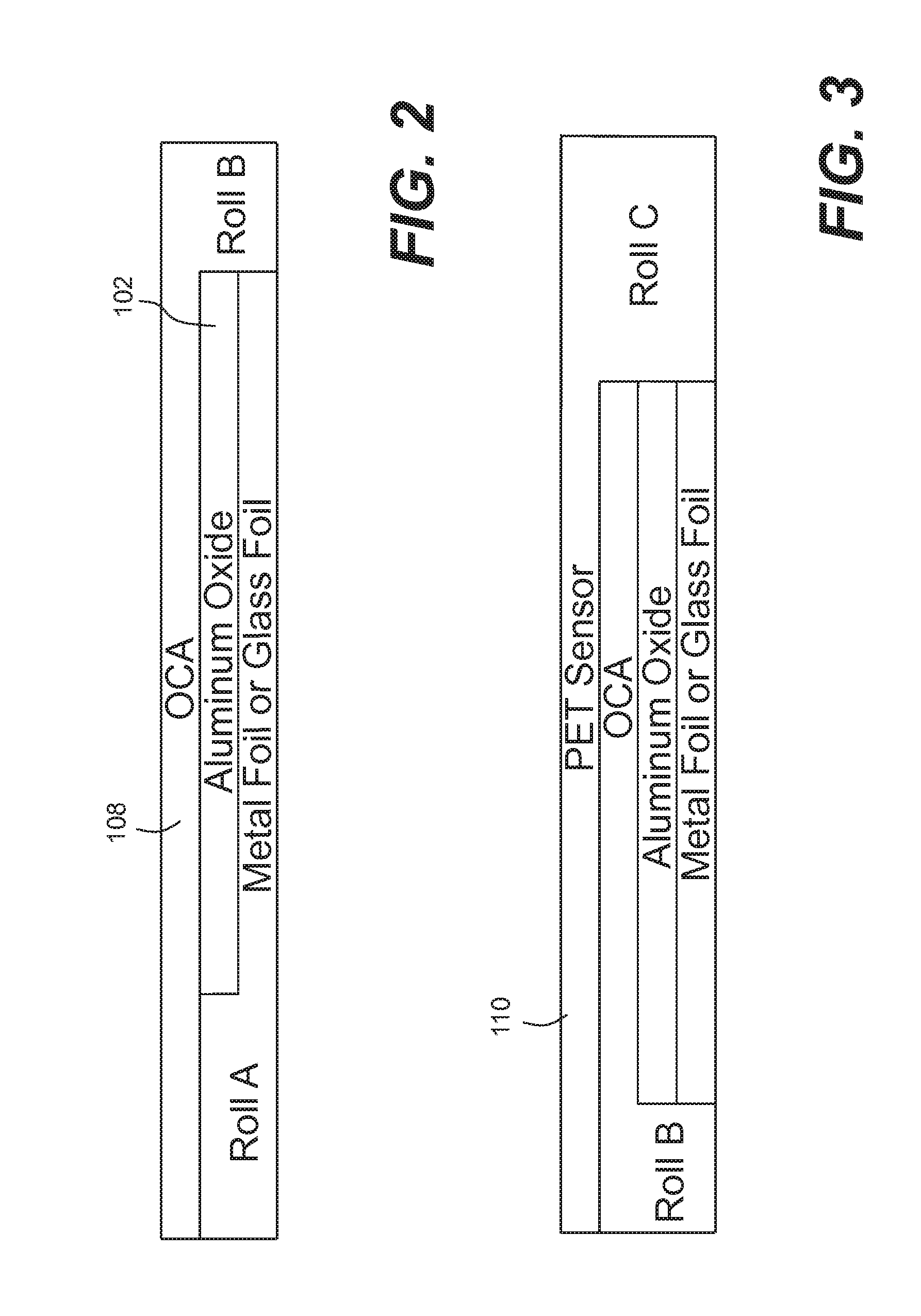

Single flexible cover for touch screen

ActiveUS20150324042A1Easily turn regular displaySynthetic resin layered productsElectrical equipmentPolyethylene terephthalateAdhesive

Techniques for manufacturing a single flexible cover to equip a display with touch screen capabilities are disclosed. The single flexible cover is easy to be applied to nearly all displays and maintains its durability on the displays. According to one aspect of the present invention, the single flexible cover includes at least three layers, a crystalline aluminum oxide layer, a polyethylene terephthalate (PET) film sensor stacking layer and an adhesive layer to bond the PET film sensor stacking layer to the crystalline aluminum oxide layer. The single flexible cover is produced by a manufacturing process including processes comprises: providing a foil as a substrate; coating the substrate with a set of materials including primarily aluminum oxide; curing the set of materials with heat to cause the set of materials to be crystallized to form the crystalline aluminum oxide layer; bonding the PET film sensor stacking layer to the crystalline aluminum oxide layer with optically clear adhesive (OCA); and applying anti-etching ink to top of the PET film sensor stacking layer. Then the foil and anti-etching ink are removed.

Owner:HU DARWIN

Aluminium oxide slurry for surface passivation for crystalline silicon solar cell and preparation method for passivating film

InactiveCN105489670AImprove efficiencyPromote absorptionFinal product manufacturePhotovoltaic energy generationScreen printingSilicon solar cell

The invention discloses aluminium oxide slurry for surface passivation for a crystalline silicon solar cell and a preparation method for a passivating film. The slurry comprises the following components in parts by weight: 65-70 parts of aluminium oxide sol, 10-13 parts of complexing agent, 3-5 parts of cross-linking agent, 1-3 parts of thickening agent and 0.1-0.3 parts of flatting agent. A base material is coated with the aluminium oxide sol through a silk-screen printing mode to form a coating layer with a predetermined pattern; then the coating layer is dried and sintered to form a passivation layer with the predetermined pattern on the base material. The preparation method is simple, and all the preparation processes can be completed by using laboratory equipment; the aluminium oxide passivating film is manufactured on the back of a cell piece, so that the absorption on long-wavelength light of the cell is improved, the back surface compound of the cell is lowered, and the efficiency of the solar cell is improved.

Owner:何晨旭 +1

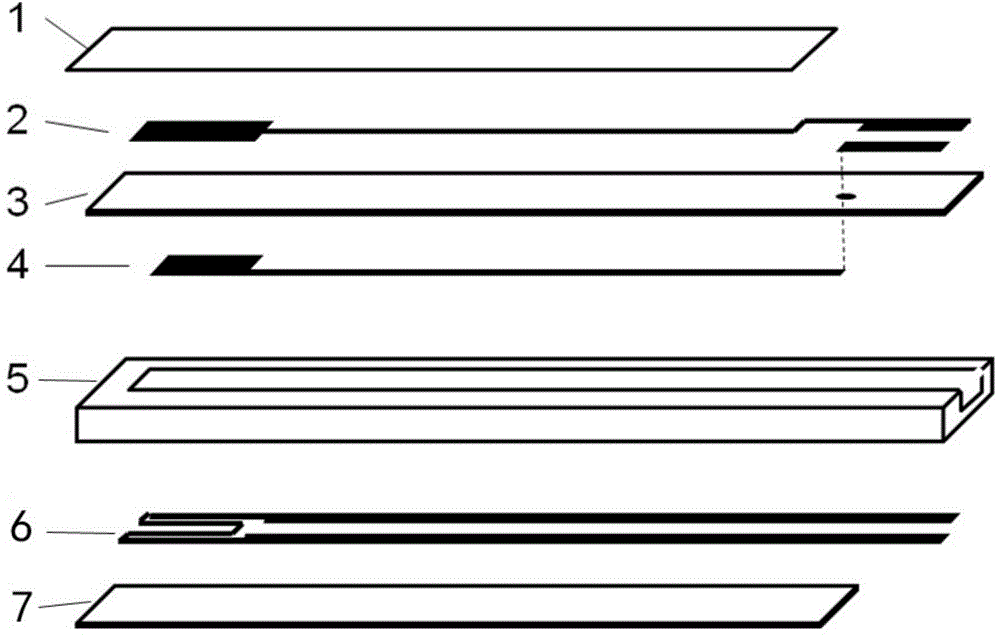

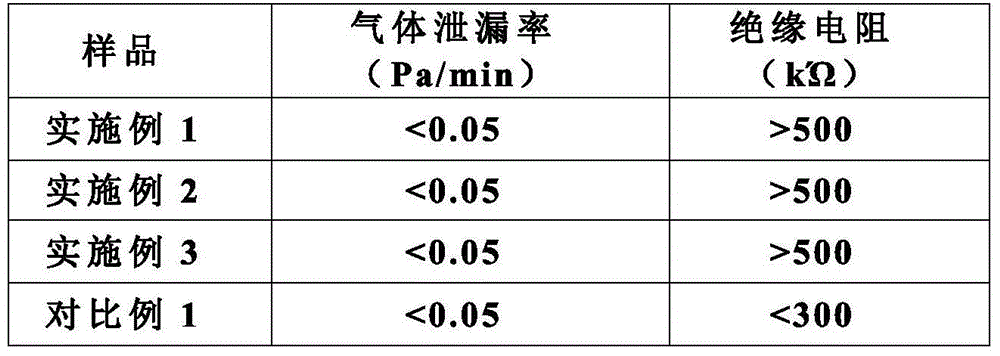

Preparation method of novel chip-type oxygen sensor

InactiveCN104569108APerformance impactImprove insulation performanceMaterial analysis by electric/magnetic meansOxygen sensorSilicon oxide

