Waste paper aerogel, aerogel derivative and preparation method thereof

A technology of airgel and derivatives, applied in the direction of chemical instruments and methods, carbon preparation/purification, phosphide, etc., can solve the problem that the honeycomb porous structure cannot be effectively maintained, the metal organic framework structure is easily damaged, and the aerogel Not resistant to high temperature calcination, etc., to achieve the effect of easy large-scale production, short cycle and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

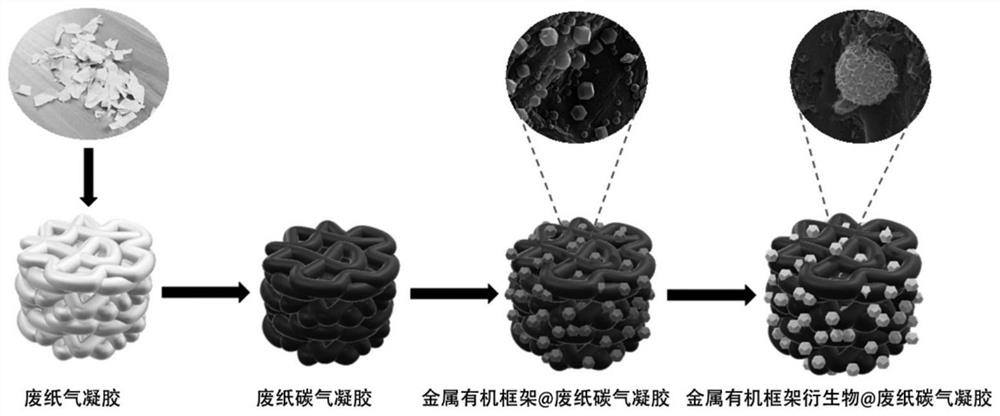

[0058] In order to solve the third technical problem of the present invention, the preparation method of the metal organic framework derivative@composite carbon airgel includes:

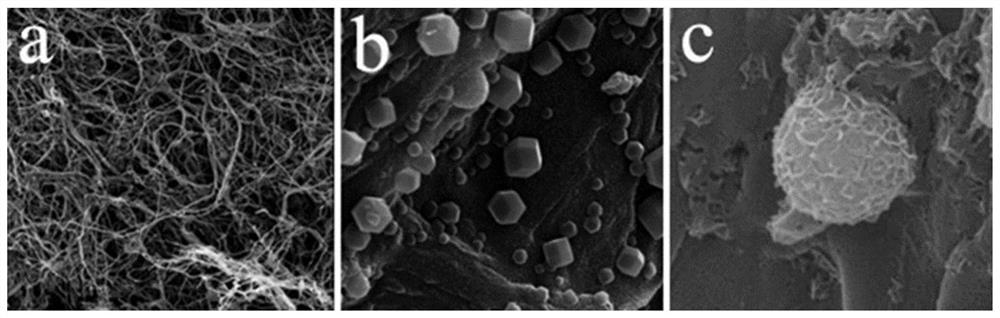

[0059] a. Mix the airgel with the metal-organic framework precursor solution to obtain a mixture, aging or hydrothermal treatment to obtain a metal-organic framework@carbon aerogel;

[0060] Preferably, the mass ratio of the airgel to the metal-organic framework precursor is 3-5:50-100

[0061] b. Phosphating or phosphating metal-organic framework@carbon aerogel, using high-temperature carbonization or hydrothermal treatment to obtain metal-organic framework derivatives@composite carbon aerogel;

[0062] The metal organic framework precursor solution is a mixed solution of at least one of cobalt nitrate, iron nitrate, zinc nitrate, cerium nitrate, zirconium nitrate and an organic ligand, and the organic ligand is isophthalic acid, terephthalic acid , at least one of 2-methylimidazoles;

[0063] The...

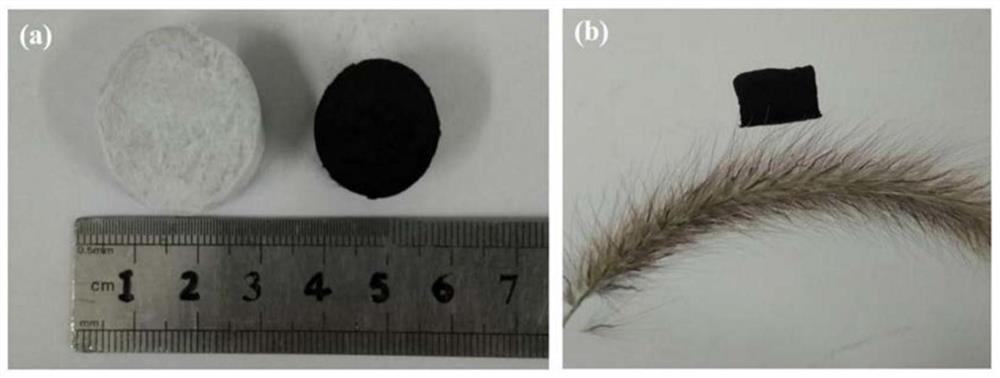

Embodiment 1

[0077] Shred 10 g of printed waste paper, add 1 L of deionized water, and stir mechanically for 6 h. After the waste paper was stirred into debris, 0.14mol sodium hypochlorite was added, and the pH was adjusted to 4.5 with glacial acetic acid. The waste paper slurry was stirred at a constant temperature in a water bath at 80°C for 2h. Water and ethanol were used to repeatedly suction filter and wash the waste paper slurry 3 times. Finally, 1L of ethanol was added to the waste paper to disperse evenly, the waste paper airgel was obtained by suction filtration, and the waste paper airgel was obtained by drying. Put the waste paper airgel into a tube furnace, pass through Ar, heat up at a heating rate of 5°C / min, carbonize at a specified temperature of 1000°C for 2 hours, and naturally cool down to obtain waste paper carbon airgel. 300 mg of cobalt nitrate and 600 mg of 2-methylimidazole were dissolved in 20 ml of methanol, respectively. The cobalt nitrate solution was quickly...

Embodiment 2

[0085] Shred 10 g of printed waste paper, add 1 L of deionized water, and stir mechanically for 6 h. After the waste paper was stirred into debris, 0.14mol sodium hypochlorite was added, and the pH was adjusted to 4.5 with glacial acetic acid. The waste paper slurry was stirred at a constant temperature in a water bath at 80°C for 2h. Water and ethanol were used to repeatedly suction filter and wash the waste paper slurry 3 times. Finally, 1L of ethanol was added to the waste paper to disperse evenly, the waste paper airgel was obtained by suction filtration, and the waste paper airgel was obtained by drying. Put the waste paper airgel into a tube furnace, pass through Ar, heat up at a heating rate of 5°C / min, carbonize at a specified temperature of 1000°C for 2 hours, and naturally cool down to obtain waste paper carbon airgel. 300 mg of cobalt nitrate and 600 mg of 2-methylimidazole were dissolved in 20 ml of methanol, respectively. The cobalt nitrate solution was quickly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com