Method of preparing composite photocatalytic material for air purification

A composite photocatalysis and air purification technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low photocatalytic efficiency, poor adsorption capacity, weak bonding between titanium dioxide and the carrier, etc. Problems, to achieve the effect of uniform compounding, improved adhesion, and improved photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

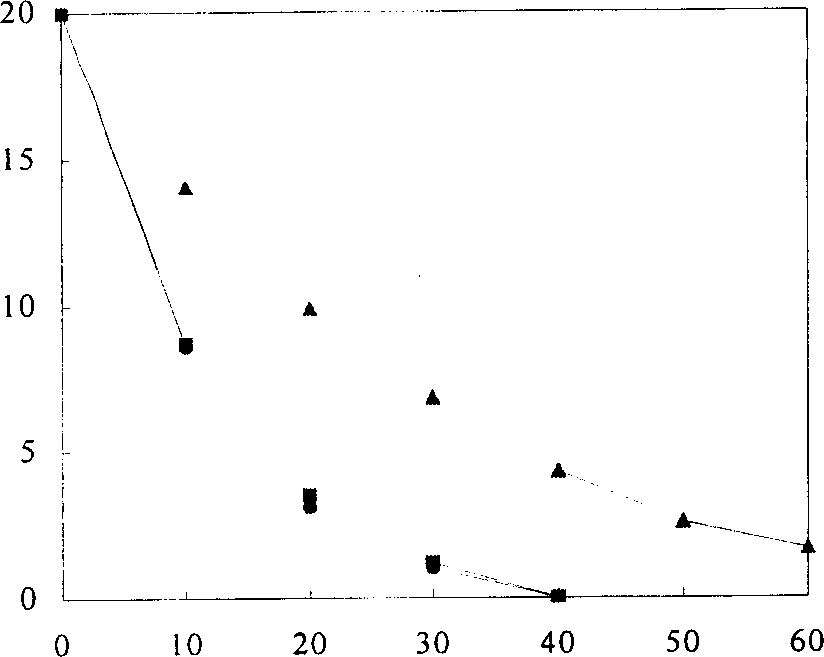

Embodiment 1

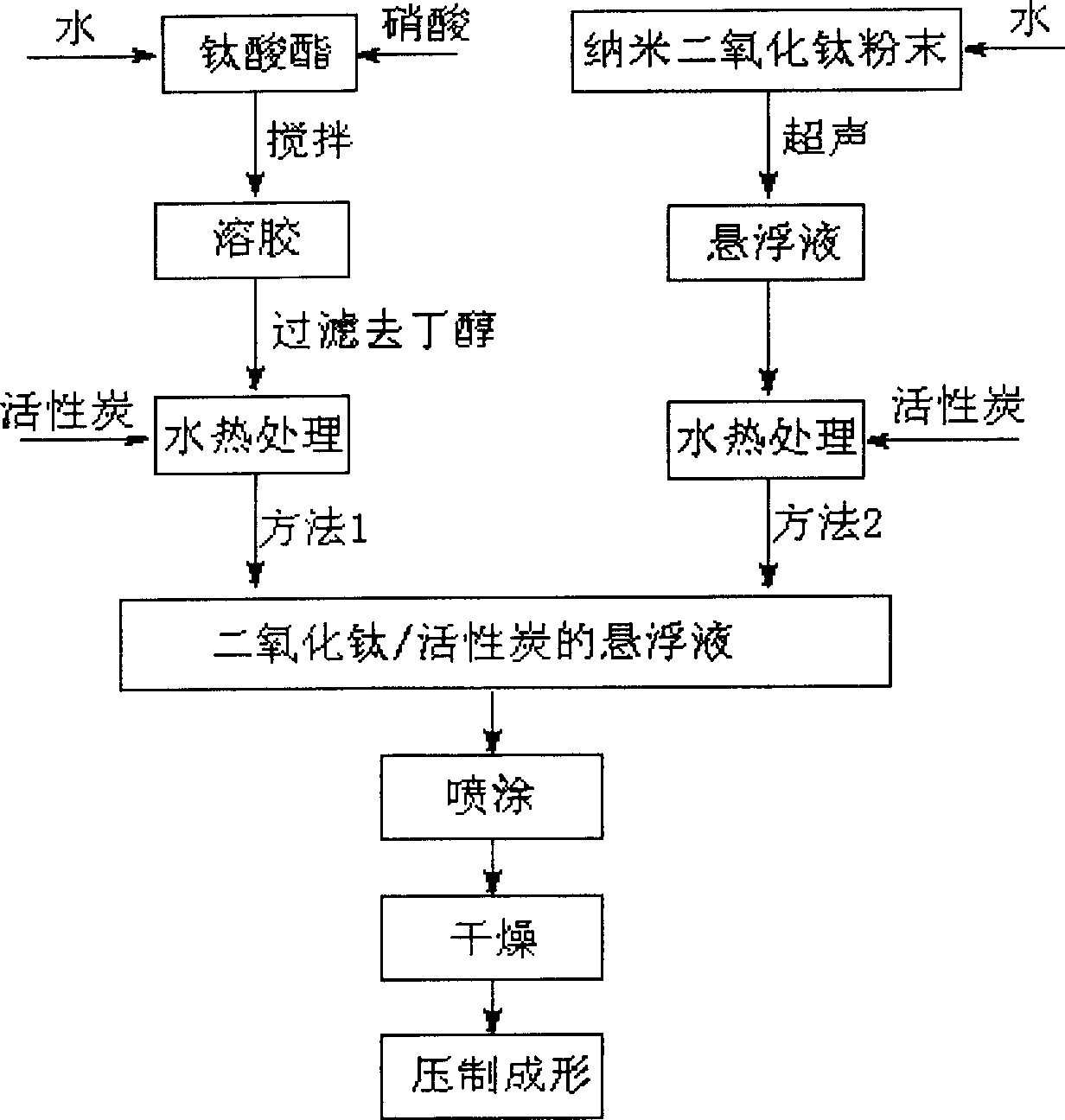

[0021] Preparation of titanium dioxide / activated carbon composite air purification material from sol

[0022] Add 0.1mol (34g) tetrabutyl titanate dropwise to 360ml, 1M aqueous nitric acid solution under stirring at room temperature, drop and stir while controlling the dropping and stirring speed, continue stirring for 2 hours after dropping, tetrabutyl titanate The ester is hydrolyzed to form a slightly light yellow transparent sol. After standing for several hours, the decomposed butanol is layered with the sol and floats on the upper layer in light yellow color. The butanol layer is separated with a separatory funnel to obtain a nearly colorless sol . Add 3 g of 200-mesh activated carbon powder to the prepared sol and put it into a pressure-resistant container. After hydrothermal treatment at 160° C. for 10 hours, a suspension of titanium dioxide / activated carbon composite catalyst is obtained. Combined with the papermaking process, spraying is carried out before the paper...

Embodiment 2

[0024] Preparation of titanium dioxide / activated carbon composite air purification material from titanium dioxide powder

[0025] Add 8g of nano-titanium dioxide powder to 340mL of water, and ultrasonically disperse for 20min to obtain a white suspension. Add 3 g of 200-mesh activated carbon powder into a pressure-resistant container, and after hydrothermal treatment at 160° C. for 5 hours, a suspension of titanium dioxide / activated carbon composite catalyst is obtained. The same operation as in Example 1 was carried out later to obtain Sample 2.

Embodiment 3

[0027] Titanium dioxide air purification material prepared from sol

[0028] Titanium dioxide sol was prepared by the same method as in Example 1, and sample 3 was obtained in subsequent steps without adding activated carbon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com