Patents

Literature

317 results about "Aluminum oxide ore" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alumina is the common name given to aluminum oxide (Al2O3). Alumina is produced from bauxite, an ore that is mined from topsoil in various tropical and subtropical regions. The Bayer process, discovered in 1887, is the primary process by which alumina is extracted from bauxite.

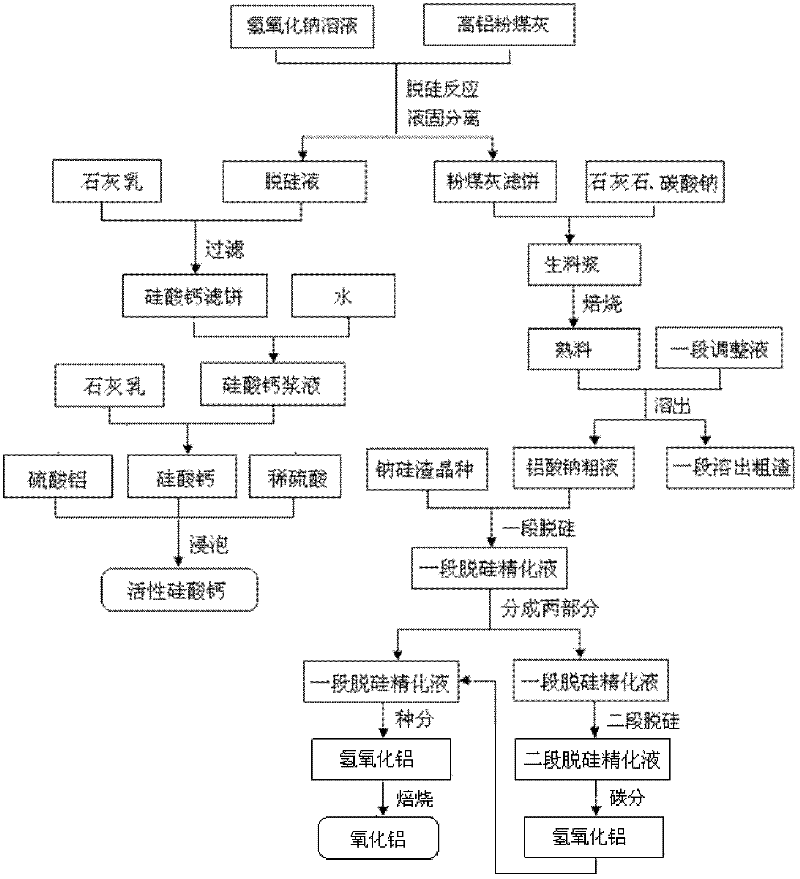

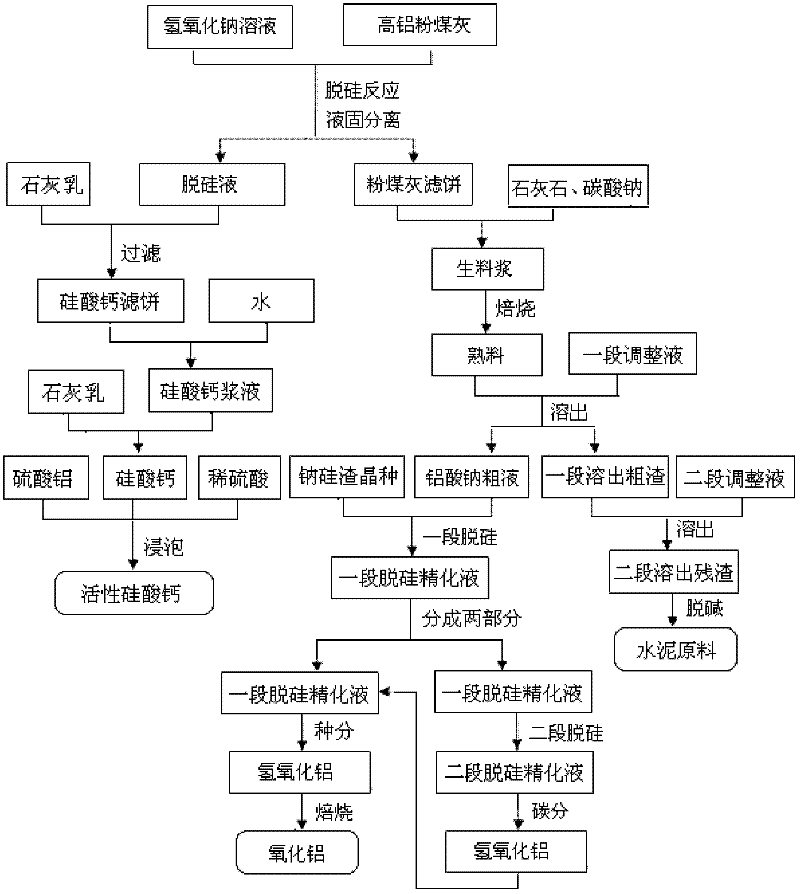

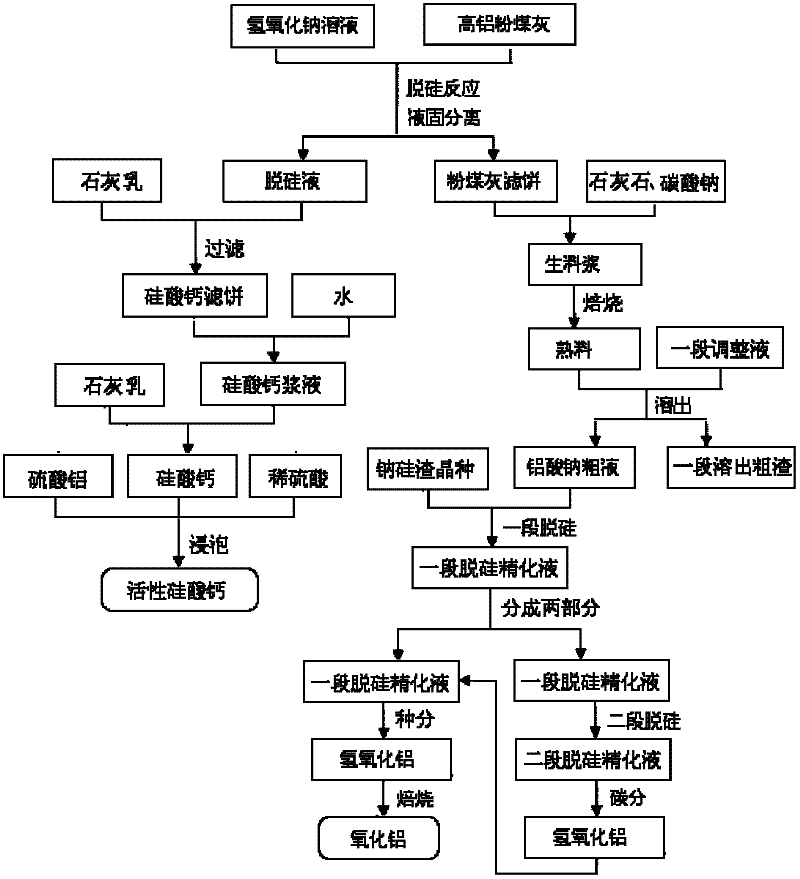

Method for producing aluminum oxide and co-producing active calcium silicate through high-alumina fly ash

ActiveCN102249253AExtraction is effective and cheapIncrease Al-Si RatioAlkaline-earth metal silicatesAluminium oxide/hydroxide preparationCalcium silicateSodium aluminate

The invention provides a method for producing aluminum oxide and co-producing active calcium silicate through high-alumina fly ash. The method comprises the following steps that: the high-alumina fly ash firstly reacts with a sodium hydroxide solution to carry out pre-desilication to obtain a liquid-phase desiliconized solution and a solid-phase desiliconized fly ash; lime cream is added to the liquid-phase desiliconized solution to carry out a causticization reaction, the resulting solid phase is active calcium silicate which is prepared through carrying out filter pressing, flash evaporation and drying to obtain the finished product; limestone and a sodium carbonate solution are added to the desiliconized fly ash to blend qualified raw slurry, then the blend qualified raw slurry is subjected to baking into the clinker, the liquid phase generated from dissolution of the clinker is a crude solution of sodium aluminate; the crude solution of the sodium aluminate is subjected to processes of first-stage deep desilication, second-stage deep desilication, carbonation, seed precipitation, baking and the like to obtain the metallurgical grade aluminum oxide meeting requirements. According to the present invention, the defects in the prior art are overcome; purposes of less material flow and small amount of slaggling are achieved; energy consumption, material consumption and production cost are relative low; extraction rate of the aluminum oxide is high; the calcium silicate with high added value is co-produced; the method provided by the present invention can be widely applicable for the field of chemical engineering.

Owner:INNER MONGOLIA DATANG INT RENEWABLE RESOURCES DEV

Method for coating high-nickel ternary material with aluminum oxide and boron oxide

InactiveCN108091830AEfficient removalUniform coverageCell electrodesBoron containingElectrical performance

The invention discloses a method for coating a high-nickel ternary material with aluminum oxide and boron oxide. The method includes the steps: 1) mixing an aluminum oxide precursor and water to prepare aluminum oxide coating liquid; 2) mixing the high-nickel ternary material with the aluminum oxide coating liquid to obtain aluminum oxide coating turbid liquid; 3) performing solid-liquid separation on the aluminum oxide coating turbid liquid, and drying obtained solid materials to obtain dry materials; 4) mixing the dry materials and a boron-containing compound and then sintering the dry materials and the boron-containing compound to obtain the finished high-nickel ternary material coated with the aluminum oxide and the boron oxide. According to the treatment method, washing and coating are combined, surface impurities of the high-nickel ternary material can be more effectively removed, coating is performed in a water phase, a coating can more uniformly cover the surface of the material, and further a positive electrode material with a good electrical performance is obtained. According to the coating method, process steps can be simplified, tempering temperature is reduced, tempering time is shortened, production cycle can be shortened, and production cost is saved.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

Preparation method of lithium-nickel-cobalt-aluminum oxide for anode materials of lithium ion batteries

ActiveCN103066257ASolve the problem of complete oxidationPrevent "cation mixing" phenomenonCell electrodesLithium hydroxideOxygen

The invention provides a preparation method of lithium-nickel-cobalt-aluminum oxide for anode materials of lithium ion batteries. The method comprises: step 1, using a nickel-cobalt-aluminum precursor prepared through a coprecipitation method and doped with mixed ions as raw materials, putting the raw materials into a sealed hearth of a pressure furnace, continuously introducing oxygen until a fixed pressure value is formed, then heating to a pre-burning temperature and keeping warm for a period of time, and cooling to obtain an oxidized precursor; and step 2, adding measured lithium salt or lithium hydroxide into the oxidized precursor, ball milling and uniformly mixing; heating the uniformly mixed raw materials to a certain temperature and keeping warm for a period of time, and meanwhile continuously introducing oxygen to complete a sintering process, thereby obtaining the finish product. According to the invention, through a hyperbaric oxygen atmosphere, the oxygen are enabled to fully infiltrate into particles of the raw materials which has a certain accumulation thickness, thereby preventing situations that only surface materials are oxidized under a normal pressure, and ensuring a full conversion of Ni<2+> to Ni<3+> by a full pre-oxidation.

Owner:GUANGZHOU LIBODE NEW MATERIAL

Preparation method of aluminum oxide coated lithium nickel manganese cobalt cathode material

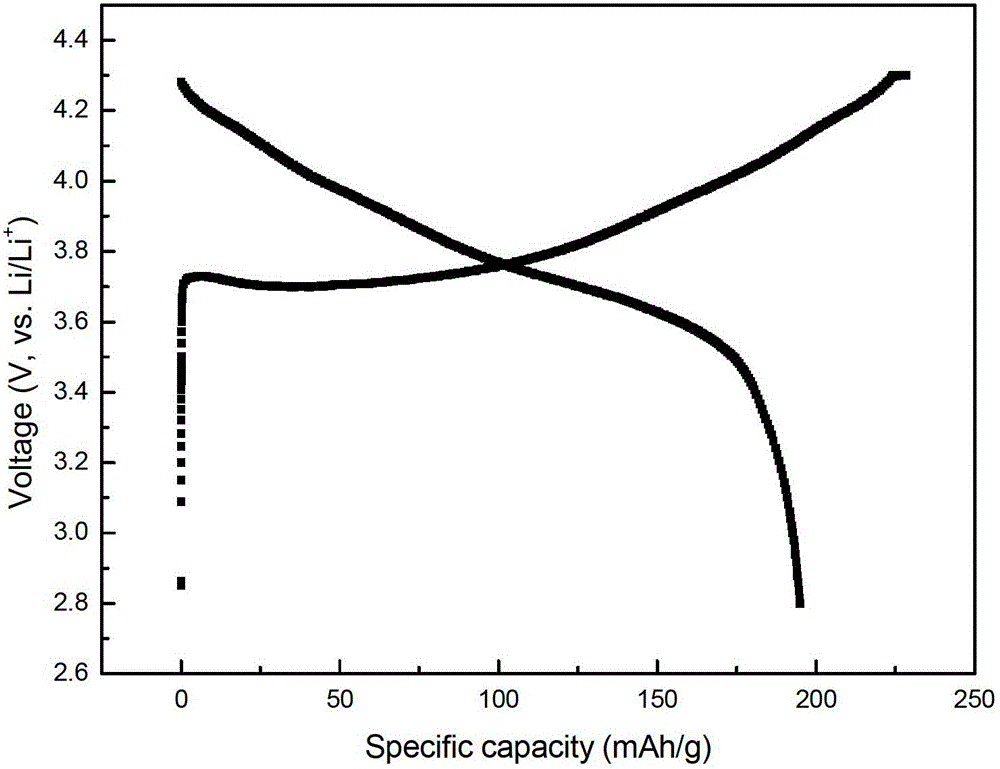

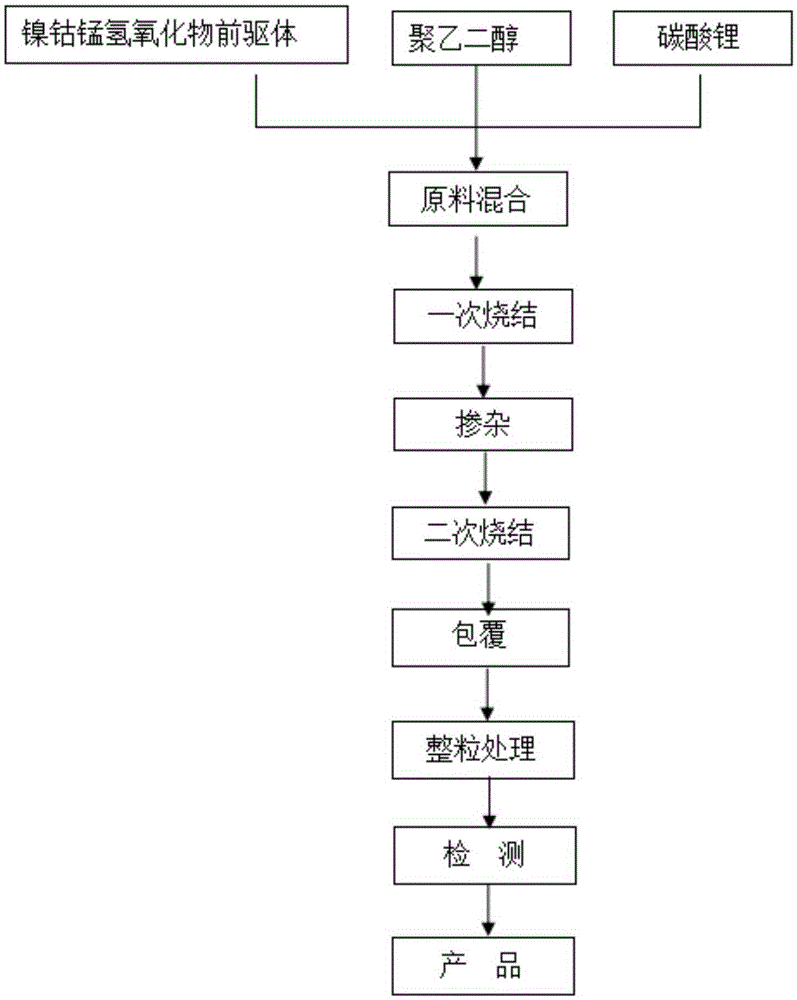

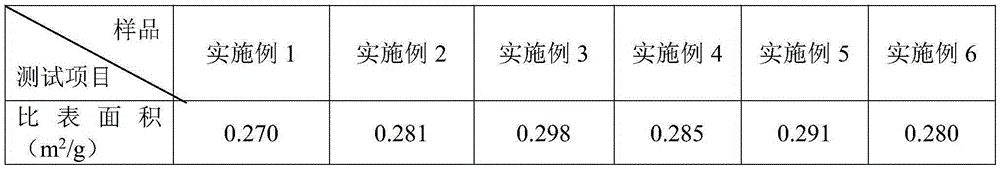

ActiveCN105355911ASimple structureImprove electrochemical cycle performanceCell electrodesSecondary cellsManganesePolyethylene glycol

