Composite stable microcrystal zirconium oxide ceramic mixed powder and manufacturing process

A technology of zirconia ceramics and mixed powder, which is applied in the field of new materials and can solve problems such as unsolved problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

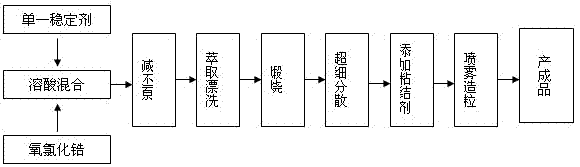

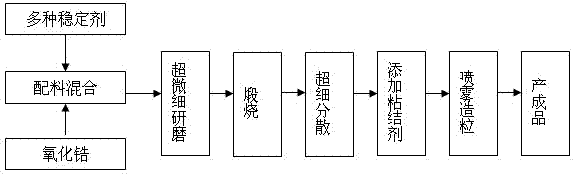

Method used

Image

Examples

Embodiment 1

[0033] A composite stable microcrystalline zirconia ceramic mixed powder and its preparation method. The main material is industrial-grade zirconia powder, and an appropriate amount of cerium oxide (CeO), yttrium oxide (Y 2 o 3 ), alumina and calcium carbonate (CaCO 3 ) as a stabilizer, and each component is formulated according to the following weight percentages:

[0034] Cerium Oxide (CeO) 10%, Yttrium Oxide (Y 2 o 3 ) 1%, alumina (AL 2 o 3 ) 3%, calcium carbonate (CaCO 3 ) 1%, the rest is industrial grade zirconia powder;

[0035] The above-mentioned powders are assembled according to the proportion, and the composite stable microcrystalline zirconia ceramic mixed powder is made through physical mixing, superfine, calcining, dispersion and granulation.

[0036] The main ingredient is industrial grade zirconia powder;

[0037] The above composite stable microcrystalline zirconia ceramic mixed powder is physically mixed, superfine, calcined, dispersed, and granulated...

Embodiment 2

[0043] A composite stable microcrystalline zirconia ceramic mixed powder and its preparation method. The main material is industrial-grade zirconia powder, and an appropriate amount of cerium oxide (CeO), yttrium oxide (Y 2 o 3 ), alumina and calcium carbonate (CaCO 3 ) as a stabilizer, and each component is formulated according to the following weight percentages:

[0044] Cerium oxide (CeO) 12%, yttrium oxide (Y 2 o 3 ) 2%, alumina (AL 2 o 3 ) 8%, calcium carbonate (CaCO 3 ) 2%, the rest is industrial grade zirconia powder;

[0045] The above-mentioned powders are assembled according to the proportion, and the composite stable microcrystalline zirconia ceramic mixed powder is made through physical mixing, superfine, calcining, dispersion and granulation.

[0046] The main material is baddeleyite or fused zirconia powder.

[0047] The above composite stable microcrystalline zirconia ceramic mixed powder is physically mixed, superfine, calcined, dispersed, and granulat...

Embodiment 3

[0051] A composite stable microcrystalline zirconia ceramic mixed powder and its preparation method. The main material is industrial-grade zirconia powder, and an appropriate amount of cerium oxide (CeO), yttrium oxide (Y 2 o 3 ), alumina and calcium carbonate (CaCO 3 ) as a stabilizer, and each component is formulated according to the following weight percentages:

[0052] Cerium oxide (CeO) 11%, yttrium oxide (Y 2 o 3 ) 1.2%, alumina (AL 2 o 3 ) 5%, calcium carbonate (CaCO 3 ) 1.5%, the rest is industrial grade zirconia powder;

[0053] The above-mentioned powders are assembled according to the proportion, and the composite stable microcrystalline zirconia ceramic mixed powder is made through physical mixing, superfine, calcining, dispersion and granulation.

[0054] The main ingredients are industrial-grade zirconia powder, baddeleyite and fused zirconia powder, and the mixture of the three is prepared according to any combination method.

[0055] The above composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com