The invention discloses a preparation method of a novel chip-type oxygen sensor. The preparation method comprises the following steps: manufacturing a zirconium oxide sensor matrix, printing an outer electrode Pt and an inner electrode Pt on the upper surface and the lower surface of the zirconium oxide sensor matrix, printing a porous protection layer on the outer electrode, drying and sintering; manufacturing a reference matrix by mixing aluminum oxide powder and silicon oxide or magnesium oxide powder, manufacturing a recessed cavity which is used as an air channel on the reference matrix and sintering; printing tungsten resistance paste on the bottom surface of the reference matrix, printing aluminum oxide paste on the surface of a heating electrode, drying and sintering; covering the reference matrix with a sensitive layer, coating high-temperature ceramic glaze between the sensitive layer and the reference matrix and sintering. According to the preparation method of the novel chip-type oxygen sensor, the structure of the chip-type oxygen sensor is simplified, the production cost is reduced and the insulating property between the heating electrode and the sensitive layer is improved ,so that the property of the chip-type oxygen sensor is improved.

Owner:KUNSHAN SENSONOR SENSING TECH

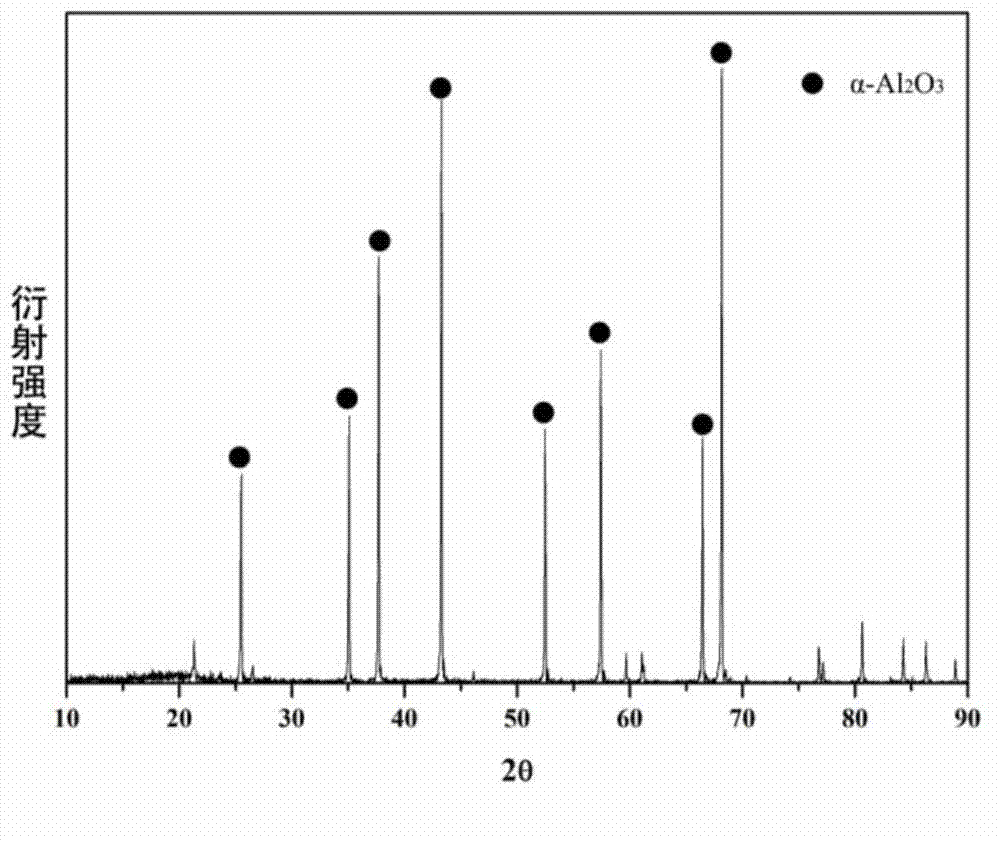

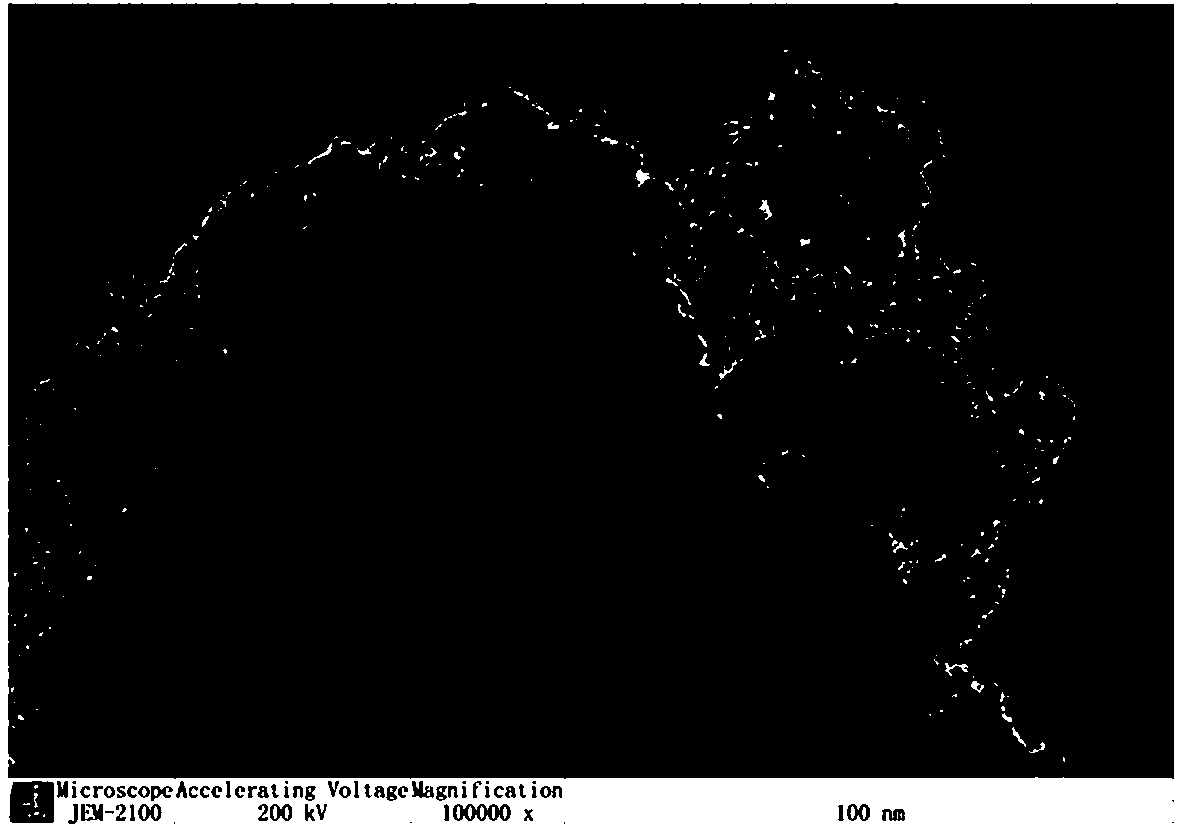

Nanoporous ultrafine alpha-alumina powders and sol-gel process of preparing same

ActiveUS7422730B2High rateHigh surface finishNanotechOther chemical processesSlurryAluminum Oxide Paste

The present invention provides α-alumina powders comprising α-alumina particles of which at least 80% of the α-alumina particles have a particle size of less than 100 nm. The invention also provides slurries, particularly aqueous slurries, which comprise α-alumina powders of the invention. The invention further provides methods of manufacturing α-alumina powders and α-alumina slurries of the invention and methods of polishing using same.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