The invention belongs to the technical field of battery materials, and discloses a preparation method of an aluminum oxide coated lithium nickel manganese cobalt cathode material. The method comprises the steps of raw material mixing, primary sintering, doping, secondary sintering, coating and size stabilization treatment, wherein the step of raw material mixing comprises the steps that a three-dimensional efficient titled mixer is adopted, polyurethane balls serve as a mixing medium, dispersing, even mixing and smashing are conducted on lithium carbonate, a nanometer spherical nickel cobalt manganese hydroxide precursor and polyethylene glycol, and a uniform intermediate mixture is formed. The preparation method of the aluminum oxide coated lithium nickel manganese cobalt cathode material is low in primary sintering temperature, short in sintering time, simple in technology, large in specific capacity and good in cycling performance. The preparation method further has the advantages of being low in investment, reliable in technology, low in operating cost and the like, and the good economic benefit and market promotion value are achieved.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

Supported noble metal hydrogenation catalyst and preparation method thereof

ActiveCN102614868AWell-developed pore structureWell-developed structureOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsActivated carbonPlatinum

The invention discloses a supported noble metal hydrogenation catalyst which is composed of a noble metal active component and a support. The invention is characterized in that the support is the mixture of one or more of gamma-aluminum oxide powder, light calcium carbonate powder and barium sulfate powder with activated carbon powder, wherein the activated carbon powder accounts for 20-60 wt% of the mixture; the noble metal is one of platinum noble metals; and the noble metal accounts for 1-10 wt% of the catalyst. The invention also discloses a preparation method of the supported noble metal hydrogenation catalyst. The support, which is the mixture of one or more of gamma-aluminum oxide powder, light calcium carbonate powder and barium sulfate powder with activated carbon powder, not only has the characteristics of developed pore structure, high specific area and strong adsorptivity of the activated carbon, but also has the characteristics of other oxide or salt supports.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

Aluminum oxide coated nickel-cobalt-manganese ternary positive electrode material, preparation method and application thereof

InactiveCN109585839AImprove cycle performanceImprove securitySecondary cellsPositive electrodesManganeseSide reaction

The invention discloses an aluminum oxide coated nickel-cobalt-manganese ternary positive electrode material, a preparation method and application thereof. The preparation method of the material comprises the following steps: (1) dripping aluminum nitrate into ammonium hydroxide, reacting until precipitates are not increased any longer, adding citric acid and nitric acid, and preparing an AlOOH sol; (2) mixing a nickel-cobalt-manganese precursor and a lithium source uniformly, and sintering to obtain a nickel-cobalt-manganese ternary material; and (3) putting the nickel-cobalt-manganese ternary material into the AlOOH sol, carrying out calcinations after drying, and finally obtaining the aluminum oxide coated nickel-cobalt-manganese ternary positive electrode material. An aluminum oxide coating layer is coated on the surface of the nickel-cobalt-manganese ternary material, so that the amount of residual alkali on the surface of the material is reduced, a side reaction between the material and an electrolyte is inhibited effectively, and the safety performance of a battery is improved; moreover, in the battery prepared from the material, an Li-Al-Co-O protective layer is formed by the aluminum oxide coating layer during working on the surface of the material, and the protective layer can resist the corrosion of HF on active materials, so that the cycle performance of the batteryis improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

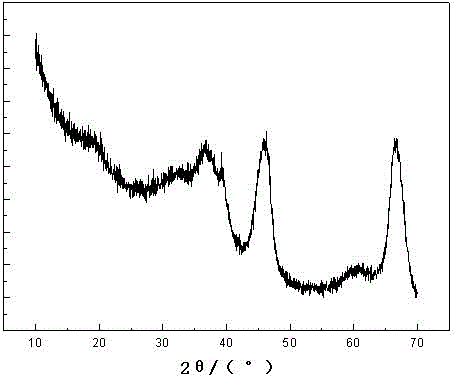

Method for producing industrial activated aluminum oxide from pulverized fuel ash

InactiveCN102020299AEasy industrial iron removalEasy to operateSolid waste disposalAluminium oxides/hydroxidesAluminium sulfatePulverized fuel ash

The invention discloses a method for producing industrial activated aluminum oxide from pulverized fuel ash, comprising the following steps: mechanically activating the pulverized fuel ash, floating and removing carbon, magnetically selecting and removing iron, impregnating in sulfuric acid to extract aluminum, separating solid and liquid, condensing rough liquid of aluminum sulfate, re-crystallizing aluminum sulfate, separating solid and liquid for the second time, dehydrating and drying aluminum sulfate, and calcining aluminum sulfate at a high temperature so as to obtain the industrial activated Al2O3 in which the content of Fe2O3 is lower than 0.5%; and the method completely meets the technical requirement of HG / T3927-2007 industrial activated aluminum oxide. The method is simple in technique, short in flow, easy to control production process, high in aluminum oxide extract rate, low in production cost, low in impurity content, and stable in quality.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +2

