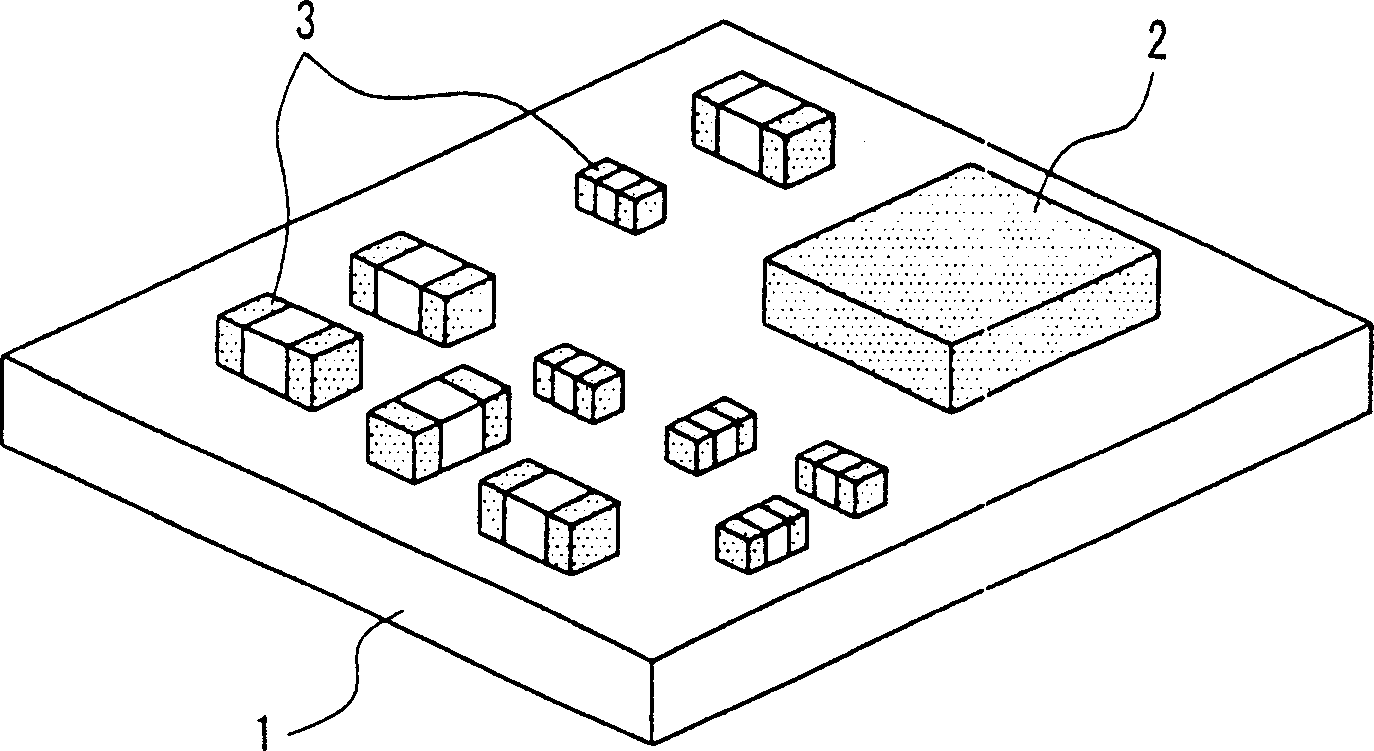

Oxide ceramic material, ceramic substrate employing the same, ceramic laminate device, and power amplifier module

An oxide ceramic, oxide technology, applied in power amplifiers, ceramic layered products, ceramics, etc., can solve the problem that the processing method is not suitable for mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] The method for preparing the molded body and the green sheet is not particularly limited, for example, uniaxial molding, isotropic pressure pressing, doctor blade method, calendering method, roll coater method and the like can be used.

[0066] As the base film for the protective sheet, polyethylene-based resin, polyester-based resin, paper, or the like can be used. Also, as a method of forming vias in the insulating sheet, punching or laser processing can be used.

[0067] As a sintering environment for molded bodies and laminates, the atmosphere can generally be used because Ag can be used as an internal conductor.

[0068] In the present invention, alumina powder and specific oxide powder are mixed, which can be sintered at a temperature significantly lower than conventional sintered alumina. This is particularly beneficial in view of the production energy and costs of the furnaces used in production. Also, since the mixture can be sintered at a temperature not hig...

Embodiment 1

[0079] As a raw material, alumina (Al 2 o 3 ) powder and various metal oxide powders of reagent grade or above purity. They were weighed for each sample so as to obtain the compositions shown in Table 1, and the sum of their masses was 200 g, and they were subjected to wet mixing for 12 hours by a ball mill using alumina balls. After the resulting powder was dried, a small amount of an aqueous solution of polyvinyl alcohol was mixed, and the mixture was passed through a 32-mesh sieve for granulation. The powder is molded into a mold while uniaxially applying 1 t / cm 2 pressure so as to have a diameter of 12 mm and a thickness of about 1 mm. The obtained molded body was heated at 500°C in air for 1 hour to remove the binder, and thereafter, it was sintered at 900°C to 1000°C for 1 hour. Measure the size and mass of the sintered body to calculate the sintered density.

[0080] Also, a plurality of said sintered bodies were prepared and pulverized, and the absolute density th...

Embodiment 2

[0089] In the same manner as in Example 1, powders of alumina, niobium oxide, copper oxide, titanium oxide, silver oxide, and bismuth oxide were prepared and mixed so that, for each sample, alumina accounted for 93% by mass and the other The total of the five components is 7% by mass, where the total amount of niobium oxide, copper oxide, titanium oxide, silver oxide and bismuth oxide is assumed to be 100% by mass, which have the mass percentages shown in Table 2. The mixture was sintered at 900° C. or 950° C. for 2 hours to prepare sintered bodies, and their relative densities were measured.

[0090] Also, on the upper and lower surfaces of each sintered body having a relative density exceeding 90%, gold electrodes were formed by sputtering, and dielectric characteristics were evaluated. The results are shown in Table 2.

[0091]

serial number

The mass ratio of auxiliary components

Dielectric loss (1MHz)

Nb 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com