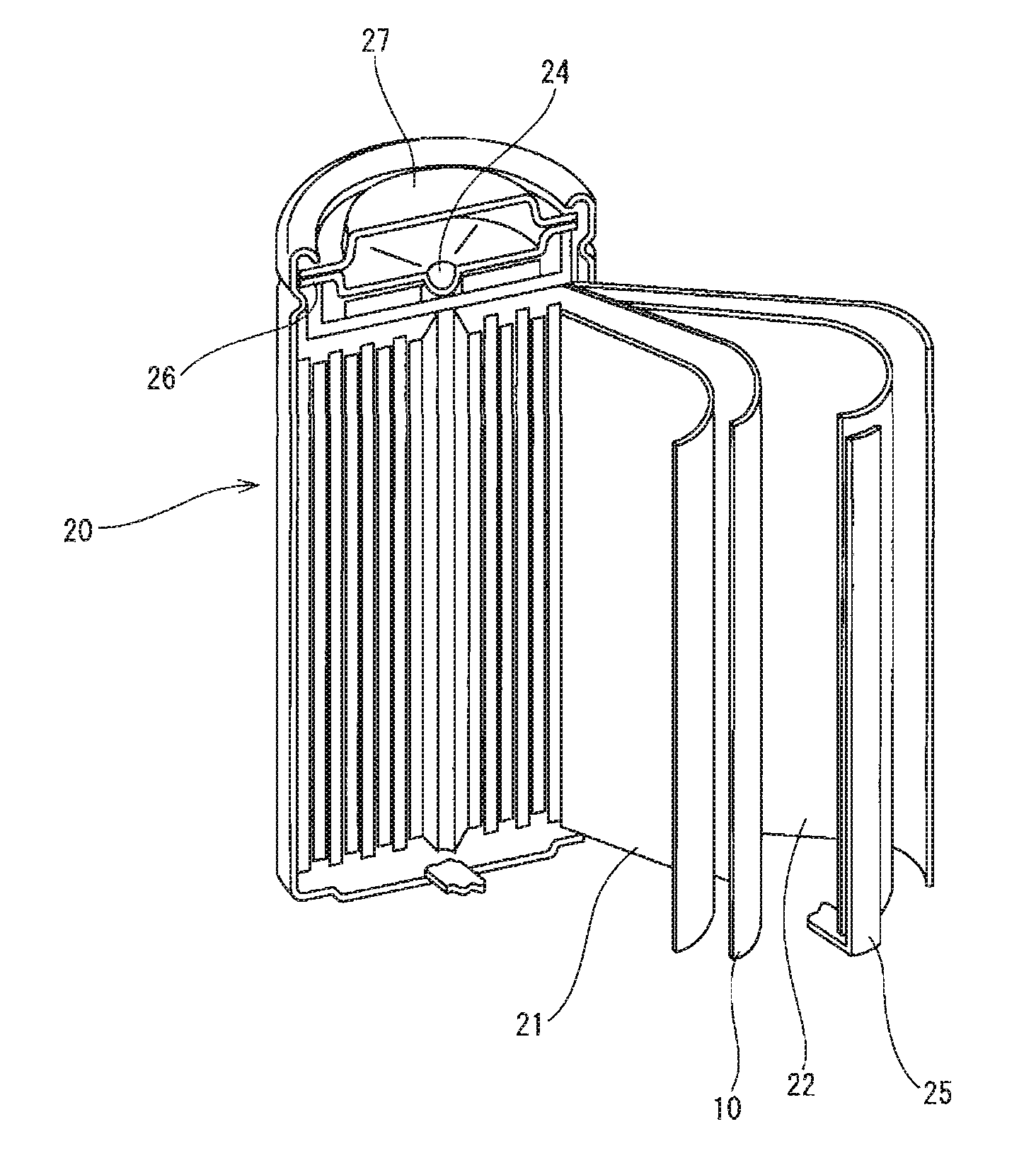

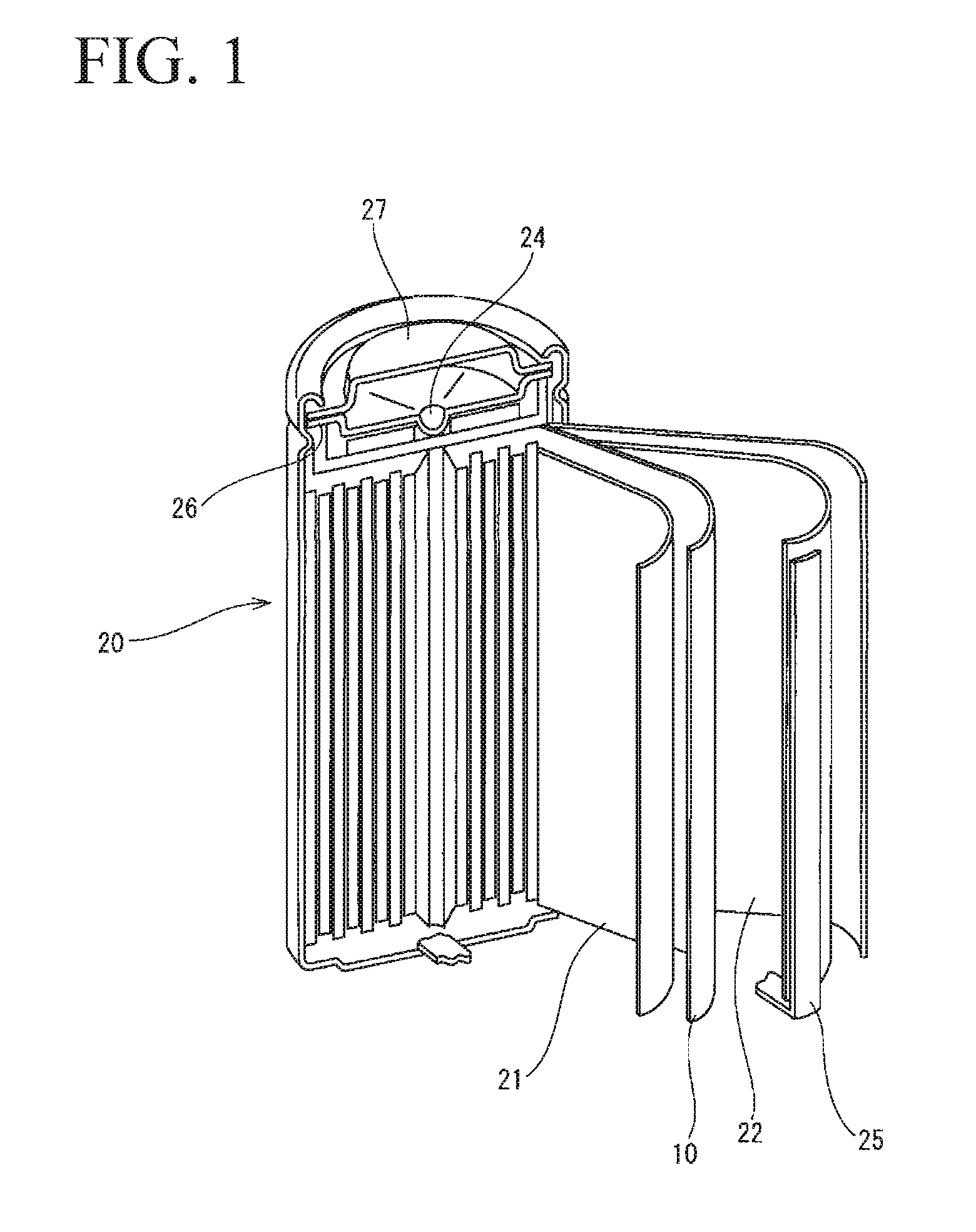

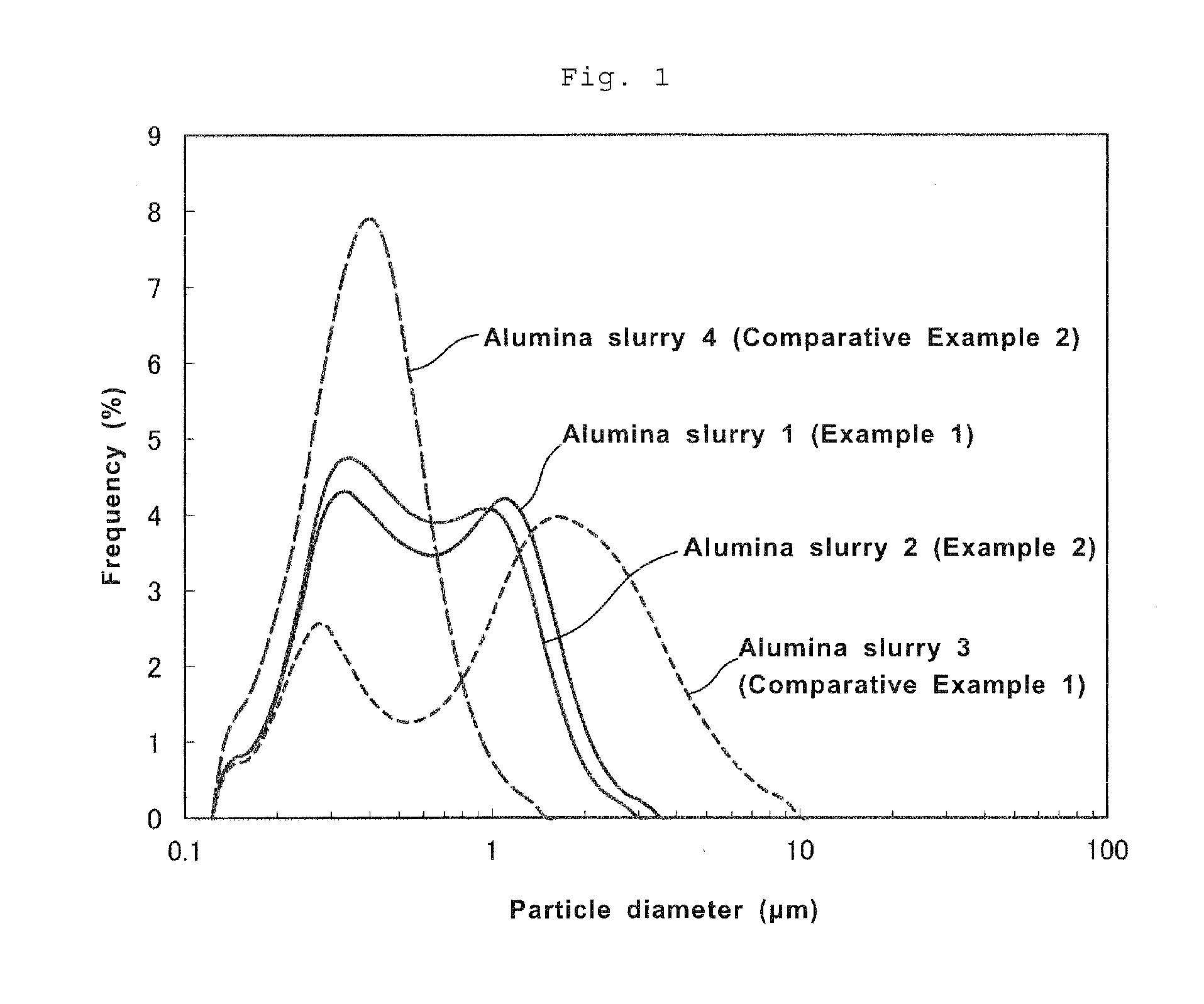

Alumina slurry

ActiveUS20160351880A1Small fluctuationIncrease productivitySynthetic resin layered productsLi-accumulatorsDesorptionNitrogen

An alumina slurry containing alumina dispersed in a dispersion medium, the alumina having an average primary particle diameter of 0.1 μm or more and 1.0 μm or less, the alumina satisfying the following condition (1), and the slurry having a content of the alumina of 30% by mass or more and 70% by mass or less and a content of water in the dispersion medium of 50% by mass or more:condition (1): in relationship of a pore diameter r1 (Å) and a pore volume Dv1 (mL / g) of the alumina measured by a nitrogen desorption method based on JIS Z8831-2 (2010), the pore volume Dv1(80) at r1=80 and the maximum value Dv1(M) of Dv1 in a range 20≦r1≦80 satisfy Dv1(M)>Dv1(80).

Owner:MITSUBISHI CHEM CORP

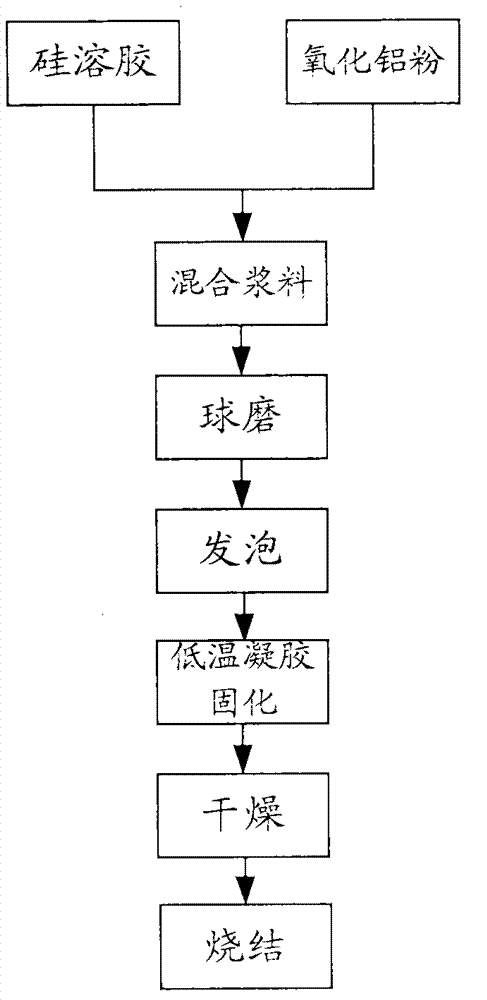

Method for preparing aluminum oxide/mullite foamed ceramic

The invention provides a method for preparing aluminum oxide / mullite foamed ceramic. The method is characterized in that a silicon sol and Al2O3 fine powder are mixed; nanometer SiO2 colloid particles in the silicon sol can be attached on the surfaces of Al2O3 particles to achieve single-layer saturation distribution; colloidal particles fill clearances of the Al2O3 particles by full contact; the silicon sol is gelatinized under the low temperature to generate a Si-O-Si lattice space structure