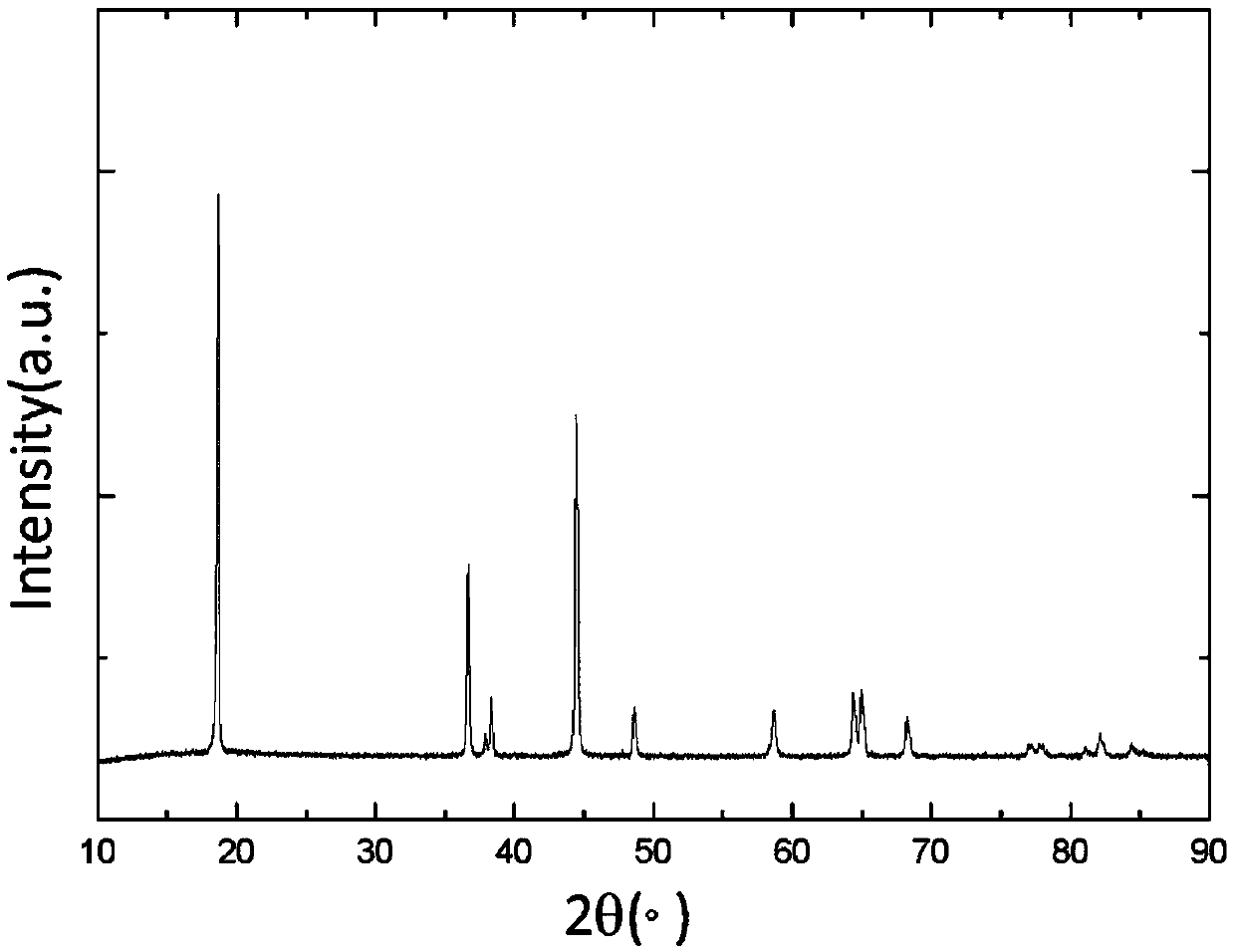

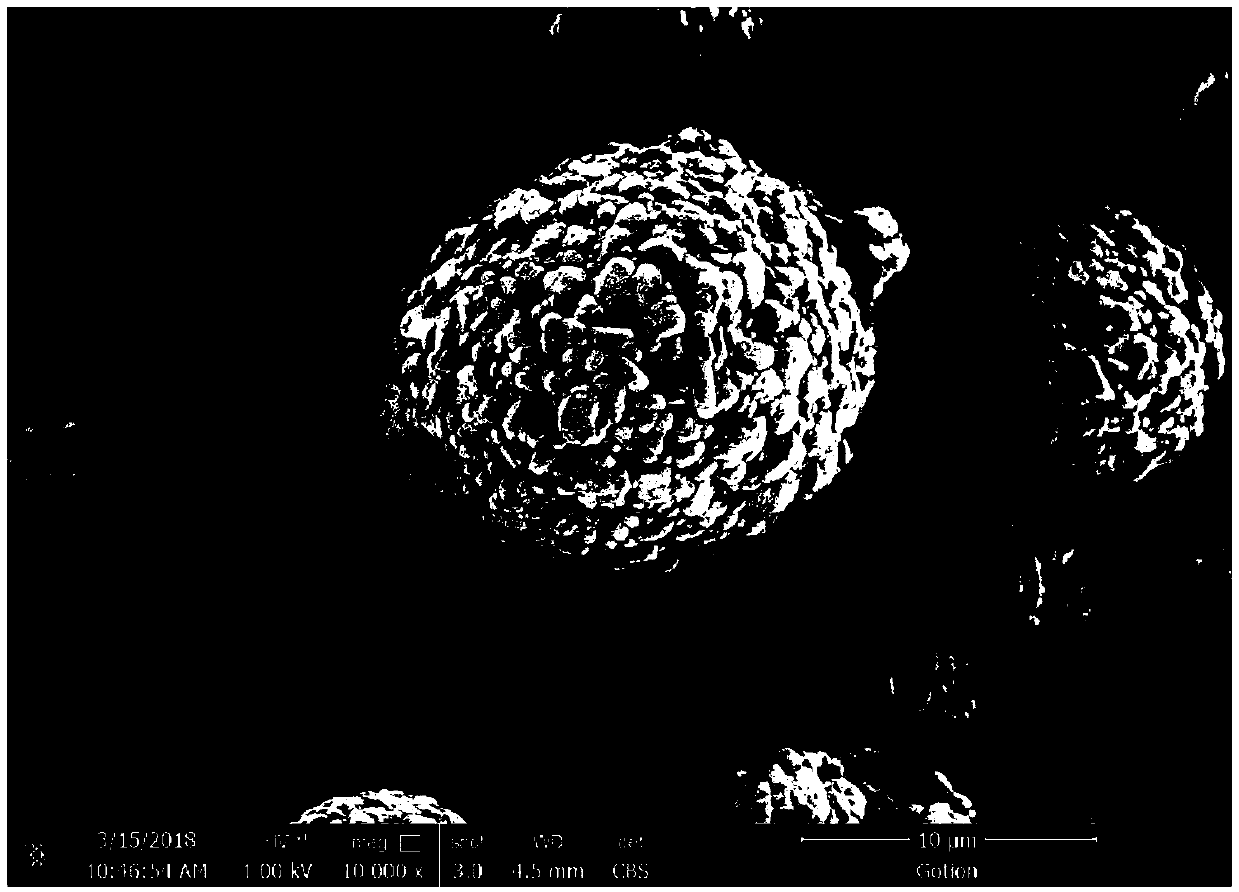

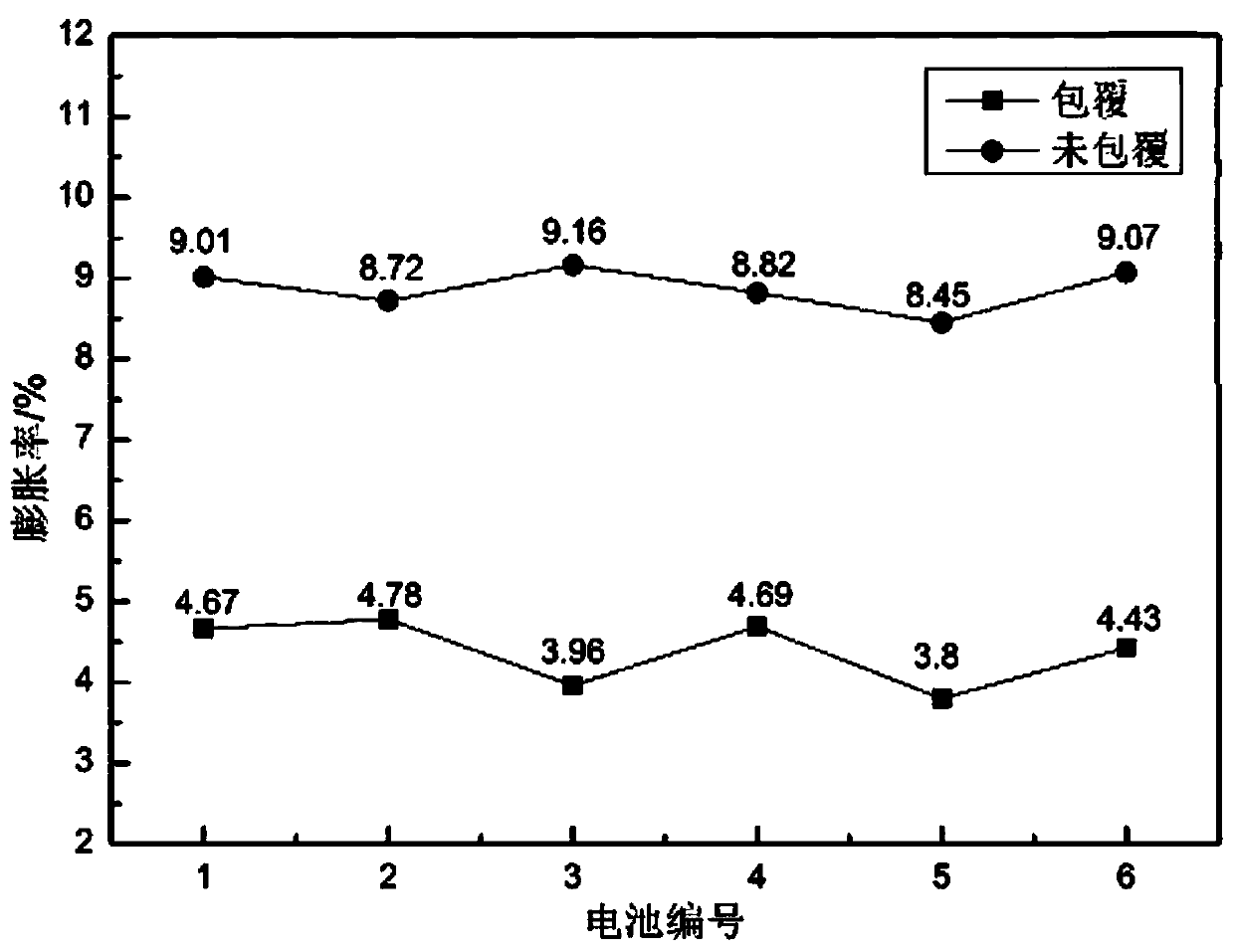

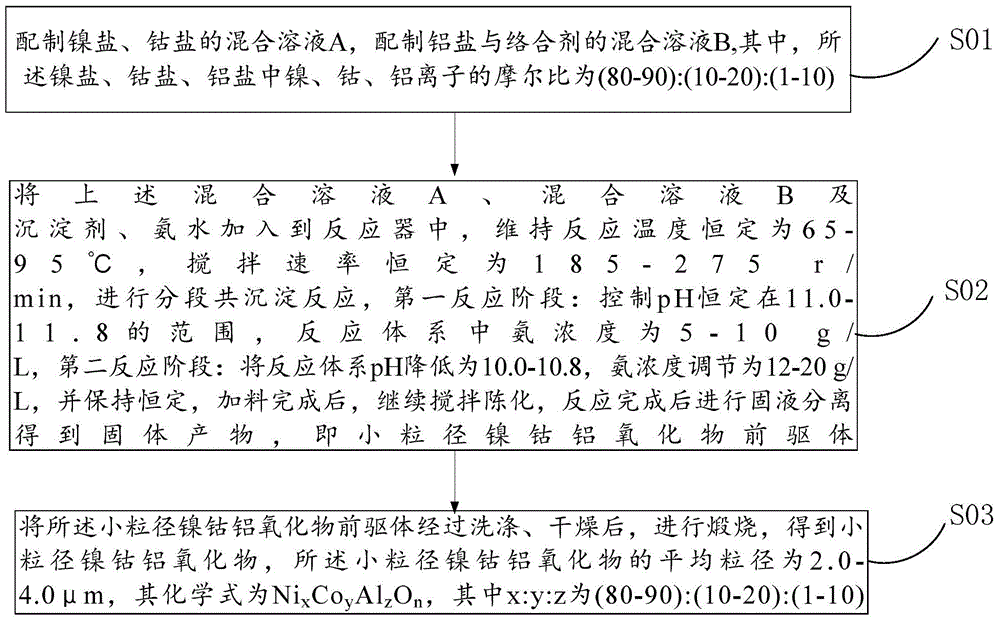

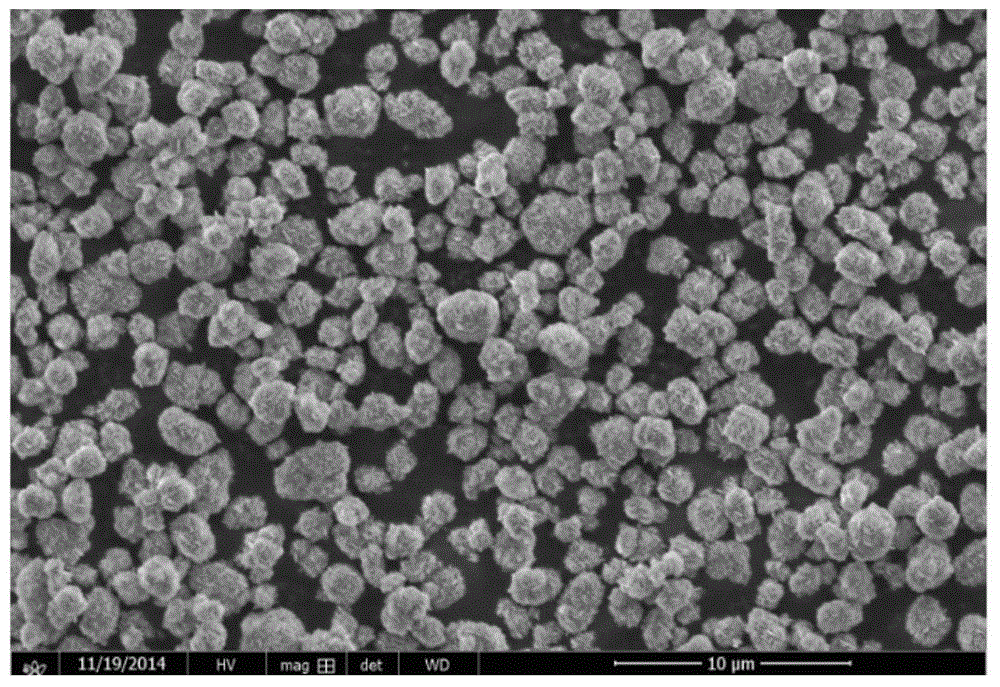

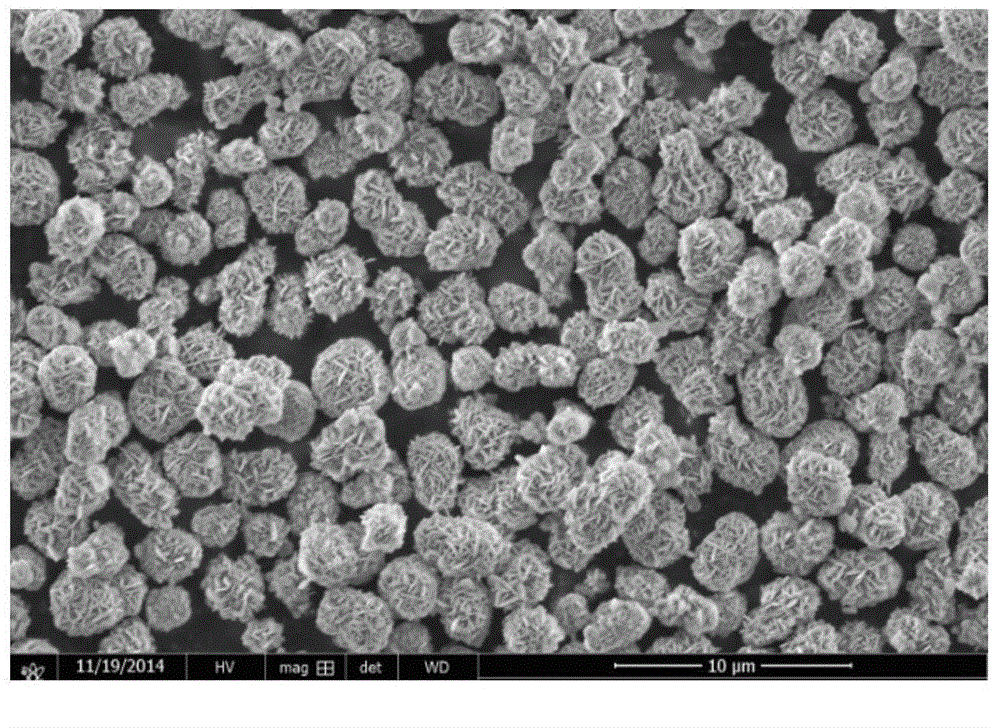

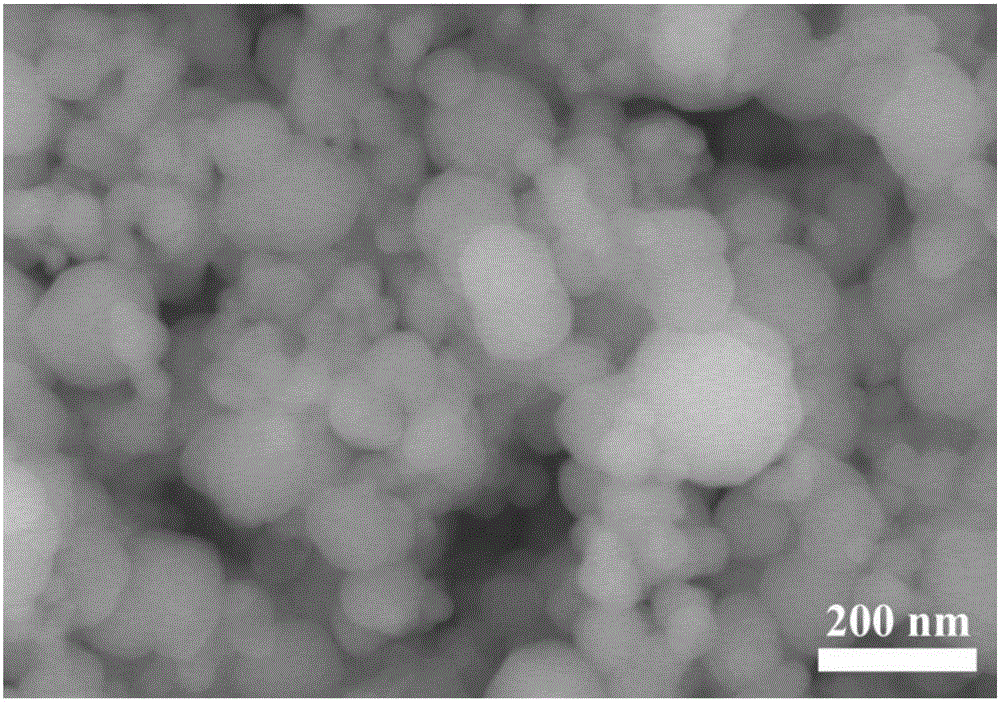

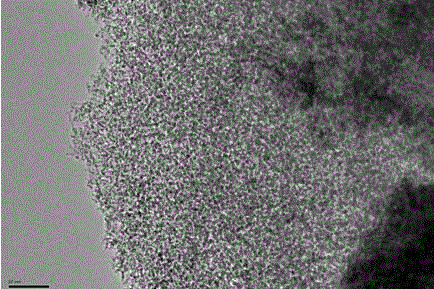

Small-particle-size nickel-cobalt-aluminum oxide and preparation method thereof

The invention provides a small-particle-size nickel-cobalt-aluminum oxide which is regular spherical, relatively good in sphericity degree and uniform in particle size distribution and has the average particle size of 2.0-4.0 [mu]m; the bulk density is greater than 0.8 g / cm<3>, the tap density is greater than 1.2 g / cm<3>, and the small-particle-size nickel-cobalt-aluminum oxide can be used for stacking and filling with a large-particle-size nickel-cobalt-aluminum oxide, so as to solve the application problem of low tap density of a positive electrode material. The invention also provides a preparation method of the small-particle-size nickel-cobalt-aluminum oxide, wherein the preparation method comprises the steps: adding a nickel and cobalt mixed solution, an aluminum-complexing agent mixed solution, a precipitating agent and ammonia water into a reactor in a parallel flow manner, and controlling conditions of high pH and low ammonia concentration during an initial stage of a reaction; in the reaction process, under conditions of low pH and high ammonia concentration, making nucleation and growth of a nickel-cobalt-aluminum precursor implemented separately, preparing a small-particle-size nickel-cobalt-aluminum oxide precursor, and calcining to obtain the small-particle-size nickel-cobalt-aluminum oxide with good sphericity degree and high tap density. The preparation method has the advantages of simple process, high controllability and low cost.

Owner:格林爱科(荆门)新能源材料有限公司

Method for recovering aluminum oxide, chlorine salt and villiaumite from aluminum ash

InactiveCN103060566AImprove efficiencyHigh recovery rateProcess efficiency improvementAluminium oxides/hydroxidesBall millMolten slag

The invention discloses a method for recovering aluminum oxide, chlorine salt and villiaumite from aluminum ash. The method comprises the following steps of: A, re-smelting aluminum ash taken out of a furnace at 700-850 DEG C until aluminum in the aluminum ash is separated from molten slag; B, ball-milling the molten slag, and then, screening by using a 30-mesh screen so as to obtain residual ash of the aluminum ash through screening; C, leaching the residual ash of the aluminum ash in water for 90-200min; D, carrying out solid-liquid separation, and recovering a solid phase and a liquid phase; and E, evaporating the liquid phase to obtain a mixture of the chlorine salt and the villiaumite. According to the embodiment of the invention, more substances are recovered, the recovery rate is high, the recovery rate of aluminum is increased to over 95%, almost of all the aluminum oxide can be recovered, and the recovery rates of the chlorine salt and the villiaumite can also be up to over 85%.

Owner:HUNAN CHUANGYUAN ALUMINUM IND

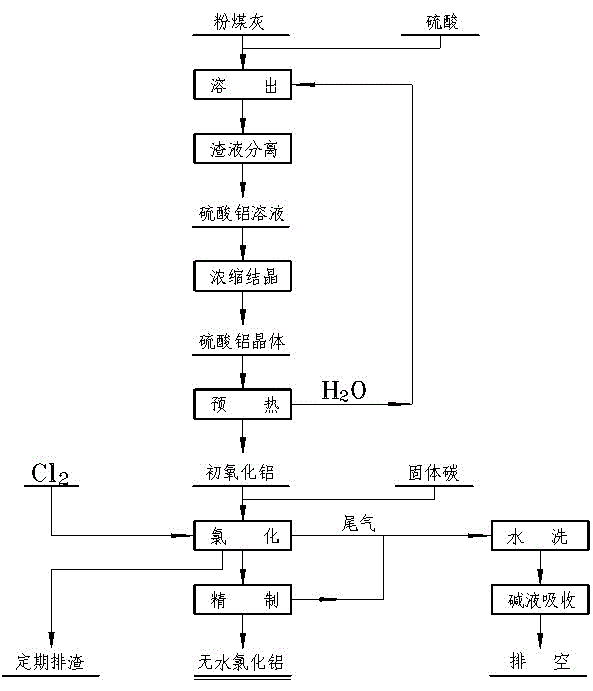

Preparation method of anhydrous aluminum chloride

ActiveCN103936047AReduce consumptionReduce manufacturing costAluminium chloridesSolid carbonElectrolysis

The invention discloses a preparation method of anhydrous aluminum chloride; and the method is as follows: using fly ash or aluminum ore with more than 25% of alumina as a raw material for leaching with sulfuric acid to obtain an aluminum sulfate solution, then concentrating for crystallization to obtain an aluminum sulfate crystal, and preheating at above 80 DEG C for more than 30 minutes to remove crystal water to obtain aluminum sulfate; mixing the aluminum sulfate and solid carbon, then adding into a chlorination furnace with the temperature above 600 DEG C and the pressure of normal pressure or slightly negative pressure, letting in chlorine gas to produce an anhydrous aluminum chloride mixed gas with the mass percent content of more than 30%, and then refining and purifying to obtain the anhydrous aluminum chloride with a purity above 99%. Chlorination tail gas is washed with water, absorbed by use of an alkaline solution, and then discharged. The preparation method has the characteristics cheap and easily-available raw materials, less energy consumption, simple process, easiness in industrial large-scale production and the like. Because of the characteristics, the preparation method is especially suitable for the anhydrous aluminum chloride preparation in the production of metal aluminum by aluminum chloride molten salt electrolysis method.

