Process for preparing TiO2 (titanium dioxide) film on aluminum-oxide foamed ceramic

A foamed ceramic, alumina technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of photocatalytic efficiency catalyst immobilization and other problems, achieve good acid and alkali corrosion resistance, good resistance High temperature and oxidation resistance, the effect of increasing the effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

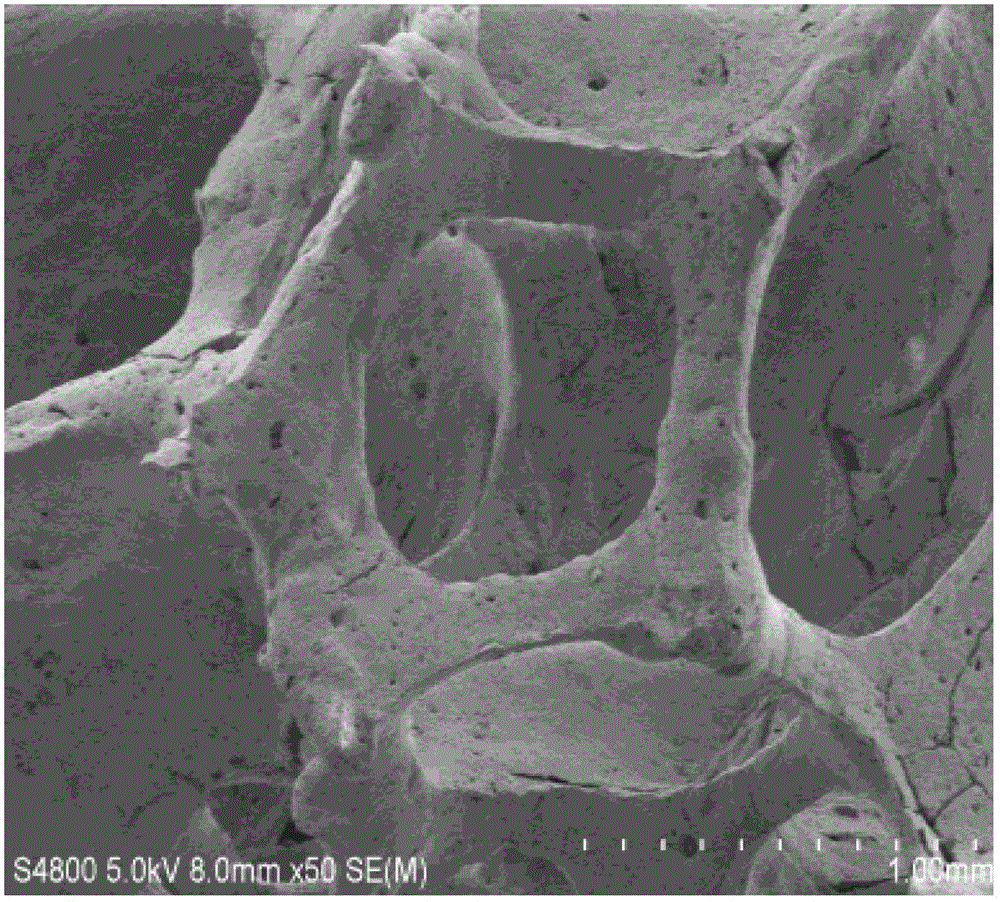

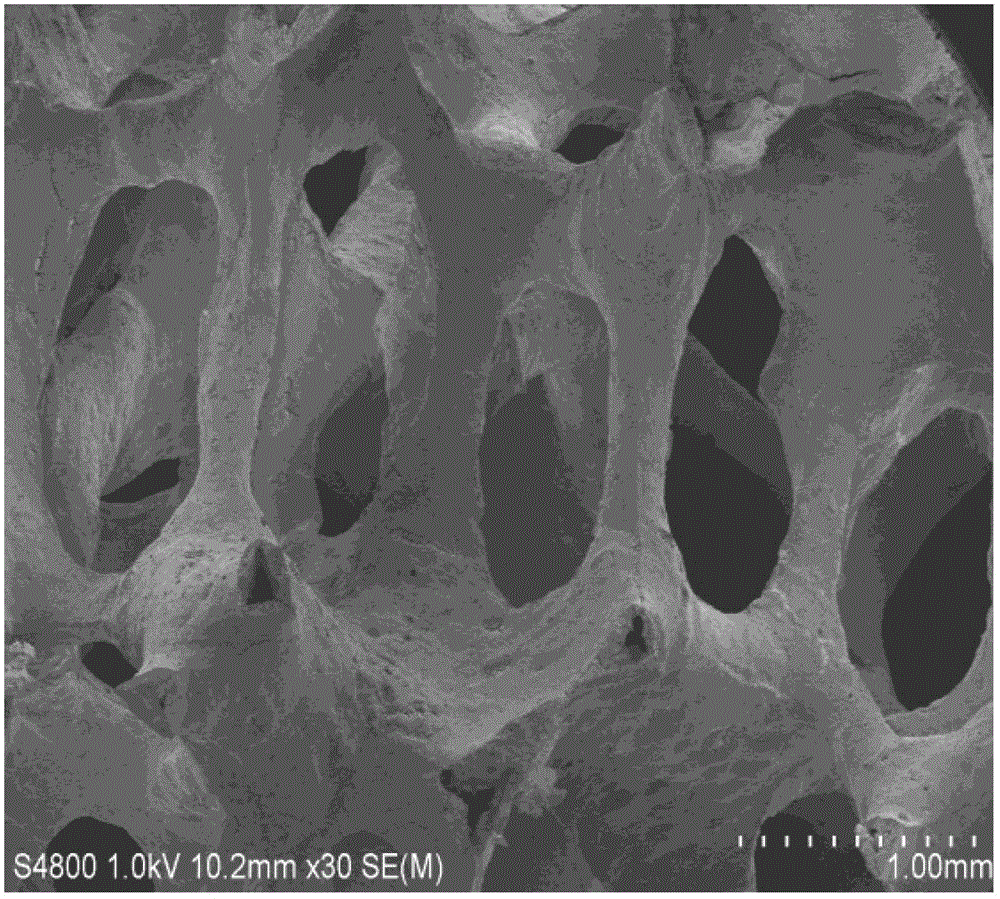

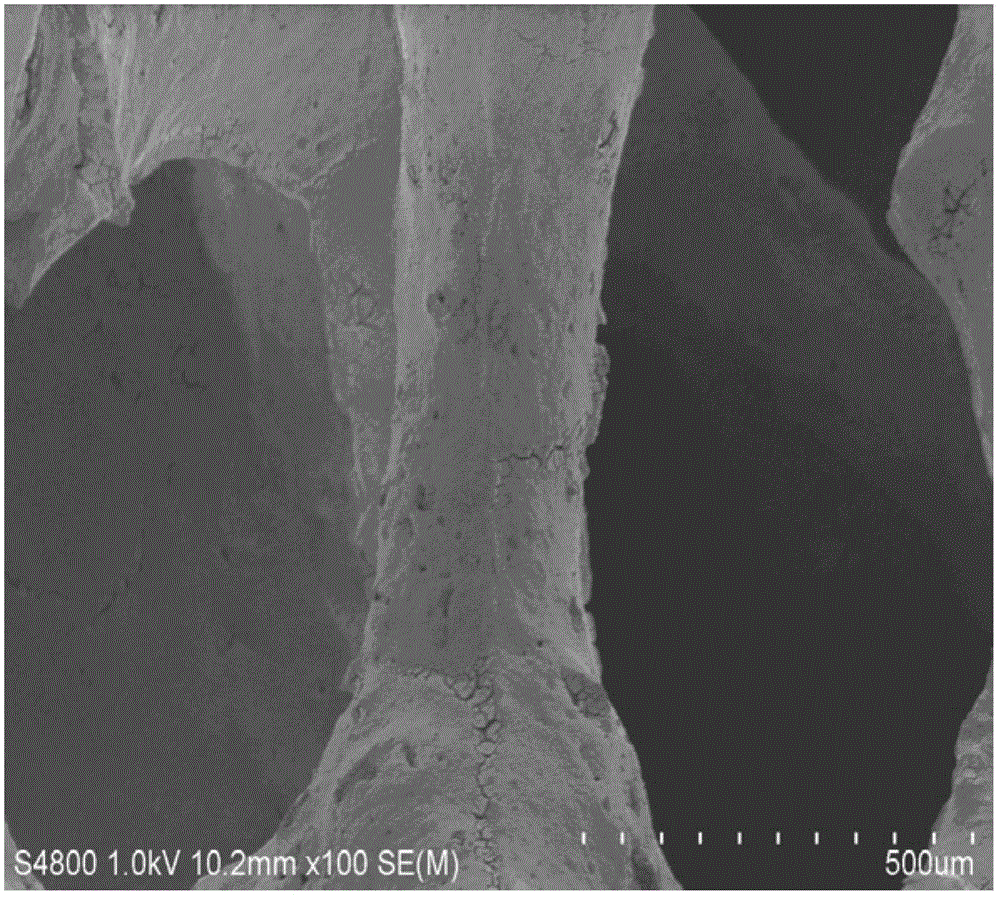

Image

Examples

Embodiment 1

[0032] The specific operation of the preparation of alumina slurry is as follows:

[0033] Select deionized water as the dispersant, and divide the added deionized water into two parts, add 2wt% ammonium polyacrylate as a dispersant to one part of the deionized water, ultrasonically vibrate for 10 minutes, and add 0.5 wt% to the other part of the deionized water wt% carboxymethyl cellulose and disperse it evenly; then use ammonia water to adjust the pH value of the well-mixed ammonium polyacrylate solution to about 11, then add 2wt% silica sol, and ultrasonically oscillate for 10 minutes to mix the evenly mixed ceramic powder Stir in ingredients until lumpy. Finally, pour the carboxymethyl cellulose aqueous solution into it and stir evenly to obtain a ceramic slurry with a solid content of 70 wt%. Then pour the ceramic slurry into a closed round bottle, put it on a homemade drum mixer, roll and stir for 24 hours, pour it out and put it in a beaker. The polyurethane foam acti...

Embodiment 2

[0038] (1) Preparation of alumina foam ceramic substrate;

[0039] 1) Preparation of alumina slurry:

[0040] a) Configure alumina powder: mix 75% alumina, 10% silica, 7% kaolin, 3% bentonite and 5% talc according to the mass ratio to obtain alumina powder;

[0041] b) Configuration solution A: According to the mass percentage of alumina powder, take 2% ammonium polyacrylate, add it to deionized water, and ultrasonically oscillate for 10-20 minutes, then adjust the pH value of the solution to 11 with ammonia water, Then add 2% silica sol, and then ultrasonically oscillate evenly to obtain solution A;

[0042] c) Prepare solution B: according to the mass percentage of alumina powder, take 0.5% carboxymethyl cellulose, add it into deionized water and mix evenly to obtain solution B;

[0043] d) Add alumina powder into solution A, stir until lumpy, and then add solution B to obtain alumina slurry; the mass ratio of the total amount of deionized water to the total amount of alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com