for achieving the curing and forming of foamed slurry; after being cured, the ceramic foams can be directly heated and dried without independent drying or rubber discharging links and then are roasted at the high temperature to obtain the aluminum oxide / mullite foamed ceramic. According to the method, the process operation is simple, and the conditions are easily controlled; a produced green body is small in shrinkage and deformation during forming and drying; the yield of the aluminum oxide / mullite foamed ceramic is high; the production cycle is short; the production cost is low; mass production is achieved.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

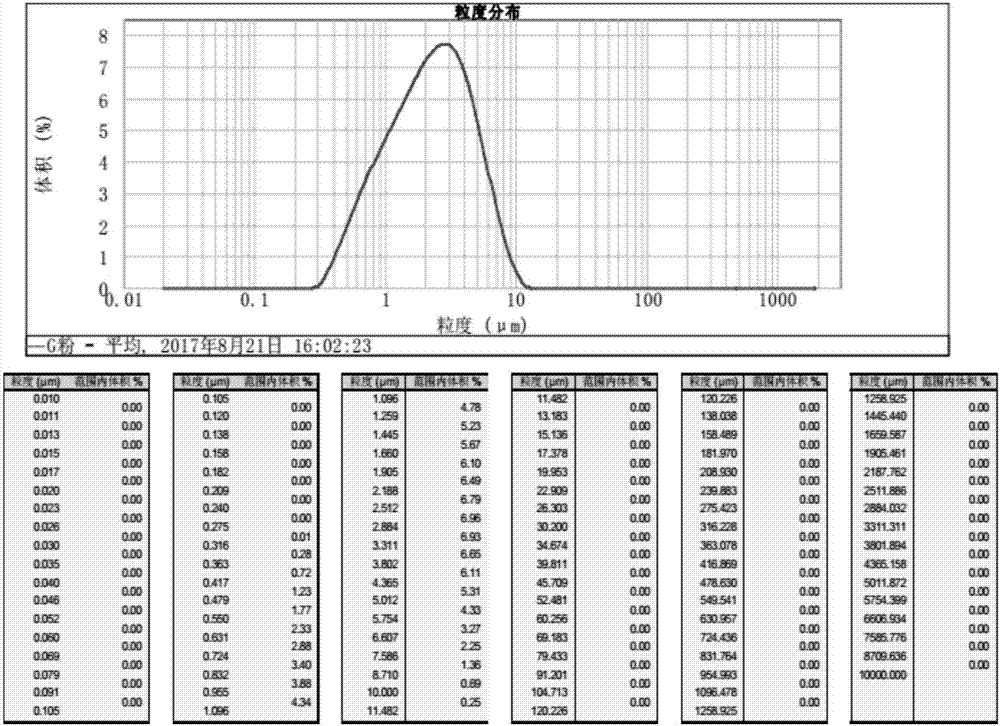

Method for preparing superfine alumina powder

The invention provides a method for preparing superfine alumina. The method comprises the following steps: (1) performing coarse grinding on alumina slurry in presence of a first dispersing agent; (2)filtering the alumina slurry subjected to coarse grinding; (3) performing fine grinding on the filtered alumina slurry in presence of a second dispersing agent; and (4) drying and grinding the alumina slurry subjected to fine grinding, wherein the first dispersing agent is ammonium polyacrylate, and the second dispersing agent is a mixture of polyacrylic acid and ammonium polyacrylate. The invention further provides superfine alumina powder prepared by the preparation method, and a lithium ion battery diaphragm coating or an electrode coating containing the high-purity superfine alumina powder.