Owner:GUIYANG AL-MG DESIGN & RES INST

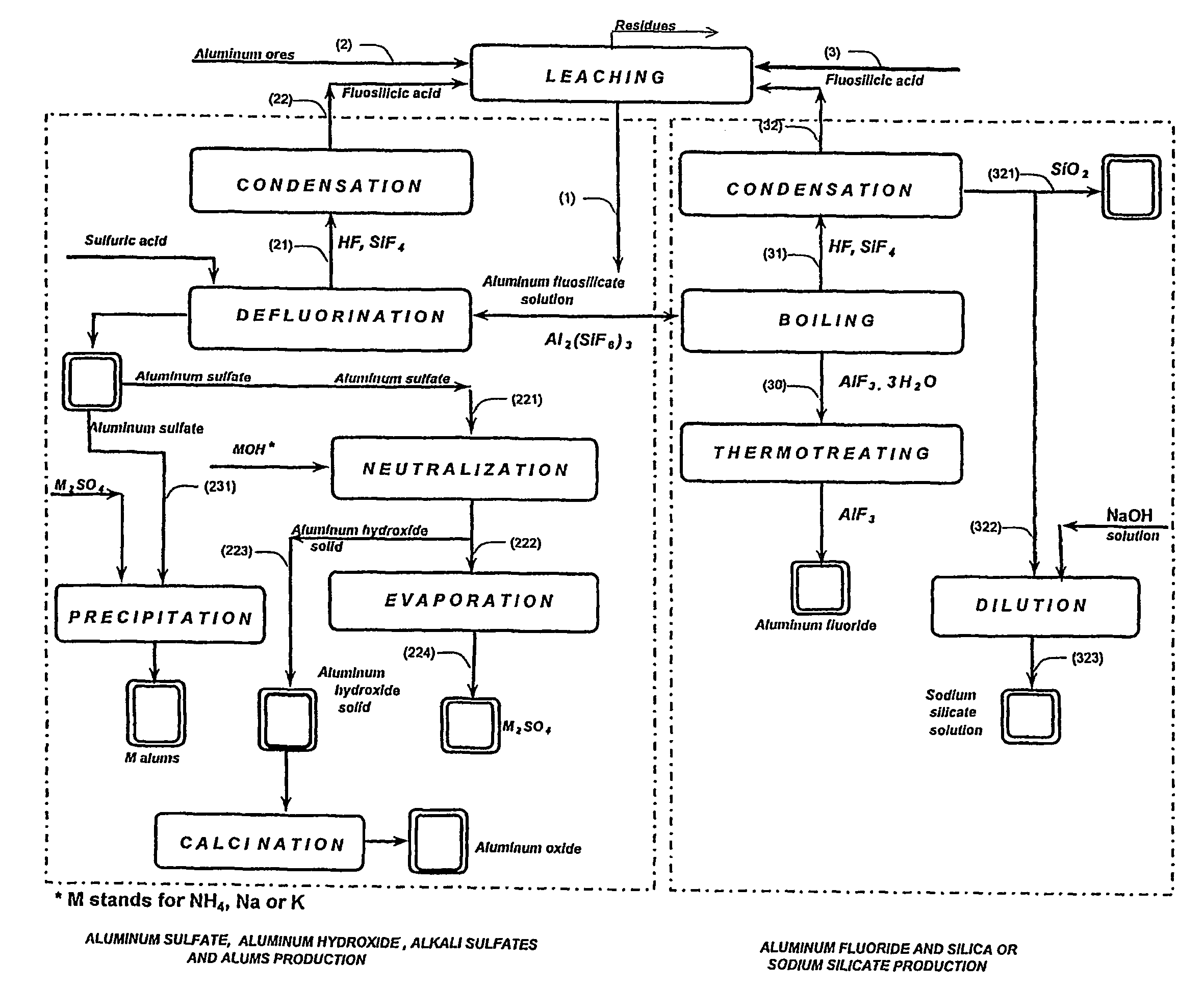

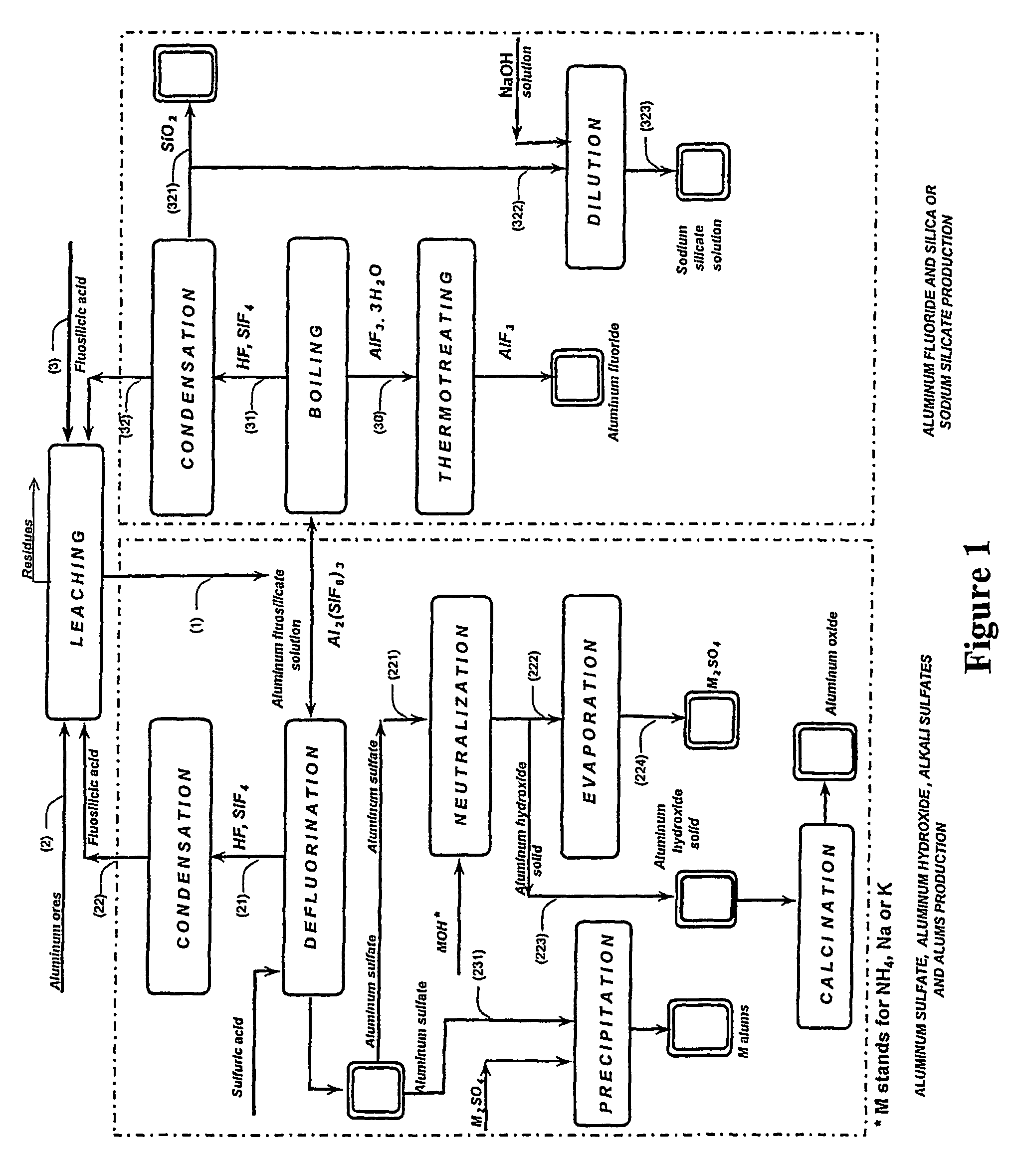

Production of aluminum compounds and silica from ores

A method for the production of inorganic aluminum substances and amorphous silica from aluminum oxide containing ores, comprising: (a) leaching of said ores with fluorosilicic acid to obtain aluminum fluosilicate solution; (b) filtering said leached solution from insoluble materials; and (c) washing said insoluble materials.

Owner:ATI ALUMINUM TECH ISRAEL

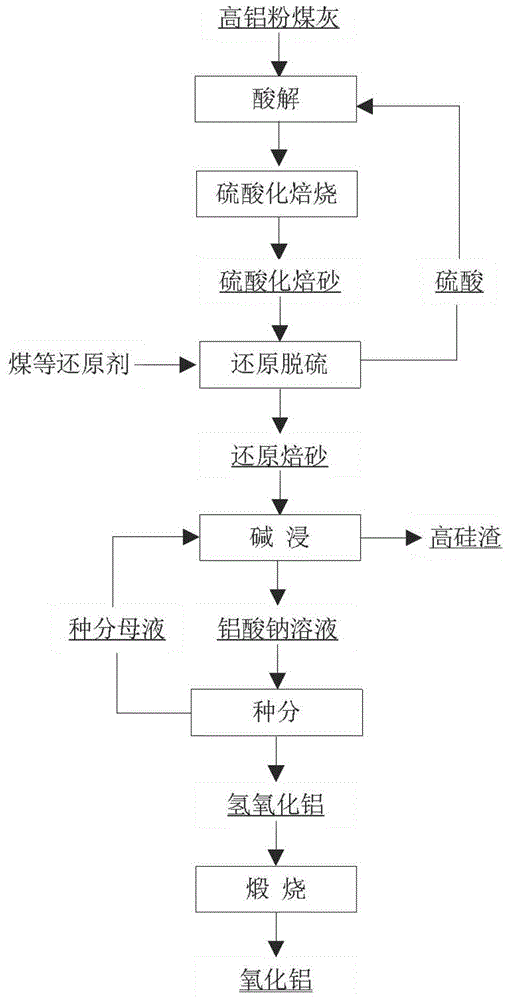

Method for producing aluminum oxide from high-alumina fly ash

ActiveCN104787788AKeep aliveImprove product qualitySolid waste disposalAluminium oxides/hydroxidesHigh energySlag

The invention discloses a method for producing aluminum oxide from high-alumina fly ash. The method comprises the following steps: adding concentrated sulfuric acid into fly ash in batches, stirring uniformly, performing acidolysis and curing after adding concentrated sulfuric acid and stirring uniformly each time, then heating to 200-500 DEG C, performing sulfating roasting for 1-4 hours, and obtaining a sulfated roasted product; performing reduction roasting on the sulfated roasted product and a reducing agent at a temperature of 550-900 DEG C, leaching a reduced roasted product with a solution containing sodium hydroxide, performing liquid-solid separation to obtain a sodium aluminate solution and silicon-rich slag, removing silicon from the sodium aluminate solution, performing seed precipitation and calcination to produce aluminum oxide, and returning a seed precipitation mother solution for leaching out the reduced roasted product. The method not only guarantees the activity of aluminum oxide in the reduced roasted product but also cancels a high-energy-consumption process in a conventional sulfuric acid method; the method is simple in process and low in energy consumption, and an aluminum oxide product is good in quality; by adding acid by step in the sulfuric digestion step, the acid utilization ratio is increased, the acidolysis process is convenient to operate, and the reducing agent consumption in subsequent reduction roasting is reduced.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

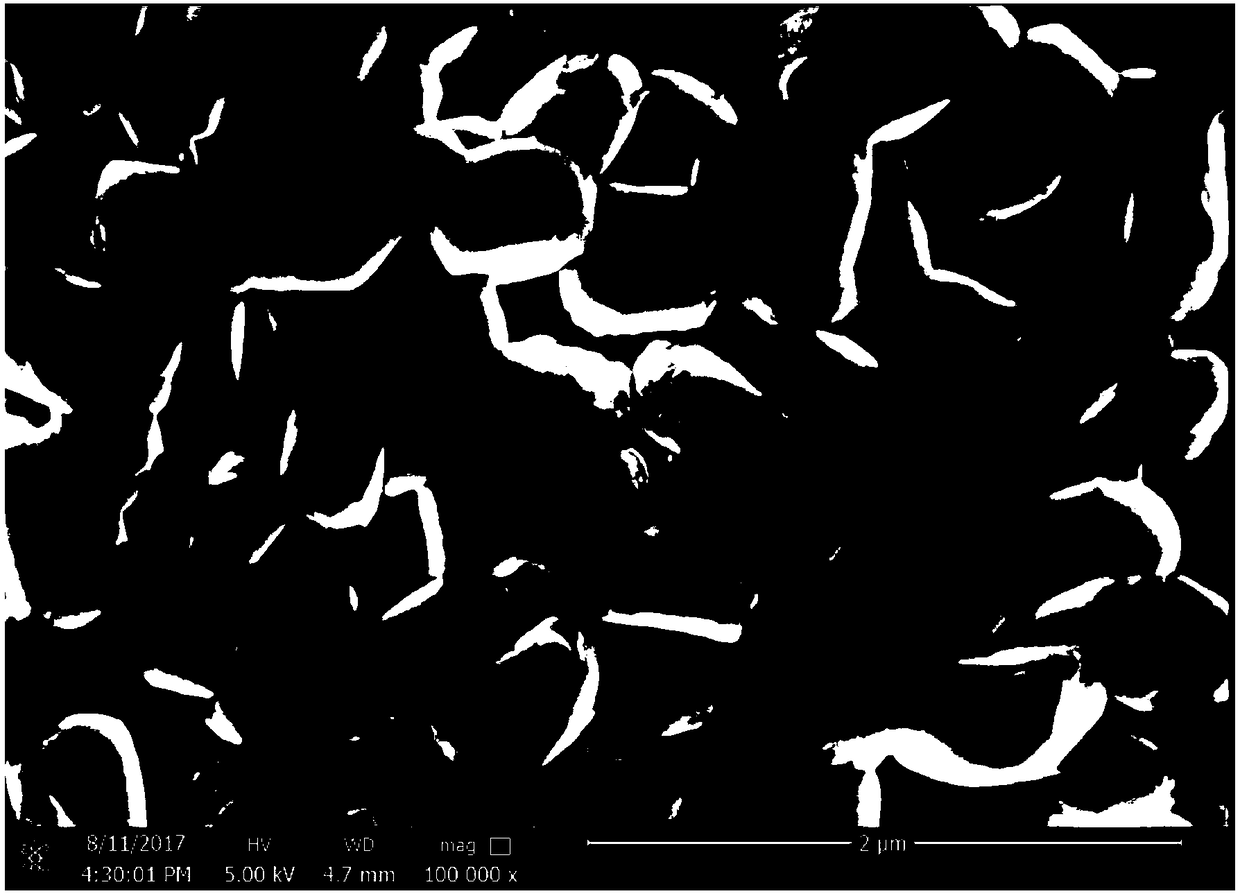

Aluminum oxide particle and polishing composition containing the same

ActiveCN102105266AReduce polishing rateReduced wash-off easeOther chemical processesAbrasion apparatusSemiconductorSemiconductor device

Disclosed are aluminum oxide particles wherein primary particles have a hexahedral shape and an aspect ratio of 1-5. The average primary particle diameter of the aluminum oxide particles is preferably 0.01-0.6 [mu]m. The a-particle ratio in the aluminum oxide particles is preferably 5-70%. The average secondary particle diameter of the aluminum oxide particles is preferably 0.01-2 [mu]m, and the value obtained by dividing the 90% particle diameter of the aluminum oxide particles by the 10% particle diameter is preferably 3 or less. The aluminum oxide particles are used as abrasive grains for polishing semiconductor device substrates, hard disk substrates or display substrates.

Owner:FUJIMI INCORPORATED

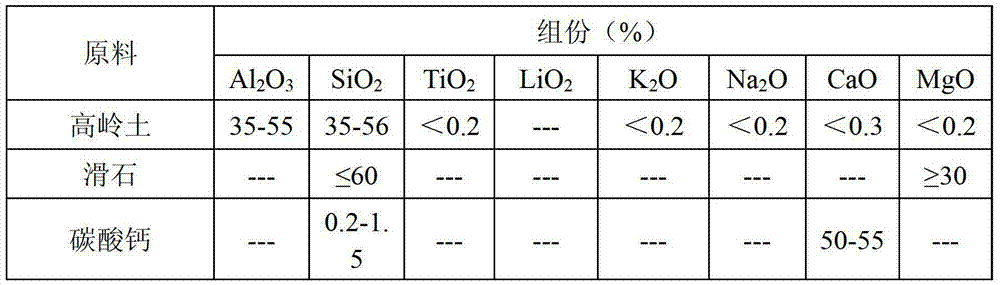

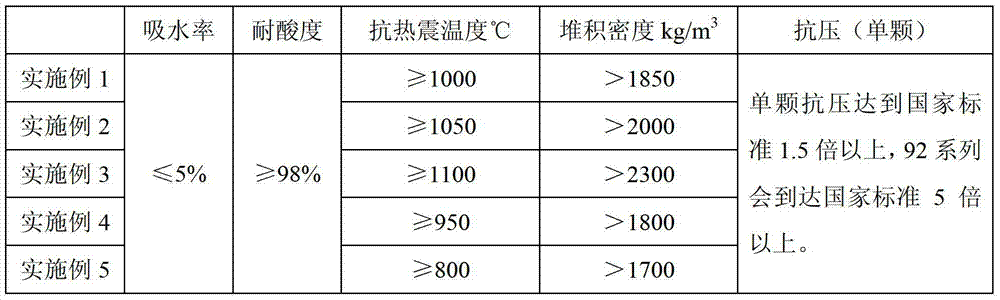

Method for preparing inert porcelain ball by using aluminum oxide dust-recovery powder

The invention discloses a method for preparing an inert porcelain ball by using an aluminum oxide dust-recovery powder and belongs to the technical field of new materials. A lot of aluminum oxide dust-recovery powder is used in the formulation of the method disclosed by the invention, the cost is obviously reduced, meanwhile a waste material is used and the environment is protected. According to the method disclosed by the invention, a composite sintering aid comprising calcium carbonate, talcum, and spodumene mineral powder is added into the formulation to facilitate the formation of magnesia-alumina spinel and mullite for enhancing in the product so as to improve the thermal shock resistance and strength of a product; a little kaolin is added into the formulation for improving the plasticity of a perform body, promoting molding conveniently and improving the strength of a green body; meanwhile in order to reduce the high energy consumption caused by wet ball milling, the powder for preparing the inert porcelain ball disclosed by the invention is subjected to continuous dry wet milling; the inert porcelain ball prepared by the method disclosed by the invention has the characteristics of high temperature resistance, high strength, good thermal shock resistance and the like, is excellent in comprehensive performance, and is completely suitable for requirements for a catalyst carrier and supporting performance in various industries.