Owner:浙江爱科新材料有限公司

Aluminum oxide slurry used for the photocuring technique and a preparing method thereof

Aluminum oxide slurry used for the photocuring technique is disclosed. The slurry includes Al2O3 powder, a sintering aid the mass of which is 0.05-5% of the mass of the Al2O3 powder, a dispersing agent the mass of which is 1.0-2.0% of the mass of the Al2O3 powder, a compatilizer the mass of which is 0.75-1.25% of the mass of the Al2O3 powder, a monomer the mass of which is 25-30% of the mass of the Al2O3 powder, and a photoinitiator the mass of which is 0.75-1.25% of the mass of the monomer. The slurry has a high solid content and low viscosity and is uniform. A preparing method of the slurryis also disclosed.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

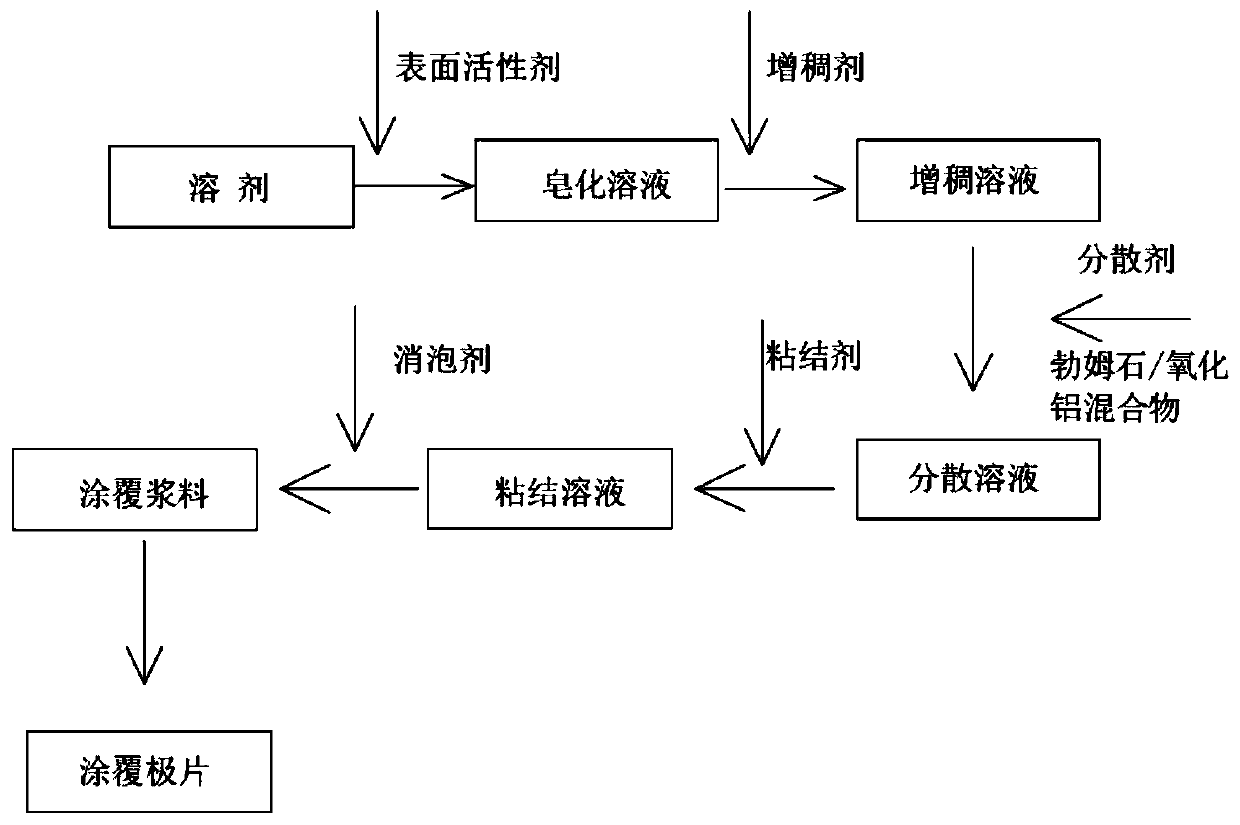

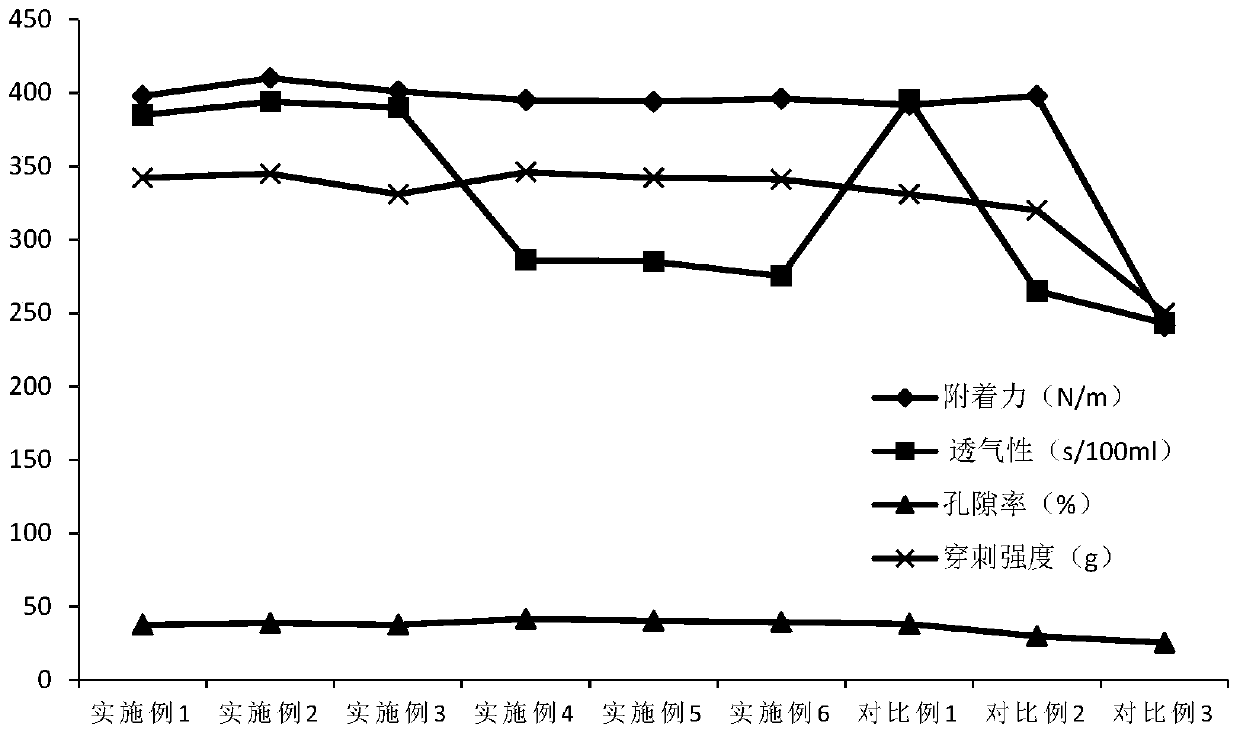

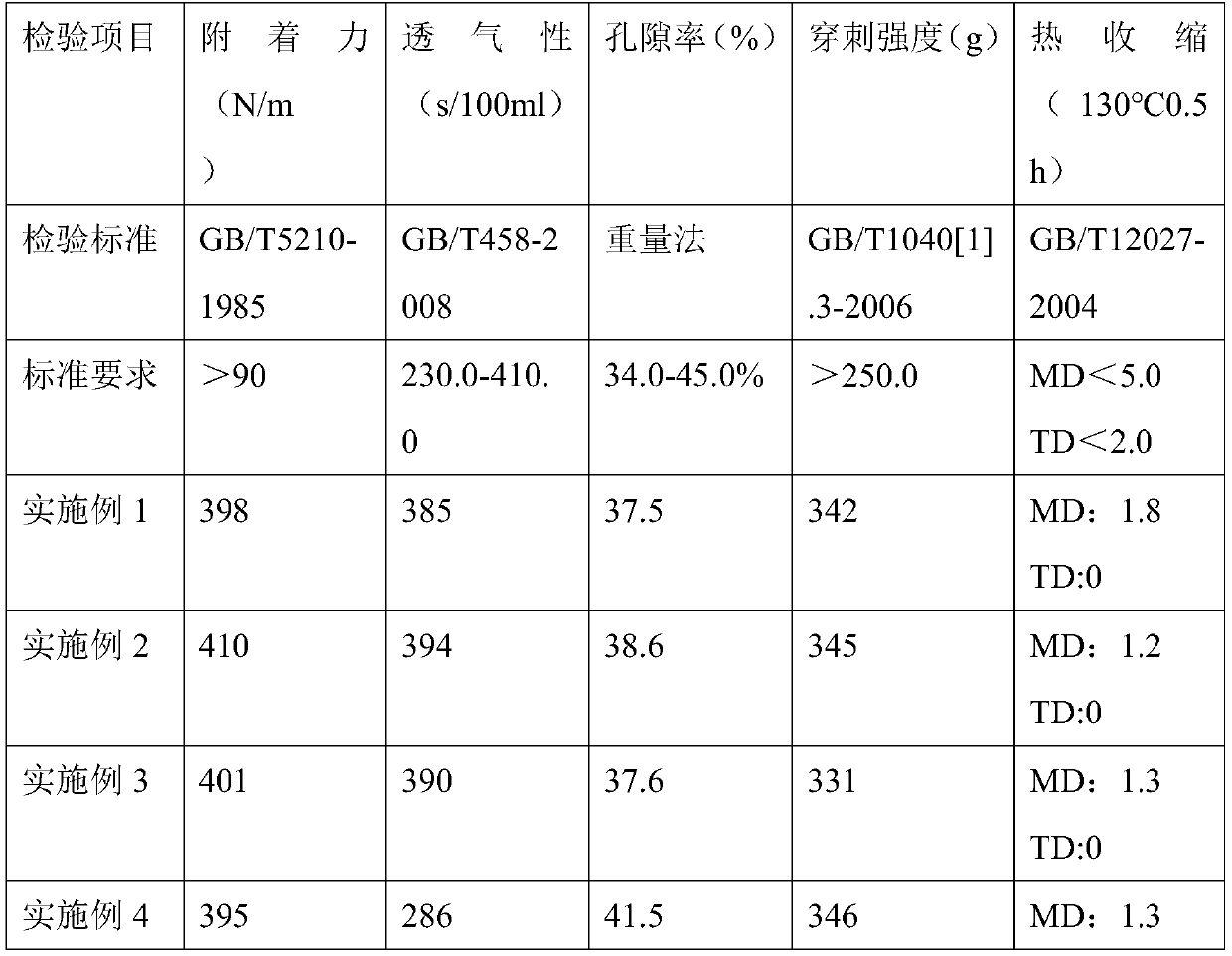

Boehmite/aluminum oxide composite lithium ion battery coating electrode piece

ActiveCN110380002AImprove performanceLow priceElectrode thermal treatmentElectrode collector coatingSlurrySolvent

The invention discloses a boehmite / aluminum oxide composite lithium ion battery coating electrode piece. Boehmite / aluminum oxide slurry is prepared from the following raw materials in percentage by mass: 0.5-1.3 parts of a surfactant, 0.5-1.0 parts of a thickening agent, 5.0-10.0 parts of a binder, 0.1-0.5 parts of a dispersing agent, 20.0-50.0 parts of a boehmite / alumina mixture, 2.0-6.0 parts ofa defoamer and 30.0-70.0 parts of a solvent. The invention further discloses a preparation method of the boehmite / aluminum oxide composite lithium ion battery coating electrode piece. The boehmite islow in price, the cost is greatly reduced, and the market competitive advantage is greatly improved; compared with a coated diaphragm, the coated electrode piece can save more space, and the energy density of batteries with the same volume is high.

Owner:江西力能新能源科技有限公司

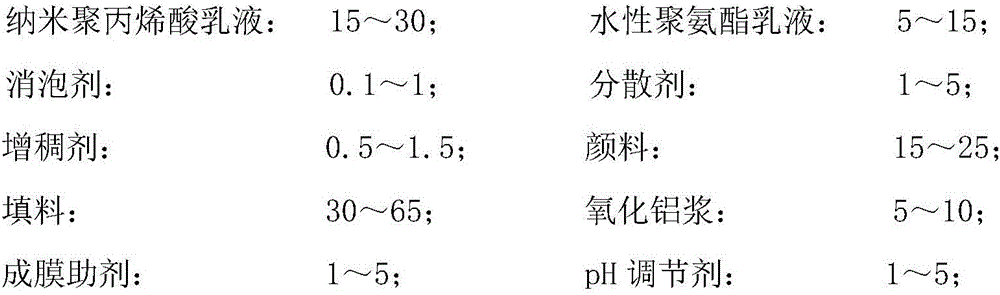

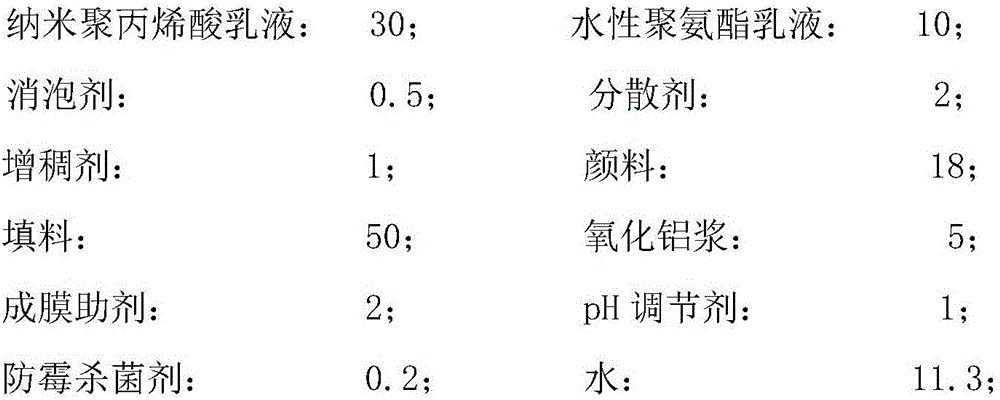

Waterborne one-component coating and preparation method thereof

InactiveCN106810973AEasy to manufactureEasy to operateFilling pastesPolyurea/polyurethane coatingsEmulsionHardness

The invention discloses a water-based one-component paint and a preparation method thereof. The water-based one-component paint is composed of the following raw materials: nano polyacrylic acid emulsion, water-based polyurethane emulsion, defoamer, dispersant, thickener, pigment, filler , alumina slurry, film-forming aids, pH regulator, anti-mold and bactericide and water; the water-based one-component coating obtained by the present invention has good fullness, good airtightness, excellent adhesion and fast drying, and anti-collapse Strong resistance and high hardness; the water-based one-component paint obtained by the present invention can be used directly by adding water, no use time limit, no water is added for use, and can be used as white putty without collapse; the water-based one-component white background obtained by the present invention The paint is a water-based green environmental protection product; the preparation method of the water-based one-component paint provided by the invention is simple in operation and convenient in preparation, and is suitable for large-scale industrial production.