Owner:JINGANG NEW MATERIALS

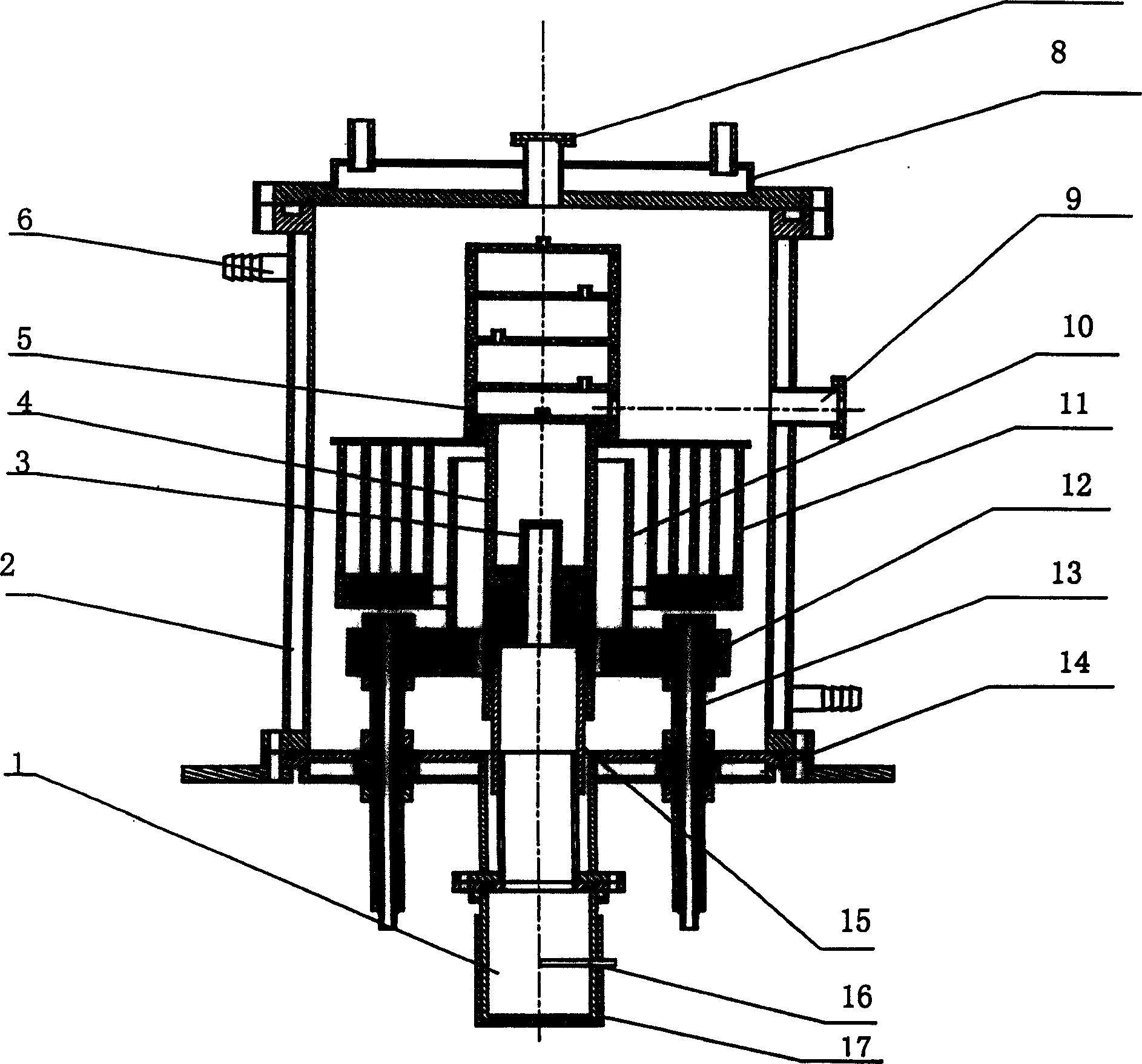

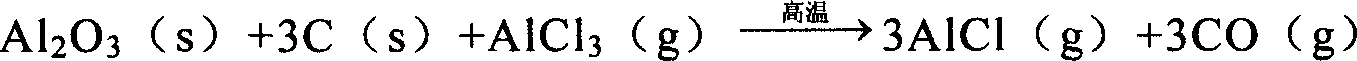

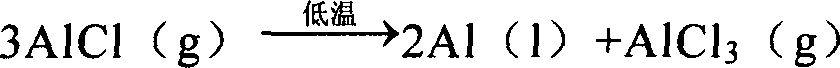

Vacuum carbon heat reduction aluminium smelting method

A process for refining Al from alumina ore by vacuum carbothermic reduction method includes such steps as loading alumina ore, reducing agent and chlorinating agent in internally heated vacuum furnace, reaction at 1270-1570 deg.C under 5-400 Pa for 100-120 min to obtain AlCl, and lowering the temp to lower than 900 deg.C to obtain metallic Al with high purity (more than 95%) and AlCl3 with more than 78% in recovery rate.

Owner:KUNMING UNIV OF SCI & TECH

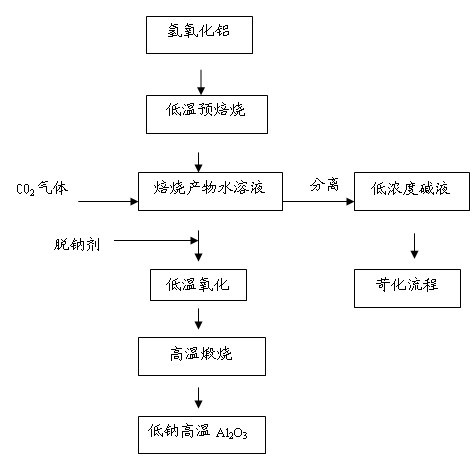

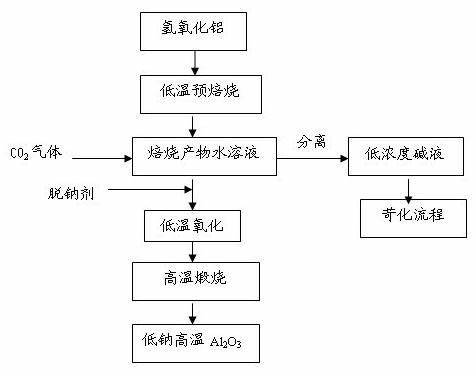

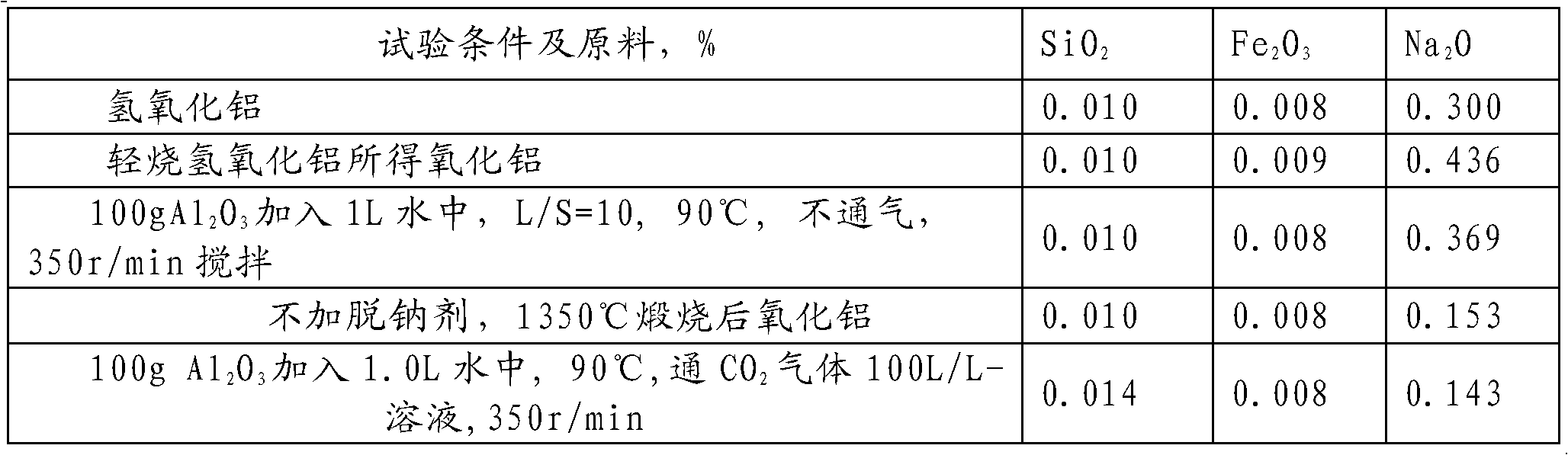

Method for reducing sodium oxide in aluminum oxide by using carbon dioxide

ActiveCN102070168AReduce sodium oxide contentLow costAluminates/aluminium-oxide/aluminium-hydroxide purificationAluminium oxide/hydroxide preparationCooking & bakingFree cooling

The invention discloses a method for reducing sodium oxide in aluminum oxide by using carbon dioxide. The method comprises the following steps of: pre-baking aluminum hydroxide and adding a baked product into water to prepare baked product aqueous solution for later use; introducing CO2 gas into the baked product aqueous solution and fully stirring; adding a small number of sodium removing agents into the baked product aqueous solution into which the CO2 gas is introduced; performing liquid-solid separation; drying to obtain a solid; calcining the solid at a high temperature; and naturally cooling to obtain low-sodium aluminum oxide. By the method, the cost for manufacturing the high-temperature low-sodium aluminum oxide can be reduced, the variation in product performance caused by the sodium removing agent can be reduced, and a new approach is discovered for utilization of the carbon dioxide.

Owner:中铝山东有限公司

Method for producing aluminum oxide by using fly ash

The invention provides a method for producing aluminum oxide by using fly ash. The method comprises the following steps of: 1) performing predesilicification on the fly ash to obtain desiliconized fly ash; 2) mixing the desiliconized fly ash and sodium carbonate, and roasting to obtain clinker; 3) dissolving the clinker into acid, filtering, and collecting the solution; 4) concentrating the solution to precipitate aluminum salt crystal; and 5) preparing the aluminum oxide product from the aluminum salt crystal. The method for producing the aluminum oxide by using the fly ash has the advantages of low production energy consumption, low waste slag discharge and high product purity.

Owner:DATANG INT POWER GENERATION +1

Preparation method of aluminum oxide powder 3D printing material

InactiveCN104788081APrevent splashSmall median diameterAdditive manufacturing apparatusEpoxyPetroleum resin

The invention discloses a preparation method of an aluminum oxide powder 3D printing material. The preparation method is characterized by comprising the following steps: adopting a sodium hexametaphosphate aqueous solution to pretreat the aluminum oxide powder, and obtaining the pretreated aluminum oxide powder; adding the following constituents into a grinding miller according to mass percent: 80-87% of aluminum oxide powder, 2-6% of photosensitive epoxy resin, 1-3% of petroleum resin and 0.5-3% of hydroxylamine hydrochloride; starting the grinding miller, keeping the revolving speed to be 400 rpm, grinding for 5 minutes, and then adding 8-15% of acetone, wherein the sum of the constituents in mass percent is 100%; keeping the revolving speed of the grinding miller to be 400 rpm, then grinding for 20-30 minutes, drying, and at last obtaining the aluminum oxide powder 3D printing material. The material can be directly molded instead of being sprayed with an adhesive substance under a laser sintering condition, is high in molding precision, simple in preparation process, easy to control conditions, low in production cost, and easy for industrial production.

Owner:UNIV OF JINAN

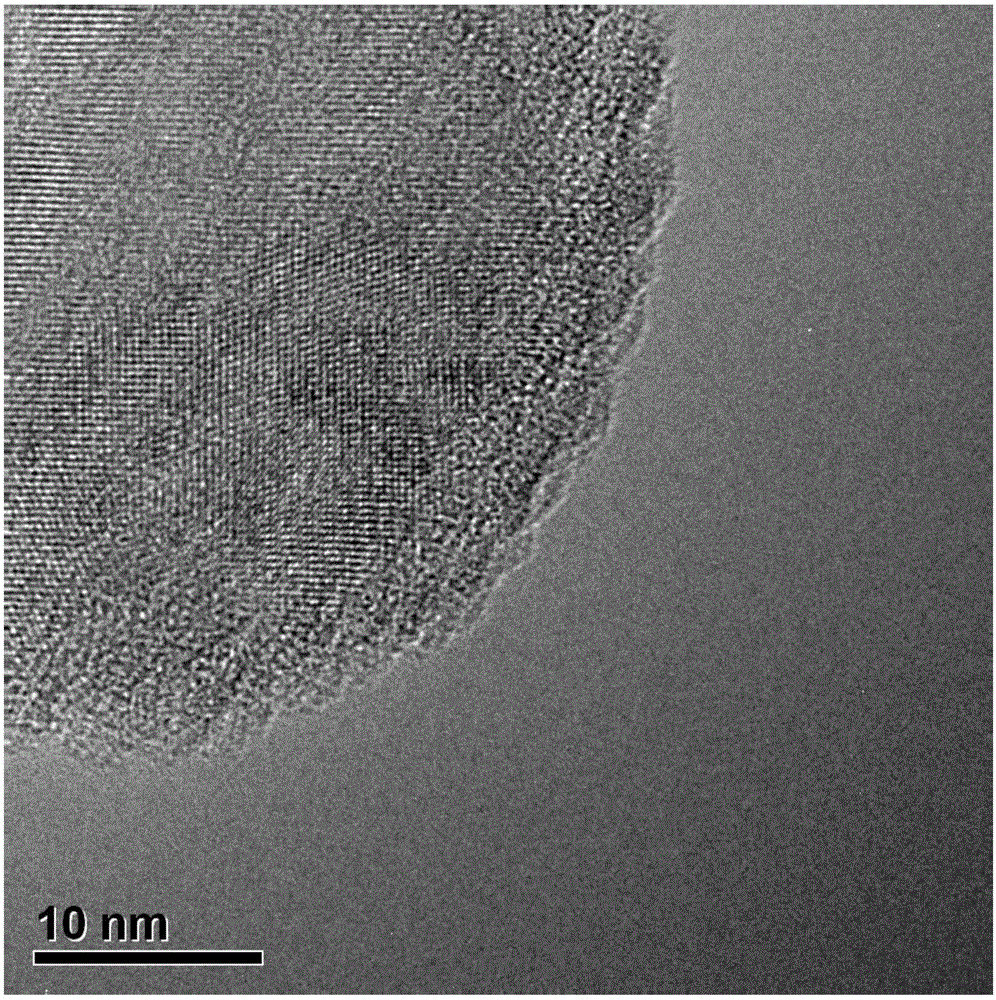

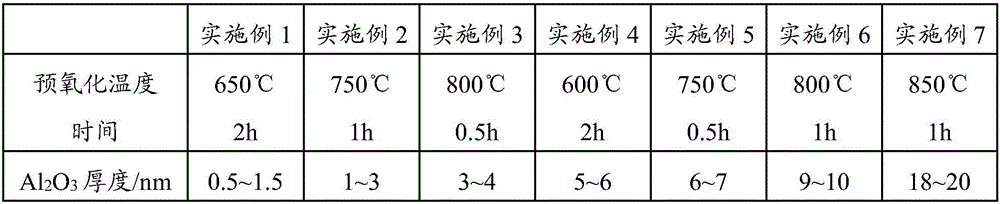

Preparation method of aluminum oxide coated silicon cathode material

ActiveCN105958023AHigh capacity retentionLow costCell electrodesSecondary cellsOrganic reactionOxygen

The invention provides a preparation method of an aluminum oxide coated silicon cathode material. The preparation method comprises the following steps: (A) in an oxygen-containing atmosphere, carrying out heat treatment of 500-1000 DEG C on nanometer silicon powder to obtain preoxidized nanometer silicon; (B) mixing the preoxidized nanometer silicon with aluminum powder and tin powder, and carrying out heat treatment of 400-900 DEG C to obtain an intermediate; and (C) treating the intermediate with acid or an oxidant to obtain the aluminum oxide coated silicon cathode material. In the preparation method, the thickness of an aluminum oxide coating layer can be controlled by adjusting the technological conditions of nanometer silicon preoxidization; the reaction raw materials are simple, flammable and combustible organic reactants and complex vacuum systems do not need to be used in the preparation process, the operation process is simple and practicable, the practicability degree is high, and the cost is low. The silicon substrate cathode material prepared and obtained by the preparation method has more stable surface structure in the lithium deembedding and embedding process, and is high in capacity retention ratio, high in cycling stability and high in performance.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

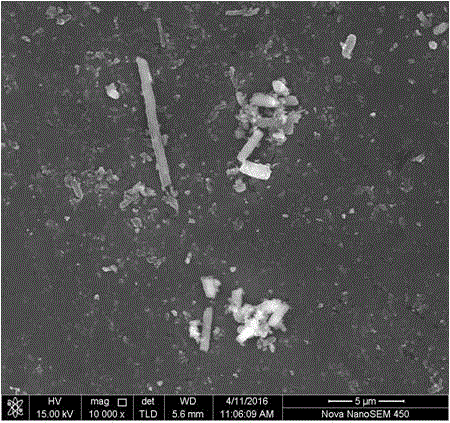

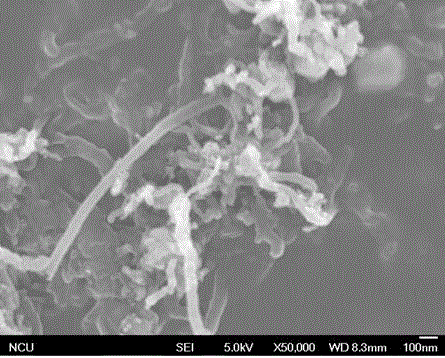

Preparation method for whisker carbon nanotube-reinforced aluminum matrix composite coated with aluminum oxide

The invention provides a preparation method for a whisker carbon nanotube-reinforced aluminum matrix composite coated with aluminum oxide. The preparation method comprises the steps that a whisker carbon nanotube coated with aluminum oxide is prepared firstly, then aluminum alloy powder is guided into turbid liquid of the whisker carbon nanotube coated with the aluminum oxide, so that a mixture is obtained, the mixture is dried in a vacuum mode at the temperature of 50-100 DEG C and then guided into a ball-milling crucible so as to be ball-milled under argon protection; the mixture is cold-pressed into a prefabricated block under the pressure of 60-150 MPa; the prefabricated block is placed in a die, the die is heated at the heating rate of 5-10 DEG C / min till the temperature of the die is 10-20 DEG C below the solid phase line, then the die continues to be heated at the heating rate of 1-5 DEG C / min and the solid phase rate of the die is controlled to 70%-90%, and thus the multi-wall carbon nanotube-reinforced aluminum matrix composite coated with pure copper is obtained. The preparation method has the advantages of being simple, safe, low in cost, easy to operate, controllable and the like.

Owner:NANCHANG UNIV

Preparation method for aluminum oxide nano-particles

ActiveCN104556176ASmall particle sizeNarrow particle size distributionMaterial nanotechnologyAluminium oxide/hydroxide preparationAluminium hydroxideSlurry

The invention discloses a preparation method for aluminum oxide nano-particles. The preparation method comprises the following steps: (1) dripping precipitant solution into aluminum salt solution under a stirring condition to generate aluminum hydroxide precipitation; controlling the adding amount of the precipitant to enable the pH value of a system to be 5-10 finally to obtain aluminum hydroxide precipitation slurry; (2) adding polyatomic alcohol in the precipitation slurry in the step (1); then transferring the slurry into a high-pressure reactor; sealing the high-pressure reactor for hydro-thermal treatment; filtering, washing, drying and roasting the precipitation after the hydro-thermal treatment to prepare the aluminum oxide nano-particles. The method is simple in process, and environmental-friendly; the prepared aluminum oxide nano-particles are uniform in particle diameter, and have wide application prospect in the fields of chemical engineering catalysis, ceramic, paint, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

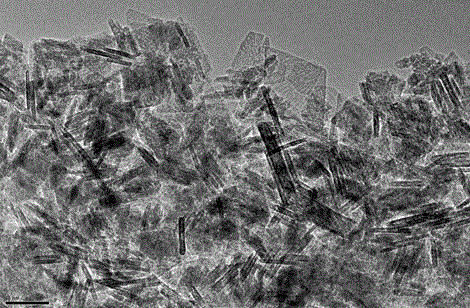

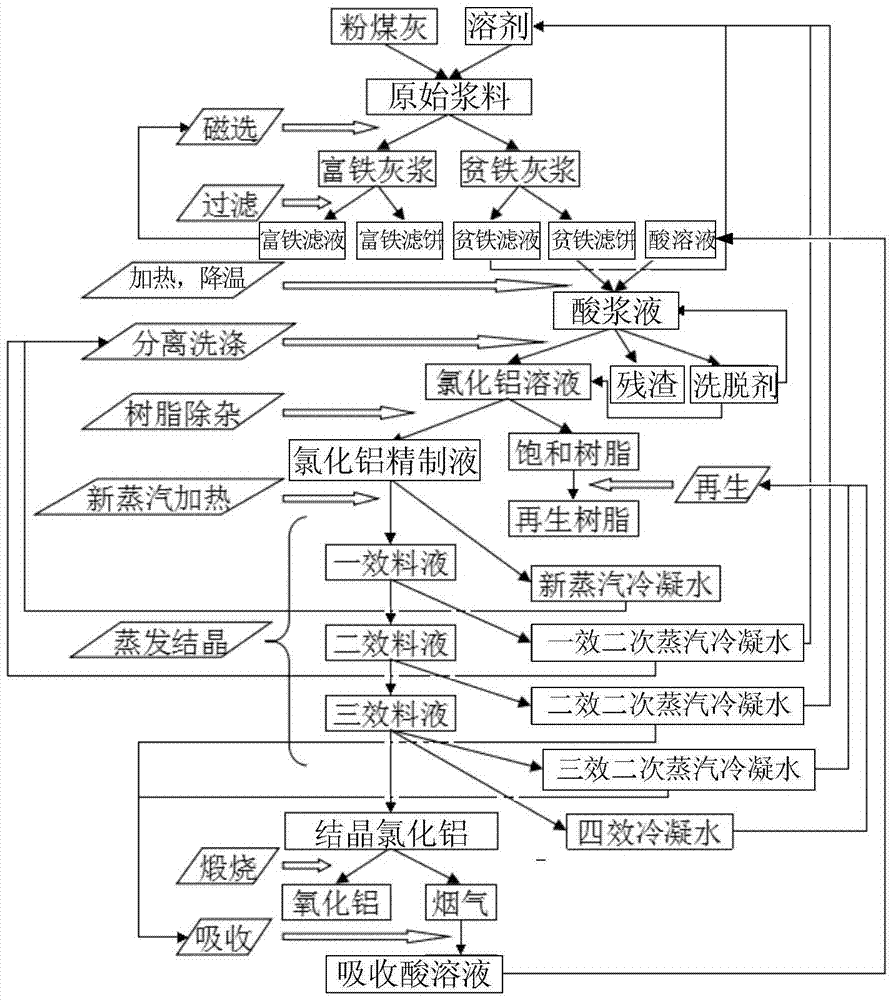

Method for producing aluminum oxide from coal ash through acid process

ActiveCN103803617ARelieve stressReduce water consumptionAluminium oxides/hydroxidesAluminium chlorideAcid dissolution

The invention provides a method for producing aluminum oxide from coal ash through an acid process. The method comprises the steps: S1, mixing coal ash and a solvent to obtain primary slurry, carrying out magnetic separation on the primary slurry, and filtering to obtain a Fe-poor filter cake; S2, carrying out acid dissolution on the Fe-poor filter cake to obtain acid slurry; S3, carrying out residue-liquid separation on the acid slurry to obtain an aluminum chloride solution and residues; S4, carrying out resin adsorption on the aluminum chloride solution to remove impurities to obtain a refined aluminum chloride solution; S5, carrying out concentration and crystallization treatment on the refined aluminum chloride solution to obtain an aluminum chloride crystal and condensed water; S6, calcining the aluminum chloride crystal to obtain aluminum oxide. The solvent in the step S1 comprises at least part of the condensed water in the step S5. The condensed water generated in the step S5 is used for preparing the primary slurry, so that the condensed water is reutilized, the condensed water treating burden in the traditional process is relieved, and the water consumption and cost are reduced.

Owner:CHINA SHENHUA ENERGY CO LTD +1

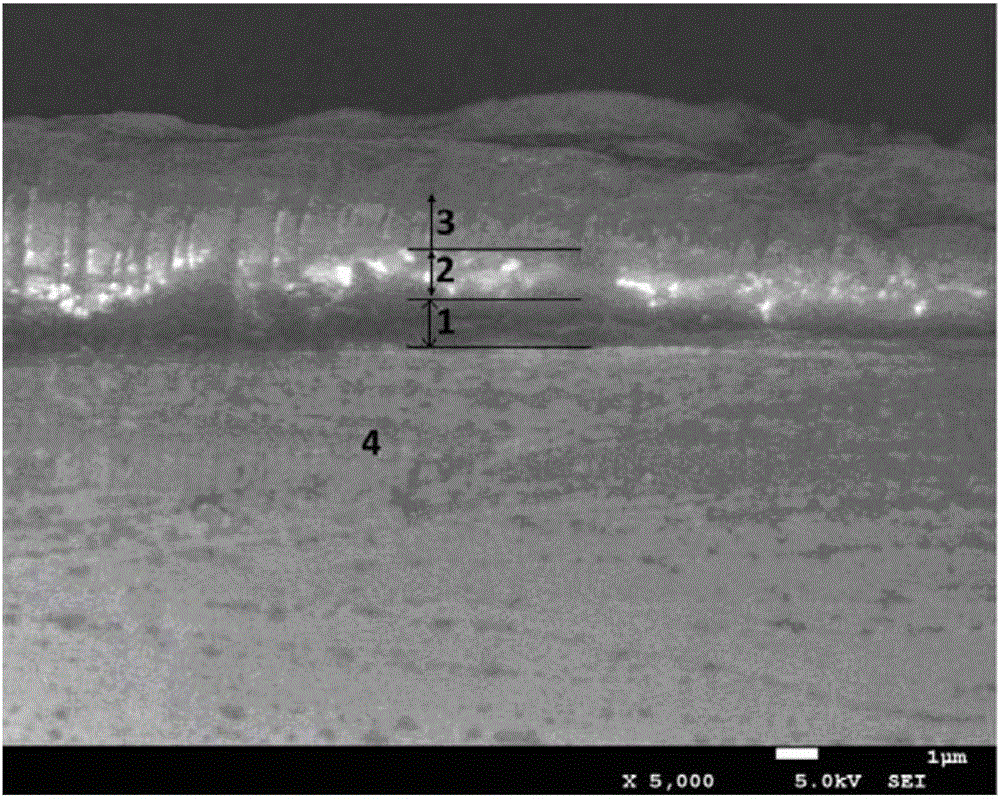

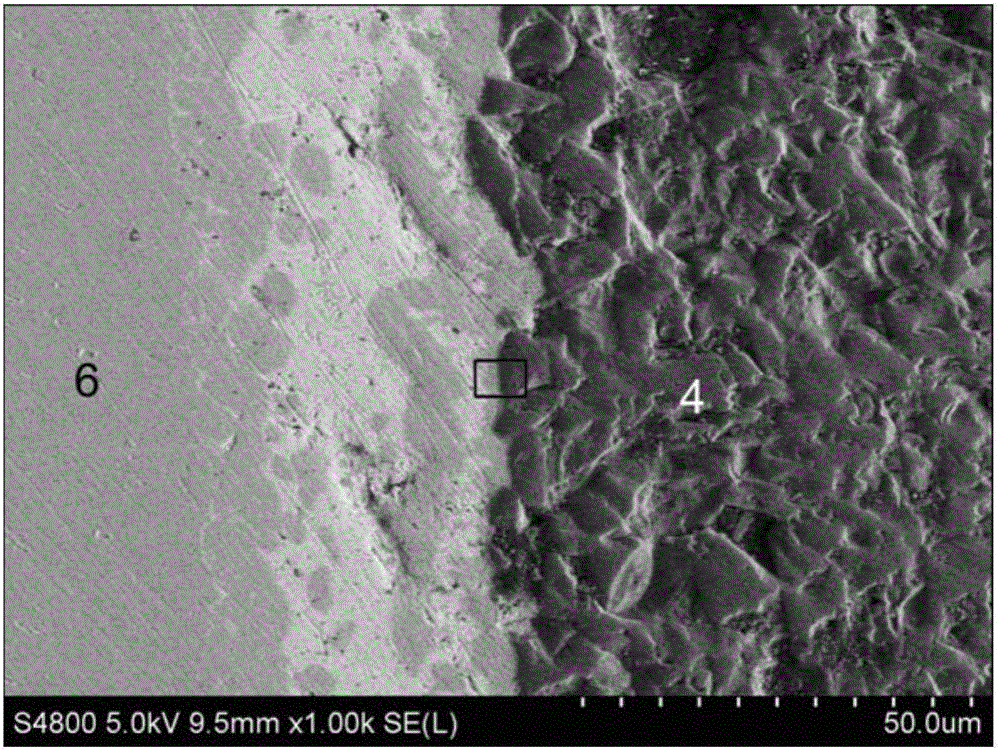

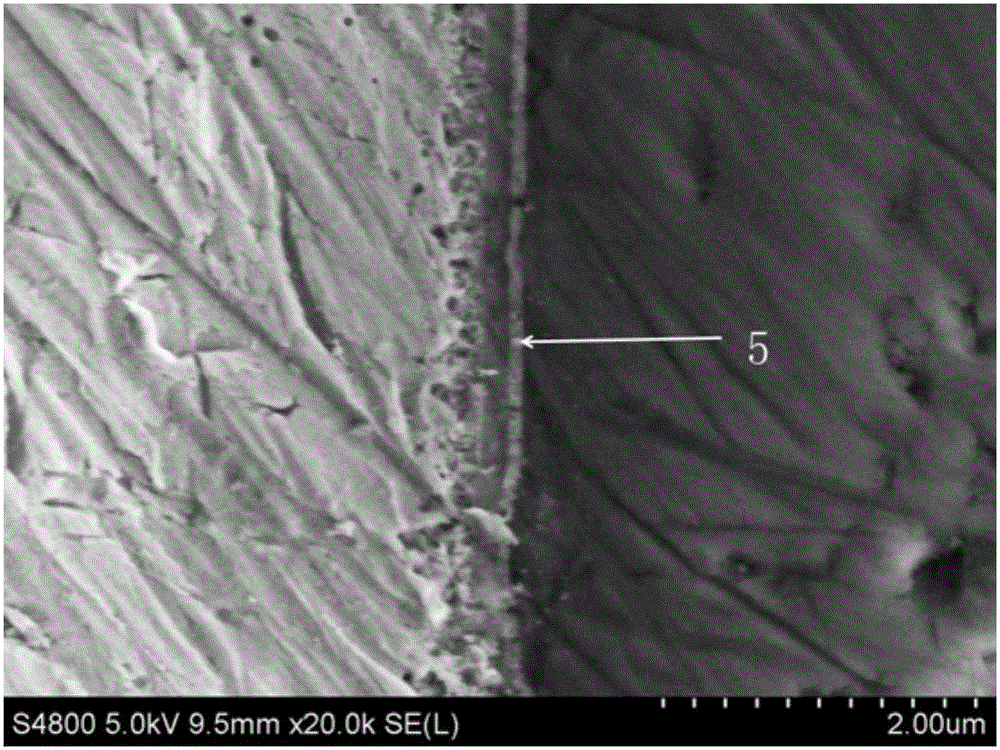

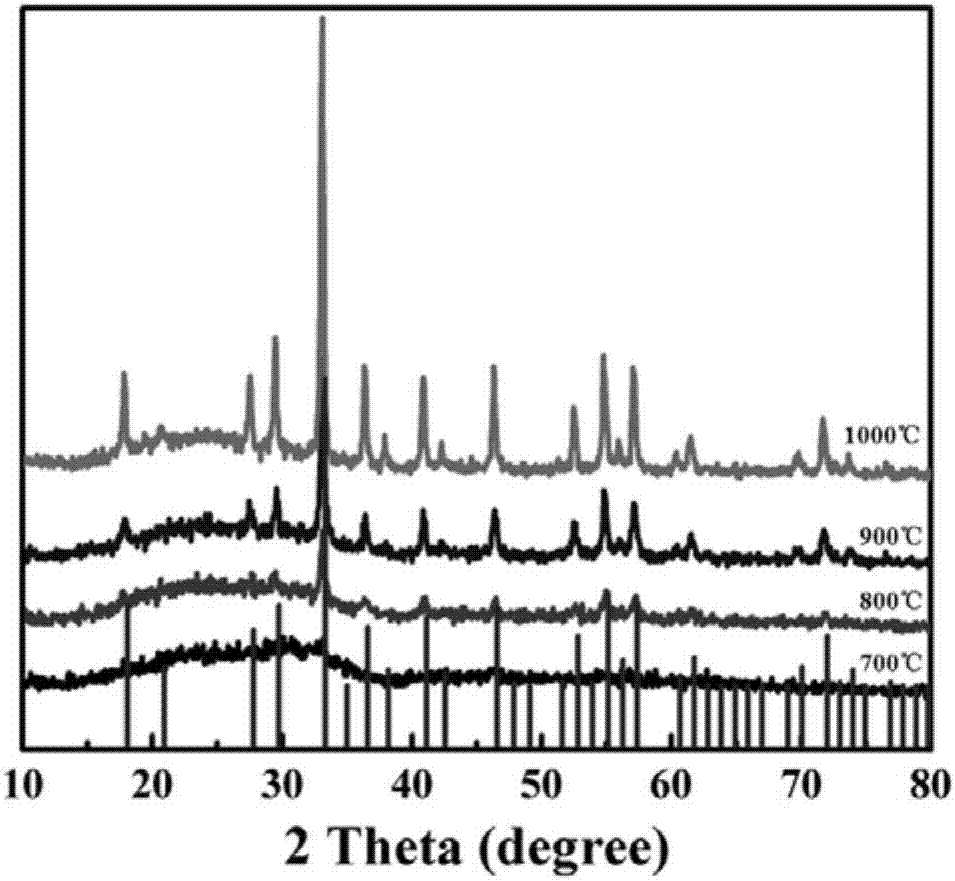

Aluminum oxide ceramic metallization method used for brazing

The invention provides an aluminum oxide ceramic metallization method used for brazing. The method comprises the steps that 1, aluminum oxide ceramic is cleaned and then sintered for 50-70 min with the temperature kept at 1,000 DEG C-1,200 DEG C; 2, a vacuum magnetron sputtering or vacuum evaporating or ion plating method is adopted for sequentially depositing a Ti or Zr or Hf metal layer, a Mo or Cr metal layer and a Ni or Cu metal layer on the surface of the part, uncovered with aluminum foil, of the aluminum oxide ceramic; 3, the aluminum oxide ceramic on which the metal layers are deposited is placed into a vacuum sintering furnace, the vacuum sintering furnace is vacuumized, heating is started when the vacuum degree in the furnace reaches 4*10<-3> Pa, the temperature in the furnace is raised to 430 DEG C-480 DEG C and is kept for 20-40 min, then the temperature is raised to 900 DEG C-1,200 DEG C and is kept for 20-60 min, after temperature keeping is finished, the aluminum oxide ceramic is cooled along with the furnace to the room temperature so that metallization of the aluminum oxide ceramic can be completed, and in the temperature rising and keeping processes, the vacuum degree in the furnace is kept higher than 6*10<-3> Pa. The process can be simplified, the metallization cost can be reduced, and the metallization effect of the high-purity aluminum oxide ceramic can be improved.