Owner:CHENGDU ZHANCHEN PAINT

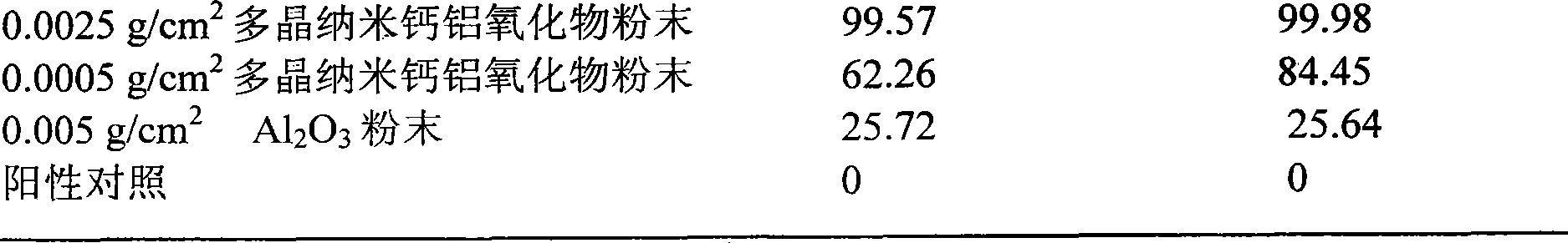

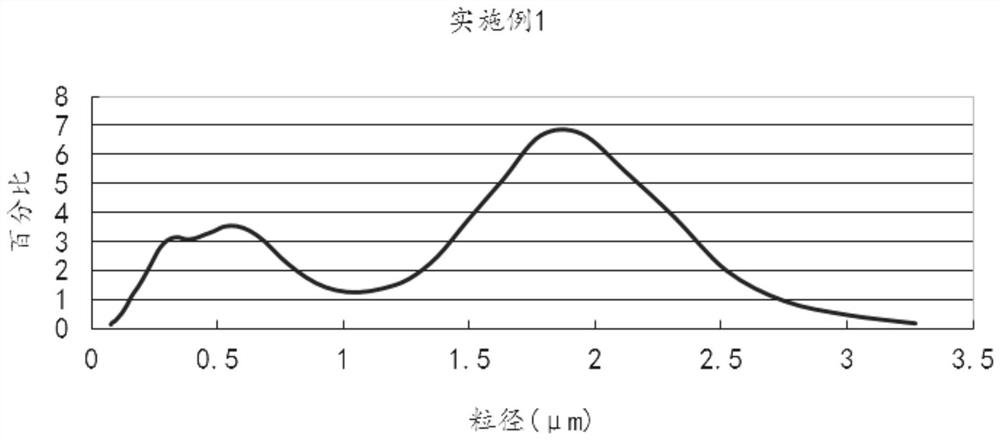

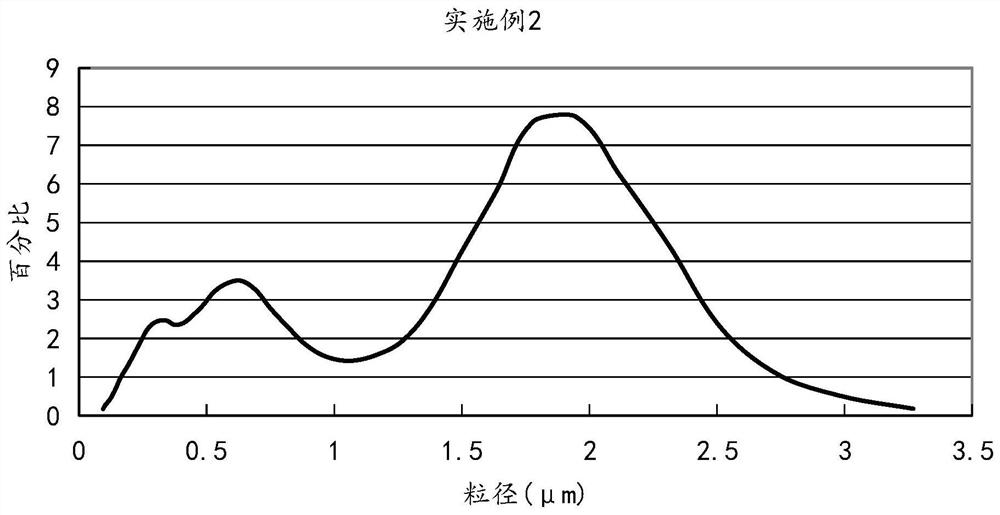

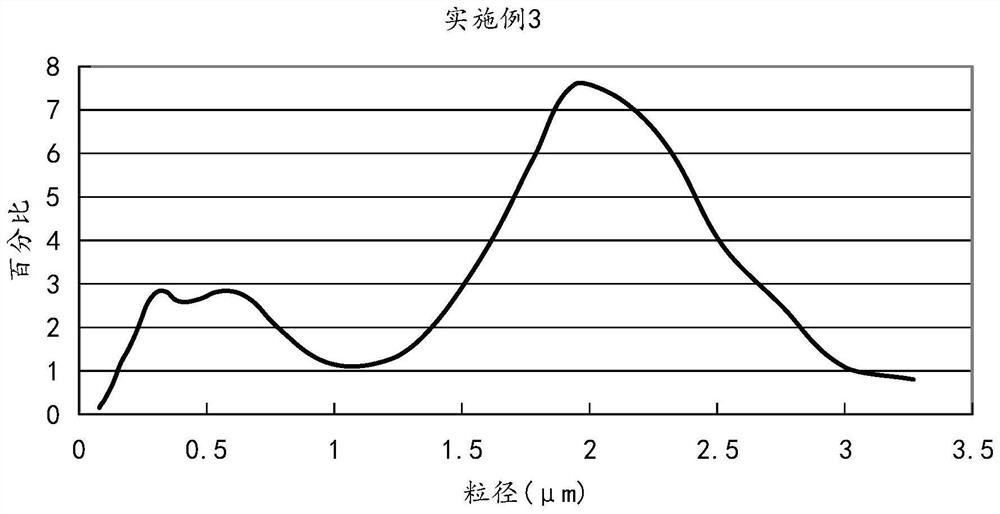

Alumina slurry, method for producing same, and coating liquid

InactiveUS20150203686A1Suppresses powder fallingImproved shape stabilityAluminium compoundsFinal product manufactureSlurryAluminum Oxide Paste

Disclosed is an alumina slurry substantially including alpha-alumina particles and water, wherein the alpha-alumina particles satisfy all particle diameter distribution conditions (a) to (d) mentioned below, the alpha-alumina particles have an alumina purity of 90% by weight or more, the content of alumina in the slurry is 20% by weight or more and 50% by weight or less, and the slurry has a viscosity of 0.5 Pa·s or more and 15 Pa·s or less: condition (a): the average particle diameter is 1 μm or less, condition (b): particles having a particle diameter of less than 0.2 μm account for 7% by weight or less, condition (c): particles having a particle diameter of more than 1.5 μm account for 15% by weight or less, and condition (d): one or more frequency maximums exist in a particle diameter range of 0.1 μm or more and less than 0.5 μm.

Owner:SUMITOMO CHEM CO LTD

Production method of freehand microcrystalline glass board

The invention relates to a production method of a freehand microcrystalline glass board. The production method comprises the following steps of respectively preparing seven microcrystalline glass aggregates with different colors, getting the microcrystalline glass aggregates with any two or more colors and uniformly scattering the microcrystalline glass aggregates with different colors in a stainless steel mould frame with a textured grating in sequence; moving a glass gate board at the bottom of the stainless steel mould frame for dropping the microcrystalline glass aggregates into a fireproof mould sprayed with an aluminum oxide sizing agent which is 1mm thick, and the fireproof mould carrying the microcrystalline glass aggregates enters a roller kiln; preheating, fusing the aggregates, crystallizing and preserving the heat at 1100 DEG C-1150 DEG C, cooling and discharging out of the kiln for firing a freehand microcrystalline glass board crude product with whole-body textures; and carrying out surface coarse-grinding, fine-grinding and polishing to obtain a freehand microcrystalline glass board finished product with clear texture patterns and board glossiness of over 90 degrees. The freehand microcrystalline glass board prepared by the production method disclosed by the invention has abundant colors, line textures from the inside to the outside, and physical and chemical performances better than those of a stone.