Owner:CHENGDU KENINGDA MATERIALS

Preparation method of aluminum oxide-doped lithium titanate composite negative material

ActiveCN106602053AInhibit gas productionStrong electrostatic adsorptionAlkali titanatesNegative electrodesHydrated aluminaPhysical chemistry

The invention relates to a preparation method of an aluminum oxide-doped lithium titanate composite negative material, and belongs to the technical field of lithium ion battery negative materials. The preparation method comprises the steps of firstly preparing titanium dioxide turbid liquid, and keeping in a stirring effect; then adding soluble aluminum salt solution and aqueous ammonia into the turbid liquid, thus obtaining hydrated alumina sediment, keeping a pH value in a range of 7.1-9, and attaching the hydrated alumina to the surface of titanium dioxide via electrostatic incorporation; and at last after lithium salt is mixed with the titanium dioxide / hydrated alumina, preparing the aluminum oxide-doped lithium titanate composite negative material, Li(4+x)Al(x)Ti(5-x)O12, by using a segmented sintering method, wherein x is not more than 0.5 and not less than 0.05. According to the method provided by the invention, the purpose of restraining lithium titanate from producing gas is achieved by replacing a part of Ti<4+> ions on the surface with Al <3+> ions. The material is prepared by using the electrostatic adsorption method, and thus the acquired material is high in consistency, low in cost and prone to industrial production.

Owner:四川国创成电池材料有限公司

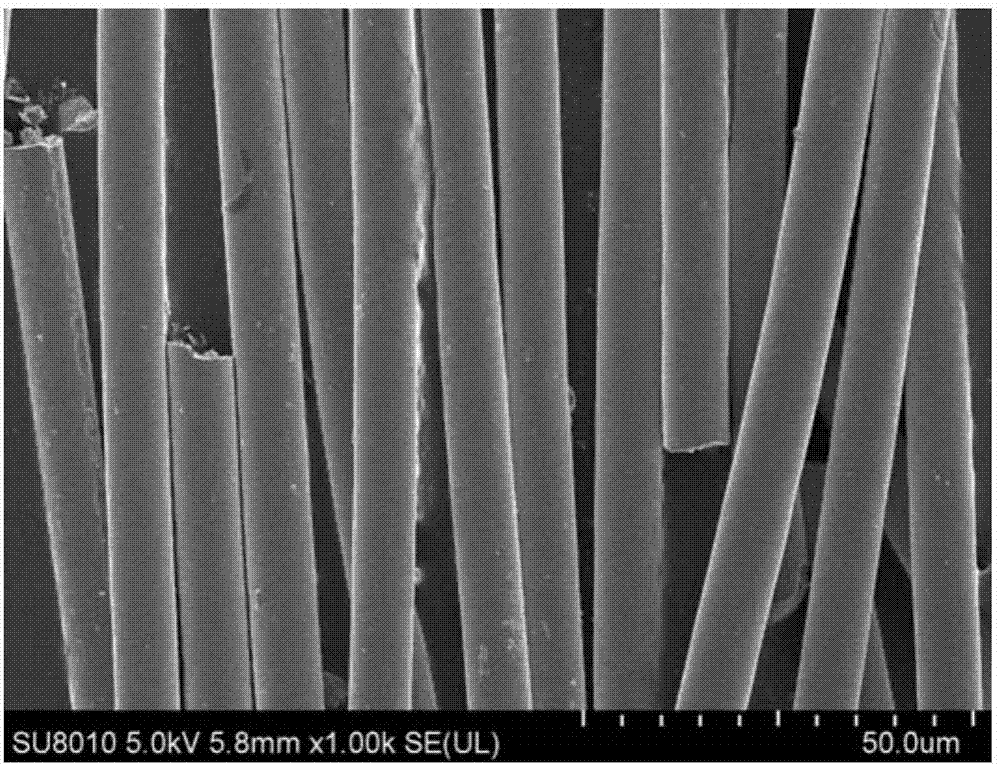

Preparation method of continuous fiber of yttrium aluminum garnet

ActiveCN106927808AGood effectUniform diameterInorganic material artificial filamentsMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention relates to a preparation method of a continuous fiber of a yttrium aluminum garnet. The method comprises the steps of preparing a spinnable precursor sol from aluminum oxide sol containing Al13 colloidal particles, a gamma-AlOOH nano dispersion liquid, yttrium oxide sol, glacial acetic acid and polyvinylpyrrolidone (PVP), preparing a gel continuous fiber by adopting a dry spinning technology and carrying out thermal treatment to obtain the continuous fiber of yttrium aluminum garnet, which is 6-12 microns in diameter. The precursor sol prepared by adopting a sol-gel method is uniform and stable, and can be stored for a long period of time. The length of the gel continuous fiber prepared with dry spinning can reach 3,000m, the fiber subjected to thermal treatment is smooth in surface, the internal structure is compact, the strength is high, and the fiber has very good flexibility, is small in high-temperature creep in a high-temperature using process, and can be widely applied to a composite material and a thermal protection material in the industries such as aerospace. The method is simple in process and short in production period, and industrialization is easy to implement.

Owner:SHANDONG UNIV

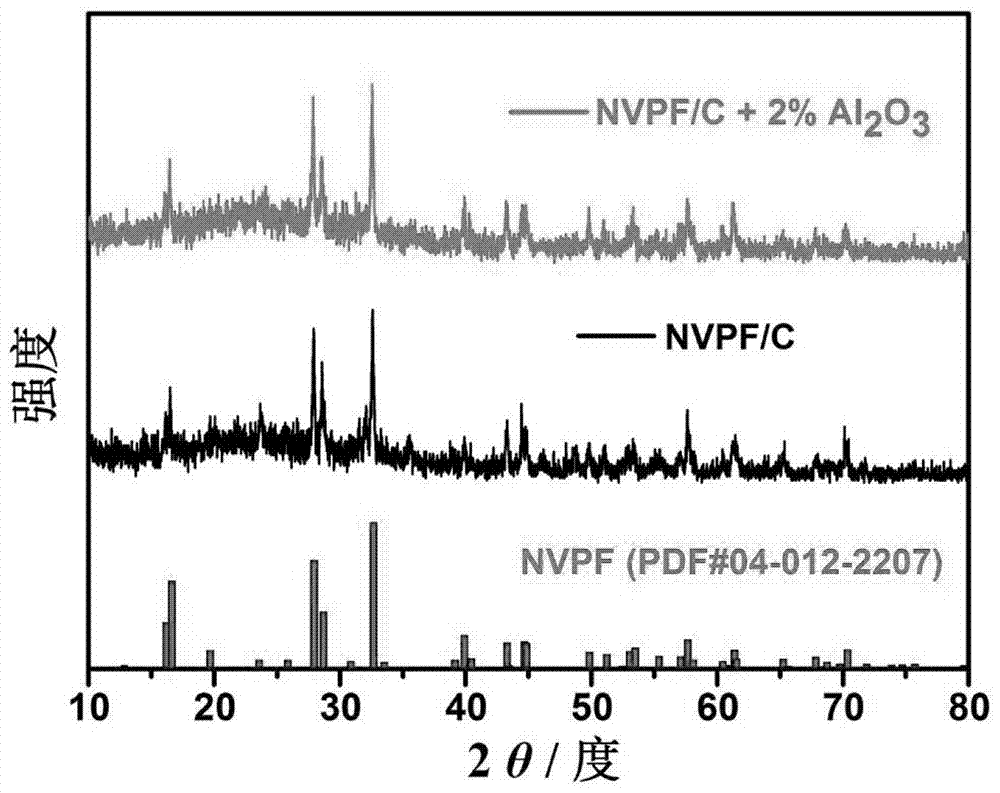

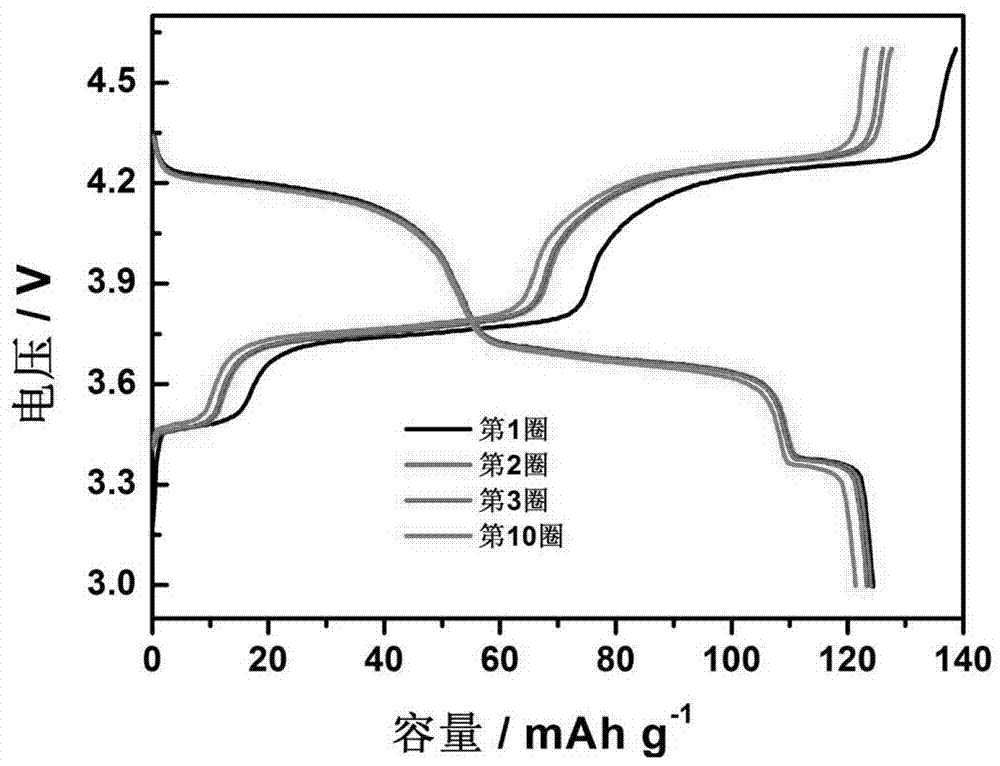

Preparation method for aluminum oxide and carbon composite coated sodium vanadium fluorophosphate positive electrode material

ActiveCN106920946ASimple processImprove cycle performanceCell electrodesSecondary cellsCarbon compositesFiltration

The invention provides an aluminum oxide and carbon composite coated sodium vanadium fluorophosphate positive electrode material and a preparation method therefor. The preparation method comprises the steps of dissolving oxalic acid H<2>C<2>O<4>, sodium fluoride NaF, a vanadium source and a phosphorus source into deionized water, and stirring at a temperature of 60 DEG C to form gel, and performing pre-calcining on the obtained powder after drying in a tubular furnace to obtain a precursor; and adding a carbon source to the precursor, performing ball milling and drying and then performing calcining in the tubular furnace in nitrogen atmosphere, and then sieving to obtain carbon-coated sodium vanadium fluorophosphate positive electrode material, performing uniform ultrasonic dispersion on the carbon-coated sodium vanadium fluorophosphate in deionized water, then adding aluminium nitrate nonahydrate Al(NO<3>)<3>.9H<2>O and performing ultrasonic processing for 20min and then stirring for 30min, next, adding ammonium hydroxide NH<3>.H<2>O, continuously stirring at a temperature of 60 DEG C for 1.5h and then performing suction filtration, washing by deionized water for multiple times and drying, and finally performing final calcining in the tubular furnace, and cooling and then sieving to obtain the aluminum oxide and carbon composite coated sodium vanadium fluorophosphate positive electrode material.

Owner:CHINA THREE GORGES UNIV

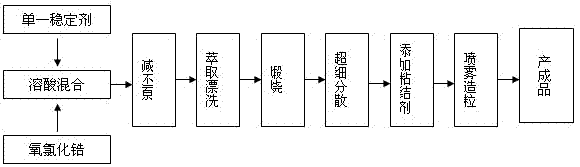

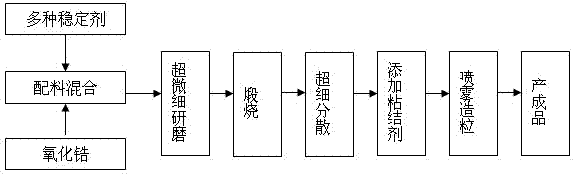

Composite stable microcrystal zirconium oxide ceramic mixed powder and manufacturing process

The invention provides composite stable microcrystal zirconium oxide ceramic mixed powder and a manufacturing process. Industrial-grade zirconium oxide powder is used as a main material and a suitable amount of cerium oxide (CeO), yttrium oxide (Y2O3), aluminum oxide and calcium carbonate (CaCO3) are used as stabilizing agents; all the components are prepared according to the following percentage by weight: 10-12% of the cerium oxide (CeO), 1-2% of the yttrium oxide (Y2O3), 3-8% of the aluminum oxide (Al2O3), 1-2% of the calcium carbonate (CaCO3) and the balance of the industrial-grade zirconium oxide powder; and the powder materials are mixed according to the proportion and the composite stable microcrystal zirconium oxide ceramic mixed powder is prepared by the steps of physically mixing, super-thinning, calcining, dispersing and granulating. With the adoption of a plurality of the stabilizing agents, the stable composition of zirconium oxide is realized, and zirconium oxide ceramic which is stably composited has better physiochemical performances.

Owner:株洲市创锐高强陶瓷有限公司

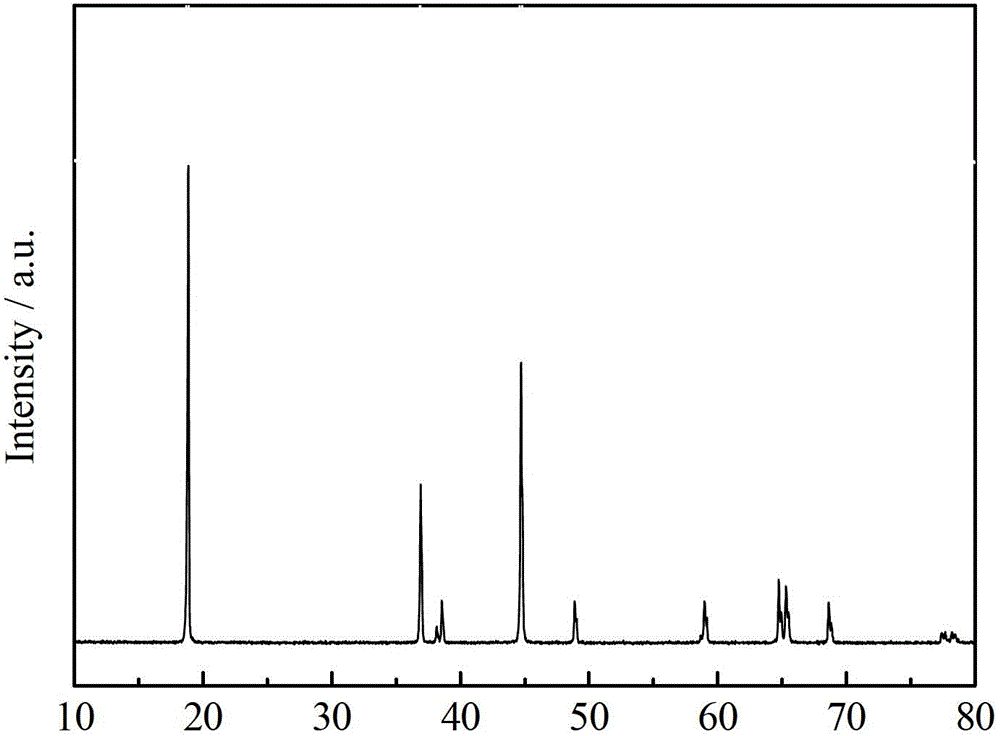

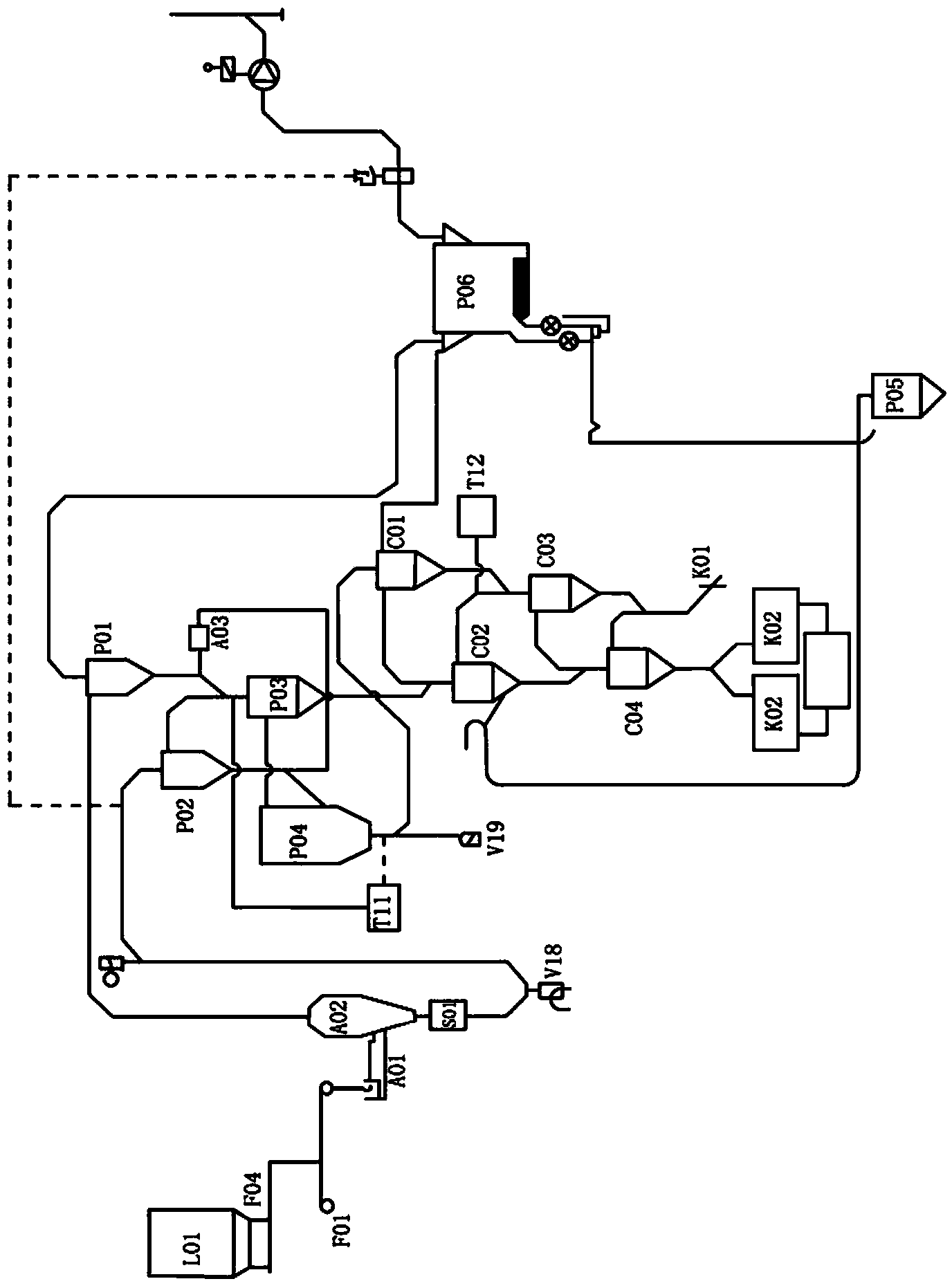

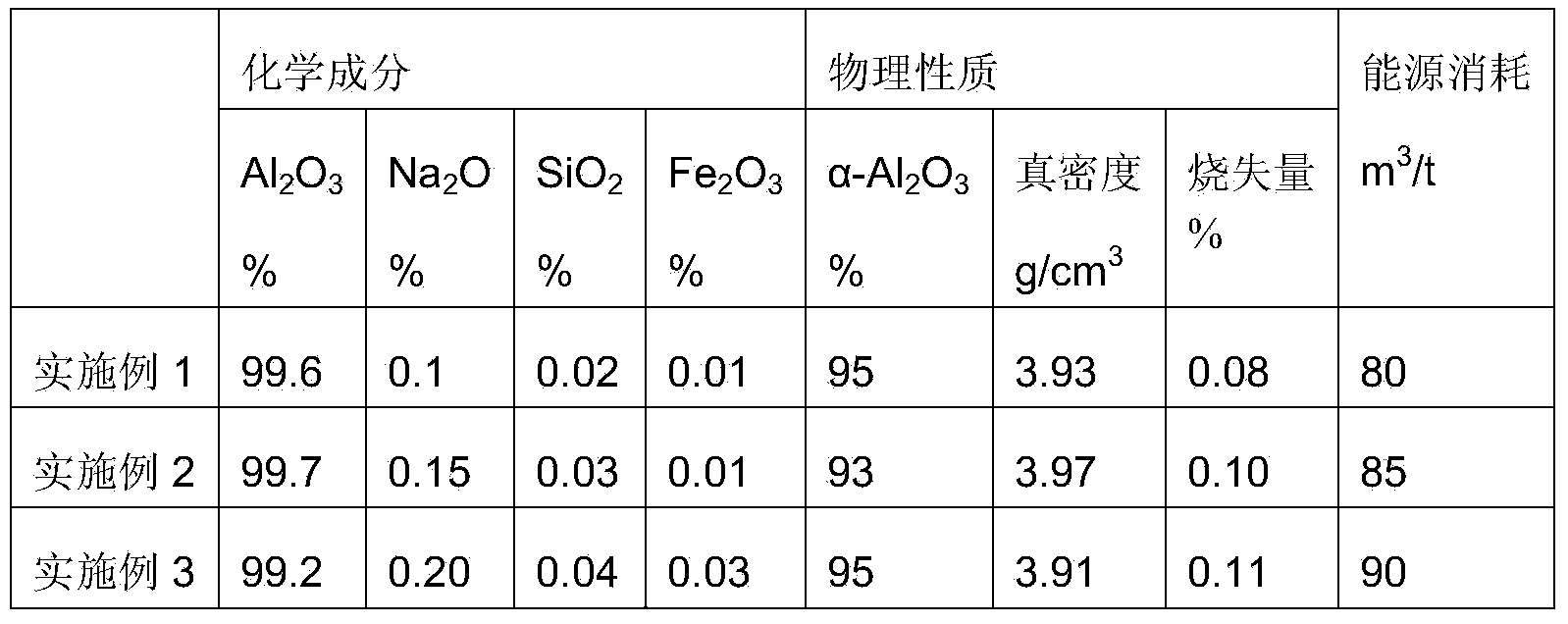

Method for producing alpha-aluminum oxide by utilizing gas-suspension roasting furnace

InactiveCN103771476AWell mixedSevere dehydrationAluminium oxide/hydroxide preparationCycloneChemical composition

The invention relates to a method for producing alpha-aluminum oxide by utilizing a gas-suspension roasting furnace. A quantitative mineralizing-agent discharging device is added between a cyclone preheater and a thermal-separation cyclone drum of the gas-suspension roasting furnace; and an electric dust collector is provided with a collecting device of dust and enriched particles. The production method comprises the following steps of: (1) feeding of aluminum hydroxide; (2) drying; (3) preheating; (4) roasting and separation; (5) primary cooling; (6) secondary cooling; (7) dust removal and ash return. The produced alpha-aluminum oxide comprises the following chemical components in percentage by weight: 99.2%-99.7% of Al2O3, 0.1-0.35% of Na2O, 0.02-0.05% of SiO2 and 0.01-0.03% of Fe2O3; and the physical properties are as follows: alpha-Al2O3 is 89-95%, the true density is 3.89-3.97g / cm<3> and the loss on ignition is 0.08-0.13%.

Owner:ZHENGZHOU JINYANGGUAN CERAMICS CO LTD

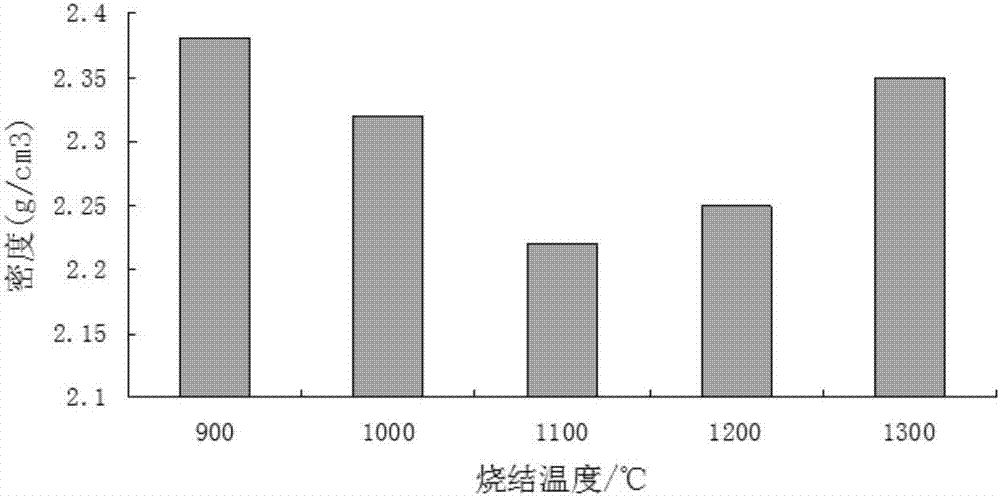

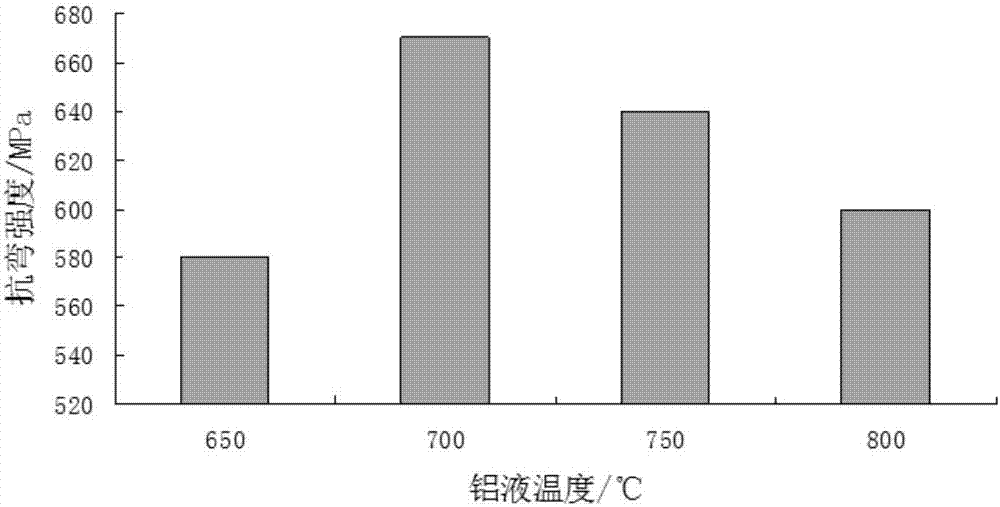

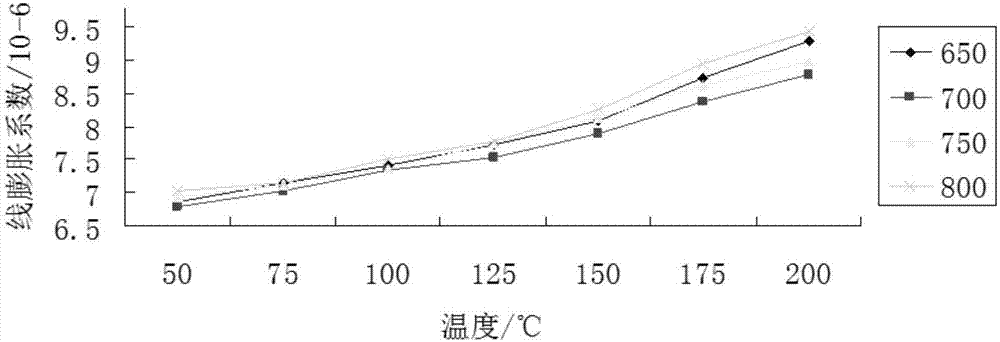

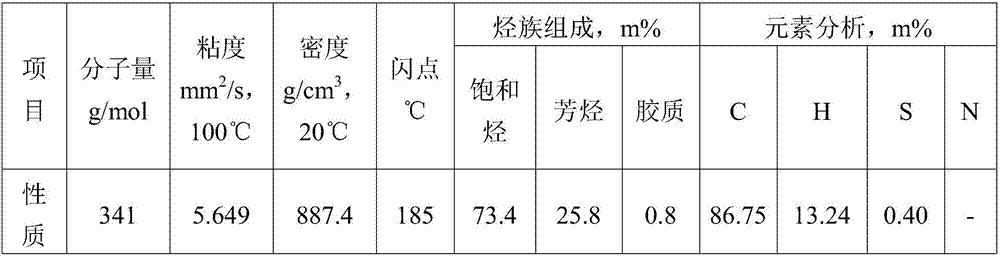

Preparation method of hollow aluminum oxide ball/silicon carbide synergetically enhanced aluminum-based composite material

The invention provides a preparation method of a hollow aluminum oxide ball / silicon carbide synergetically enhanced aluminum-based composite material. Hollow aluminum oxide balls and micron-level silicon carbide with different sizes are used as enhancement bodies, so that the overall density of the composite material is reduced on the premise of guaranteeing the mechanical property and a low thermal expansion coefficient. The adoption of the hollow aluminum oxide balls aims at reducing the density of the whole material to the maximum extent due to the characteristic of high strength of used aluminum oxide ceramic and the hollow structures of hollow aluminum oxide balls; furthermore, the interface activation energy of aluminum oxide and aluminum is relatively low; and after silicon carbide particles are added, the composite interface activation energy can be enhanced, so that the mechanical property of the composite material is higher. Due to different particle size ratios, the volume fractions of the enhancement bodies can be increased to the maximum extent, so that the mechanical strength of the composite material is enhanced, and the toughness of the aluminum and the rigidity of the enhancement bodies can reach the optimal ratios.

Owner:西安明科微电子材料有限公司

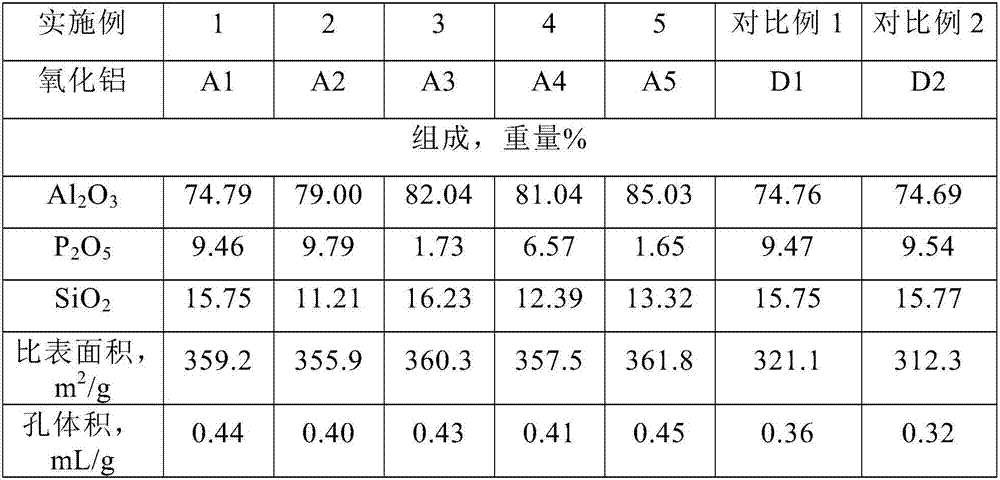

Preparation method of aluminum oxide containing phosphorus and silicon

ActiveCN107303507AProtect the micellar structureGuaranteed uniformityCatalyst carriersMolecular sieve catalystsPhosphoric acidSlurry

The invention relates to a preparation method of an aluminum oxide containing phosphorus and silicon. The method comprises the following steps: (1) mixing and pulping pseudo-boehmite and enough water for pulpifying the pseudo-boehmite and dispersing evenly; (2) adding an ammonium salt with univalent anions, stirring and standing; (3) stirring slurry in the step (2) evenly, adding a phosphoric acid or a mixture of the phosphoric acid and phosphate; and (4) finally adding a silicon-containing compound to the slurry obtained in the step (3), stirring evenly, drying and roasting to obtain the aluminum oxide containing the phosphorus and the silicon. An aluminum oxide carrier prepared through the method is capable of keeping the characteristics of high specific surface area and large pore volume of the pseudo-boehmite, the acid content of the aluminum oxide carrier can be simply adjusted by using the content of the phosphorus and the silicon within a relatively large range, and the carrier can be applied to multiple fields; and the aluminum oxide is added in the preparation process of a catalytic cracking catalyst, so that the heavy oil conversion ability of the catalyst can be improved and the yield of a target product is increased.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com