Owner:王顺军

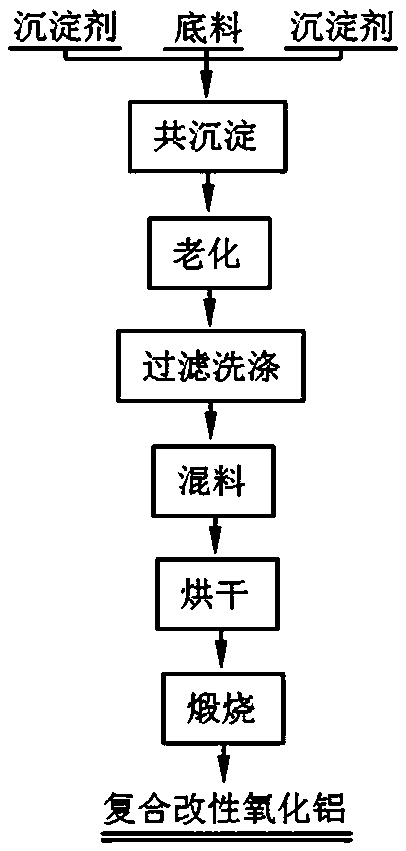

Automobile tail gas purification catalyst carrier and preparation method thereof

ActiveCN109513432ACatalyst carriersDispersed particle separationAluminium hydroxidePotassium aluminate

The invention discloses an automobile tail gas purification catalyst carrier and a preparation method thereof. The impurity Na content in the automobile tail gas purification catalyst carrier is lowerthan 400ppm; the apparent density is 1.8g / L or higher; the specific surface area at 950 DEG C at 2h is 110m<2> / g or higher; the pore volume is 0.4ml / g or higher. According to a preparation method, sodium aluminate / potassium aluminate are used as raw materials, and nitric acid, modification agents and surfactants are used as auxiliary materials; coprecipitation, aging, filtering washing, drying, roasting and crushing are performed; then, modified aluminum hydroxide or aluminum oxide is used as raw materials, surfactant and oxidizing agent containing modified aluminum hydroxide or aluminum oxide slurry is used as substrate materials; precipitators and modification agents are jointly sprayed into a bottom solution for precipitation; after the precipitation, aging, filtering washing, materialmixing, drying, roasting and crushing are performed to obtain the composite modified automobile tail gas purification catalyst carrier of composite modification aluminum oxide; the contents of impurities Na, S, P and the like are low; the requirements of the automobile tail gas purification agent carrier can be met.

Owner:KUNMING METALLURGY INST +1

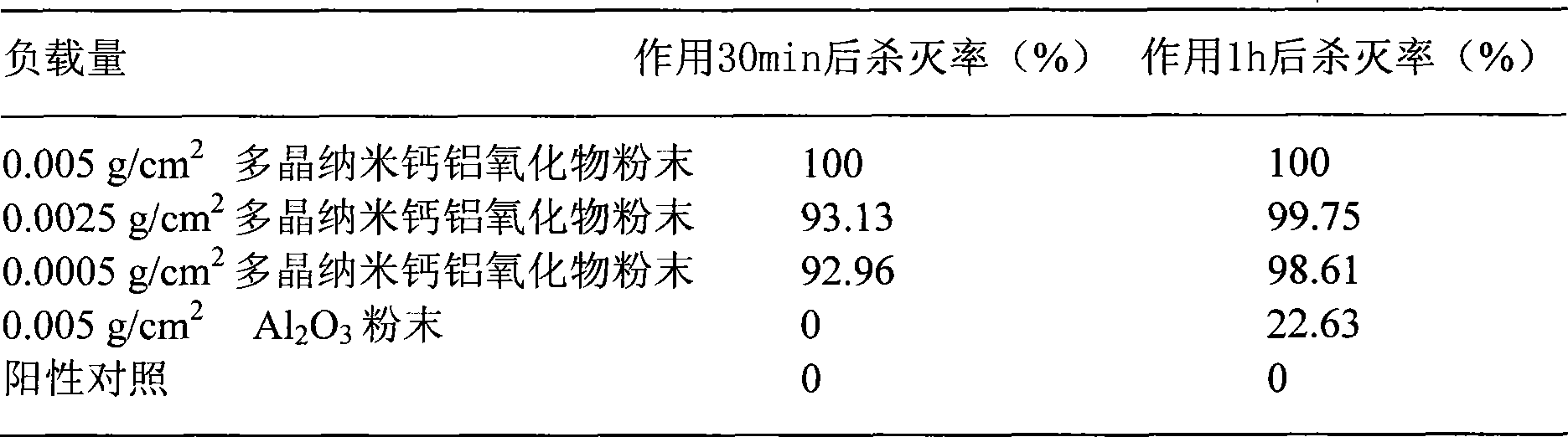

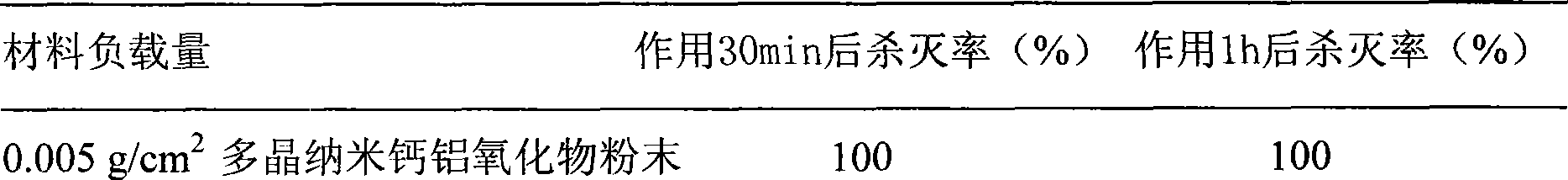

Antibacterial application of polycrystalline nanometer calcium-aluminum oxide

The invention relates to an inorganic antibacterial material, in particular to an antibacterial application of a polycrystalline nanometer calcium-aluminum oxide of C12A7-O<->. The antibacterial material has broad-spectrum bacteriostatic and bactericidal actions, i.e. has the action for exterminating golden staphylococcus, colon bacilli and hay bacillus black spore varieties at a room temperature. The polycrystalline nanometer calcium-aluminum oxide has an extermination rate of 100 percent per hour for the golden staphylococcus and the colon bacilli and has an extermination rate of 96 percent per hour for the hay bacillus black spore varieties when a load weight on a unit area of a load material is heavier than or equal to 0.005g / cm<2>; the grain diameter of the polycrystalline nanometer calcium-aluminum oxide is 10- 200nm, the load material can be textile, plastic products, ceramics, rubber products, or the like, and the room temperature means natural room-temperature conditions in four seasons. The polycrystalline nanometer calcium-aluminum oxide has the advantages of strong antibacterium function, no toxicity, high temperature resistance and strong stability and can be widely applied to fields, such as antibacterial textile, antibacterial plastics or ceramics, rubber products, and the like.

Owner:UNIV OF SCI & TECH OF CHINA

Alumina slurry and preparation method and application thereof

PendingCN112158867ARegular and smooth shapeOvercome the disadvantages of reunionPolishing compositions with abrasivesAluminium oxides/hydroxidesMetal machiningSlurry

The invention relates to the technical field of metal processing, in particular to aluminum oxide slurry as well as a preparation method and application thereof. According to the invention, a two-stage grinding process including ball milling and sanding is adopted, and a proper mixed dispersing agent is selected, so that the obtained product has regular and smooth particle morphology, narrow particle size distribution and small particles; after precise filtering, a product is in the form of slurry and can be used without drying, so that the defect of agglomeration of false particles of the traditional aluminum oxide powder is overcome, and the aluminum oxide polishing powder has higher dispersity and stability, is not easy to precipitate, ensures the polishing effect, can replace high-quality aluminum oxide polishing powder processed by an airflow mill, and can be used for high-precision mirror polishing occasions such as stainless steel mirror polishing and sapphire mirror polishing.

Owner:MATRIX GUANGZHOU CHEM CORP

Method for preparing ceramic filters with hot pressure casting process

InactiveCN108178654ALower sintering temperatureControllable porosityDischarging arrangementFeeding arrangmentsPorosityMagnesium salt

The invention relates to a method for preparing ceramic filters with a hot pressure casting process. The method comprises steps as follows: alumina powder with proper grain size distribution and paraffin are mixed in a certain ratio, one or more pore-forming agents such as carbon powder, wood chips, aluminum salt, titanium salt, magnesium salt, sodium salt, lanthanum salt, cerium salt and the likeare added according to the size and distribution of required pores, and alumina slurry is configured. Under certain pressure, the slurry is injected into a mold meeting the shape requirement for forming, and various special-shaped filter bodies meeting the requirements are prepared; the bodies are subjected to removal burning, the pore-forming agents are removed, and porous bodies are obtained; the porous bodies are sintered at the high temperature, and the special-shaped alumina ceramic filters are obtained. In the whole process, no special mechanical equipment is required, the pore size anddistribution and the shapes of the filters are controllable, and the method is an ideal process for preparing high-porosity, high-strength and special-shaped ceramic filters.

Owner:辽宁法库陶瓷工程技术研究中心

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com